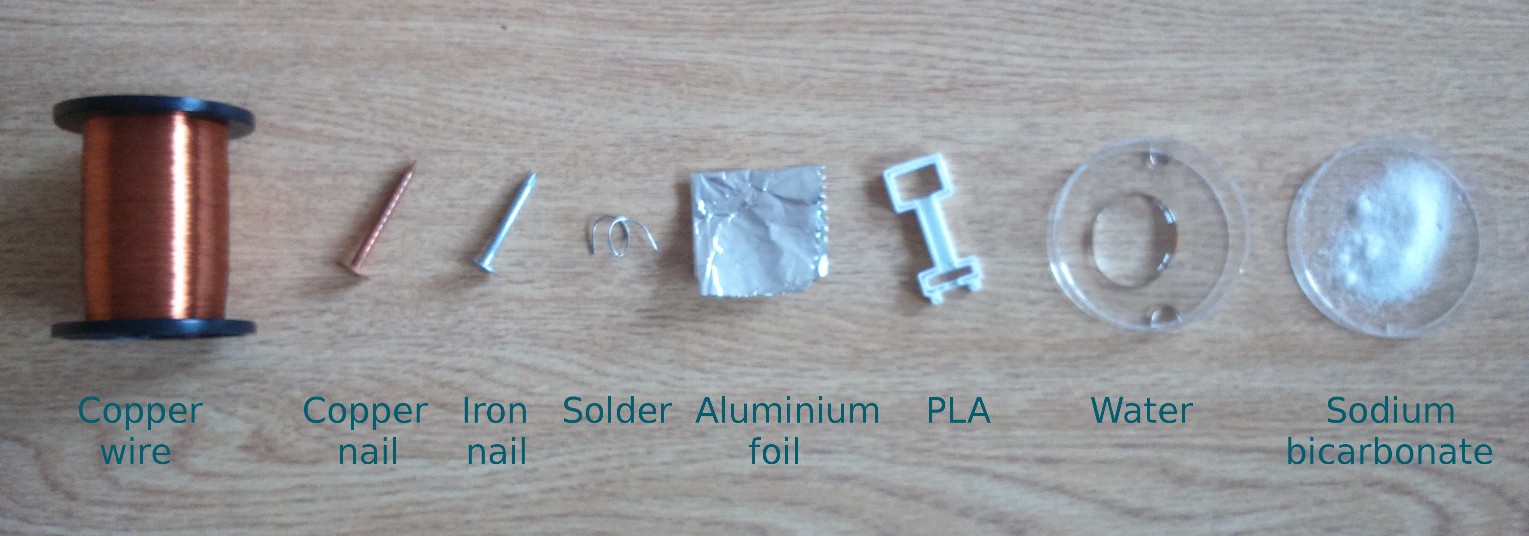

In this project I'm deliberately restricting myself to simple, easy to manufacture vitamin parts. They are shown in this image:

The parts and materials are: enameled copper wire, copper nail, iron nail (the nails I'm using are galvanized with zinc), solder, aluminium foil, PLA, water, and sodium bicarbonate.

How simple are the manufacturing steps involved in making each of these materials, and can they be simplified further?

Links to information about making PLA can be found on the RepRap wiki: http://reprap.org/wiki/PLA

It occurred to me recently that perhaps Gutta-percha (a naturally occurring victorian plastic produced by plants) could be used as a low-tech material for 3D printing. In the modern day it is used by dentists and can be purchased online.

There are 6 metals used here: copper, iron, zinc, tin, lead and aluminium. The first 5 of these have been smelted for thousands of years. The processes involved in smelting and shaping them are fairly straightforward and don't require high-tech tools. Extracting aluminium from its ore is a more complex process, first carried out in the 1820s. I'm using aluminium foil for the electrodes in DIY capacitors. It's possible that one of the other five metals would also work in this role, or that an alternative capacitor design could be used.

Sodium bicarbonate occurs naturally in large deposits in some parts of the world. My decision to use this for making capacitors is entirely arbitrary - it was one of the first thing that came up when I googled 'DIY capacitors', and I happened to have some in my kitchen cupboard. It's possible that salt water would work instead.

Regarding enameled copper wire: some ancient jewellery involved copper drawn into thin wires (I'm not sure how thin). I believe that enameled copper was invented around 100 years ago. I'm don't know what the process of enameling involves, and whether it is dependent on high-tech tools. In the 19th century electrical wire was insulted using fabric, paper and Gutta-percha. It is possible that PLA could be used for insulating copper wire, provided that the temperature of the wire never exceeds 60C.

will.stevens

will.stevens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.