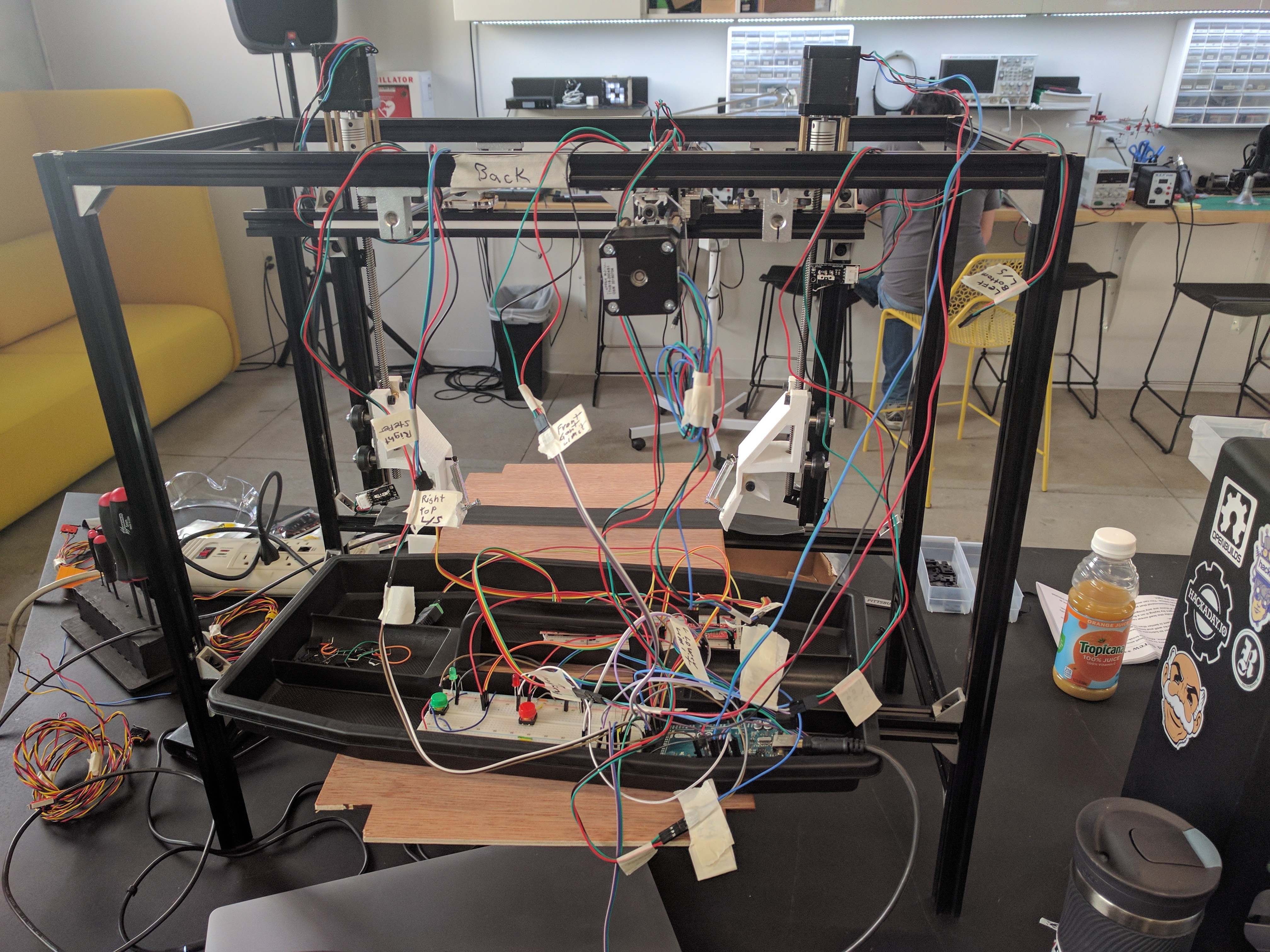

