This is where the IR port is located on the smart meter:

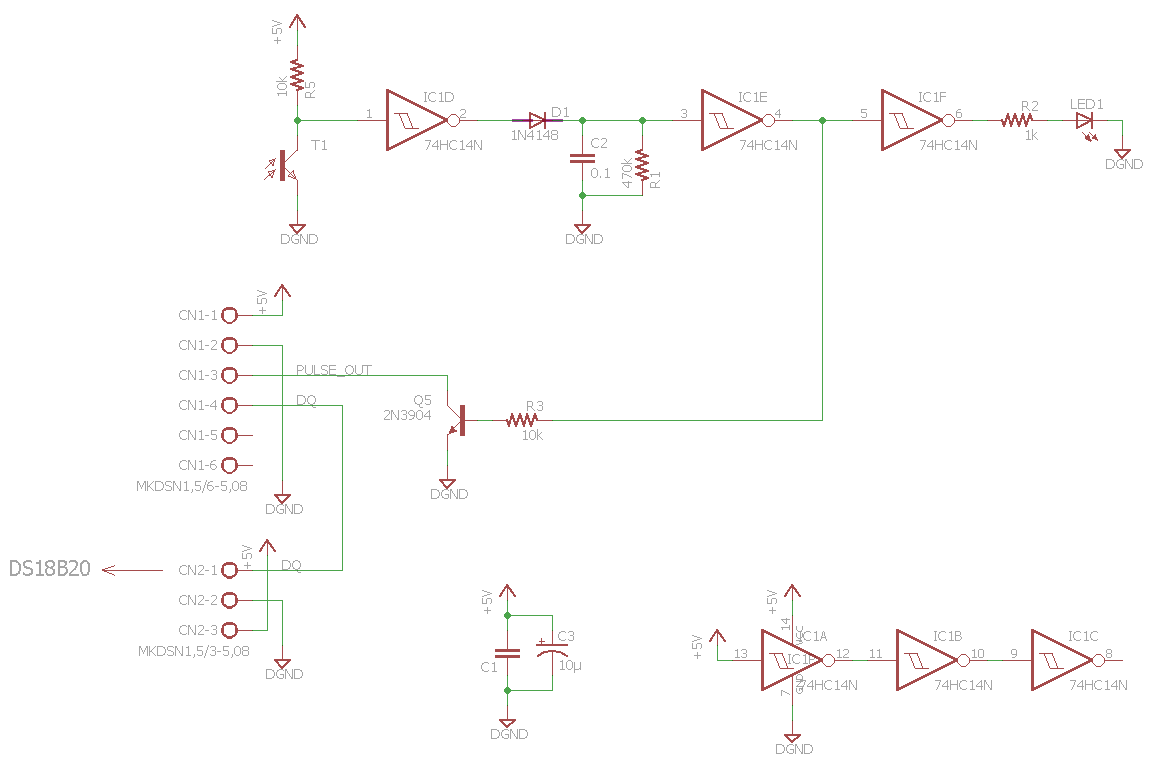

The pulse is quite narrow (10ms) and there is 20’ between the smart meter and my microcontroller so I build a circuit close to the meter to make the pulse wider and add more drive to the signal.

Tips

Tip #56945a: to prevent rain water to enter the “waterproof” box, apply some dielectric grease on the gasket. Don’t trust the gasket to be sufficient! Make sure it’s a plastic safe grease.

Tip #56945b: put a silica gel packet inside the waterproof box to remove any humidity. The temperature extremes WILL make the humidity condense!

