During the next weeks (the "anything goes" section of the HackadayPrize) I will start building linear drives mainly using parts from old printers, scanners, mice and whatever I find useful to disassemble:

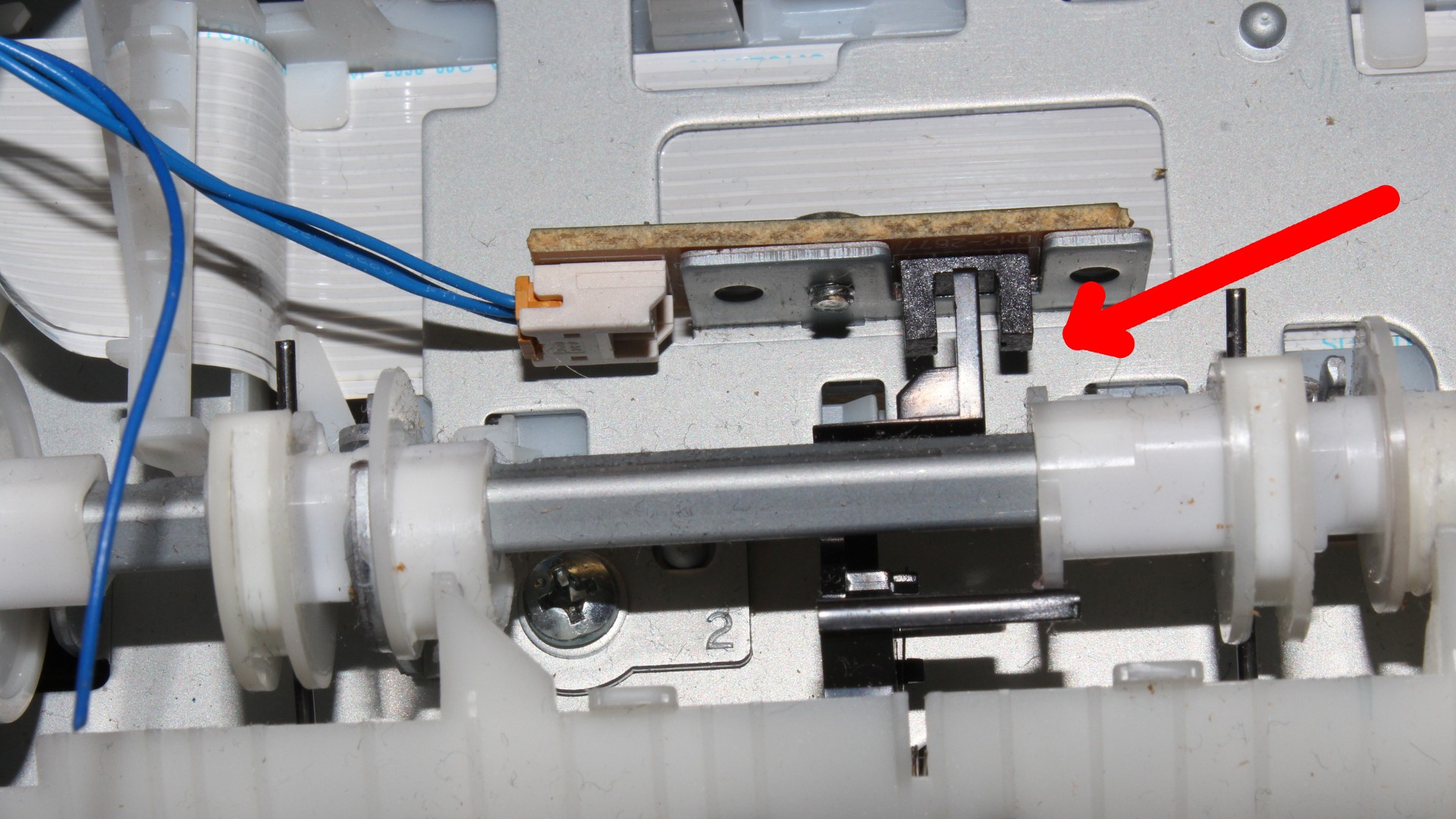

First thing I need is motion detection. Printers use transmissive photo sensors as end switches and rotary encoders:

