Initially I was planning on using new 1" angle extruded aluminum welded into the base frame. Nice and simple, right? Even with the challenge of welding the thin aluminum, it seemed like a good look.

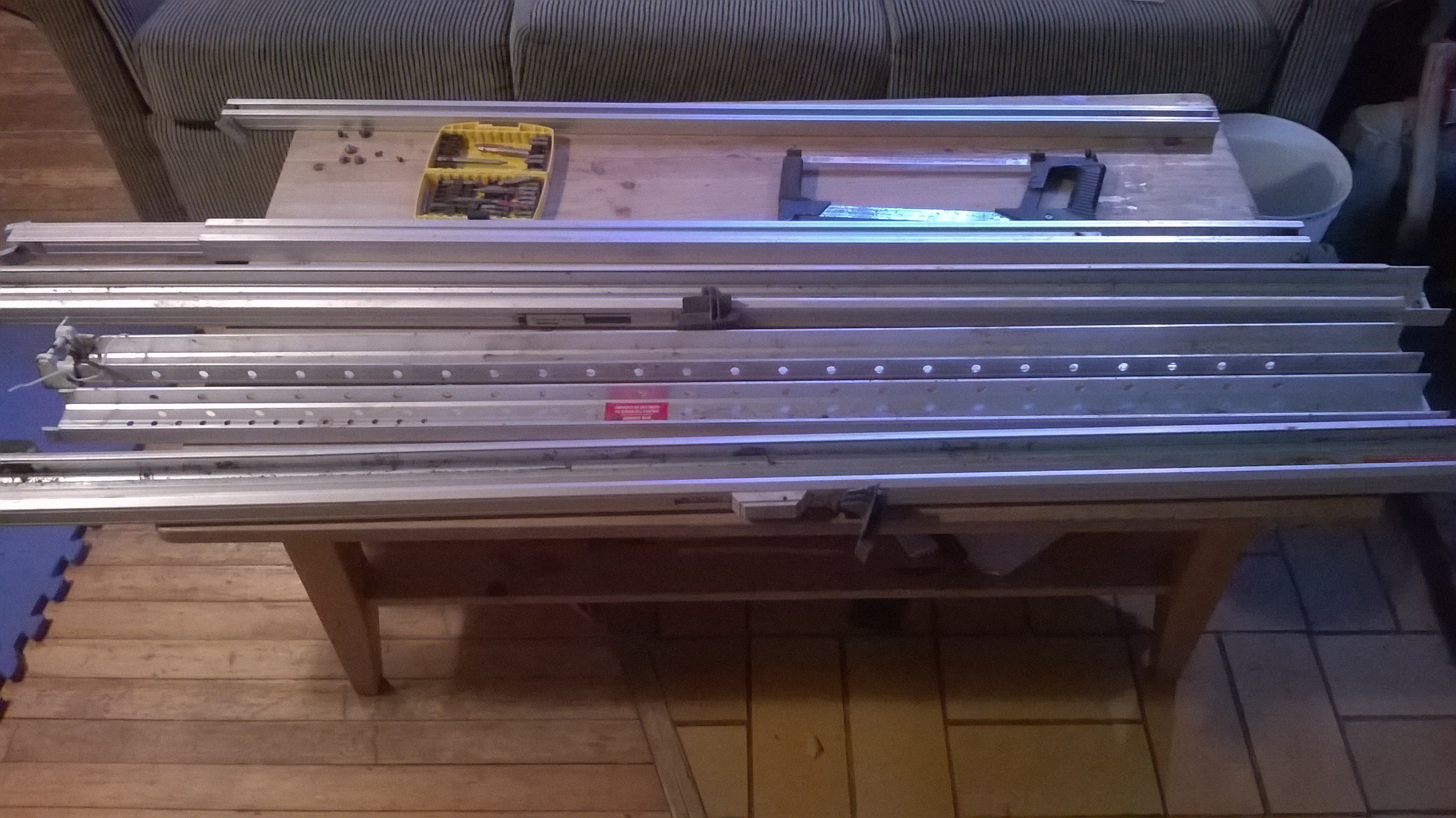

However, I remembered that I had taken the awning off my 1976 motorhome more than a year ago and thought that some of that aluminum channel may be salvageable. Turns out I found the perfect pieces.

The channel second from the top of the picture right below the hacksaw is going to work great. It is the same height as the nose of the main printrbot stock body and is super strong due to its profile. The channel at the top of the photo fits into it, so I am trying to think of ways to use that to my advantage. I am planning to add printed inserts to make it look 20% more awesome as well.

I have a bevy of projects in mind for the rest of the pieces too. (of course) One such project is a core-xy printer with exterior framing/cabinet.

ken.do

ken.do

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.