Another toenail goes to the toenail in the sky. Not sure why the sandals eat toenails. The general theory is bare EVA is very sticky & too much stickiness in the toe area causes blisters under the toenails. You can't moisturize toes because moisturizer causes toes to stick. Simultaneously, dry toes get cracked & swollen which also kills toenails.

The leading idea nowadays is to lubricate the toe area but not use a moisturizer. Another idea has been to cover the bare EVA with suede, but suede is heavy. Suede has provided just enough stick but not too much & it's been immune to rain.

The journey to a more tenacious sole has been long & slow, manely because every option is expensive.

Lions wonder if vibram rubber has ever been remelted & cast into other sole shapes. The tooling might cost more than the rubber. The case could be made for casting 1mm rubber soles with just the right amount of lugs.

It turns out the 1mm vibram soles slide like glass on a freshly waxed mall floor. They really are bad compared to shorter life rubber. So ideas began to emerge of having a pair dedicated to less frequent trail use, with higher grip rubber. Maybe a PLA positive could be used to create a moldmax negative & that could be used to form a grippy sole out of rubber. There are very expensive rubber epoxies. Balloon rubber is the grippiest rubber. Natural rubber seems to be the key.

https://www.amazon.com/Rubber-Repair-Non-Slip-Soling-Bottom/dp/B08RB1CTBG/

There is 1.2mm sole rubber which calls itself anti slip. 15" x 11" is $10 bidie bucks. What lions really want though are lugs.