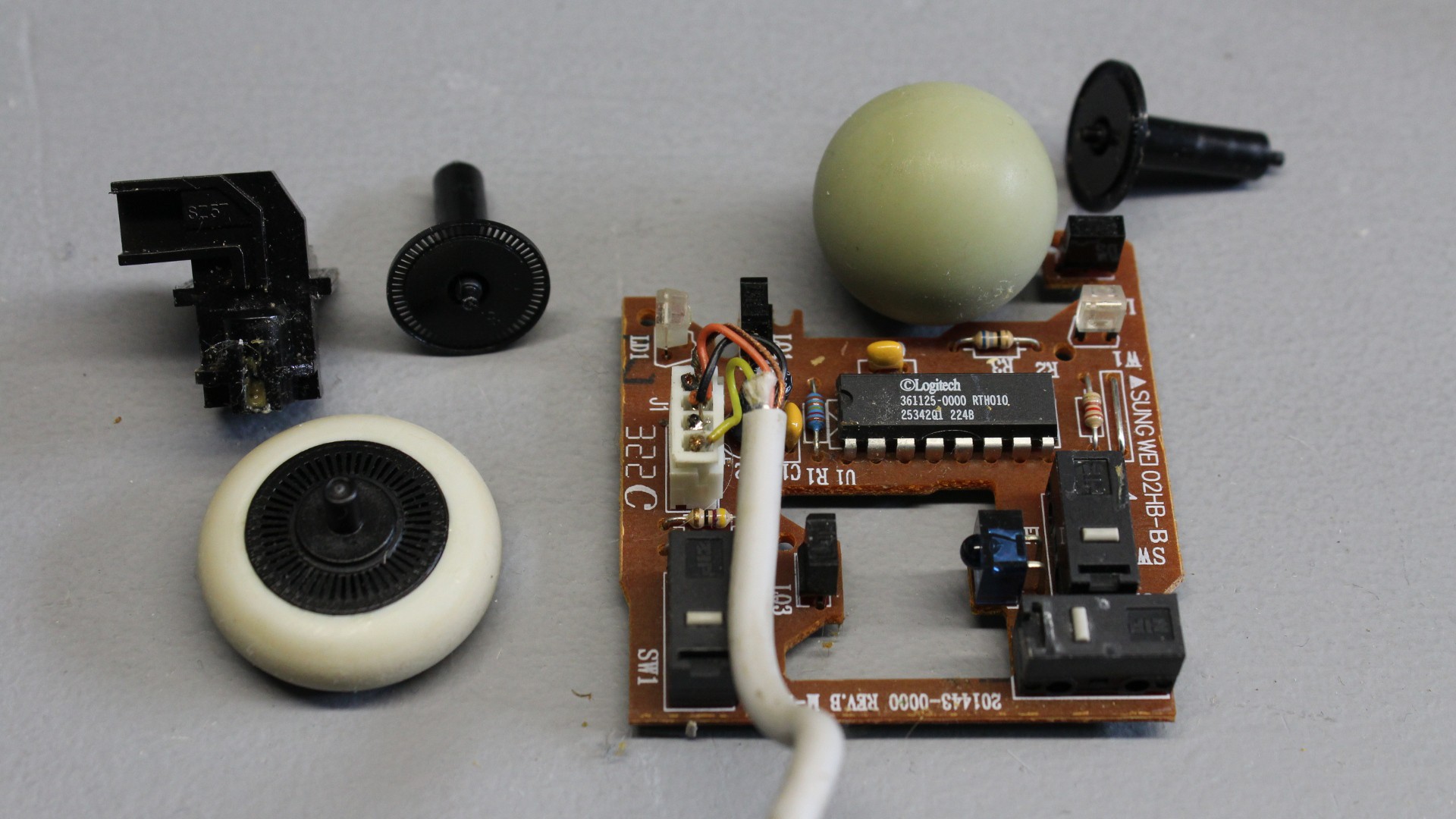

I have already demonstrated in a video how to use them in drives. I will address in more detail how to figure out the pin configuration of unknown sensors and what resistors to use on the sensor and the LED side. Old computer mice with balls were build around such sensors, too:

...but this one is still in use while I am typing this log, thus it's no good option...

