-

Why Do Stepper Motors Lose Steps When They Get Hot?

04/11/2024 at 03:06 • 0 commentsWhen a stepper motor gets hot, it loses steps and fails to rotate. Under no-load conditions, the following may be the reasons:

- Excessive load or stuck: If the motor load is too large or the motor bearings are stuck, it will cause the motor controller to continuously output current, causing the motor to overheat, and it will easily lead to loss of steps and the motor not rotating.

- Drive circuit problems: Unreasonable drive circuit design or unstable drive voltage will cause the motor to heat up and affect its normal operation.

- Poor heat dissipation of the motor shell: When working in a high temperature environment for a long time, poor heat dissipation of the motor will cause the motor temperature to be too high and easily damage the motor.

- The stepper motor generates serious heat: The stepper motor itself generates a certain amount of heat due to its working principle. However, if the motor heats up severely, there may be a problem with the motor's internal windings or iron core, which requires inspection and repair.

![]()

To solve this problem, the following measures can be taken:

- Check the load: Make sure the motor load is within the normal range to avoid overload or underload. At the same time, check whether the motor bearings are normal. If any abnormalities are found, they need to be replaced in time.

- Check the drive circuit: Make sure the drive circuit design is reasonable and the drive voltage is stable. If there is a problem with the drive circuit, it needs to be repaired or replaced in time.

- Optimize heat dissipation: Ensure that the motor casing has good heat dissipation conditions. You can install heat sinks or fans and other heat dissipation equipment on the motor casing to help the motor dissipate heat quickly.

- Check the motor: If the motor heats up severely or other abnormalities occur, the motor needs to be inspected, repaired or replaced in time.

-

Several Types of DC Stepper Motors with High Waterproof Levels

04/11/2024 at 03:03 • 0 comments1. IP65 DC stepper motor

DC stepper motors with protection class IP65 have a high degree of dust and water tightness and are suitable for some special working areas, such as production halls, sewage treatment plants, etc. This type of motor has a tightly sealed housing that can prevent the ingress of dust, sand and splashing water, and has the ability to adapt to harsh environments.

2. IP67 DC stepper motor

The DC stepper motor with IP67 protection has a fully enclosed structure, is waterproof, can work underwater and is dustproof. This type of motor is generally used in applications that require long-term operation in harsh environments. These include rain and snow weather, swamps, hot springs and other places.

![]()

3. IP68 DC stepper motor

The IP68 DC stepper motor is a fully enclosed, waterproof structure that can completely isolate the ingress of water molecules and will not be damaged even if immersed in water for a long time. such as underwater detection and other fields.

4. IP69K class DC stepper motor

The IP69K-rated DC stepper motor is a fully enclosed high-temperature and high-pressure structure with very high waterproof, dustproof, high-temperature resistance and corrosion resistance. Such motors are commonly used in the food and beverage processing industry, medical equipment, shower equipment and other applications where high hygiene standards are required.

In general, DC stepper motors with different waterproof levels have different characteristics and application ranges. When selecting, users should determine the required waterproof level based on the specific working environment and needs.

-

What are the components of a DC motor?

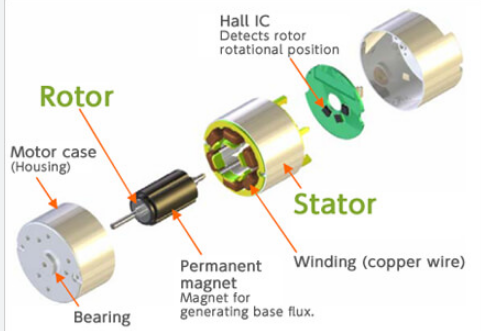

03/12/2024 at 06:48 • 0 comments1. Structure of brushless DC motor

Brushless DC motors are complex mechanical system composed of multiple parts. Its main components include the motor body, rotor, stator, bearings, end covers, magnets, encoders, drivers, etc.

1.1 Motor body: The motor body is the core part of the brushless DC motor and usually consists of two parts: the rotor and the stator. The rotor can be an inner rotor or an outer rotor, which is composed of magnetic poles, shafts, bearings, etc.; the stator is the fixed part of the motor and is composed of coils, iron cores, and motor brackets.

1.2 Rotor: The rotor is the rotating part of the motor, which consists of permanent magnets, shafts and other components. The permanent magnets of the inner rotor are located inside the rotor, while the permanent magnets of the outer rotor are located outside the rotor.

1.3 Stator: The stator is the directional component of the motor. It is composed of coils and iron cores and is the immovable part of the motor.

1.4 Bearings: Bearings are the core components that support the rotating part of the motor. Rolling bearings or sliding bearings are usually used.

1.5 End cover: The end cover includes the front cover and the back cover. It is a component used to seal the motor. It is usually installed at both ends of the motor body.

1.6 Magnetic steel: Magnetic steel is a component used to generate a magnetic field in a motor. It is usually composed of permanent magnets or electromagnets.

1.7 Encoder: Encoder is a component in the motor used to detect the rotor position and motion status. It usually includes photoelectric encoders, magnetic encoders and other types.

1.8 Driver: The driver is the core component of the motor control system. It can control the speed and steering of the motor based on signals.

![]()

2. Working principle of brushless DC motor

The working principle of the brushless DC motor is to generate a magnetic field between the stator and rotor through permanent magnets and current, thereby generating electromagnetic torque. Specifically, when current passes through the stator winding, a magnetic field is generated in the stator, and at this time, the rotor permanent magnets are subjected to magnetic forces and start to rotate. When the rotor rotates to a certain position, the driver changes the direction of the current so that the rotor continues to rotate. By continuously changing the direction of the current, the motor can be continuously rotated.

3. Advantages of brushless DC motor

Brushless DC motors have many advantages, such as high efficiency, high torque, low energy consumption, lightweight, low noise, etc. In addition, since brushless DC motors do not require the use of carbon brushes, their lifespan is also longer. These advantages make brushless DC motors widely used in robotics, electric vehicles, medical equipment and other fields.

My Pages

Projects I Like & Follow

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Lutetium

Lutetium niftylight

niftylight Frederic

Frederic Hari Wiguna

Hari Wiguna Mike Szczys

Mike Szczys Makarand Kapoor

Makarand Kapoor Philip Zucker

Philip Zucker David Prutchi

David Prutchi Rodolfo

Rodolfo Marius Heier

Marius Heier jon.knutton

jon.knutton Brian Brocken

Brian Brocken Celestial Robotics

Celestial Robotics Greg Zumwalt

Greg Zumwalt engineerkid1

engineerkid1