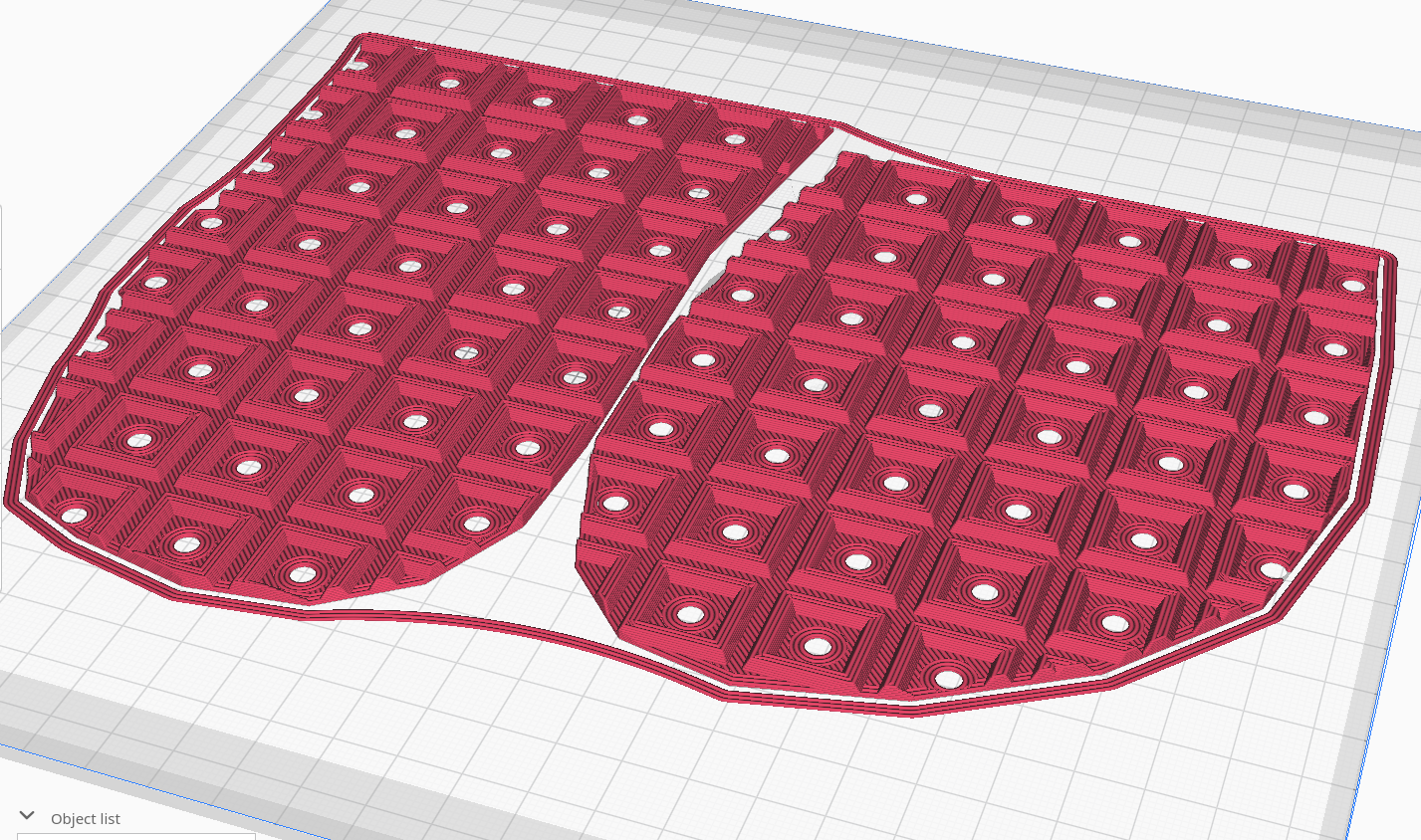

TPE has shown pretty good grip performance compared to TPU, but it's expensive. The latest idea is printing a lugged 1mm sole out of TPE & hot gluing it to the sole of a retired sandal. Maybe a pathfinder could be made of TPU to see if the lugs overcome the lack of friction. It would have to be printed in 2 halves & welded together.

