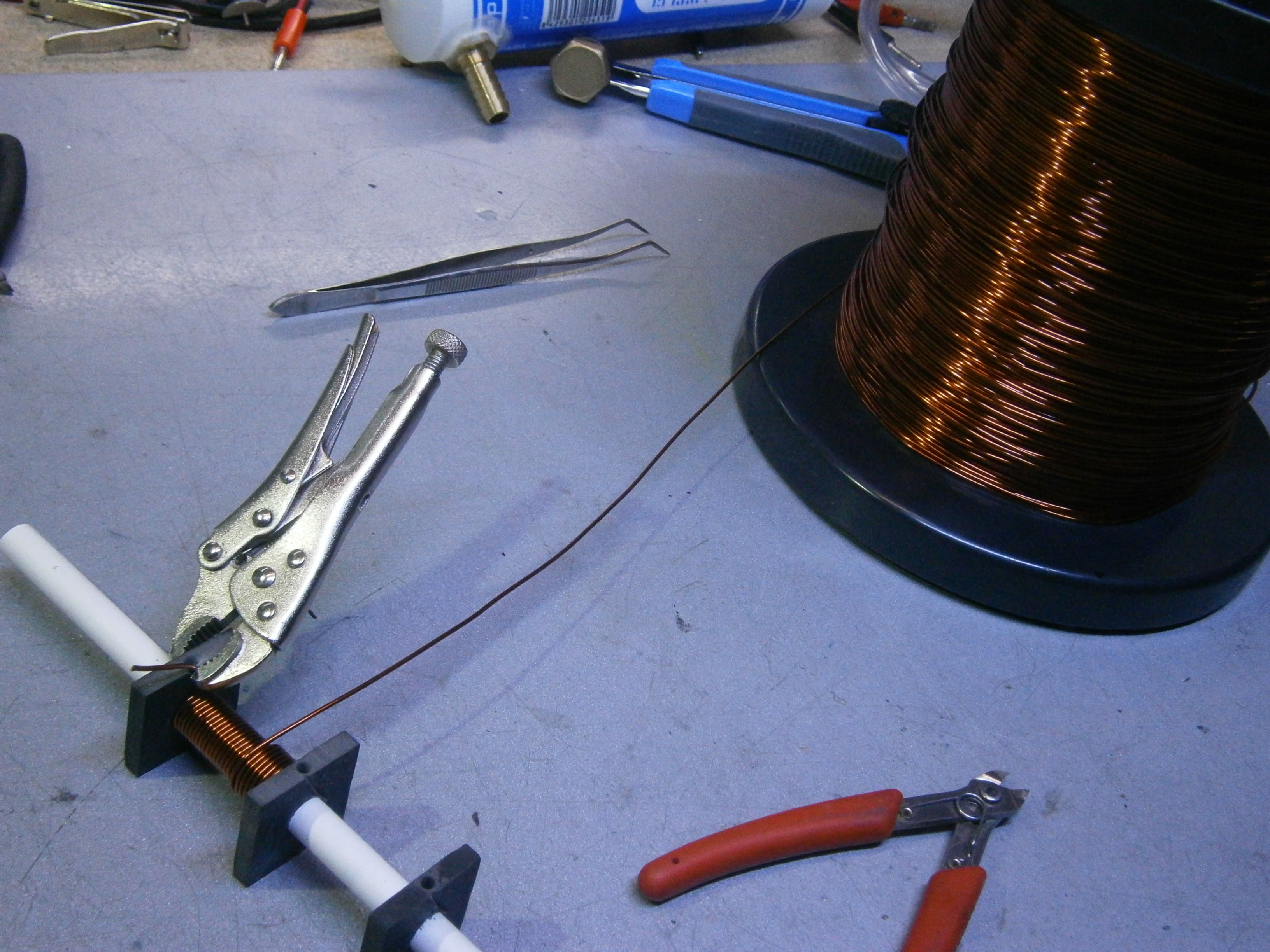

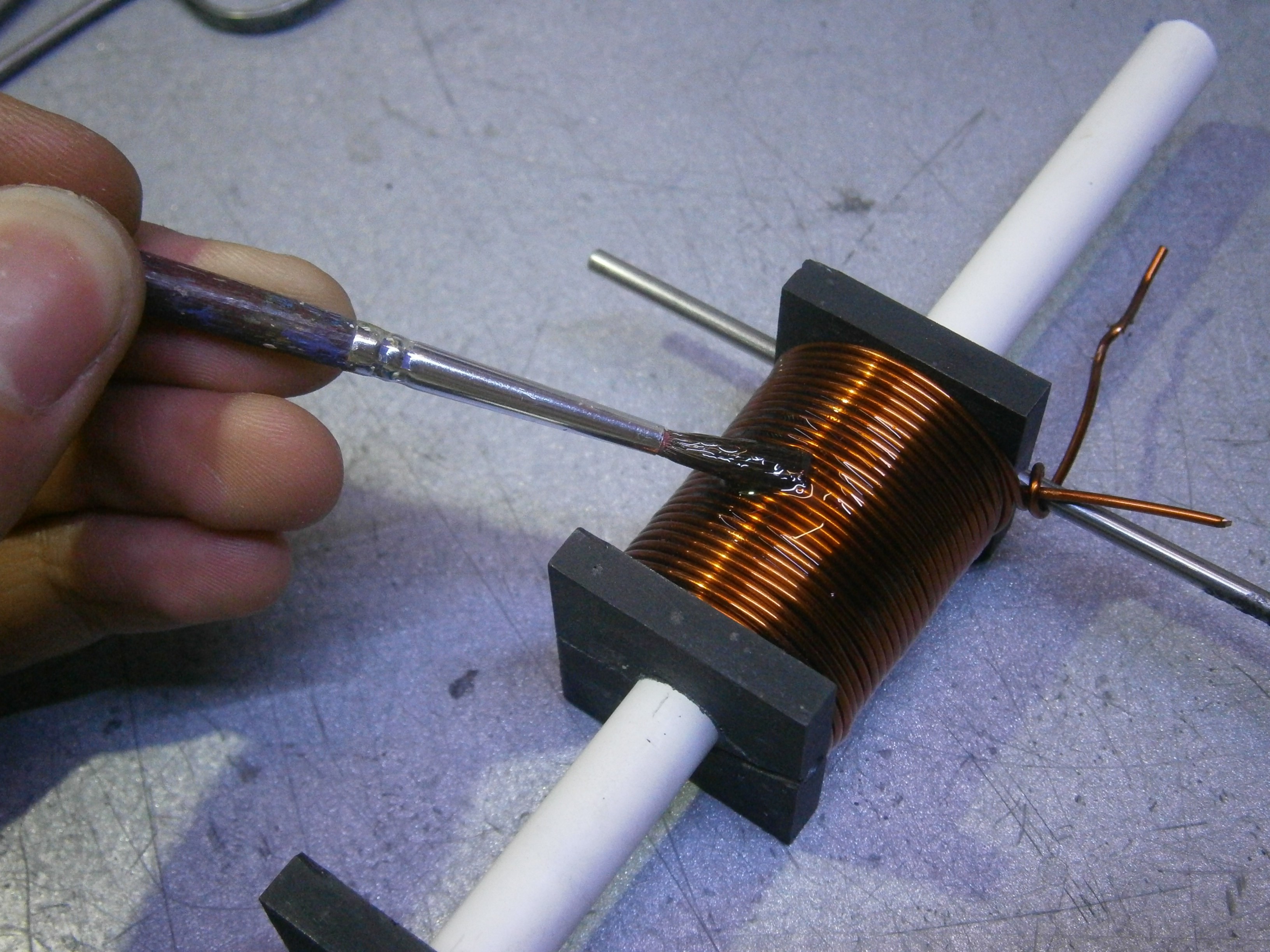

