The hip pods were something I kind of threw in- Greg wasn't expecting it. Heck, I wasn't expecting it! Greg now knows me well enough to know that I tend to first say it can't be done or isn't probable and then fifteen minutes later I figure it out- that's just my M.O. The hip pods are a perfect example of this. I first looked at the suit and said "no way." But of course it bugged me because it would be so cool to have them move... So first I figured out how to make them pop out of the hip section. Then I thought it would be great if they could rotate. Then I thought, well heck- might as well make the lever on the cover slide and have them light up!

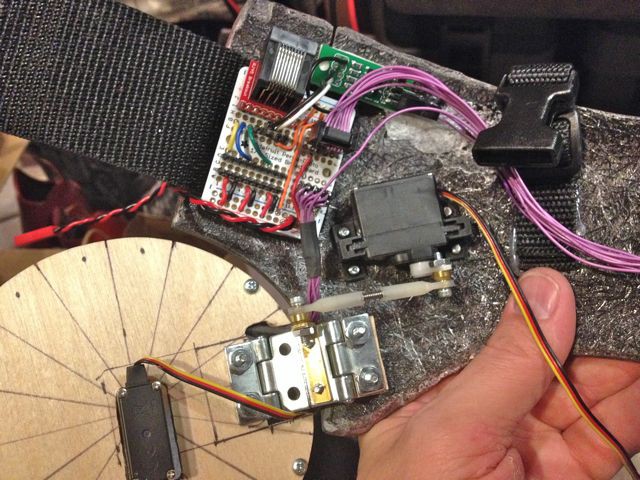

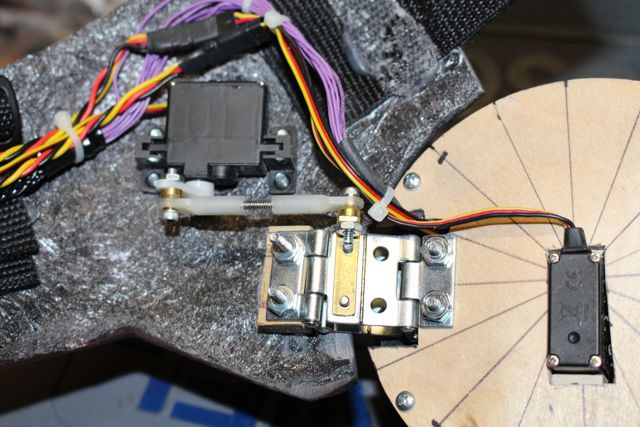

To make the pods pop out I took two small hinges and welded them together to make a parallelogram linkage and then added a micro servo to move the linkage. The finished mechanism is very low profile. Getting the pods to fit right was tricky because the fiberglass hip section with was molded as one piece so everything had to be cut apart and reconstructed. The faceplate of the pod was cut away and hollowed out to make a shell and a housing was made from ABS pipe. A backing plate was cut from birch plywood.

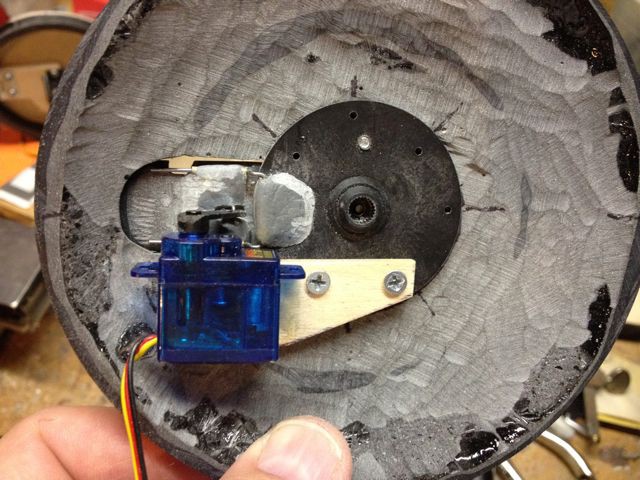

Several ideas were tried for the pod rotation system but ultimately the faceplate was driven directly by a servo as that took up the least amount of space. The rotation servo is mounted to a piece of plywood that is bolted to the hinge assembly. LEDs were mounted in the ABS ring to simulate the flares.

A servo wheel is mounted to the rotation servo and it drives the pod faceplate. To make the lever on the faceplate slide open a sub-micro servo is mounted to a plywood plate that is attached to the servo wheel. The servo output arm has a small slot cut in it and it is attached to the sliding lever using with a small section of music wire that is epoxied in place. The lever slides on a small hinge made from music wire and brass tubing- the hinge is attached to the large servo wheel. As the servo lever moves the hinge rotates slightly outward and the lever slides open. This particular mechanism required a lot of trial end error fitting to get it to move smoothly with very little friction.

Since the suit hip section had been cut away in order to use the pods we had to reconstruct the flanges on the back hip section. Sintra sheet was cut and formed to shape and was epoxied in place and then the seams were filled in with Apoxie Sculpt. In the end the hip pods worked really well and I'm glad we went to the trouble of adding them!

jeromekelty

jeromekelty

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.