AutoFold the Box Folding Robot

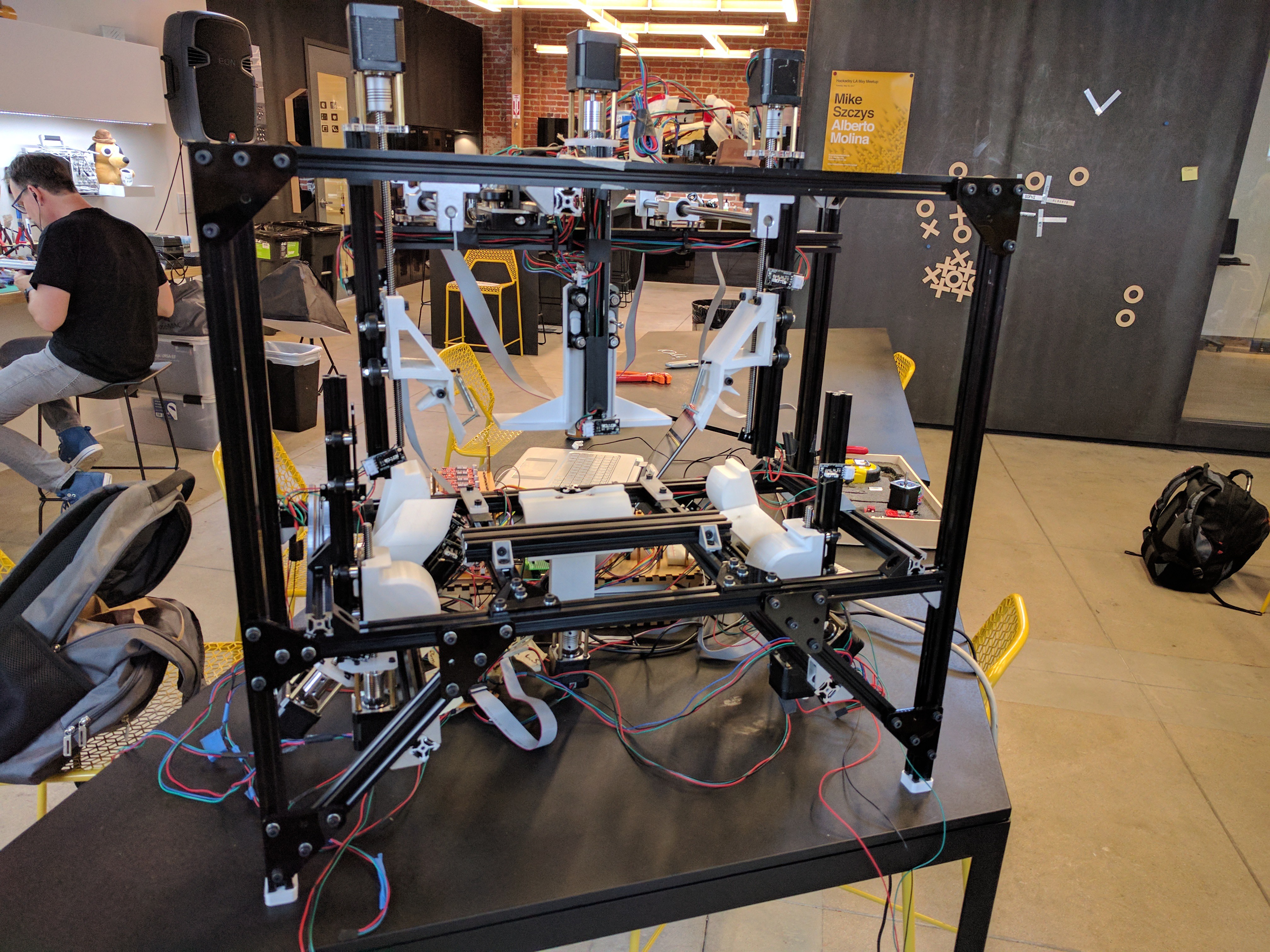

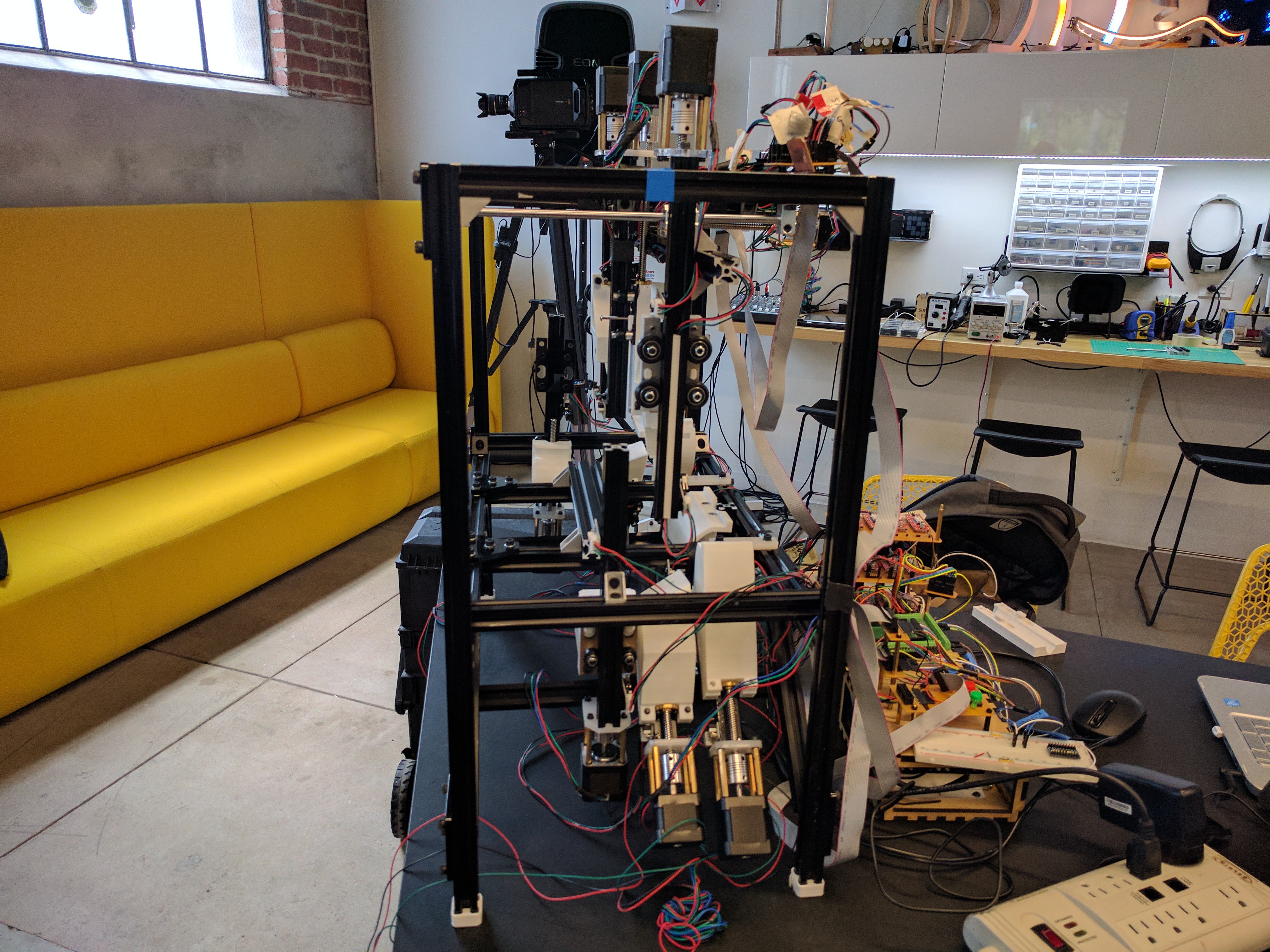

