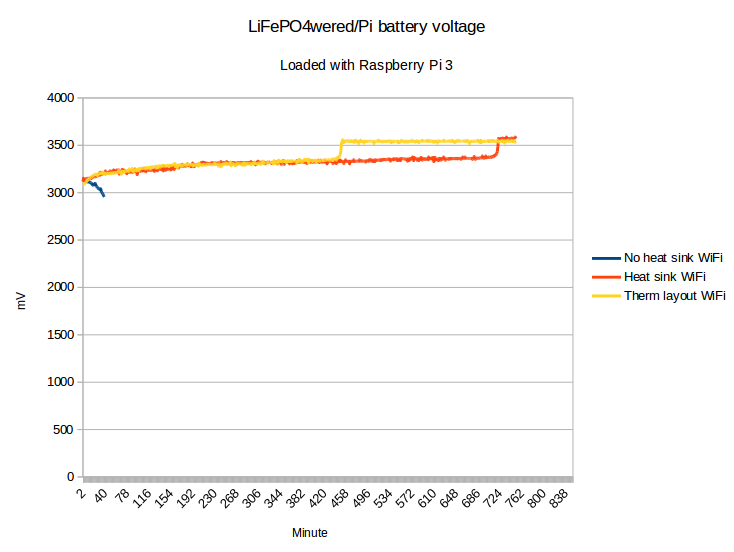

In my previous log I already hinted that the thermally improved layout does quite well. So here's the data! The graph below shows the battery voltage of the LiFePO4wered/Pi when starting to charge from empty, with the load Raspberry Pi 3 running (idle) and WiFi connected:

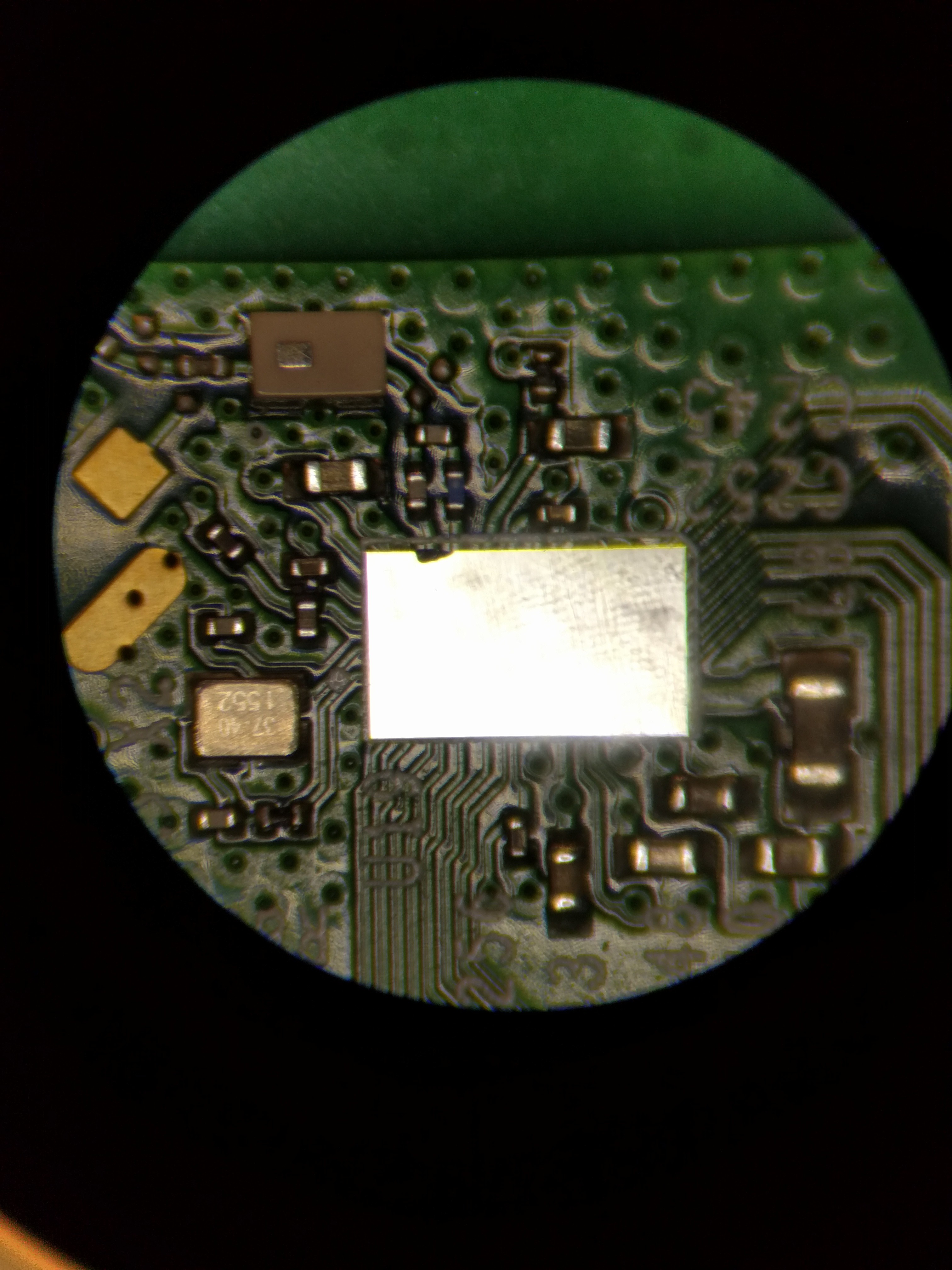

So next I wanted to see how the system would perform with the improved layout combined with a heat sink. Unfortunately, that's when I ran into a problem. The WiFi on my Pi 3 stopped working! After fighting with it for a while, I noticed this:

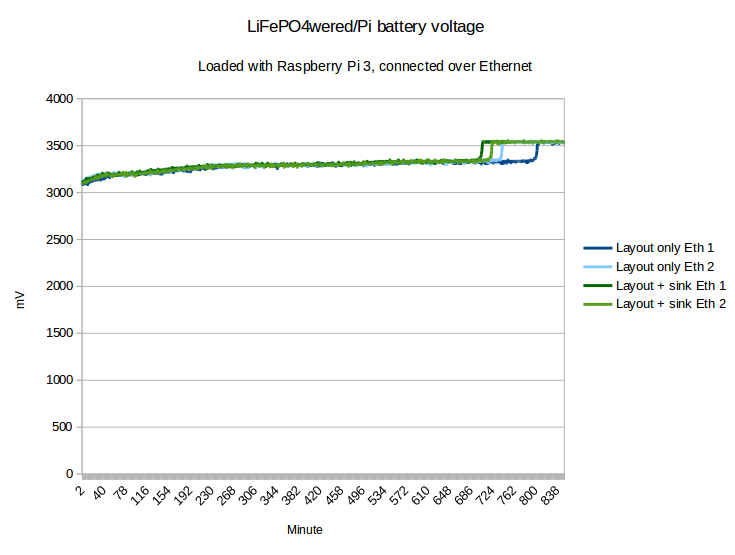

Anyway, I decided to do the testing for the improved layout plus the heat sink with an Ethernet connection. This of course results in extra load so the charge times can't be compared to the earlier WiFi tests, but they can be compared to each other.

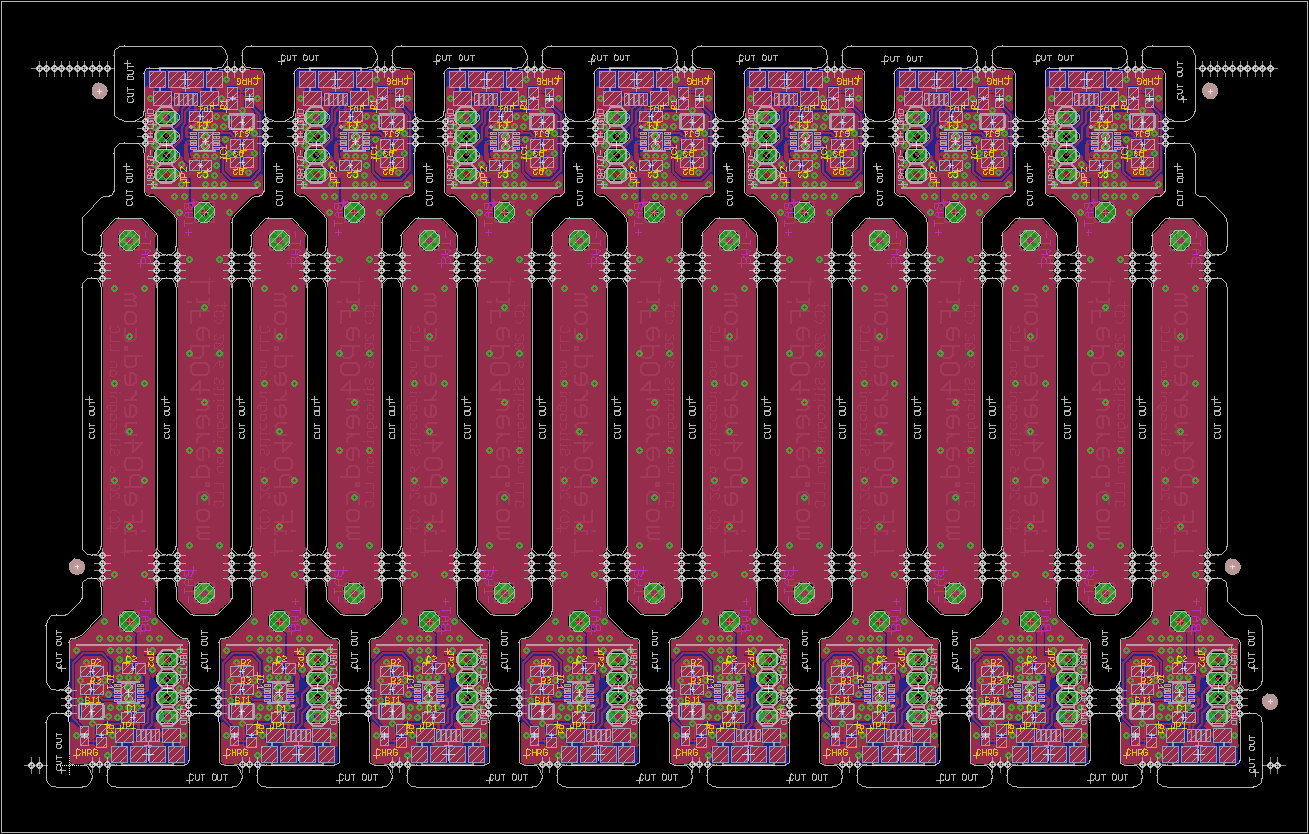

Since I'm very happy with the performance of the new layout, I went ahead and created a panel:

Another thing to note is that my improved layout prototypes were made by OSH Park and were using the standard 1 oz copper weight. My panels will be made with 2 oz copper, which hopefully will make their thermal performance even better!

Patrick Van Oosterwijck

Patrick Van Oosterwijck

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.