Features

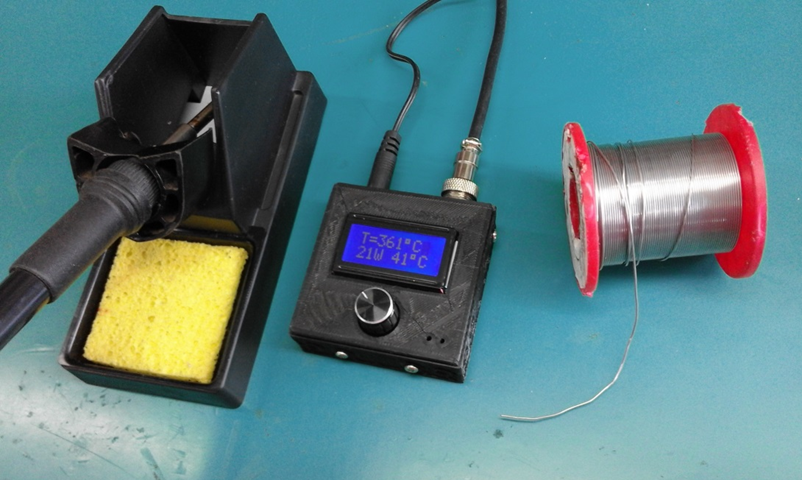

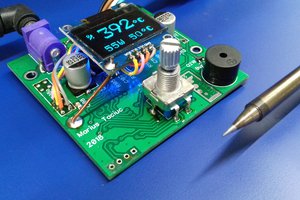

- Miniaturized size 2.6 inch square box

- Wide voltage range from 9V to 29V. Works on 60 to 150W solar panel

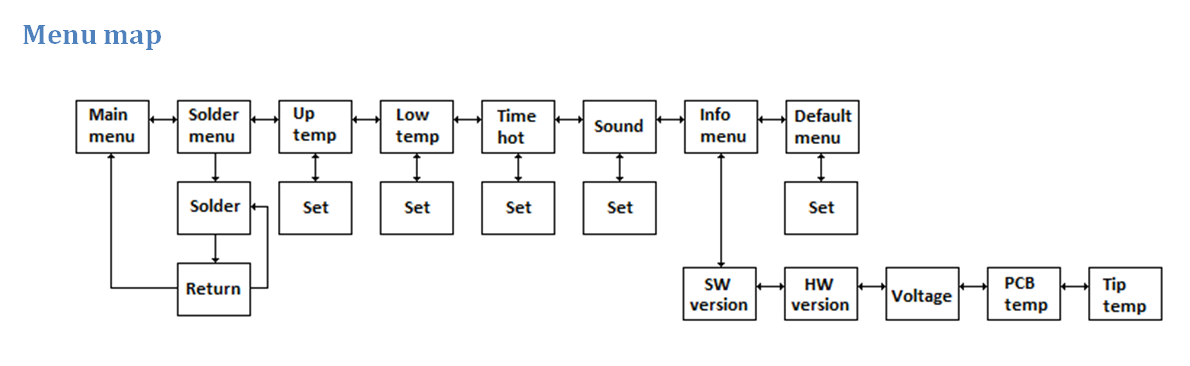

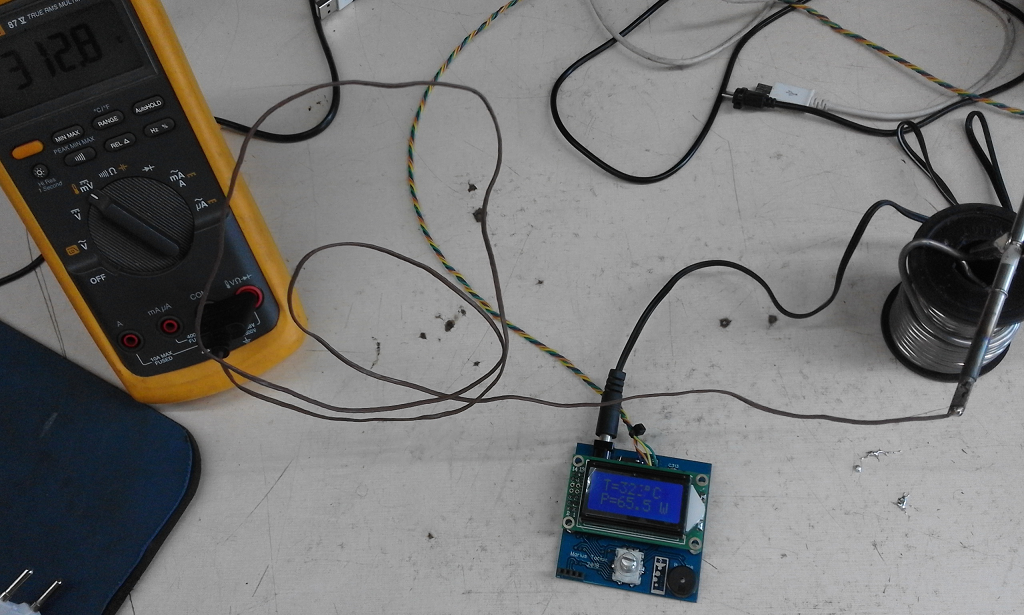

- Adjustable real value soldering temp from 60* to 430* on the tip

- Adjustable stand by temp from 60* to the soldering temp value

- Adjustable time before entering stand by up to 360s

- Adjustable sound settings

- Adjustable back light intensity

- Info menu providing details about the SW and HW versions.

- Possibility of reading the PCB and Tip temperatures

- Possibility of reading the input voltage, tip current and tip power calculation

- Embedded alarms and error messages on the screen. Warnings for loose wires, disconnected aviator plug, overvoltage and tip heating element damage.

- Thermal shut down in case of over tip temperature or over board temperature

- Reverse polarity protection for 5 seconds

- Set to default values menu

- Intuitive menu

- Single rotary encoder operation

- Low power consumption achieved by using the stand by function

- Long tip life

- Precision temperature control

- Customizable

- Ultra fast operation and short heating time

Why build your own?

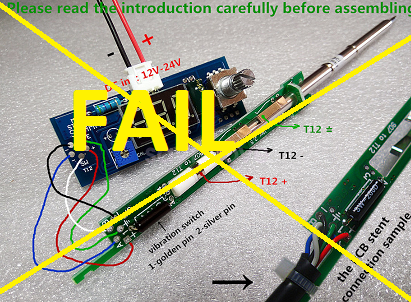

There are similar products on the market. For instance this one:

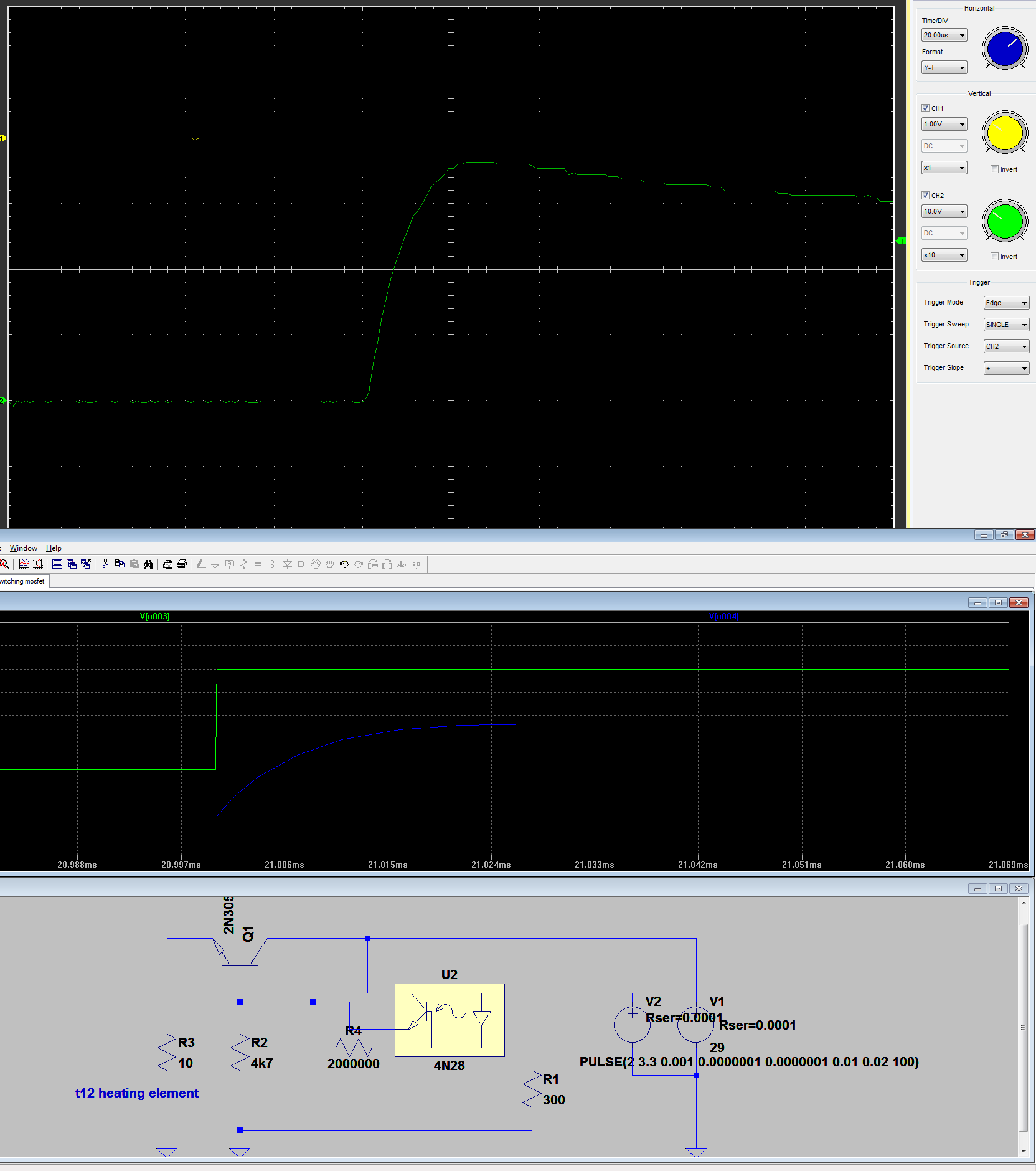

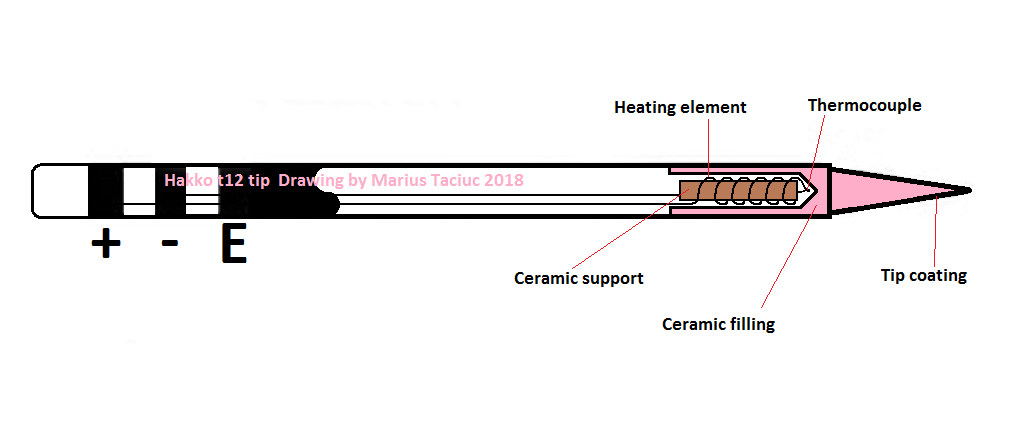

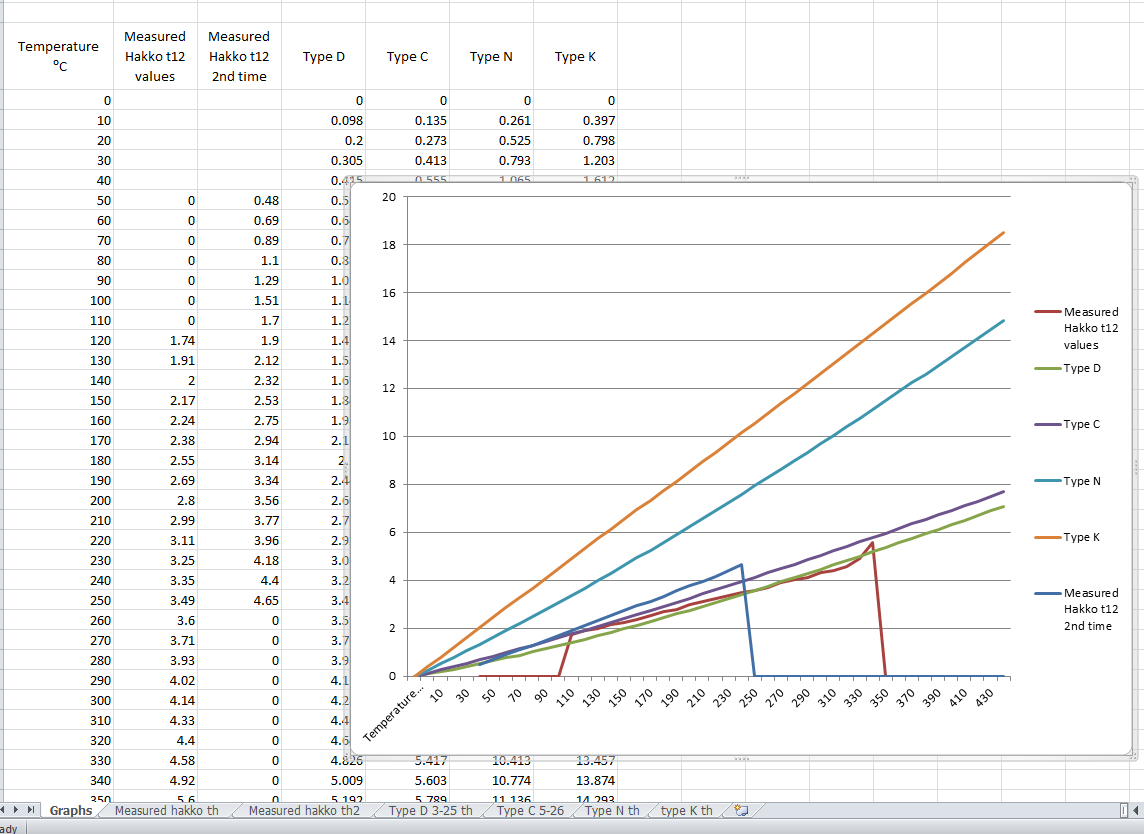

I bought one of this, but I just dislike it. The rotary encoder does not have proper SW debounce and the settings are sometimes decrementing when you want them incremented. The mV/*C setting corresponds to a type K thermocouple, but the actual tip has something like a type C one or something around 20 or 21mV/*C. This means that these funny soldering stations are displaying 350*C and they really heat up to 550 damaging the tip. The menus are just P01, P02.. and you never know what they mean when you need to set something. I just want something that I can trust.

Marius Taciuc

Marius Taciuc

Andy

Andy

David

David

Hi, sorry for posting on this old thread.

I'm designin my own soldering station and I found you project. I was wondering how do you performed the thermocouple cold junction compensation?

As far as i saw you don't implement it, but may be it's not nessecary? Do you know how much the accuracy of tip temperature measurement is degraded?