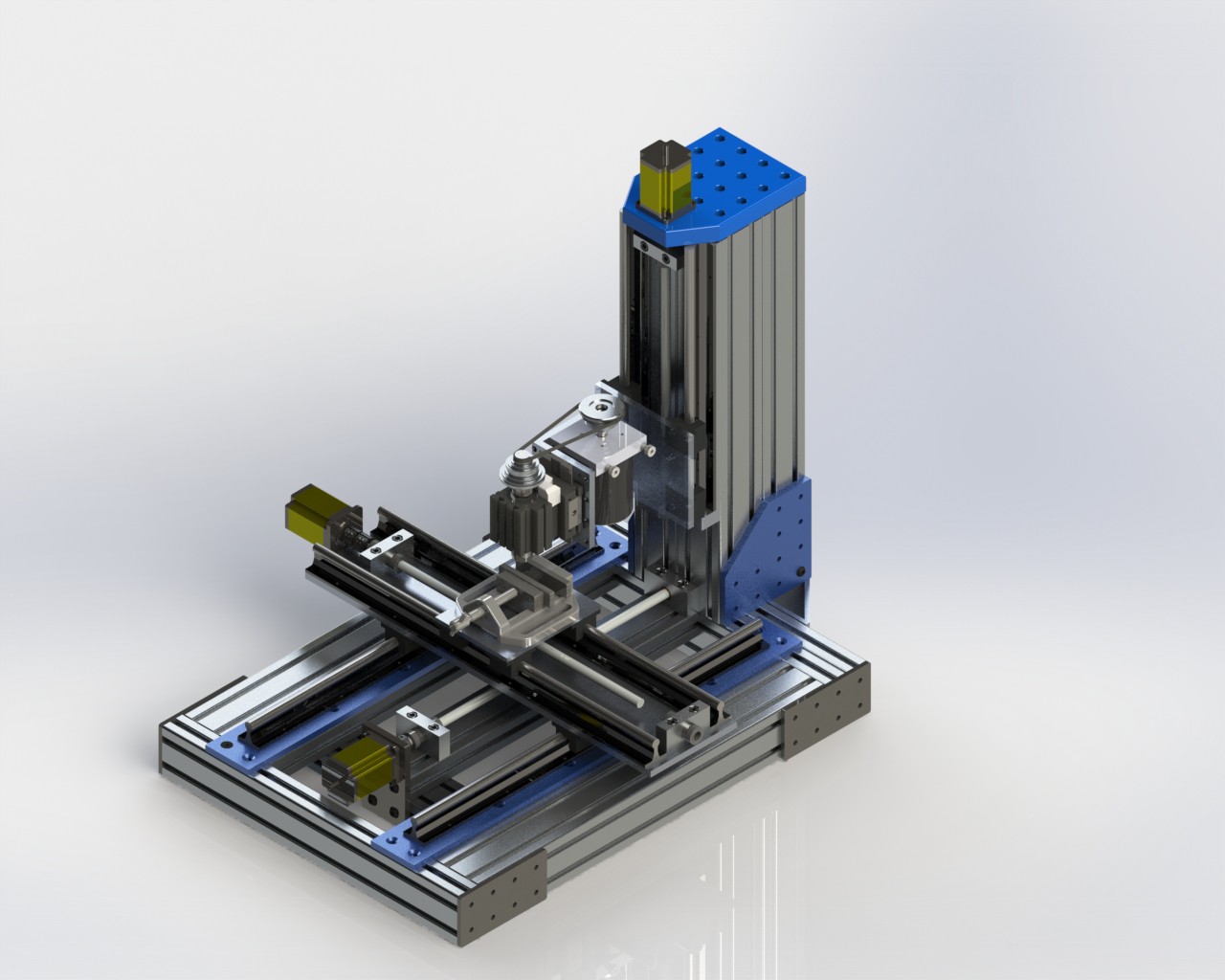

Well I really thought that I had a great design. It probably took me about 6 months to get the dang thing together enough to realize that the Z axis was just never gonna work that way. The stepper motors stalled and couldn't lift the Z axis at all. I had them directly coupled to the acme screws and that didn't work. Then I tried moving the motors to the side and connecting it with a set of pulleys and timing belt. This let me double my torque and it still stalled. It was a major set back. I really was upset. But sometimes you have to have a set back to move forward.

I set the project aside for a while and after a break I came back and redesigned it. It is a little funny but the more I worked on this project, the more it looks like a traditional cnc mill. I guess I was reinventing the wheel and as I learned what wouldn't work it steered me more and more to the traditional designs. I guess other people figured it out before me. Maybe I was a little slow.

jupdyke

jupdyke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.