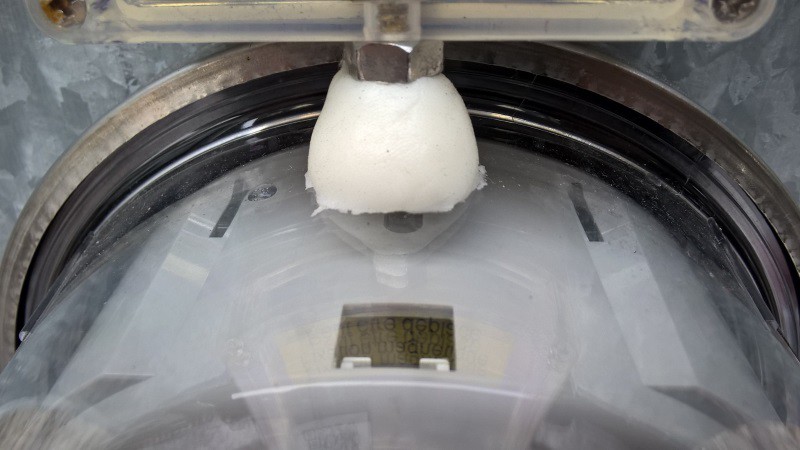

Making the sensor immune from elements

The first prototype had some issues like IR signal lost due to rain water. The solution I found was to build a “cone” to displace water. I thought about using Sugru but I couldn’t get some quickly so I looked for doing a substitute. Then I found this Instructable How To Make Your Own Sugru Substitute.

