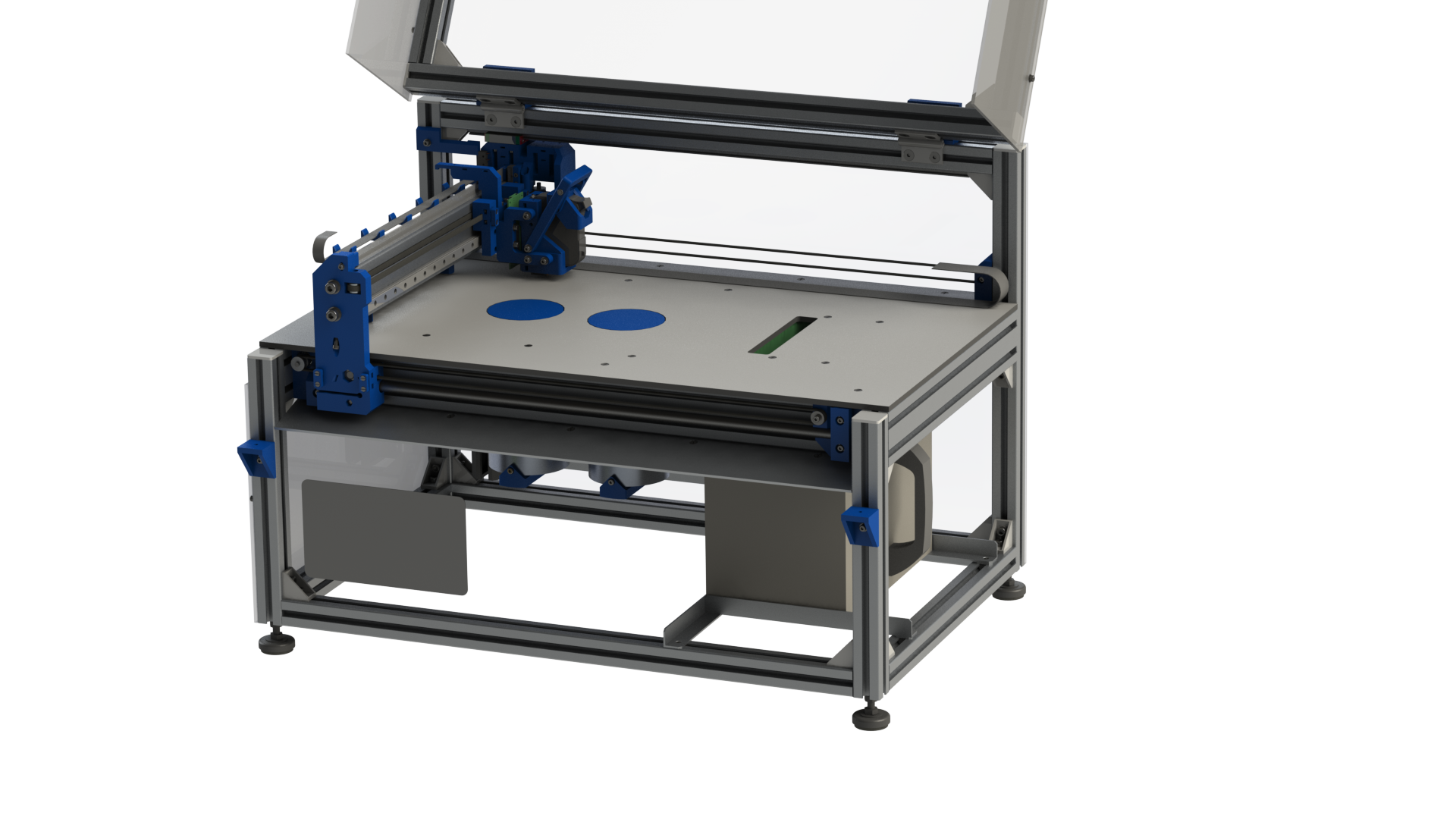

Phase 2 sounds really ominous. All I am doing is turning a DIY 2D inkjet printer into a DIY 3D one. Now that I am talking about it, things are going really well. An overview of the progress.

