Well I started another random project. I have been doing a lot with resin based injection molding lately and just got my first parts out of a professional injection molding machine. It is really cool and makes me want my own machine. I am not sure I will ever actually build this machine. There is a ton of design work to do and money to invest in the parts. But it doesn't cost me any time to design it, and it will help me determine if building a machine is practical or if I should just invest in buying my own machine.

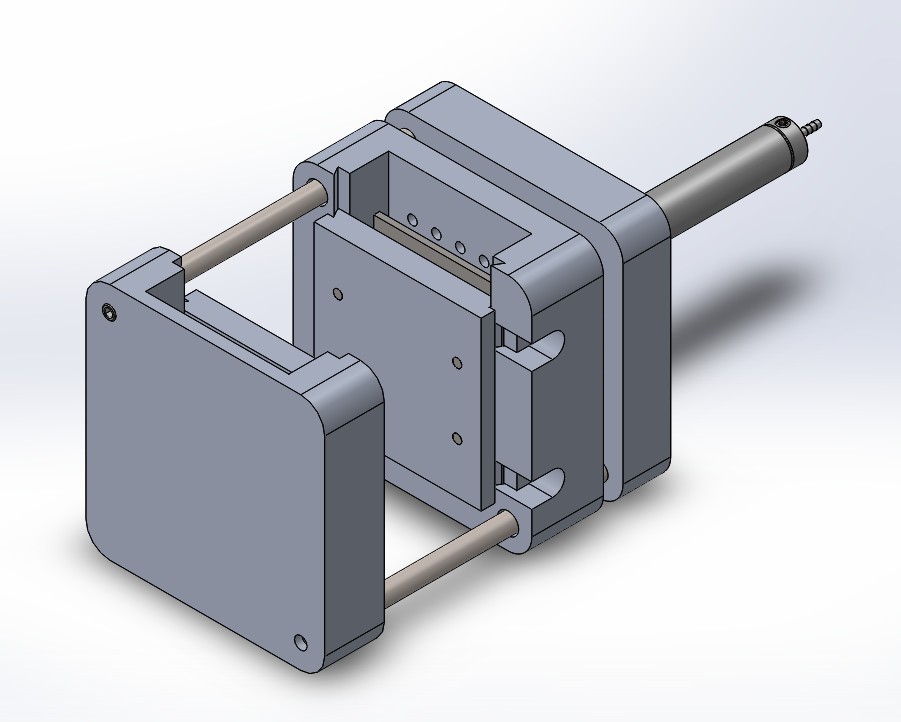

Either way I find doing CAD work like this relaxing after a stressful day at work. There are no deadlines to finish the design and I can work on whatever part I find interesting. Here is where I am at after about 1 day of design work.

jupdyke

jupdyke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Please do this! I'll be your friend forever.

I'd love to have a desktop IM machine...

Are you sure? yes | no

I'm assuming you're going for something like this?

Are you sure? yes | no

Yes that is one of the machines that inspired me. It is really awesome and I love it. My machine will need to be slightly larger because the part I want to make is larger. But I think a modular design would be possible

Are you sure? yes | no

Did anyone email the guy who posted that youtube video to see what the specs are on that machine and how much those little guys cost? They can't have much clamping strength but they are still really neat little machines.

Are you sure? yes | no

Alex, I have not contacted them. I thought about it since I lived in Japan for a year. Here is a link to their website. http://www.sellbic.com/

I agree that the clamping force must be fairly low becuase it is using a screw and motor to close the mold. I think this is the same machine in another video.

https://www.youtube.com/watch?v=5TEDhZGNkU0

Are you sure? yes | no

ooh I just found the datasheet and pricing for the machines, I don't know why it was so difficult before - their website is so easy to navigate.

http://www.sellbic.com/English.CD/COMMANDSYSTEM.UnitMold/COMMANDSYSTEMP03.pdf

The "model 13" is 980,000 yen which is a little over $8k. They say they can build it with as much as 50 tons of clamping force - that's ridiculous. They are turning their ballscrew with a tiny cycloidal drive to step up torque, really cool:

http://www.sellbic.com/English.CD/MOBILEFORMER.InjectionMoldingMachine/Mobile05.pdf

50 tons is insane for a machine that size, assuming the cross section of your cavity is what 8" x 8" = 64 in^2 - you'd be able to inject plastic at 1500 psi. Check out the injection screw design too, pretty cool:

http://www.sellbic.com/English.CD/MOBILEFORMER.InjectionMoldingMachine/Mobile04.pdf

Are you sure? yes | no

Man, 8k is reasonably cheap in comparison. I wonder if that is just the machine or also the mold tooling. Also, I suspect that is for a tiny part like that. My tank track parts are much bigger than that. Maybe I should send them a email for a quote. :) quotes are always free

Are you sure? yes | no

Yeah even if you buy one of their machines, you can have a lot of fun making modifications to it. Not to mention designing molds with auto ejector pins, etc. It wasn't clear what the various systems included, probably worth asking them.

Are you sure? yes | no

I will be adding more details over the next few days. I will be outlining my goals for the project, milestones and what capabilities I am hoping to achieve. I am designing it around having 6"x6" molds which you can put into the machine. Right now the overall machine is 10" x 10" x 24". But the design is still very rough.

Are you sure? yes | no

Nice idea! What dimensions are we talking about here? Could you add names to the parts and what they do?

Are you sure? yes | no