Here's a running list of our video parts:

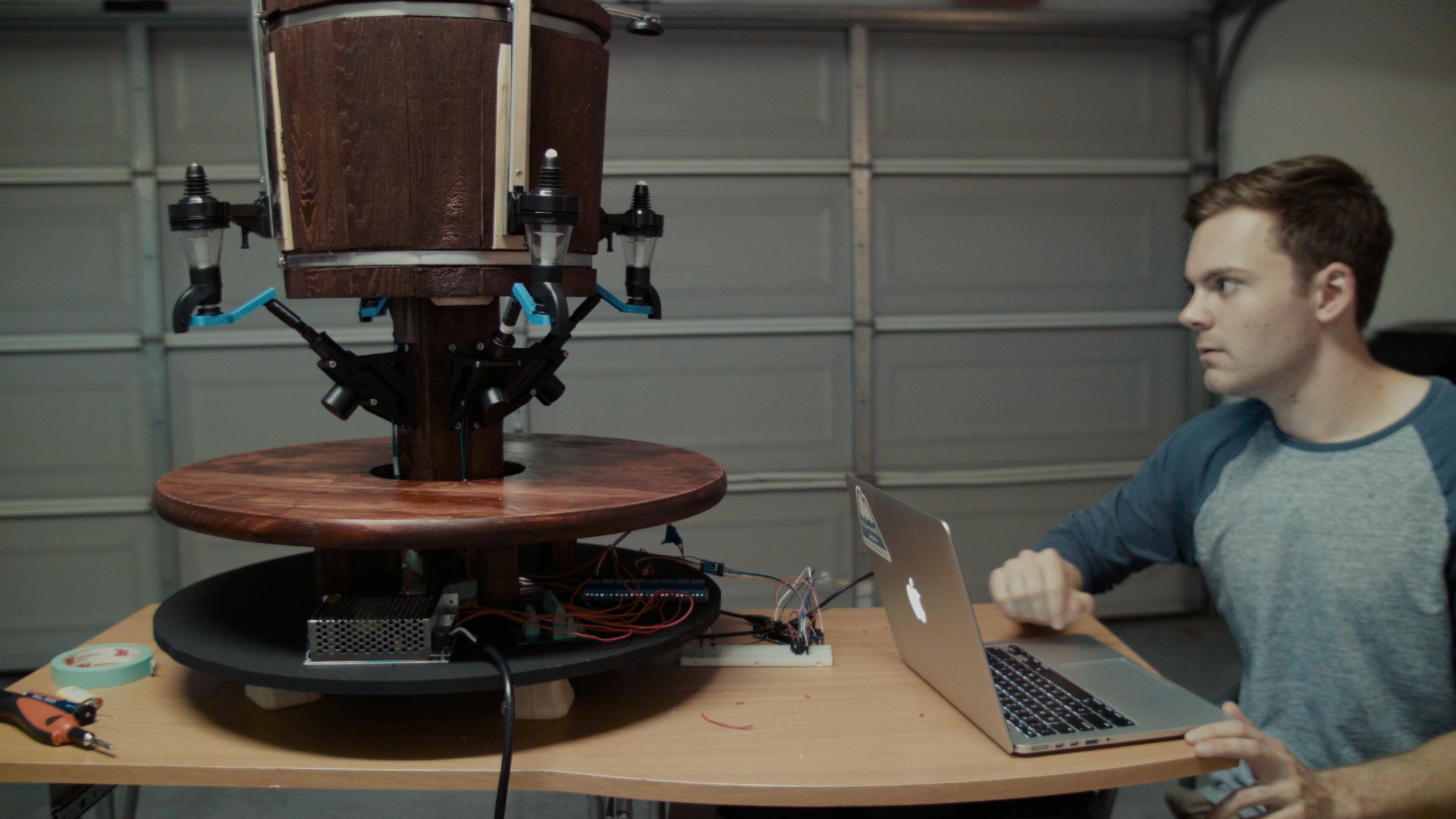

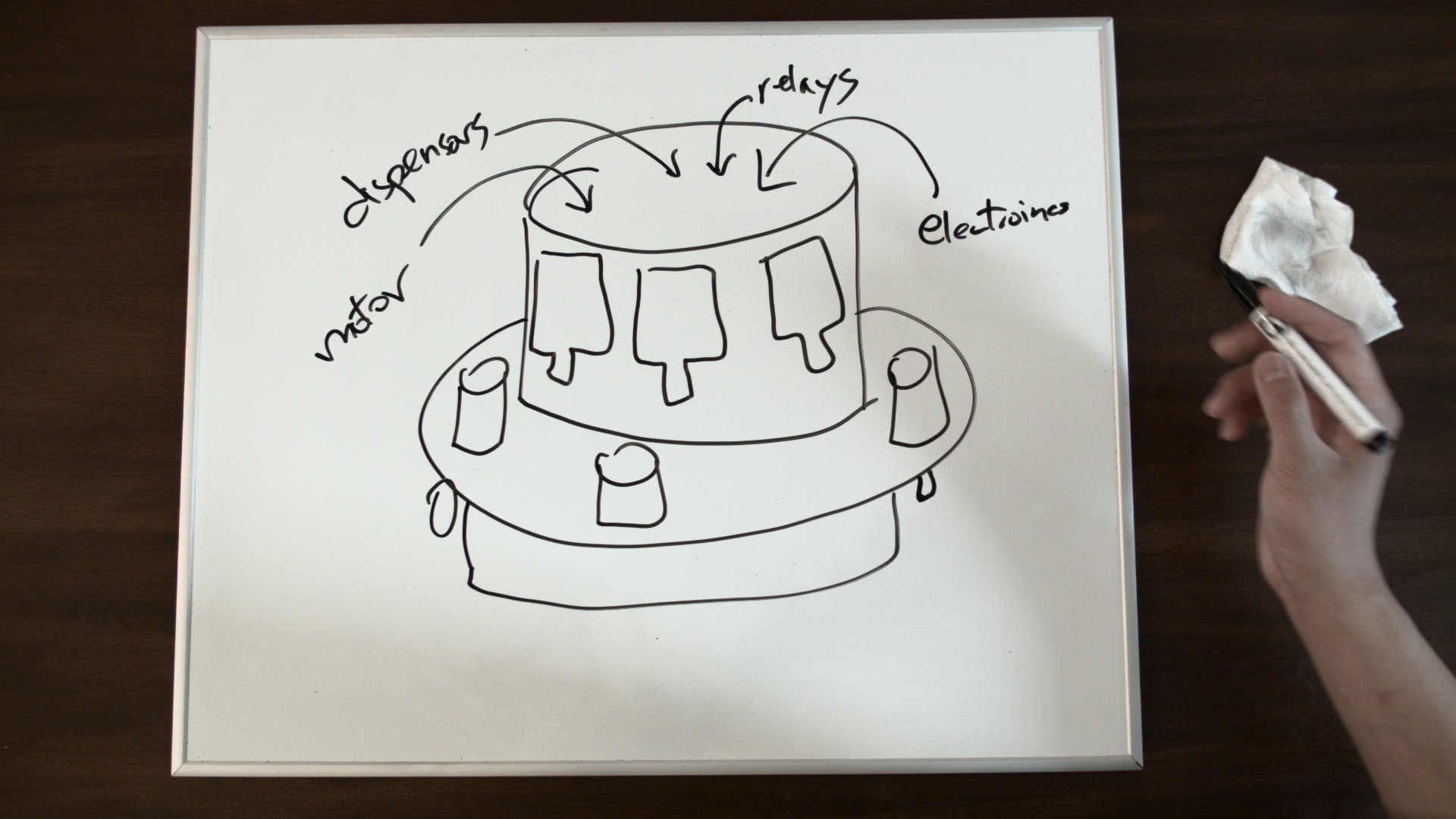

Part 1: https://youtu.be/x6QYNK6WI50 (Planning and Design)