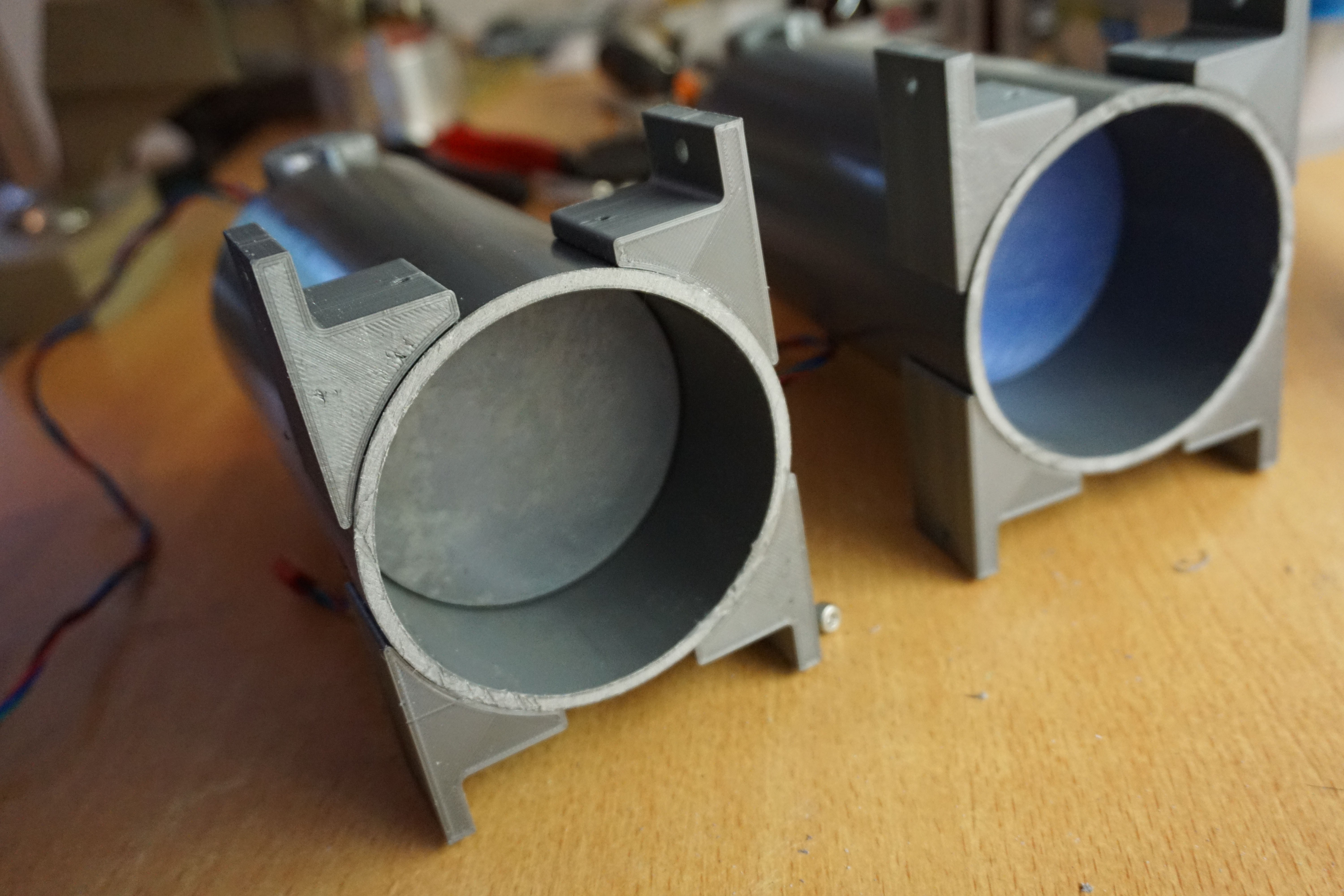

Pistons

The pistons are 2 90x3.5mm PVC tubes. The design called for 90x3mm aluminium, but I had some supply issues. The effective size of the pistons is around Ø83mm by 100mm high. This will be plenty for material testing. Once I need bigger prints I will design a better hopper with more volume (or another printer with a bigger hopper).