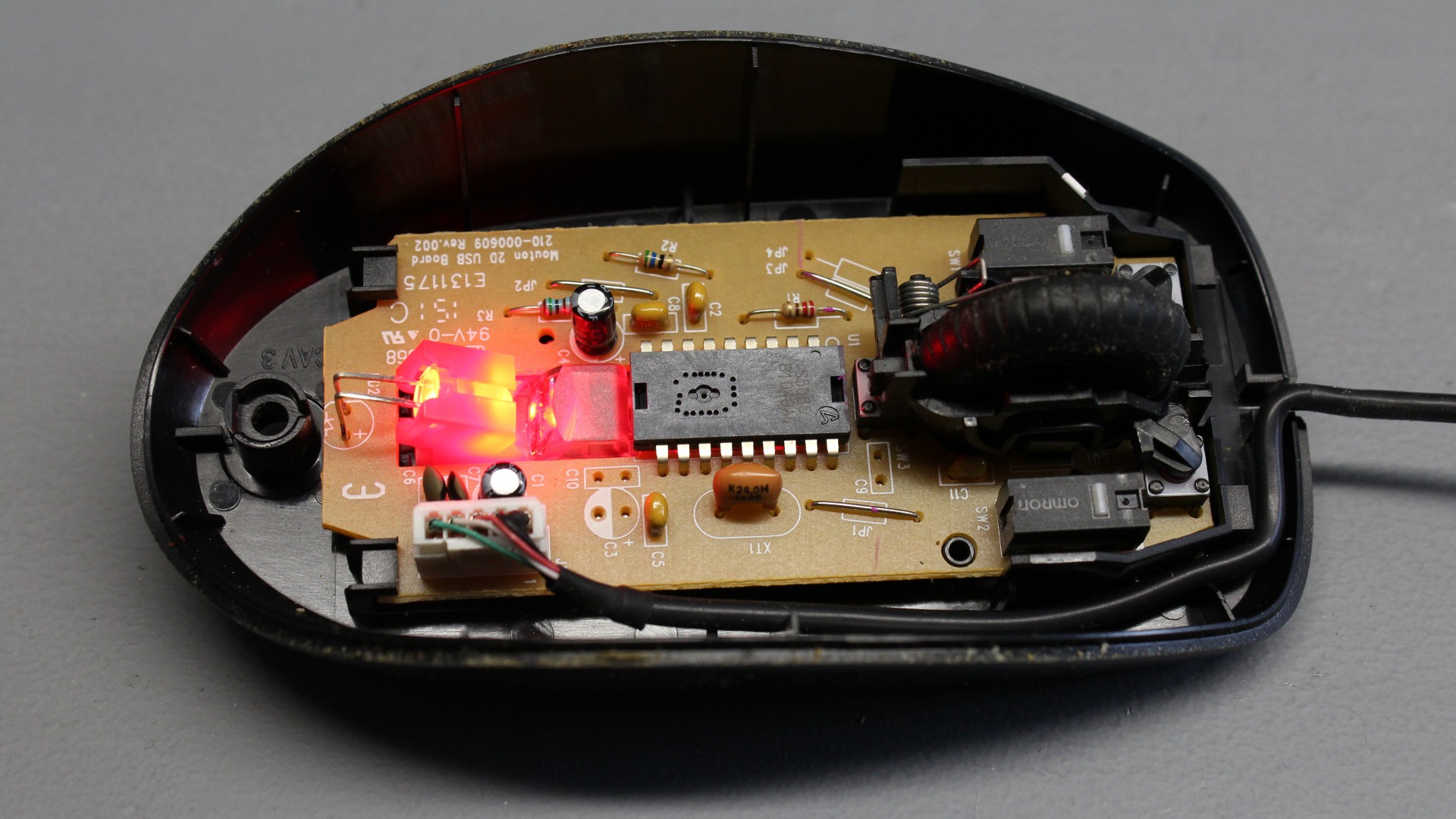

...must get another one, but they are hard to find these days. Newer, optical computer mice have an interesting option - a tiny camera:

and a "conventional", transmissive photo sensor at the scroll wheel.

Please leave a comment if you know other sources for simple motion sensors.