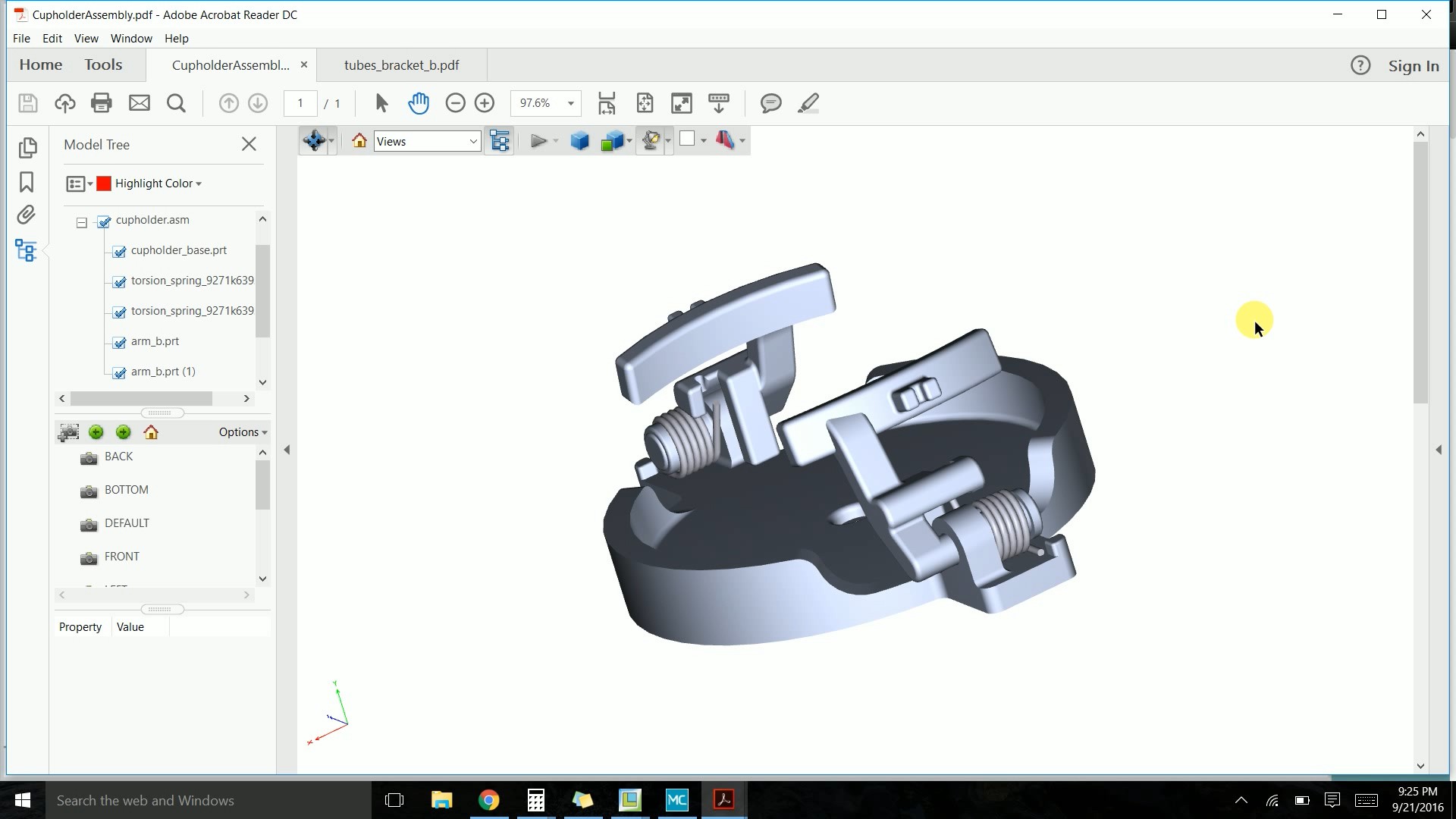

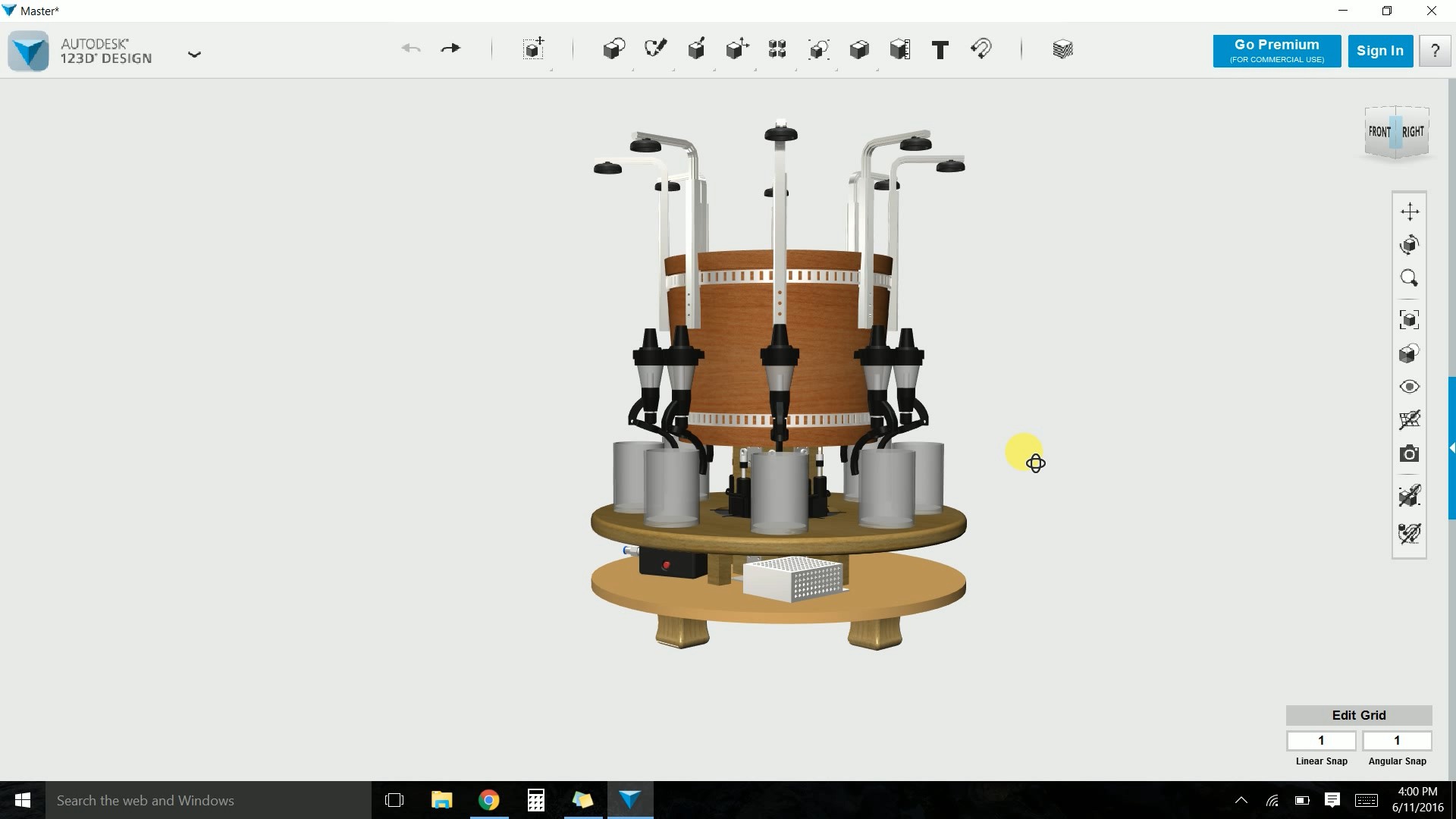

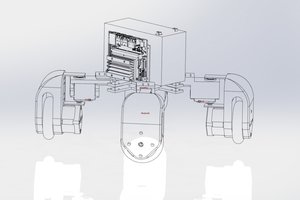

Part 2: https://youtu.be/orMLuXoaTSQ (Platform and Modeling)