The software for the 4th axis turned out to be a bit of a nasty surprise. The Arduino CNC shield has 4 stepper motor drivers, but that 4th driver is a lie, at least with default GRBL. I now run a special (https://github.com/mlambm/grbl) Version of GRBL that supports the 4th axis while giving up some spindle support. I can not run both pistons at the same time and this version is GRBL 0.9 (currently 1.1) (which required some tweaks in my software) but both axes move and provide feedback. I will upload wiring diagram and include the firmware with correct configuration when I can. Once I get around to writing instructions I will dedicate a section to wiring and configuring the GRBL driver. It has slowly grown to be quite complex.

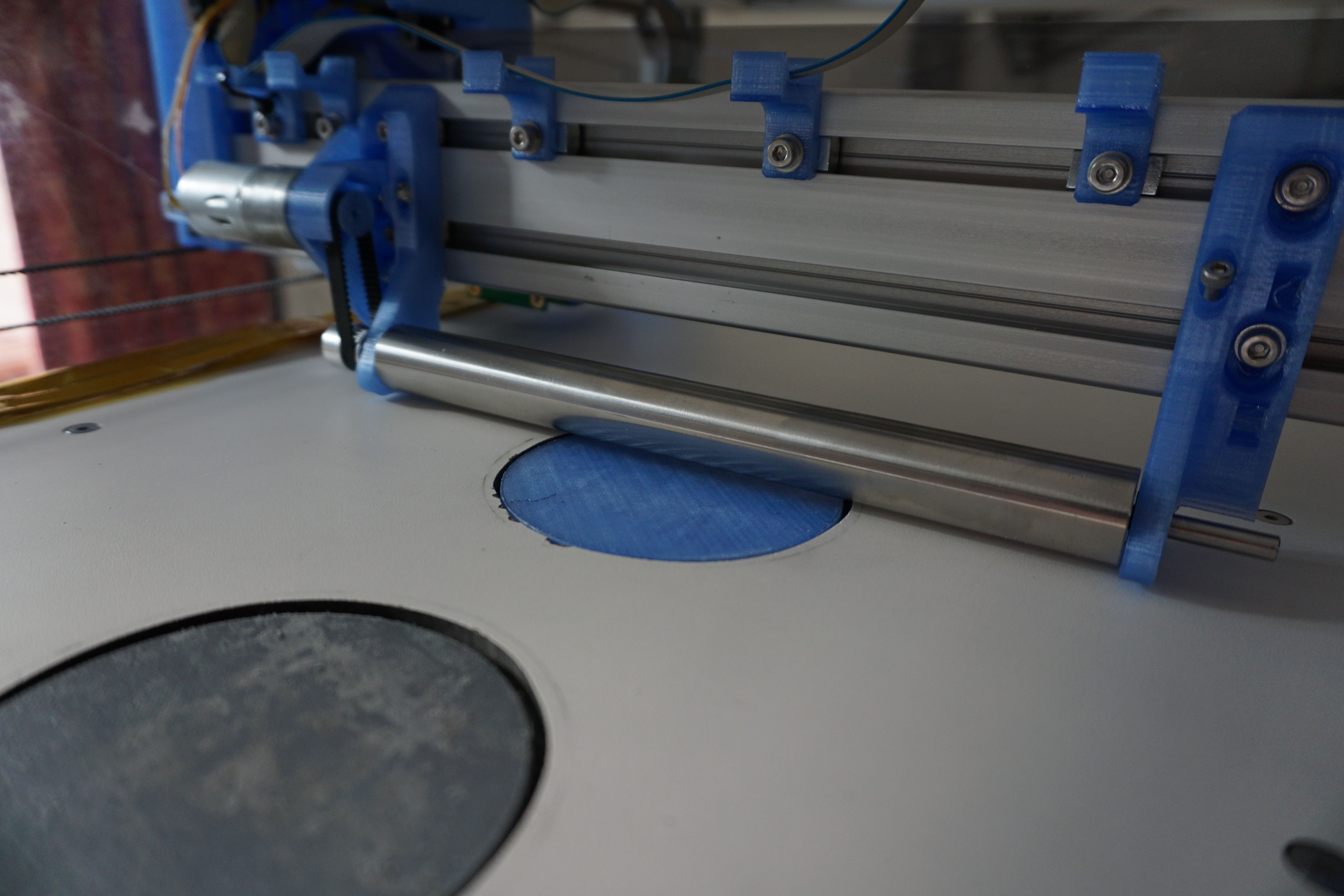

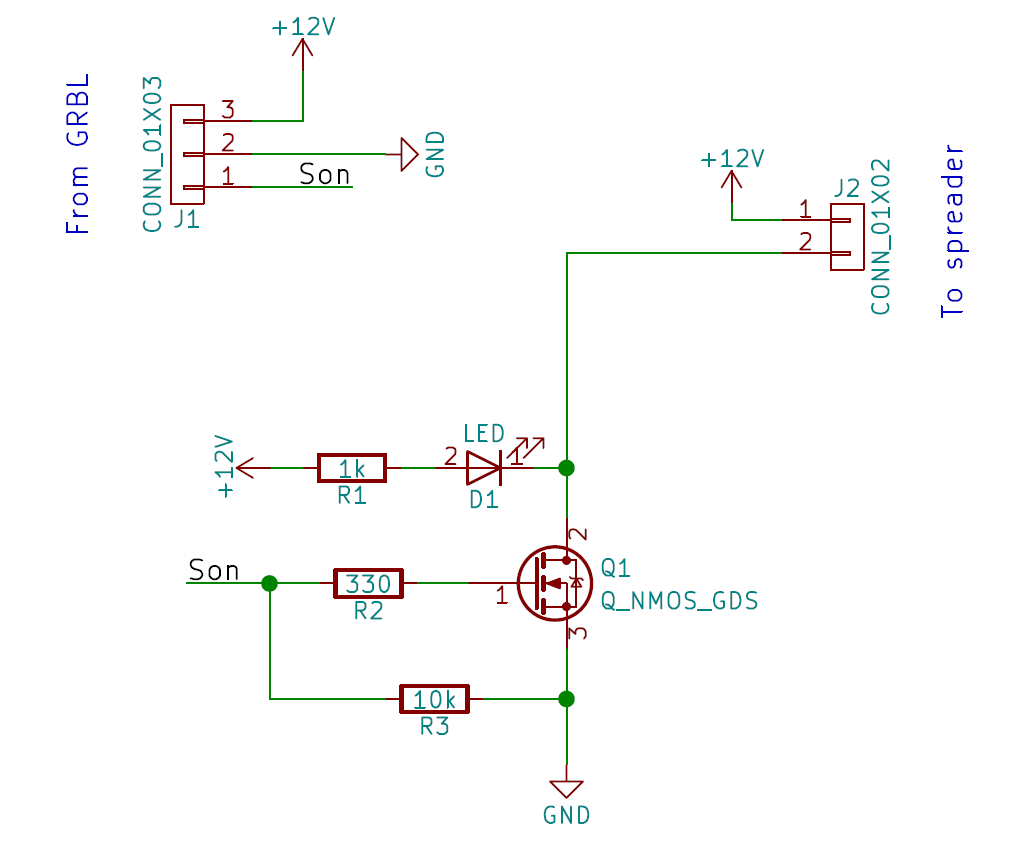

Spreader

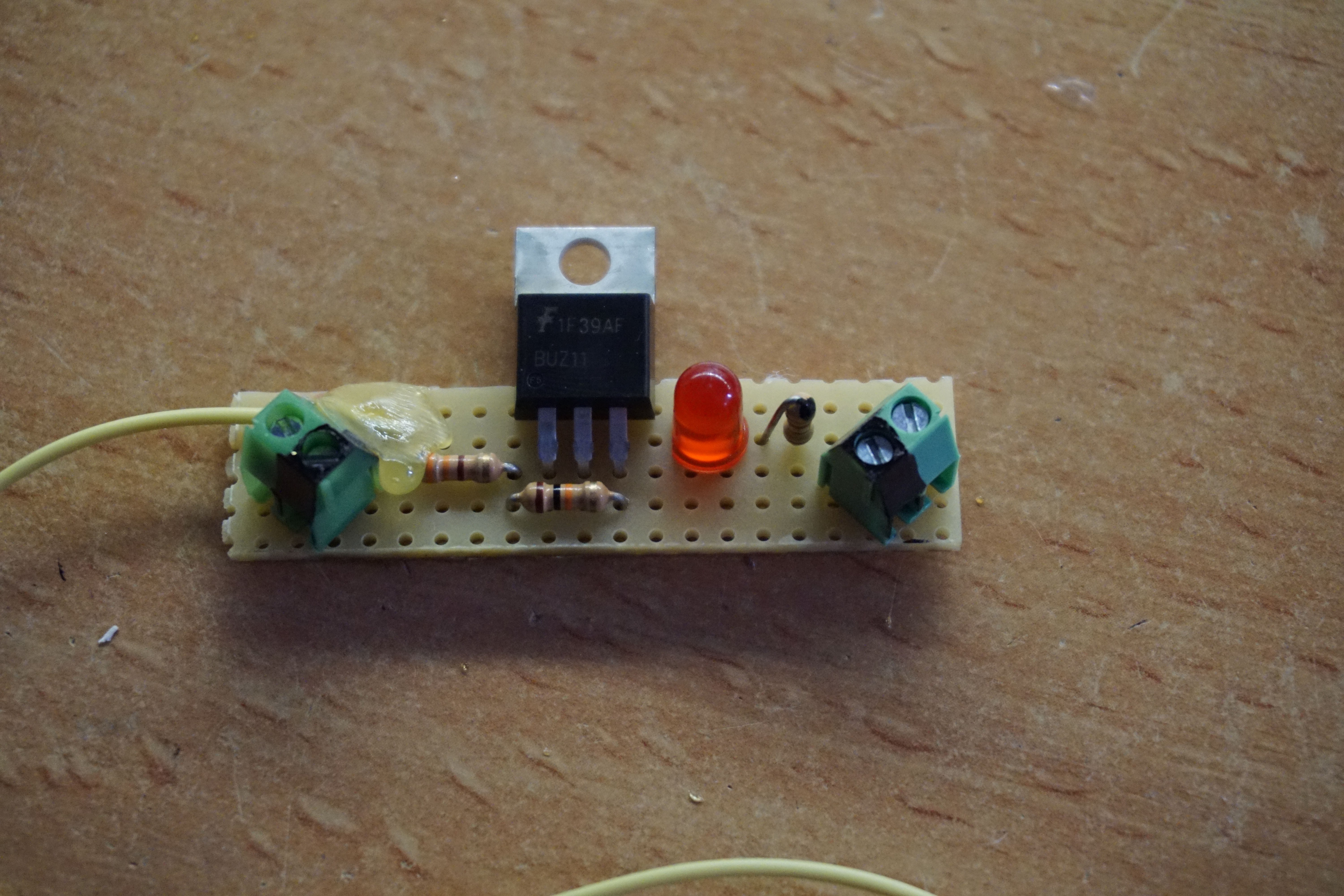