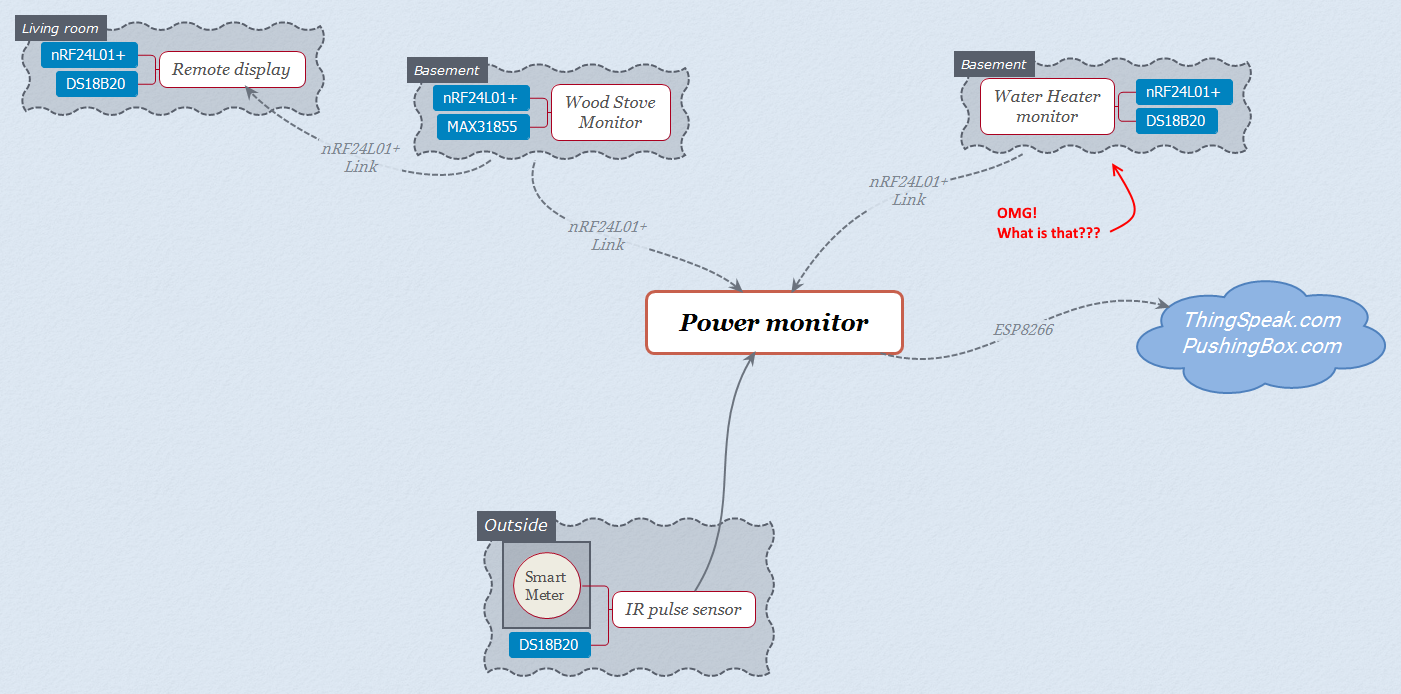

Mainboard

The main board on the power meter is a DirtyPCB I designed as a universal IOT platform. It can handle an ESP8266 ESP-01 or a ESP-07 on a breakout board. The microcontroller is a PIC18F25K22 running PicBASIC code (more on this in the FAQ). It counts the pulses and push it to my ThingSpeak channel every 15 minutes with the temperature and the peak power.

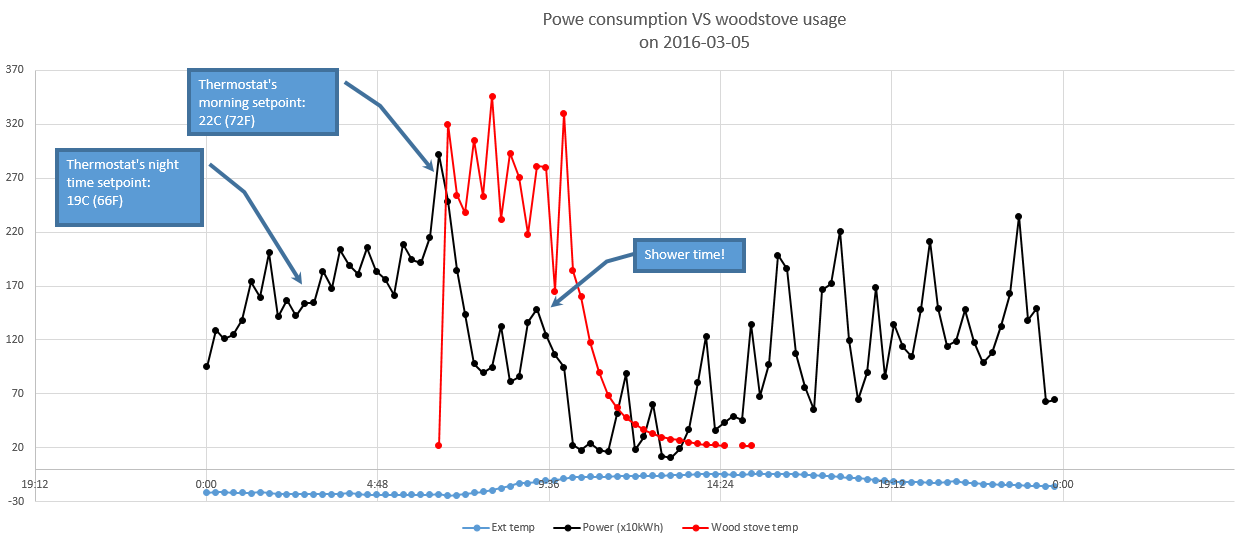

The monitor receives the wood stove temperature from a previous project via a nRF24L01+ on my nRF platform (more on this in the FAQ).

Finally, in case of a power failure a battery keeps it alive and a notification is sent via PushingBox to my cell phone.