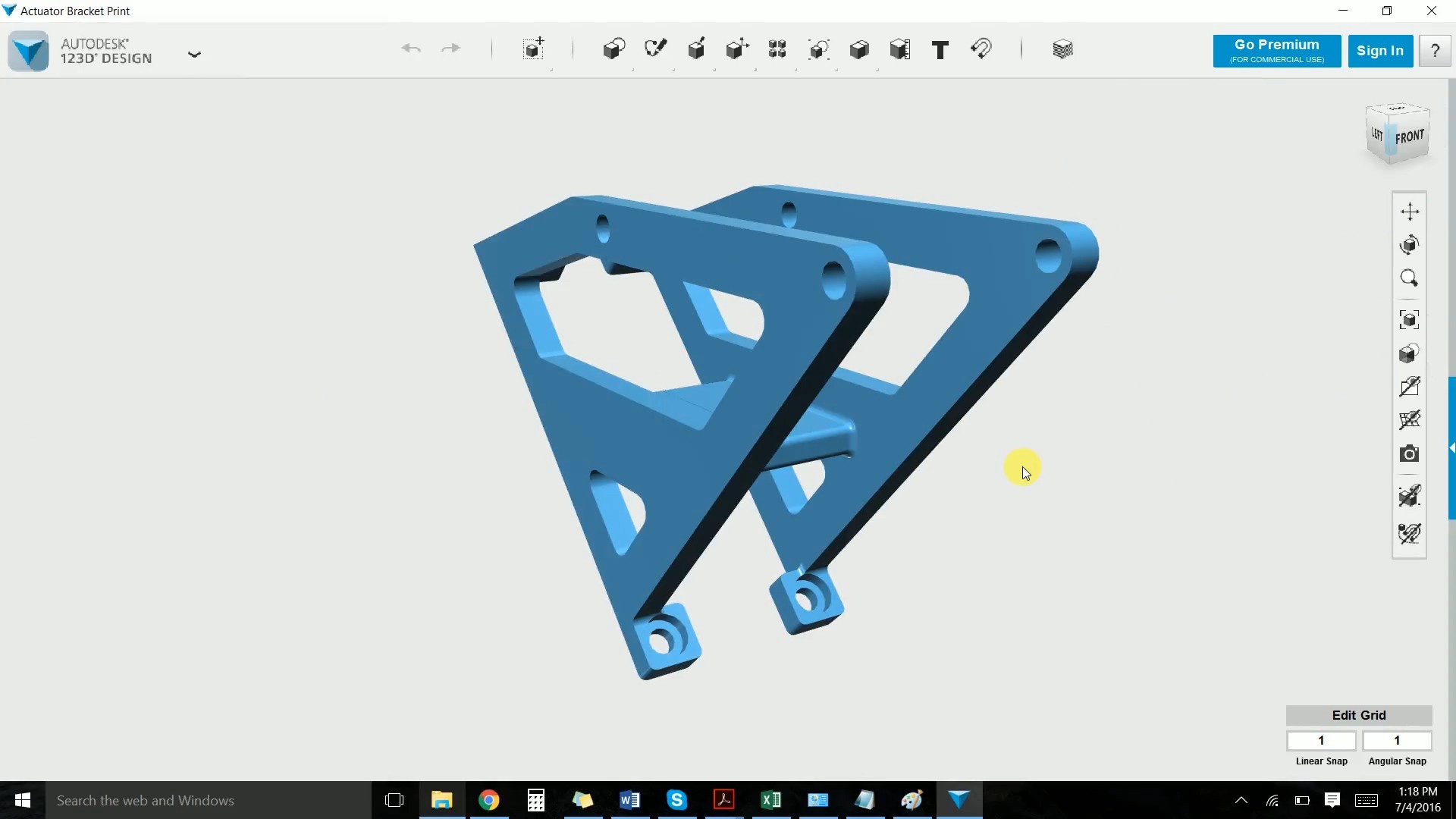

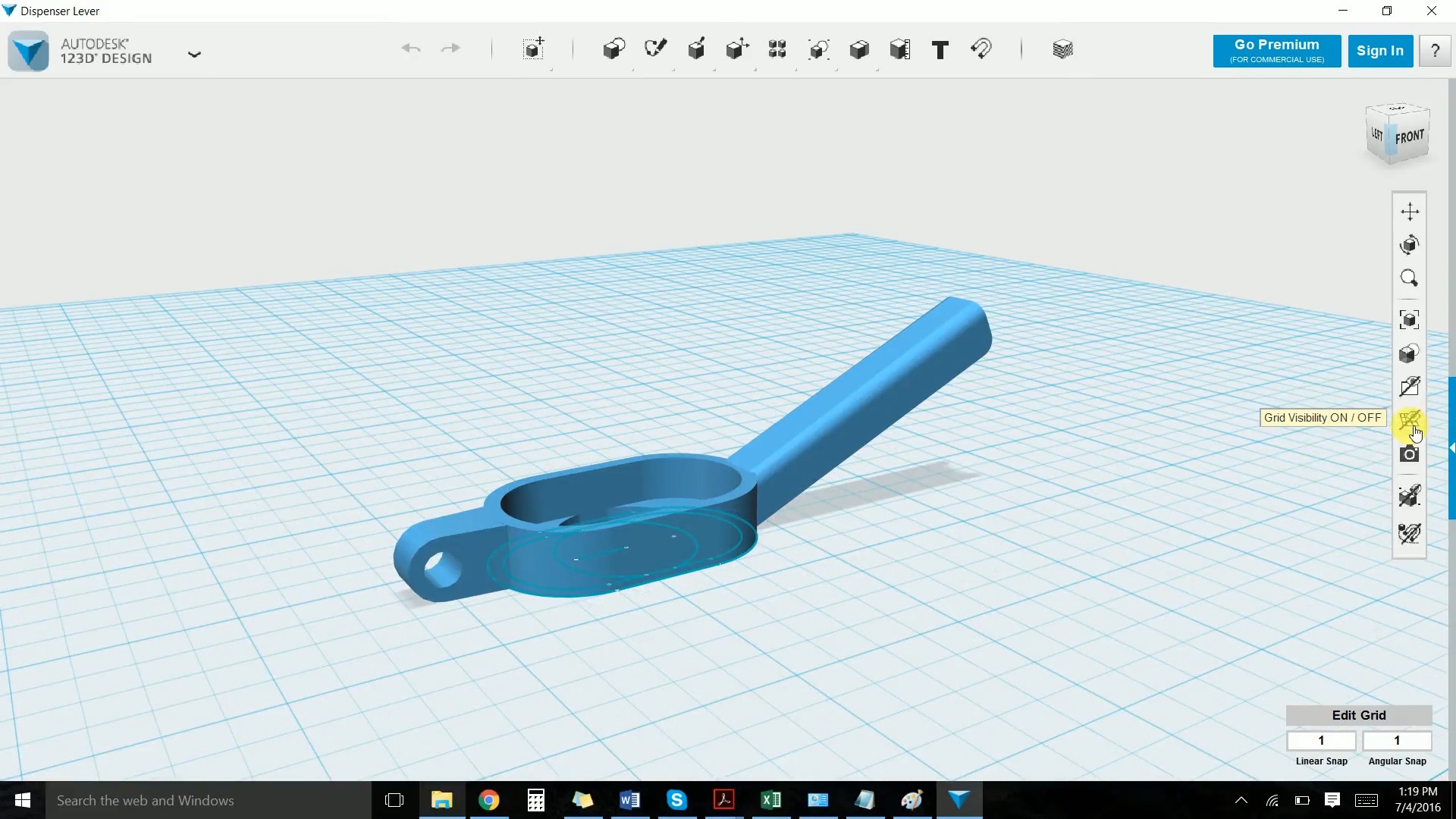

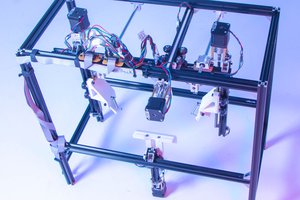

Part 3: https://youtu.be/IKZFf-zl0Bo (Frame and 3d Printed Parts)