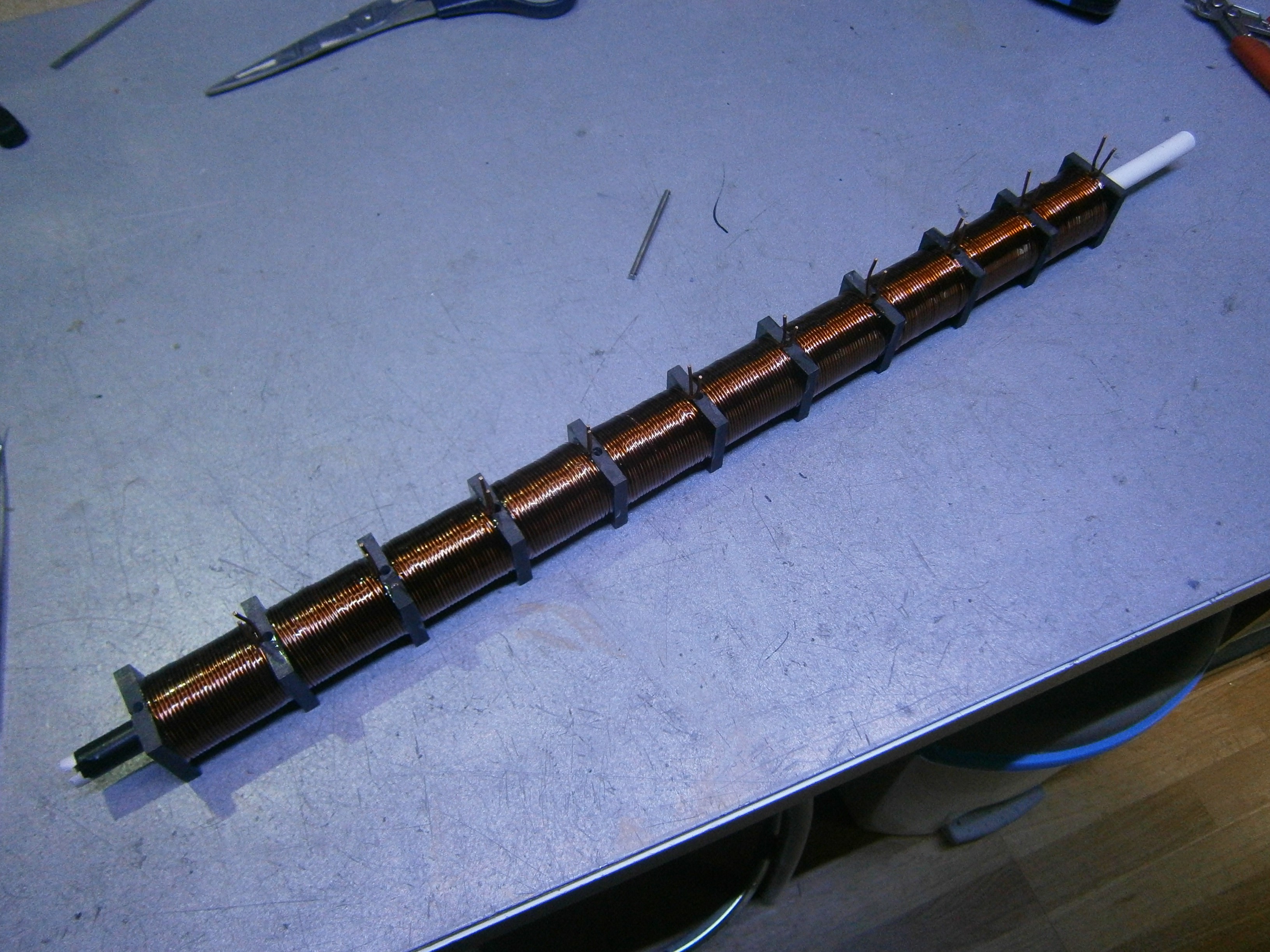

Once all the spacers were finished, the next step was winding the coils.