The spreader is now mounted and wired up. The CNC driver board I use does not have powered outputs, so I have made a tiny mosfet based circuit to power the spreader. I have attached the spreader to the coolant pin (which is controlled by spindle commands, yay alternative GRBL). Sending the M4 command starts the spreader, M5 shuts it down. The spreader itself uses a 12V 25mm gearbox motor at 300rpm. I have 120rpm available if 300 is too fast.

SVG file reader

In the last log I said that I would only write a parser for SVG files myself if nothing else worked. As it turns out I lied. I wrote a parser (I had a weird day, don't judge). It only takes Slic3r SVG files, which only use straight lines and have layers. It runs just about as fast as anything else in python does (dead slow), but so far it gives clean layers. This is a great relief, because the parser was the last potential issue (lets hope).

On the software side all I need to do now is write the code that makes all the 3D printing motions and prints the right layers at the right time, but that is peanuts compared to the SVG parsing.

See below, a GIF of software reading an SVG of a gyroid.

Next log

All I need now is the adding the right code to move the pistons, and to print the right SVG slice. I also need an overshoot bin, which is easily built. When those parts are done, there should be nothing stopping me from printing in 3D. Then I can start playing with materials and binders. I have added a new package of software to the files for anyone interested.

The next log should be interesting. It won't be too soon sadly, I have a few full weekends, so expect a bit of radio silence for 2 week.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.