Opensource 3D Printed Electronic Components

Here's what we've got planned so far & the status of each:

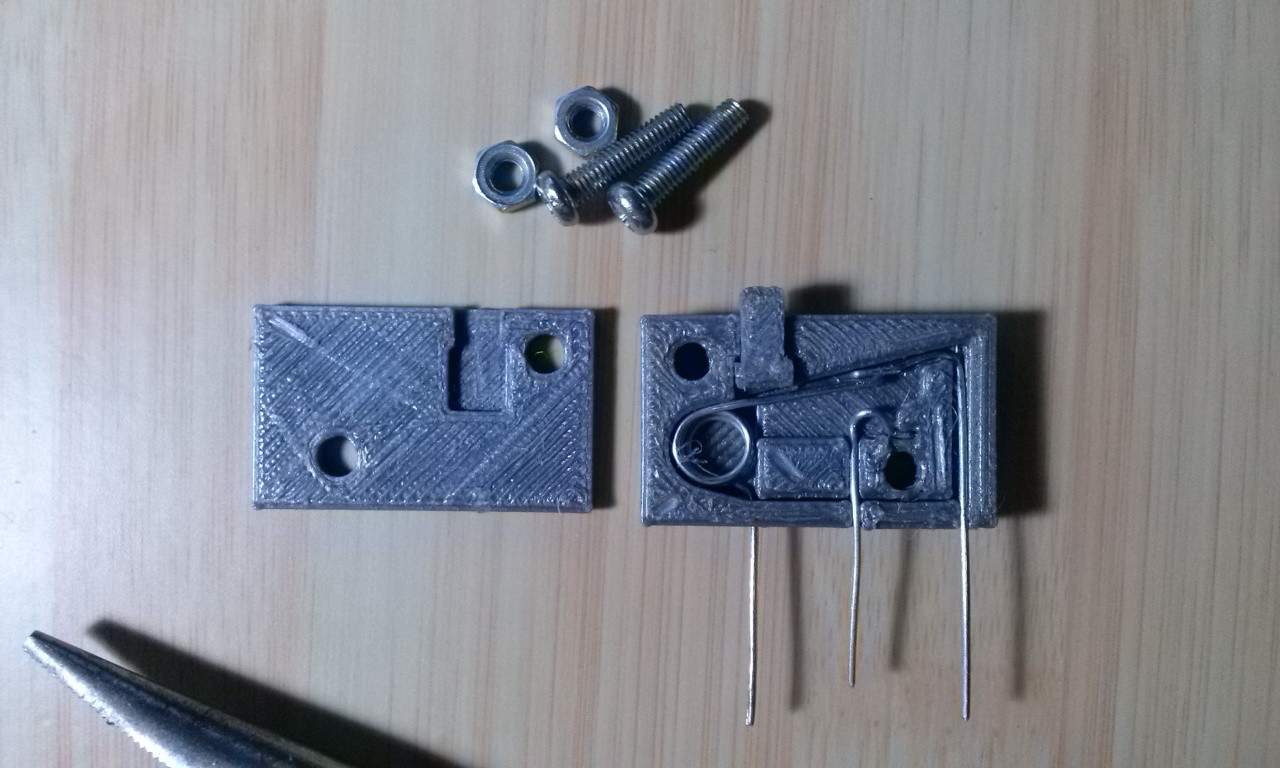

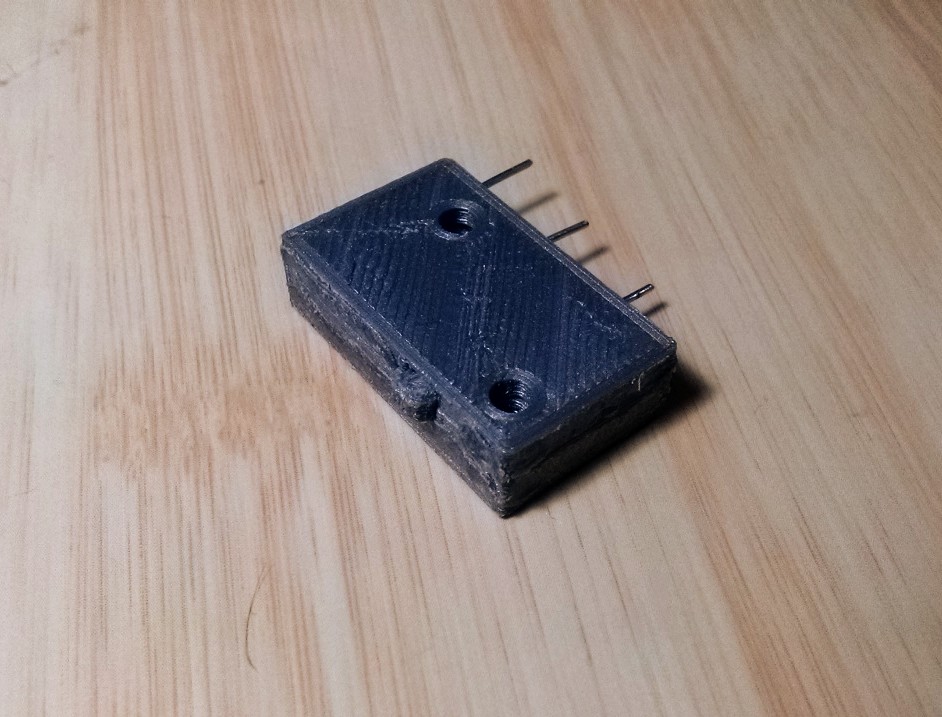

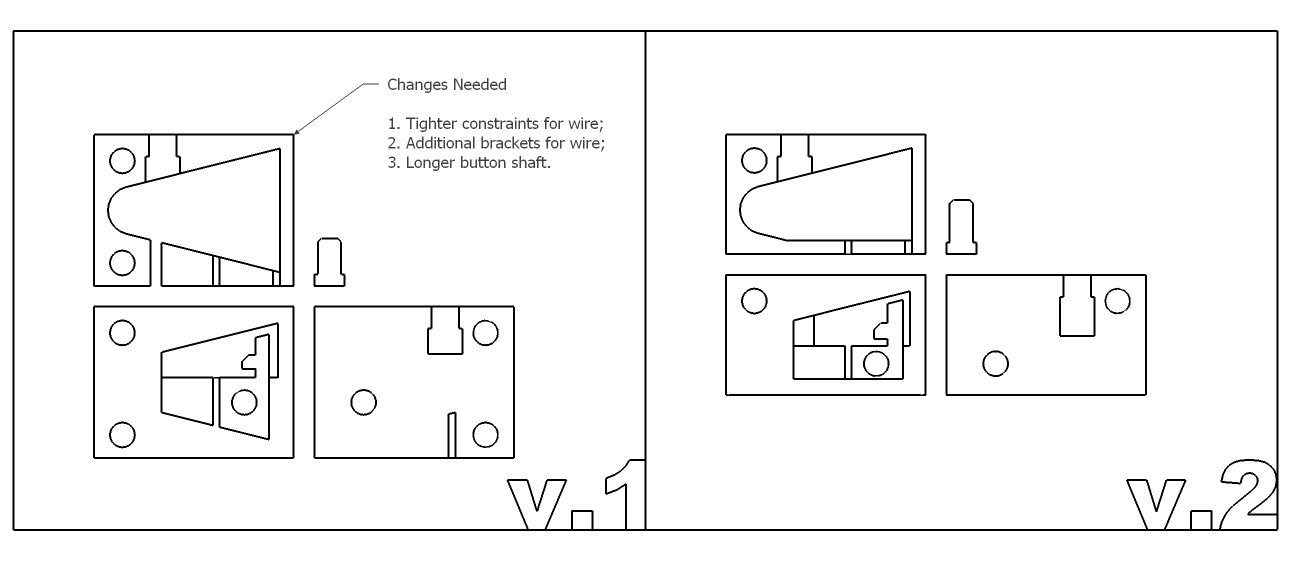

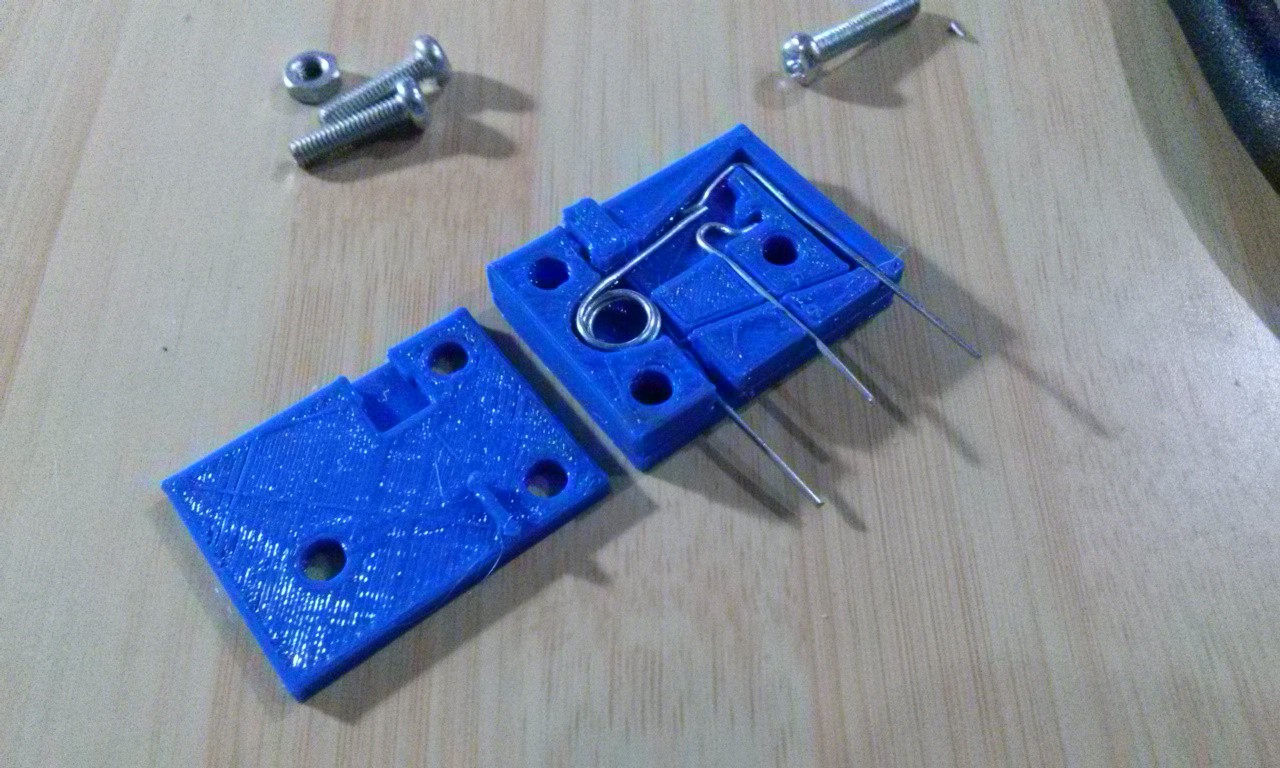

1. Microswitch (V.2 already completed)

2. Toggle-Switch

3. IoT Push-Button w/ESP8266 (have an old prototype)

4. Headers

5. Arduino Breakout Modules (have hacked together some non-3DP versions already)

ProgressTH

ProgressTH

We included the SketchUp 2015 file and the STL.

We included the SketchUp 2015 file and the STL.

ProgressTH

ProgressTH

Roger

Roger

B K

B K

Katie G

Katie G

Seems like a pretty neat proof of concept!

That said, it looks like you're using a screw and nut either to hold it together or to mount it. Any reason you wouldn't make it so that at least the nut could sit inside the plastic part?