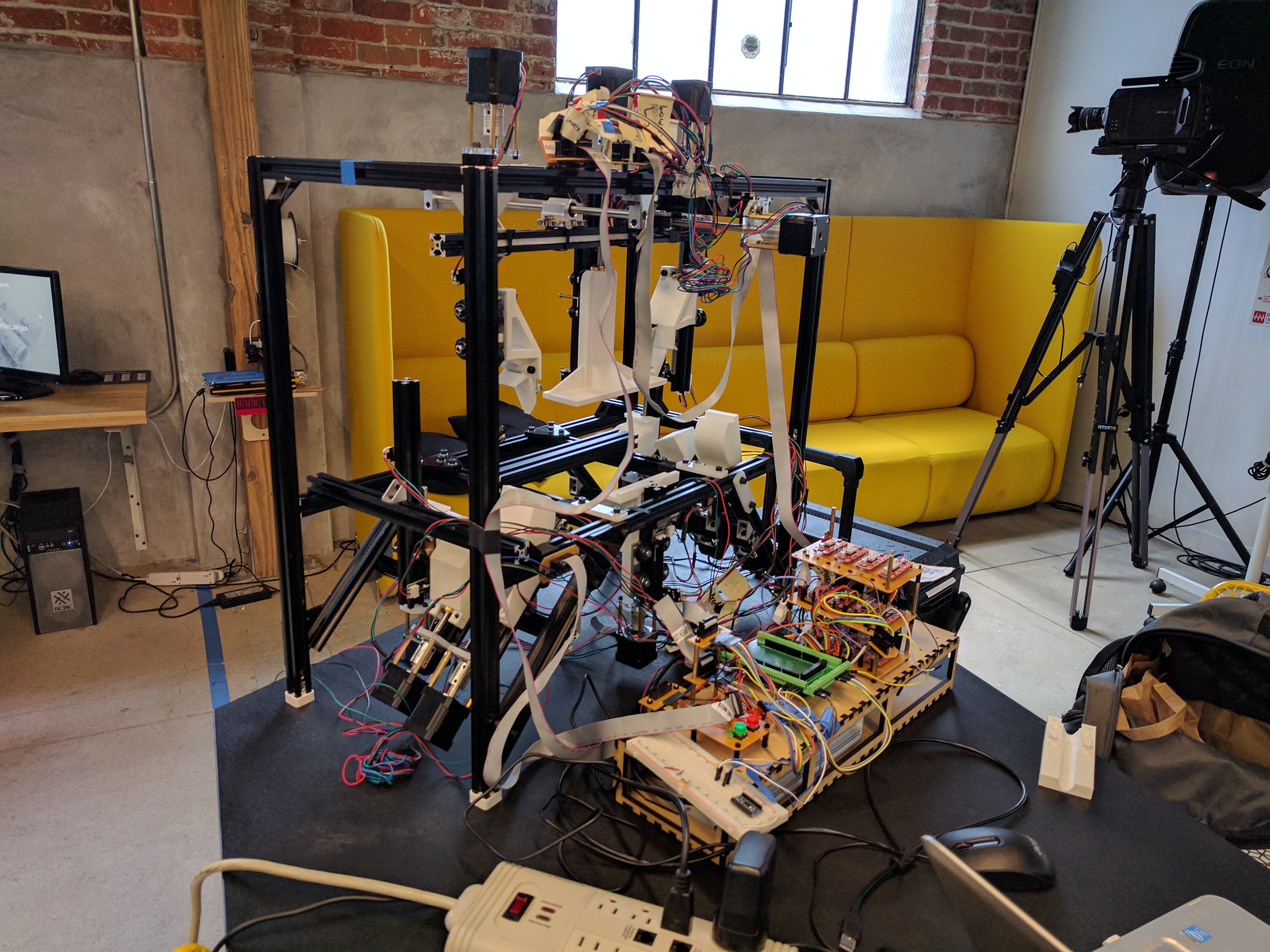