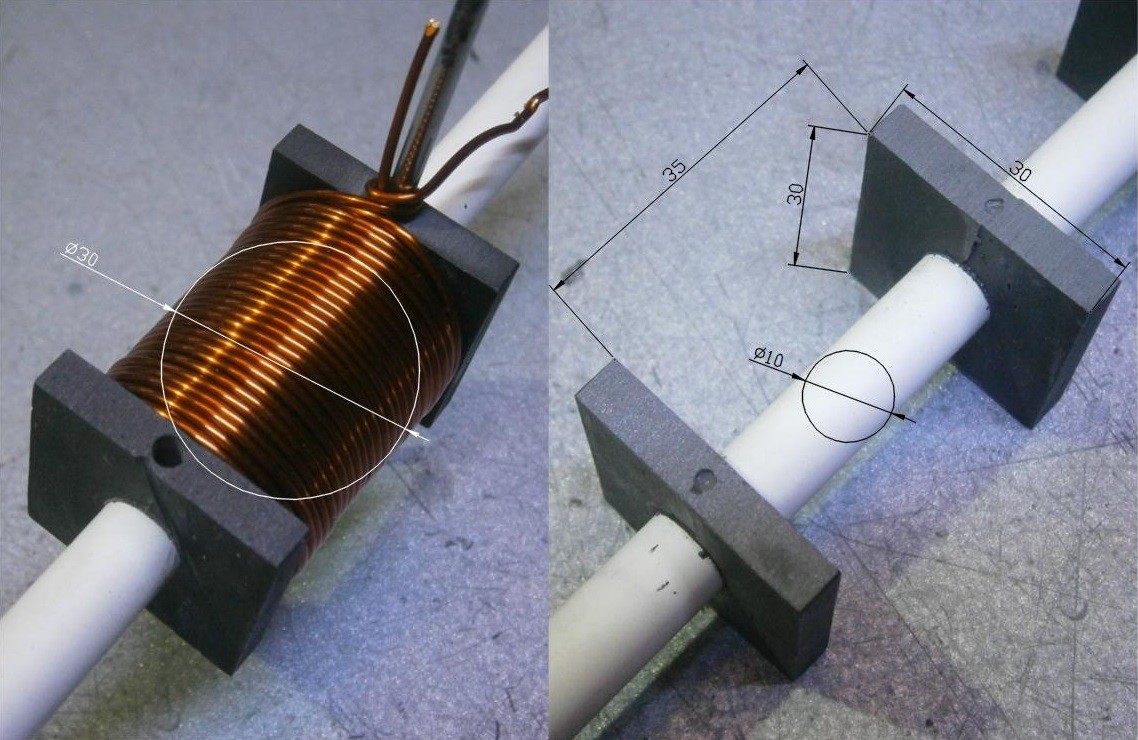

In the picture above you can see the dimensions of the barrel with spacers: the tube is 10mm in diameter, centered in a 30x30mm square, and the distance between spacers is 35mm. This meant that the coil would have an inner and outer diameters of 10 and 30mm respectively, and it would be 35mm in lenght.

The other requirement for the coils was a working current of 100A.

The coils will be powered by a 22v pack of batteries, so the resistance should be close to 220mΩ.

(If you're not interested in the math, skip to the paragraph above the next picture)

The resistance of a metal wire is given by the following equation:

Where ρ is the metal conductivity (1.678×10−8 Ω·m for copper), l is the wire lenght in m, and A is the Cross-sectional area of the wire im m2.

Writing A as a function of the wire diameter ∅:

To find the length of the cable l we need know the number of layers that the coil will have, which we get by dividing the coil thickness (the diference between the outer and inner radiuses) by the wire thickness:

Where D and d are the outer and inner diameters, (which we know).

Then we get the number of turns in each layer by dividing the coil length L by the wire diameter:

And their average circumference:

The total wire length is the the number of layers times the turns in each layer times the circumference of each turn:

Feeding this equation into the resistance one we get:

Finally, solving for ∅ we get the final equation:

This equation can be used to calculate the wire diameter for a coil made out of any metal given its dimensions (inner and outer diameters, and length) and resistance.

Using ρ = 1.678×10−8Ω·m (copper), R = 0.22Ω, D = 0.03m (30mm), d = 0.01m (10mm) and L = 0.035m (35mm), we get a wire diamteter ∅ = 1.2×10−3m (1.2mm)

A coil wound with 1.2mm copper wire would need a length of 15.3m, and it would have 8 layers with 29 turns each. The resistance would be around 0.226Ω. Close enough for me.

Once the math was done, i bought 160m of 1.2mm enameled copper wire and started winding the coils.

Pinomelean

Pinomelean

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.