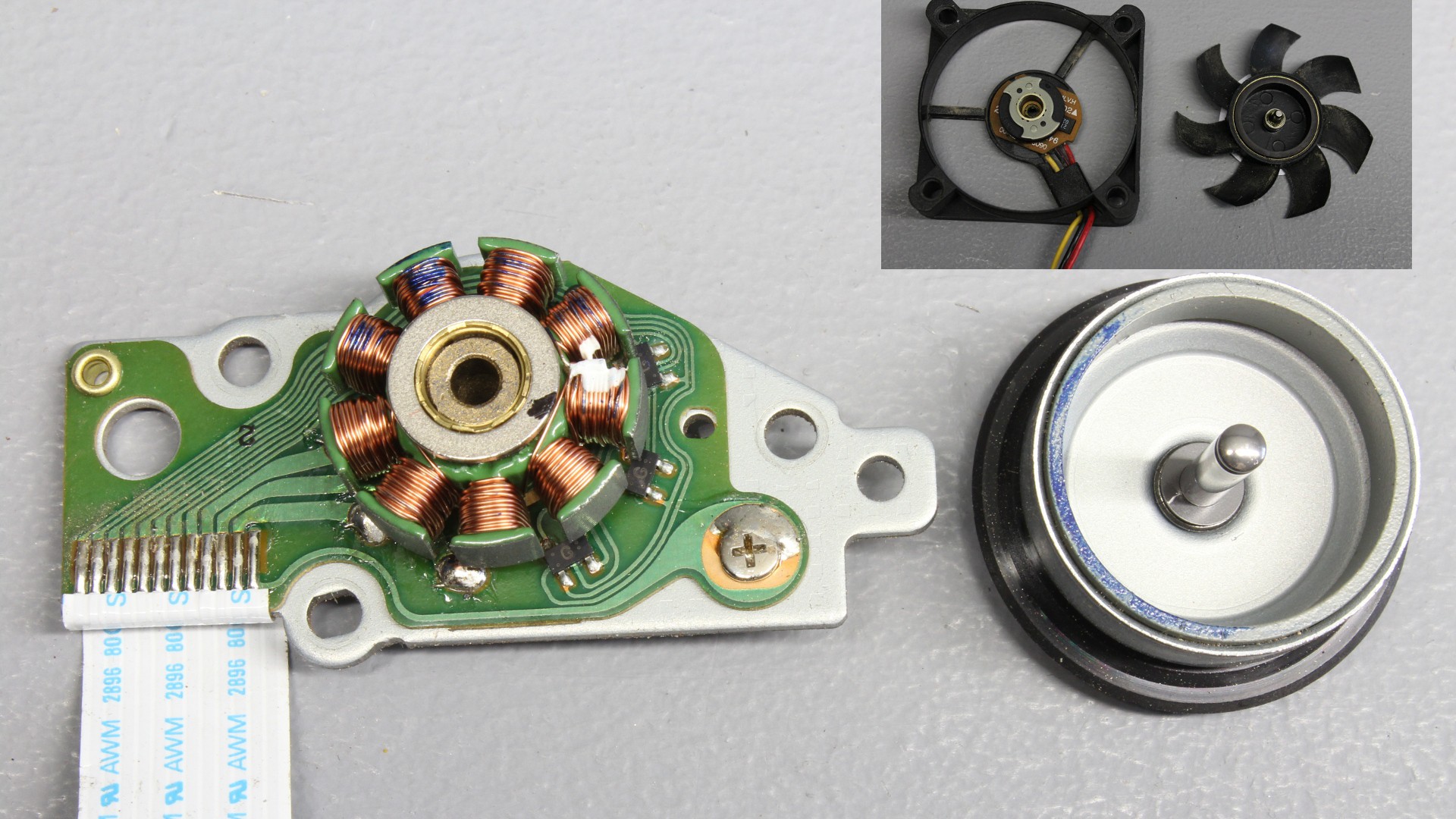

Hall sensors as used in optical drives (disc motor) or 3 wire computer fans are another way to sense motion (thanks to Robert for his email):

[Logan] posted a link in the comment section using grey scale patterns:

https://botscene.net/2012/10/18/make-a-low-cost-absolute-encoder/

Have a look at anaQuad from [esot.eric] that uses raw analog input of sensors to increase resolution of motion sensing by software - interesting approach.

What else can be used from the old Printers/Scanners?

