A difficult problem NASA has faced since the early days of space travel is the need to efficiently filter water. There is a huge cost to carry water into space: When blasting off from a Kennedy Space Center launch pad, the rocket must overcome and escape Earth’s gravity pull. Every pound counts and contributes to more rocket fuel needed to break free of Earth’s gravity pull. Water costs $10,000 per pound and one gallon of water weighs 8.33 pounds! Since astronauts are limited to three gallons a day that costs $249,000 each day---per astronaut. To mitigate this problem, all types of moisture must be recycled into drinking water aboard any spacecraft.

I met an astronaut at NASA Ames Research Center in California during a visit to a laboratory there working on a unique water filtration system. The astronaut met me with a beacon of urine in one hand and a cup of coffee in the other. His comment, with a big smile was, “On the International Space Station (ISS), tonight’s urine is tomorrow morning’s coffee!”

On the ISS, every drop of moisture, from humidity to urine, is filtered, purified, and reused. However, the current system depends heavy upon specialized filtration beds that weigh down resupply missions and need to be swapped out every 90 days. This system unfortunately fails to filter out certain semi-volatile contaminants.

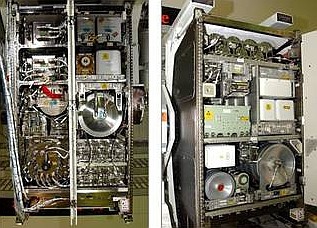

The Advanced Water Recycling group at NASA’s Ames Research Center, developed a possible unique solution which does the job and can ultimately lead to a smaller, low-cost, light weight solution for the ISS and other future endeavors to the Moon and Mars and beyond. Figure 1.

Figure 1 The water recovery component of the Environmental Control and Life Support System or ECLSS (Image from NASA)

There are two key components which make up the ISS Regenerative ECLSS: The Water Recovery System, or WRS, and the Oxygen Generation System, or OGS. The WRS conducts the water purification and filtration process in the ECLSS. From this WRS, commercial companies accessed this technology from NASA and began to adapt it to a simpler Earth-based water treatment system for areas around the world with no access to drinkable water.

NASA's previous research provided the Microbial Check Valve, or MCV, an integral component of the purification and filtration process. This is an iodinated-resin which provides a basic means of controlling microbial growth in water without using any power. By dispensing iodine into the water, an important secondary nutritional function for the populace is an added benefit. This chemical, when added to the diet, is known to promote proper brain functions and maintain bodily hormone levels to regulate cell development and growth. Children who lack iodine in their diets can exhibit growth mental retardation.

There are many, many other people around the world who are forced to use water contaminated by livestock that they sift through a cloth fabric to remove dirt and debris. Clean water, for many people, is too far away from villages which makes transporting that water to their village virtually impossible. See Figure 2.

Figure 2 Shown here are volunteers installing and testing a water purification system in Kendala, Iraq. The Microbial Check Valve is in action here (Image from Concern for Kids)

Mimicking human kidneys

Peter Holme Jensen, CEO and cofounder of the company Aquaporin A/S, commented “Nature is our biggest R&D lab. Whatever discoveries nature has made, they’re quite efficient.” Jensen met Michael Flynn, the lead for the Advanced Water Recycling group at NASA’s Ames Research Center. Flynn introduced a possible solution on which he and his NASA colleagues had been working.

The project was to develop a water filtration system based on aquaporins—the proteins that all living cells use to transfer water through their membranes. Aquaporins enable plant roots to absorb water from soil and also for human kidneys, to filter about 45 gallons of fluid per day from the human body. These proteins are highly selective, so only water passes through and not contaminates.

NASA was interested

Aquaporin provided NASA with test prototypes. Aquaporin works with two basic types of filters:

- Reverse osmosis, which uses pressure to push fluid through a filter.

- Forward osmosis, which operates without any energy or outside influence.

In forward osmosis, with polluted water on one side of a membrane and saltwater on the other, the physics of entropy enable the salt to spread evenly through all the water. However, since the salt cannot pass through the membrane, it draws all the water from the other side of the membrane, leaving only pollutants behind.

When pressure is applied, eventually the membrane will clog. However, during forward osmosis, since pressure is not applied, it acts more like a sponge sucking up water. Therefore membranes have a much lower tendency to clog. This also means forward osmosis can handle very dirty water, eliminating the need for distillation.

Ames successfully tested this solution over the course of three years, using sugar water to extract clean water from urine.

Aquaporin’s branch at NASA’s Ames Research Center hopes to eventually turn their work into a product that will never need replacing, because it will heal itself. By genetically engineering bacteria to produce Aquaporin proteins in a lipid membrane, NASA would be able to create forward osmosis filter with the resilience and regenerative power of the small intestine. Jensen commented that “You can really do horrible things to the intestine. You can swallow a paper clip, and it will fix itself.”

The technology is still 10 to 30 years from feasibility, just in time for deep space travel.

Steve Taranovich

Steve Taranovich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.