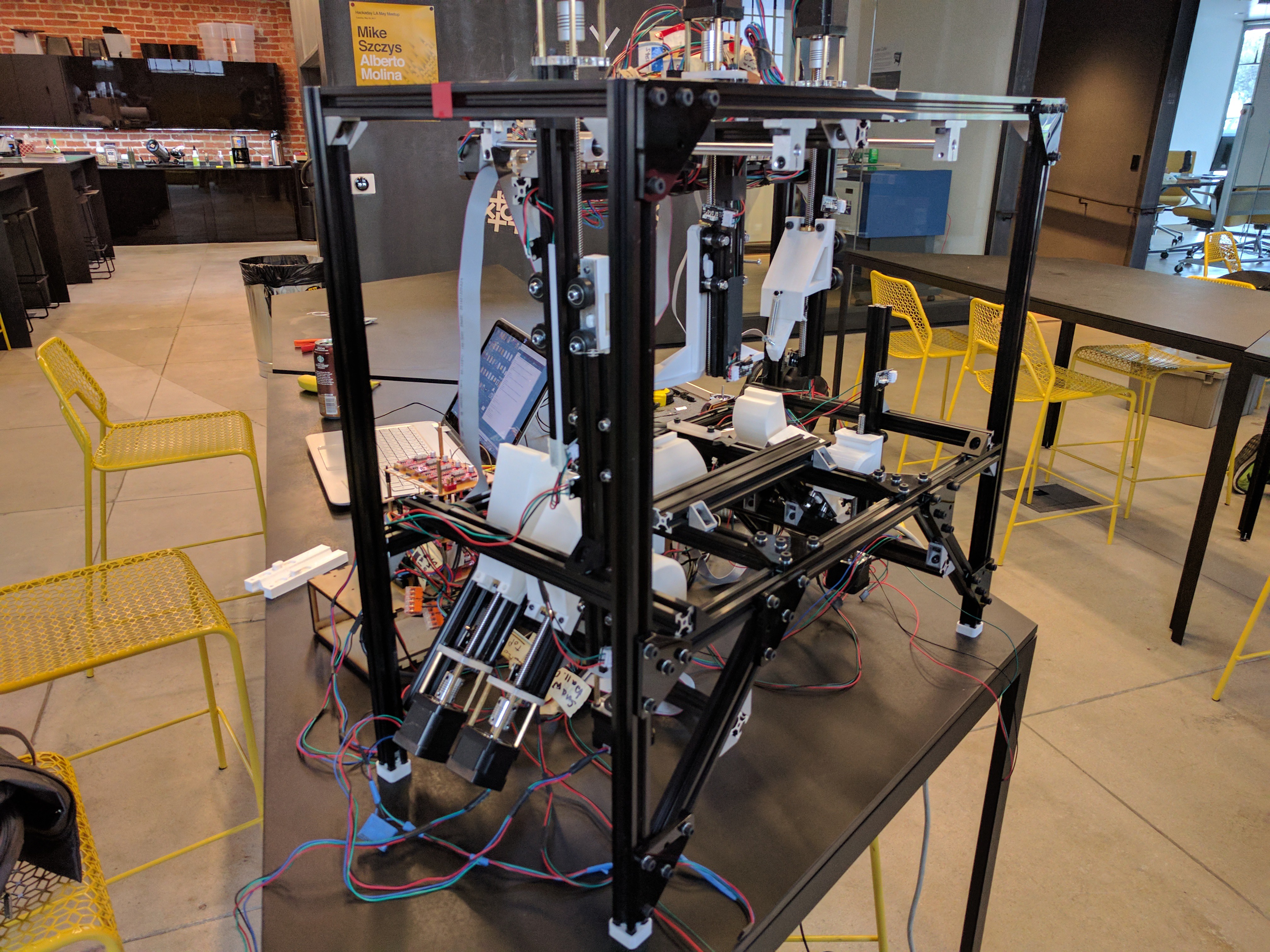