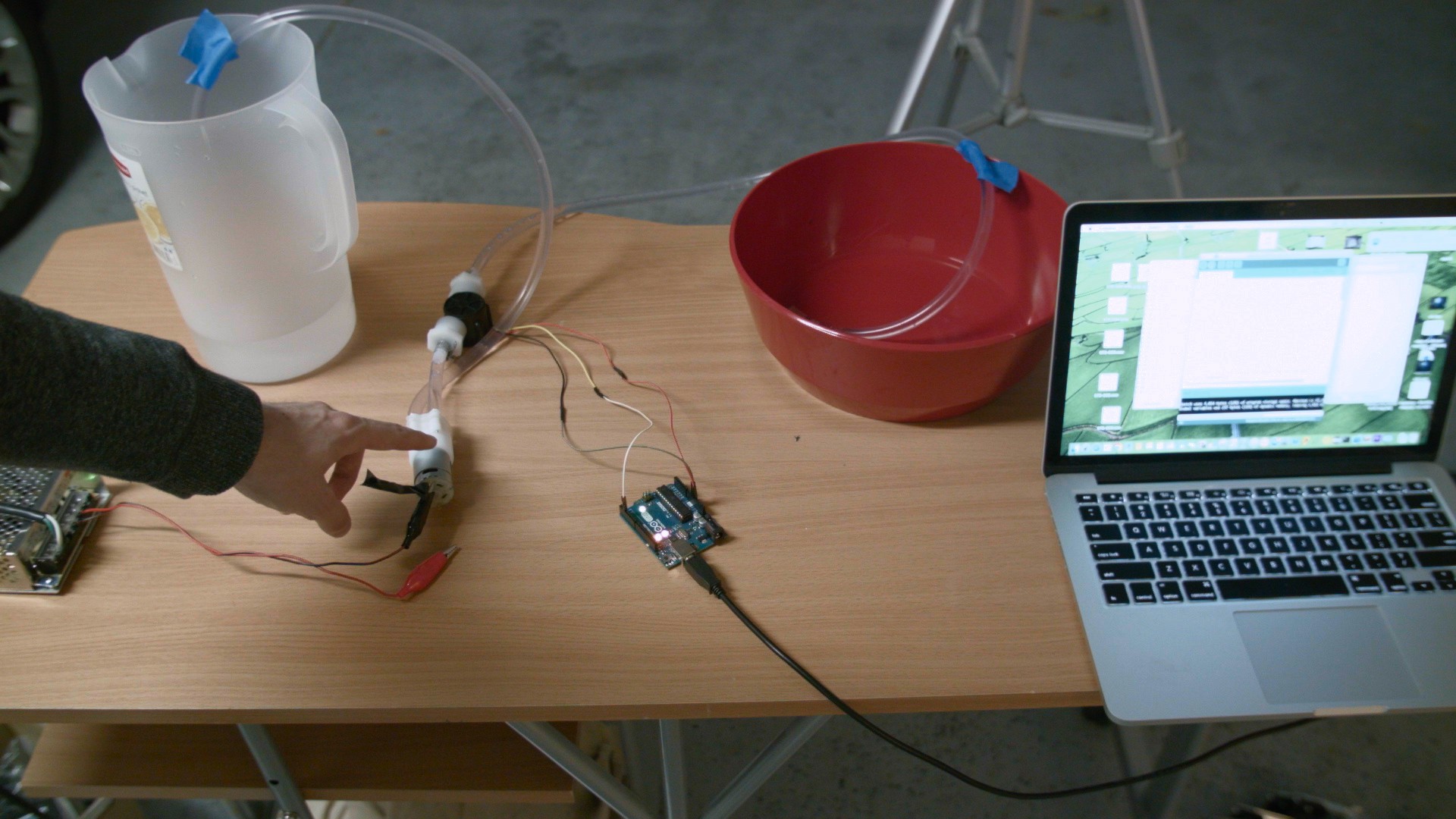

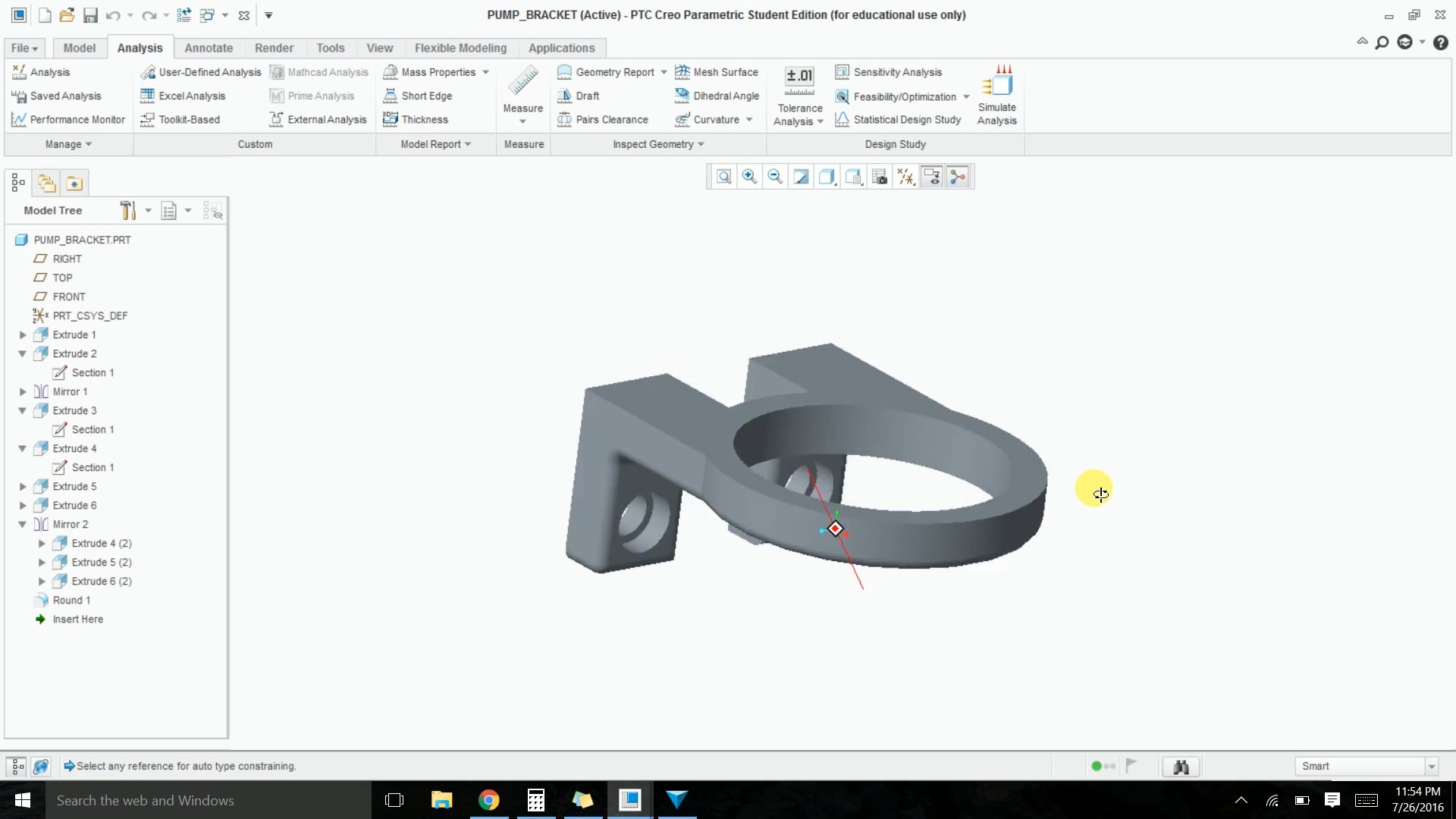

Part 4: https://youtu.be/aAgKmiabQy0 (Varnish and Flow Meters)