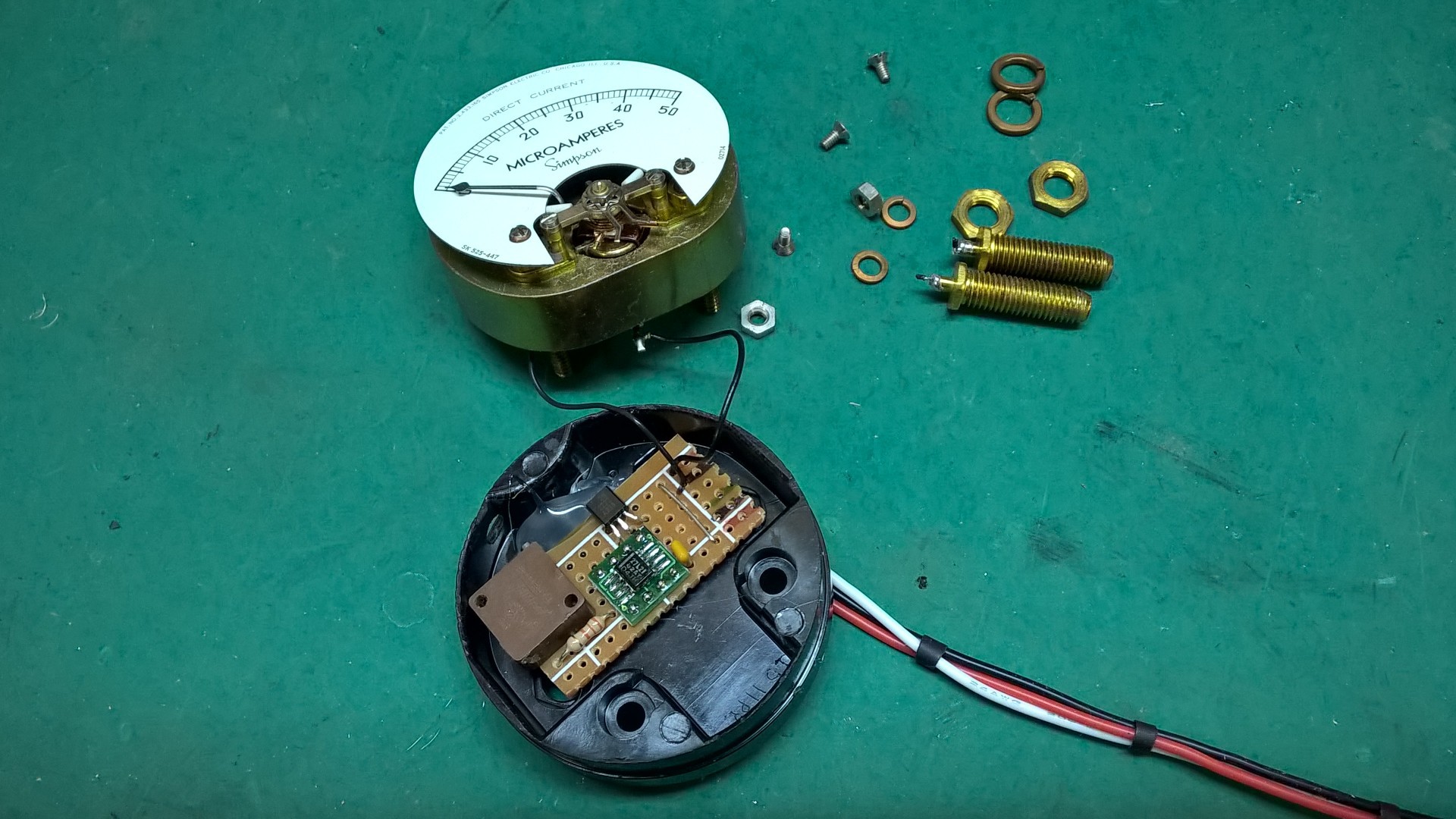

Making it sexier

The LCD is nice but seeing numbers moving is not pretty. I had a nice 50µA meter laying in a drawer and I thought it could add a nice addition to the power meter. I opened it to add 2 LEDs and a voltage to current buffer and hooked it to the DAC output of the PIC. A few lines of code later it made a nice addition!

Data analysis

Unfortunately, I do not have a lot of data to show the impact of the wood stove on the electric consumption. I had some trouble with the sensor outside and I have strict rules on the wood stove usage:- Temperature outside must be below -15C (5F)

- Never leave the wood stove unattended when heating

To be continued…

Juan Albanell

Juan Albanell