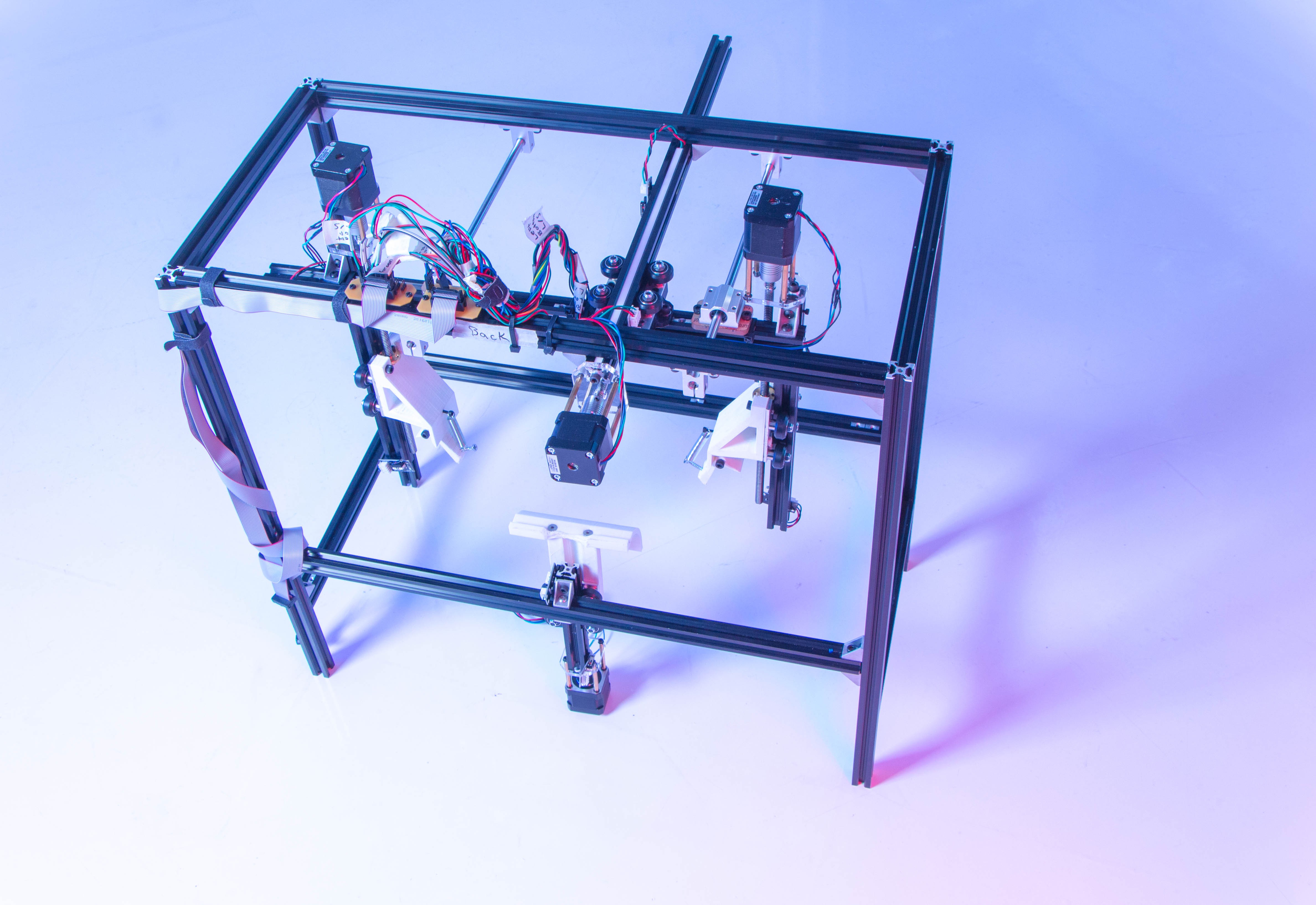