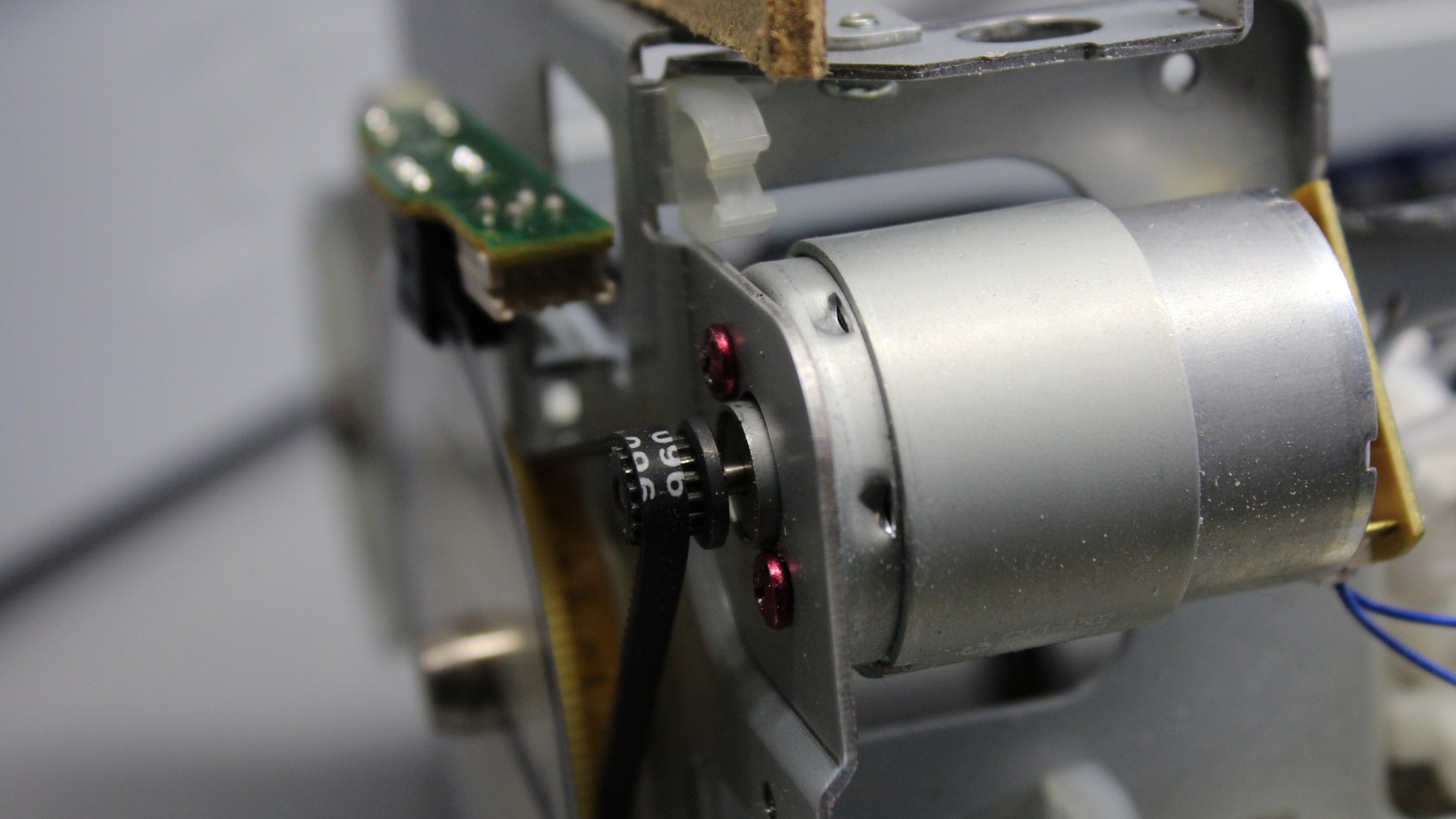

The motors:

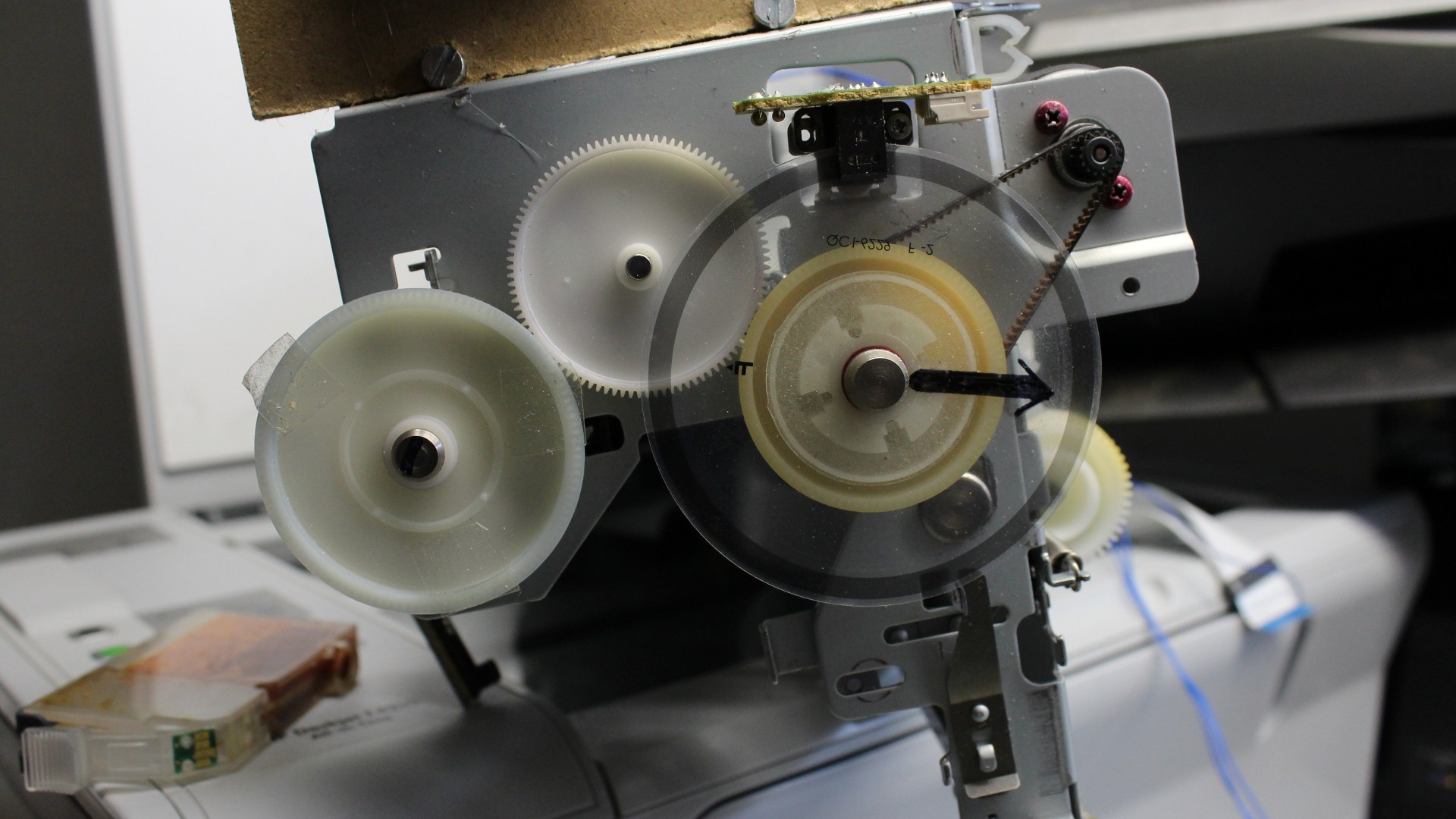

and Gears:

They all have motor drivers (h bridges) that would be useful, too, but I have no experience in reusing those chips. Please leave a comment if you can give some hints about using those motor drivers.

Cordless screwdrivers or power toys are sources for motors and gears as well (there must be one somewhere in my cellar...)

There is a lot to be done the coming weeks...

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Howdy Norbert! I just now caught your mention of #anaQuad! Thankyah, Sir! Means a lot coming from the DIY CNC Man, himself! I dig what yah do.

I will note, however, that I'm working on a log entry (coming soon) along the lines of "Do you need anaQuad?" Because it really is pretty niche...

Though, I think it fits right in with your style of DIY sensors, etc.

Thankya for the shout-out!

Are you sure? yes | no

Other stuff that can be up-cycled: linear guide rods, bushings for guide rods, led-optical sensors (in paper feed - senses if paper is present), drive belts, tactile buttons, power inverters (for CCFL lights in scanners), etc. There is a lot there and used ones range from cheap to free. Some of the optical mice even use rotary encoders.

Are you sure? yes | no

First thing I will have a closer look at is the LED optical sensors.

Tactile buttons are useful as limit switches.

Some of the mechanical stuff might become part of another CNC router or at least a plotter.

Are you sure? yes | no