First I would like to give a shoutout to James Bruton. His R6 and BB8 droids are really what inspired me to start this project. Seeing what he can make with just 3D printed parts is amazing. If you haven't seen his channel you have to check it out here:

http://www.youtube.com/user/jamesbruton

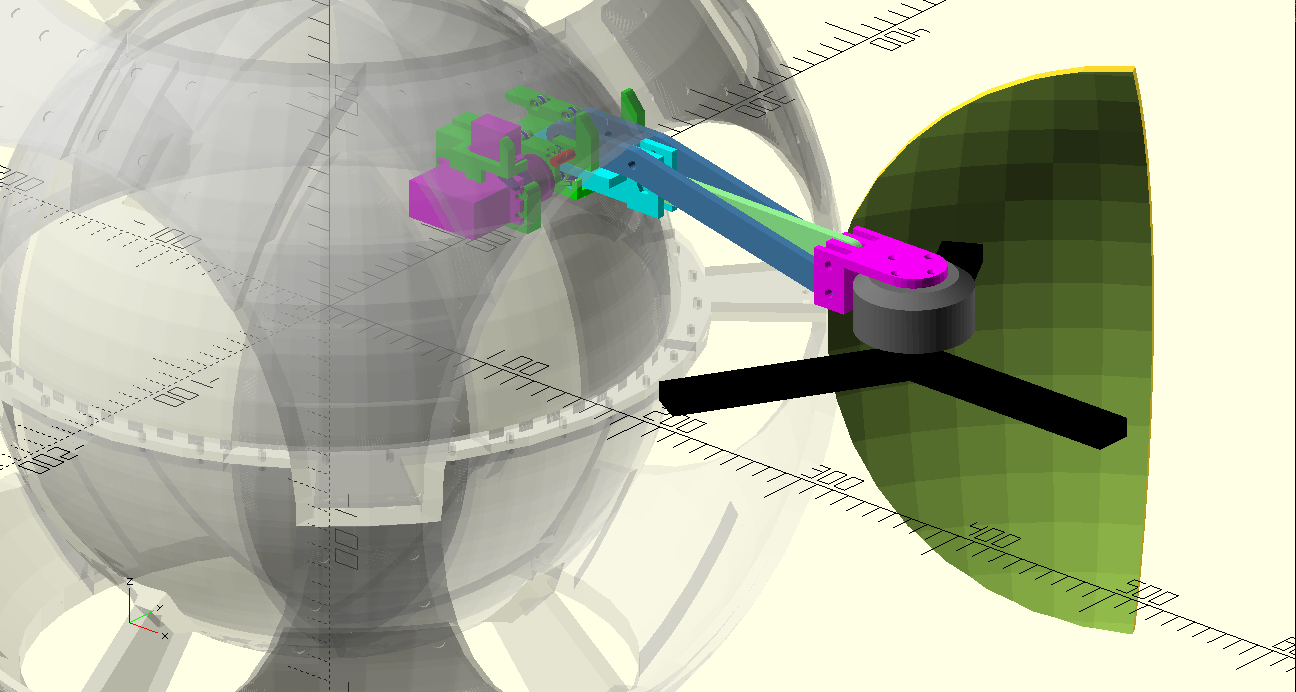

I completed the first tests of some propellers to see what I will need to get BB8 to fly as well as determine the weight of the frame.

The test's with the small propeller that just fits in the side slot was somewhat disappointing. It only produced 1.2 kG of thrust. Even with 4 its max thrust will be 4.8kG under even just the calculated frame weight of 5kG.

The real question is how do you fit an 18 inch propeller in a 12 inch hole. The answer is in fact quite simple a folding propeller however locating an appropriate one was a difficult task. After several hours of scouring the internet I found the DJI E1200's propellers. 17x6" Propeller blades that fold, just what I was looking for. So I have a set of those on order.

But a final question still remained how to fold them up so they can go back into BB8's body. The first ideas that came to mind where over-complicated. Servos on the sides of the motors that have levers to push the blade. I settled on the idea of using the doors to fold the propellers.

No not pushing it with the doors but rather rotating the motor to push the blades on the doors. This will still be a tricky task as no existing ESC has this capability to drive a brushless motor like a stepper motor. I will have to design it from scratch.

Brushless motors generally have multiple poles and a three phase input. It will take some testing to be sure but I believe it is possible by putting varying voltages on the 3 wires to position the blades at any angle. I will also need some optics to properly detect the blade position so it can move appropriately to get its propellers in the correct place to fold. This part of the system will still require some thought. Will I need a single board computer with a camera running computer vision algorithms, or can I get away with a simple optical sensor on the motor arm to detect the initial blade positions by rotating them past it.

I'm off to quite an exciting start and only more fun to come.

DrYerzinia

DrYerzinia

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.