The fun thing about over-engineering stuff (or not really engineering it at all--just over-building it) is that you can throw things together without much regard for precision. The updated thrust testing rig fits this description nicely. I also managed to build the rig with minimal additional cash outlay--I grabbed a pillow block at my handy neighborhood surplus store, but most of the other stuff was already floating around my basement.

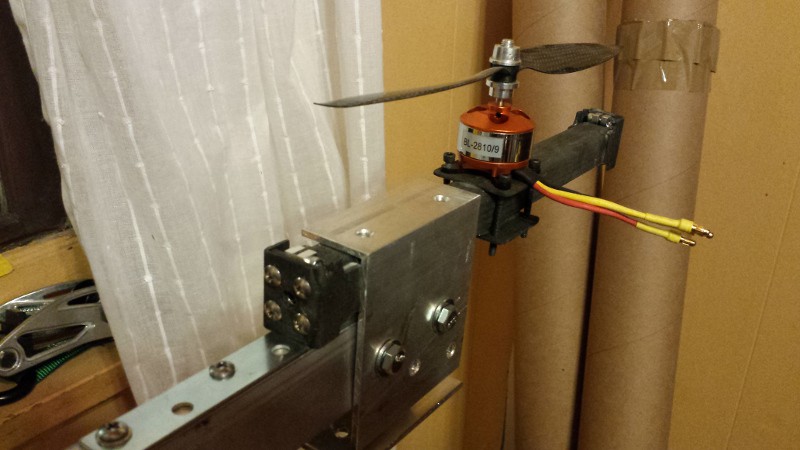

The new rig is designed specifically to test a single propeller on the motor mount, leaving room for motor cooling venturi tubes and such. I thought about recreating the motor mount with a spare chunk of CFRP square tube, but this seemed a bit wasteful. As such, the clamping mechanism is a bit awkward (especially since I re-used the aluminum extrusion from v1.0), but it's easy to use and quite secure:

The two bolts aren't tightened in the picture, but when I torque them down the motor mount is fairly secure. Well, minimal rattling.

Thrust Testing Rig v1.0 was heavy, mostly because its base was a ~5' 2x8 I had left over from another project. For v2.0, I used a mounting bracket scheme that fits to my desk; the rear part loops around the (annoyingly narrow) lip of the desk's surface, and the front bit uses a few removable brackets so I can take it off easily for transport:

I might move this down a bit so the drawer is accessible again. Who am I kidding--I don't use drawers, I just leave stuff in piles. Ha!

I had a few copper fittings left over from a plumbing project that fit the pillow block fairly well. The bearing has a few set screws that I was able to tighten securely; the shaft rotation isn't very centered, but I just needed a relatively low-friction pivot point that was also quite rigid. This definitely fits the bill:

It's fun to do a bit of 'big kid soldering' after playing around with 0402 resistors. The pillow block rides on a slip coupling fit over 1/2" copper pipe; one of the elbows is just dry fitted so I can pull the bearing out. Also, I didn't want to sweat pipes around the bearing.

So! FINALLY ready for the next round of thrust tests! My wife and I are headed to the Bay Area through 10/19 for a conference and a vacation; with luck, I'll be able to play around with motor cooling and fan ducts before the end of October. Stay tuned!

-zach

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.