What Servo System Means

Greek-derived ServoMechanism is the source of the acronym Servo, which means slave. As the name implies, it indicates that the system executes the intended movement by following external instructions, which may include position, speed, torque, and other variables.

A servo system, sometimes referred to as a follow-up system or servomechanism, is a feedback control system that is used to precisely track or replicate a particular process. An automatic control system called a servo system makes it possible for the output controlled quantities, like the object's position, orientation, and state, to adapt to changes in the input target (or given value). The primary function of this device is to increase, modify, and control power in accordance with control command specifications. This allows the drive device to control torque, speed, and position in a highly convenient and adaptable manner.

Main Function

1. Use low-power command signals to control high-power loads; 2. To achieve long-distance synchronous transmission in the absence of a mechanical connection, the input shaft controls the output shaft located at a distance; 3. Allow the output mechanical displacement to precisely track electrical signals, such as those from recording and indicating instruments, etc.

The Main Structure

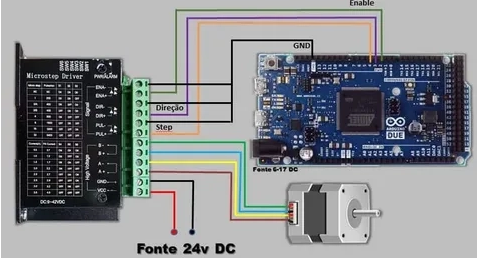

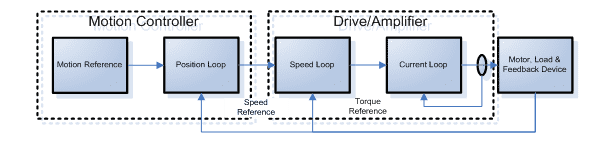

Three components make up the servo system: an electric motor (typically a servo motor), a power drive device, and a controller.

The power drive device functions as the main loop of the system, and the controller modifies the control amount based on the difference between the numerical control system's given value and the actual operating value detected by the feedback device. In accordance with the size of the control amount, it applies electric energy from the power grid to the motor on the one hand. Alternatively, it modifies the motor's torque. Conversely, it transforms the grid's consistent voltage and frequency power supply into the alternating current or direct current needed by the motor, depending on its specifications; the motor then operates the machinery in accordance with the amount of power.

Control Method for Servo Systems

Both closed-loop and open-loop control are possible with servo systems, however closed-loop control is more common.

Open-loop control system: This type of system control operates without the need for feedback data and does not feed back control outcomes to modify the system that is being controlled at the moment. For instance, when you flip on the light switch, the control activity ends the instant you press the switch; the activity of pressing the switch is independent of whether the light is on or off; shooting a basketball: the ball can't be controlled once it's released. The control activity ends when the ball is released, regardless of whether it is scored or not.

A closed-loop control system is one that can modify control actions in response to errors in control results and feed back control results for comparison with desired values. As an illustration: Prior to adjusting the faucet, determine the anticipated water flow rate in your mind. Once the faucet is opened, use your eyes to see how the current flow rate compares to the anticipated value. Then, continuously adjust it with your hands to create a feedback closed-loop control, just like when you ride a bicycle.Similarly, to create a closed-loop control, the direction and speed of travel are continuously adjusted.

Applications of Servo Systems

Automated production lines, industrial robots, CNC machine tools, aerospace, medical, optical, and other industries all make extensive use of servo systems. Owing to its exceptional accuracy, dependability, and efficiency, servo systems have emerged as a fundamental technology in the realm of contemporary machinery production.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.