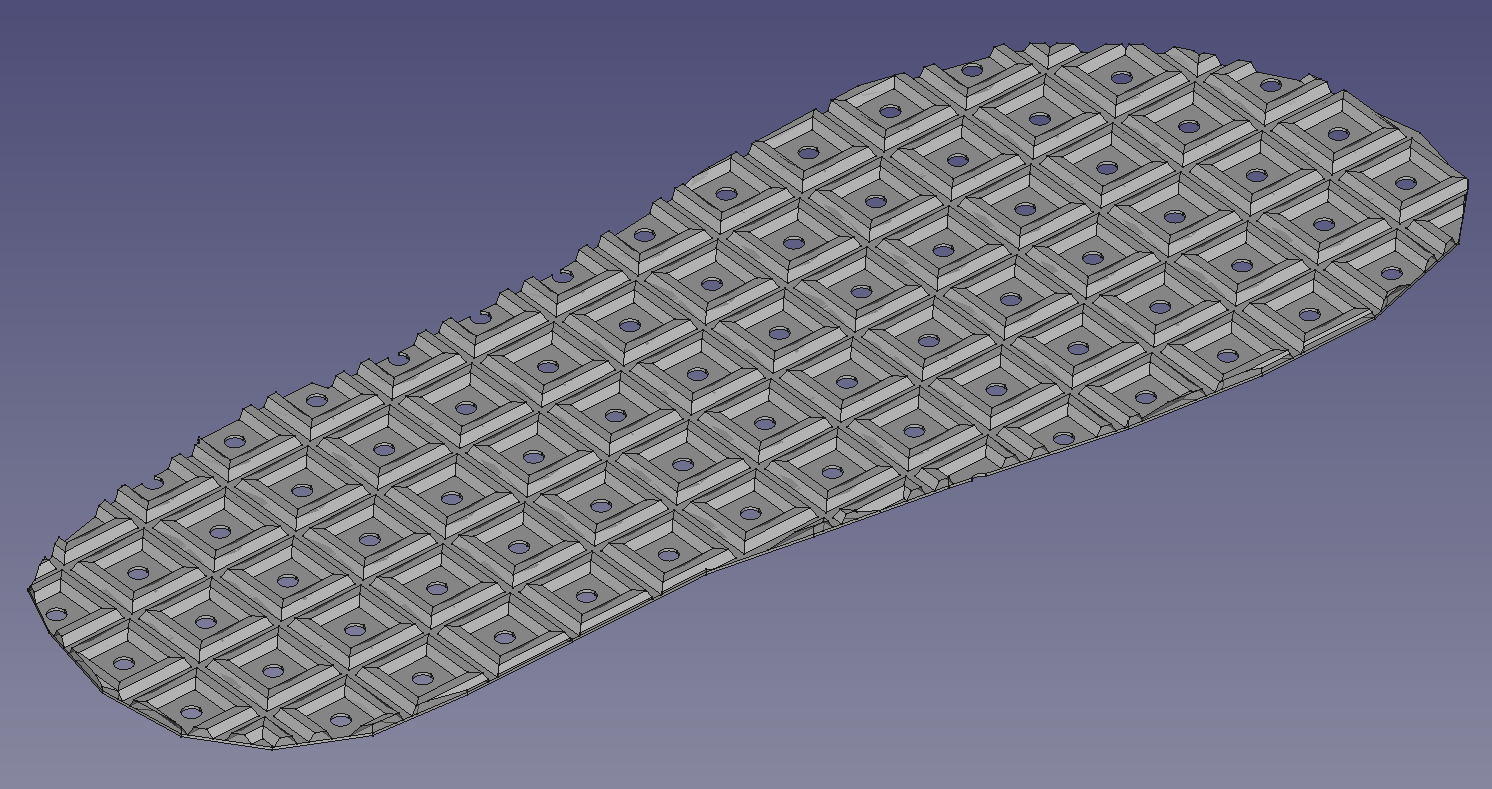

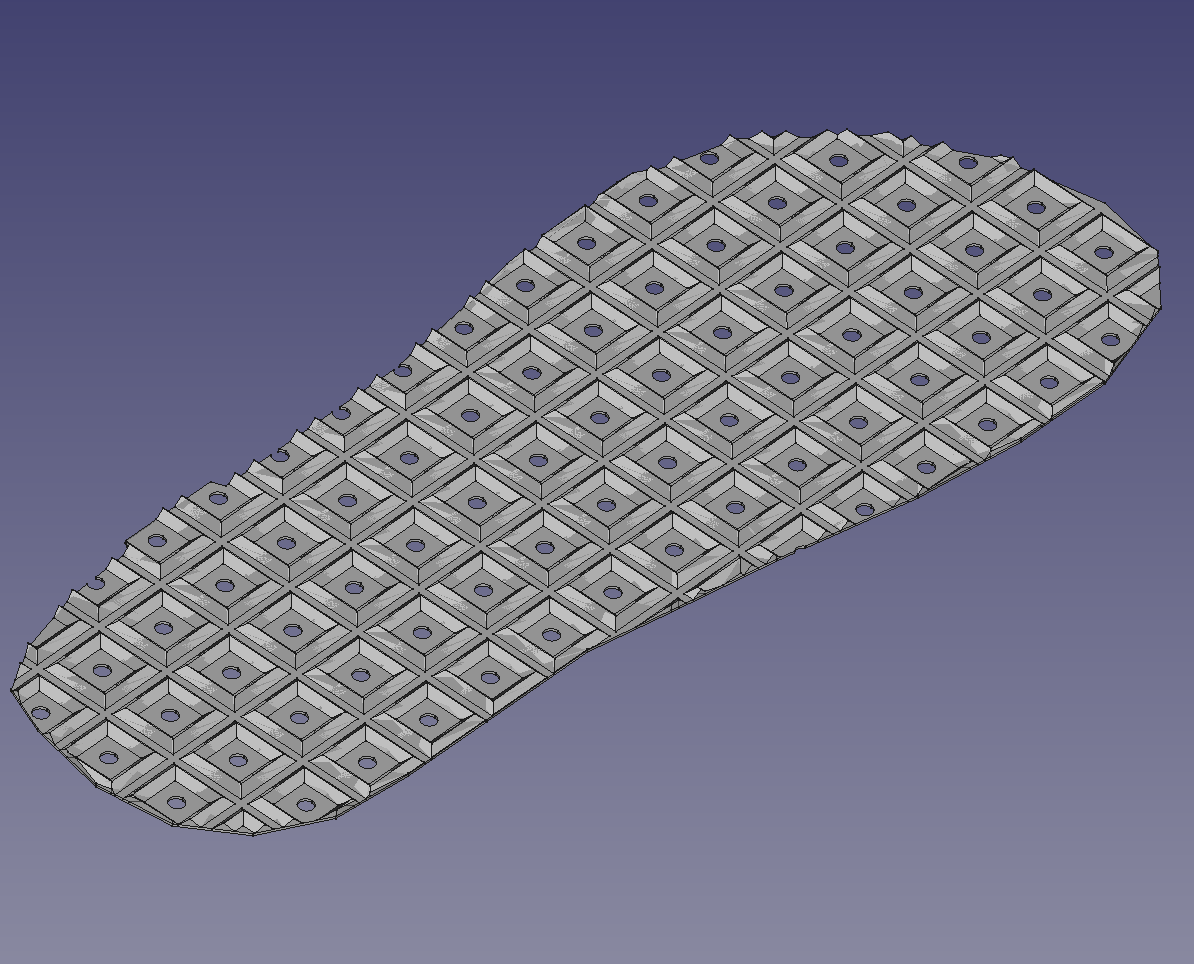

The preferred lug design is just a regular pattern of square outlines.

Hot glue rivets would go in the holes.

In today's price of $60/500g it would be $6.

A pointier lug might dig in more & reduce the price to $5.

Then comes testing it. The only place demonstrating the traction is near the very end of a long mountain climb.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.