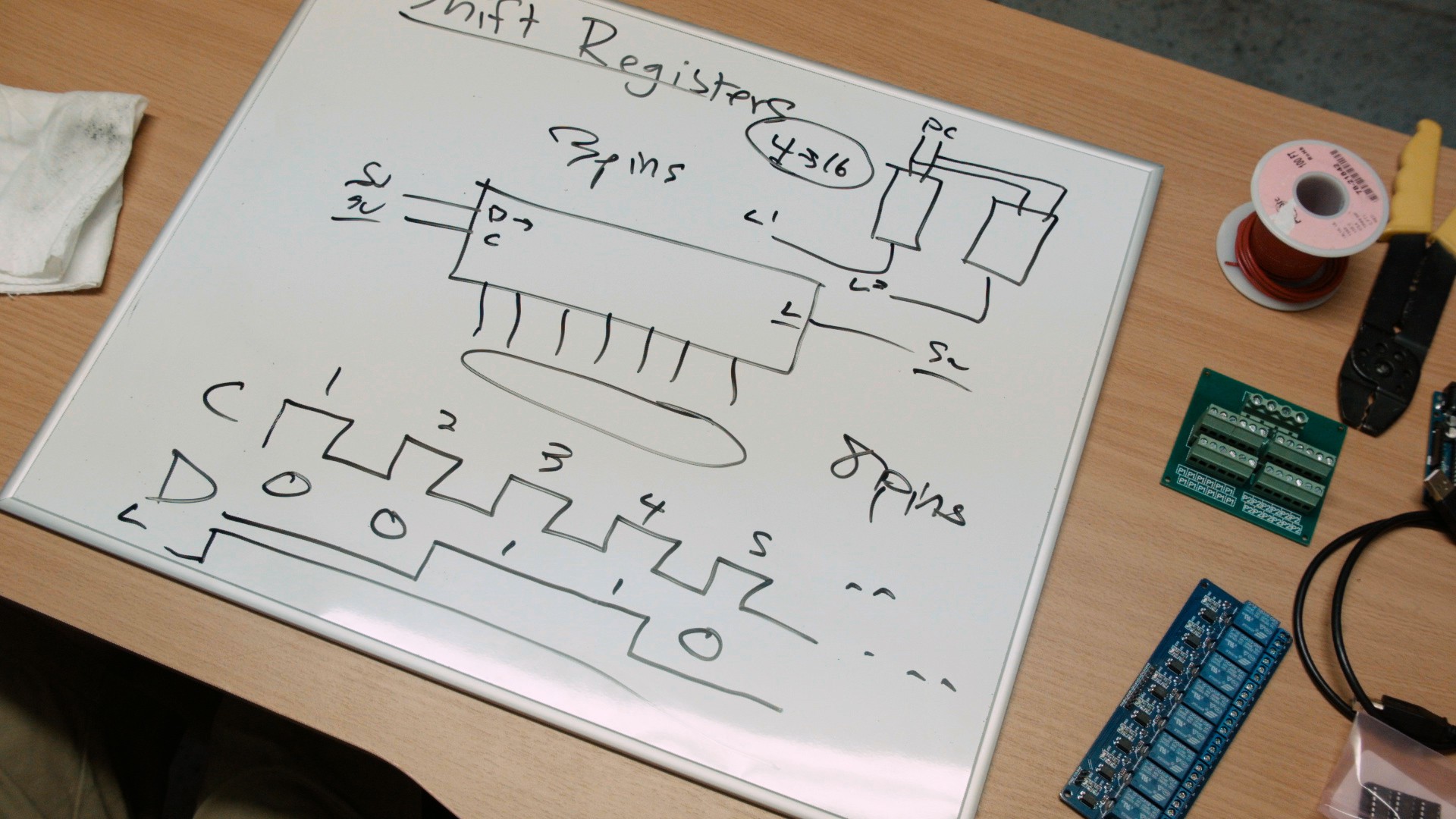

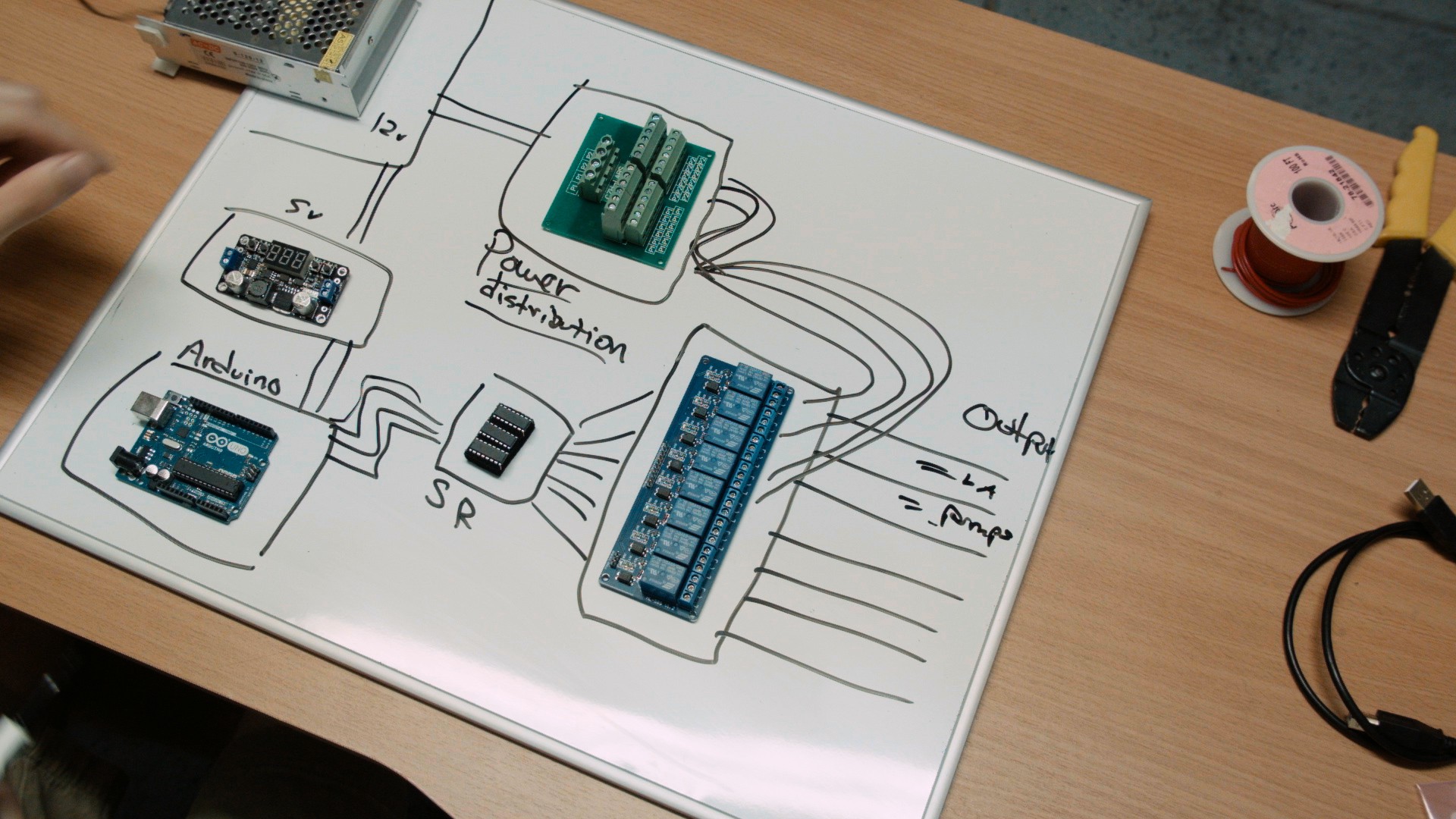

Part 5: https://youtu.be/SXW7ydvqfnM (Shift Registers and Initial Wiring)

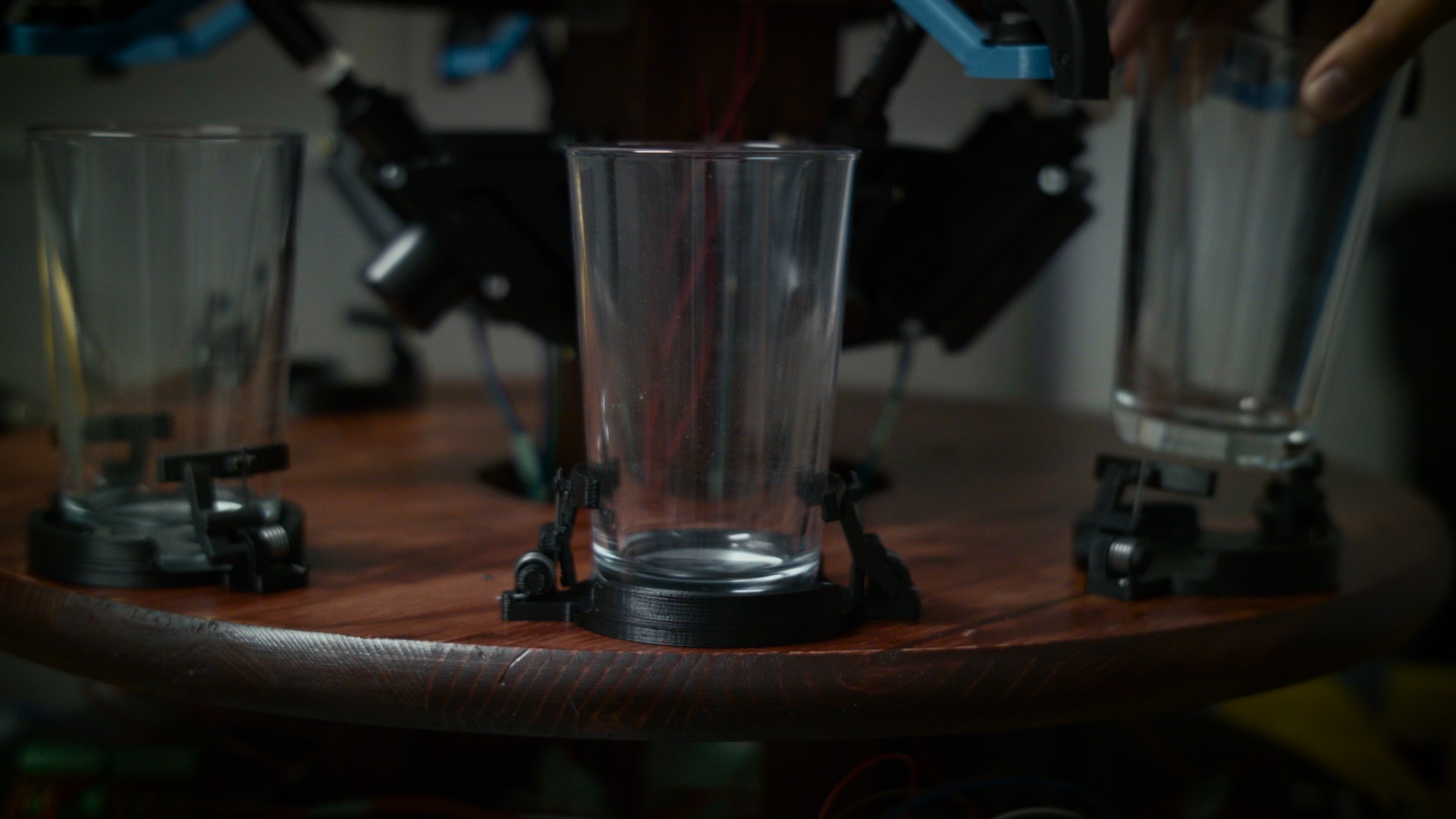

Part 6: https://youtu.be/-UzgQpltkWM (Drive Motor and Cupholders)

Part 7: Coming soon

Hacker House

Hacker House

Nick Rehm

Nick Rehm

ProgressTH

ProgressTH

Daniel Resio

Daniel Resio

You really did a great job to make this program object i want to embed it with my webpage can you see here https://vinylflooringsale.com/