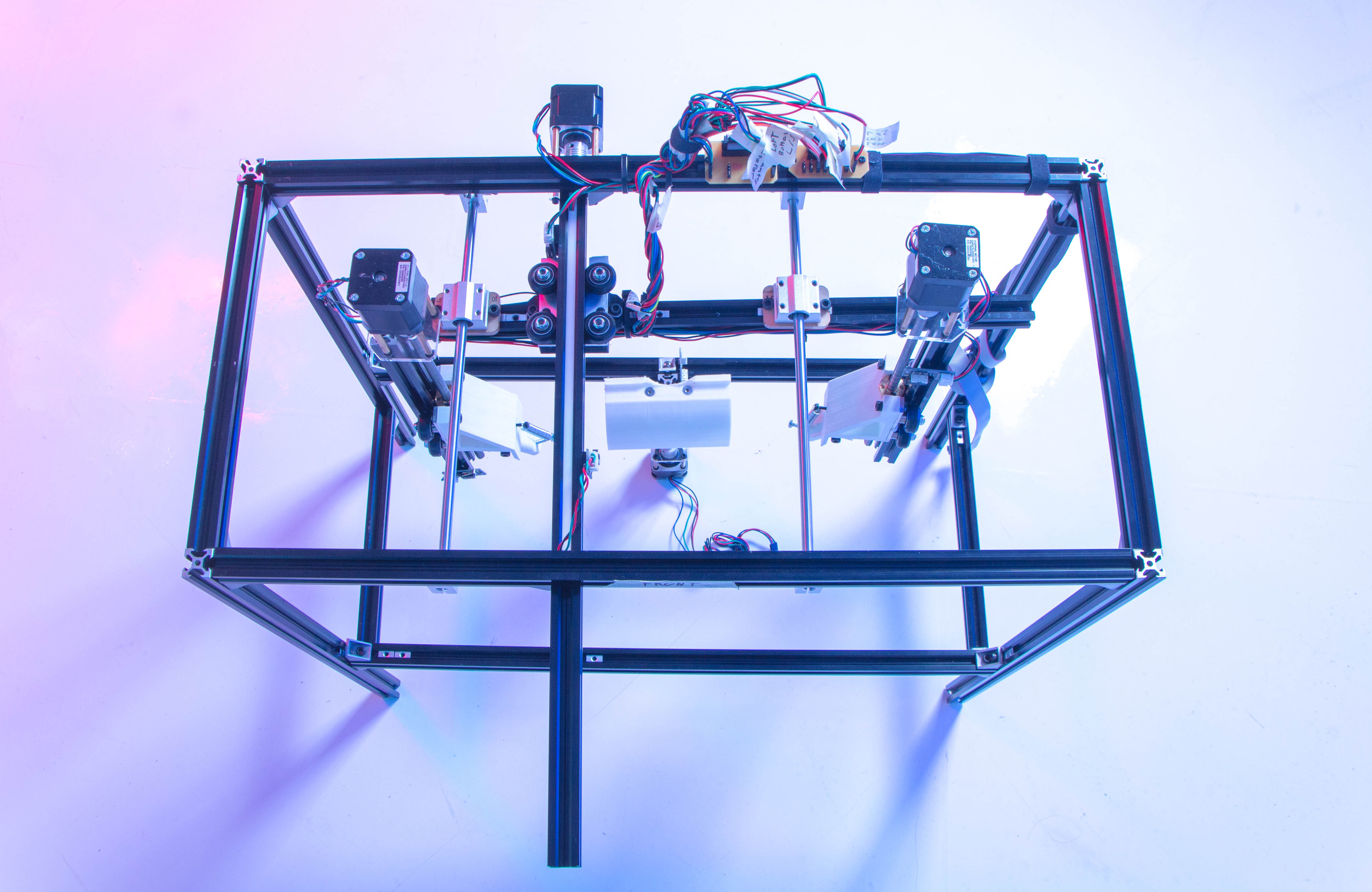

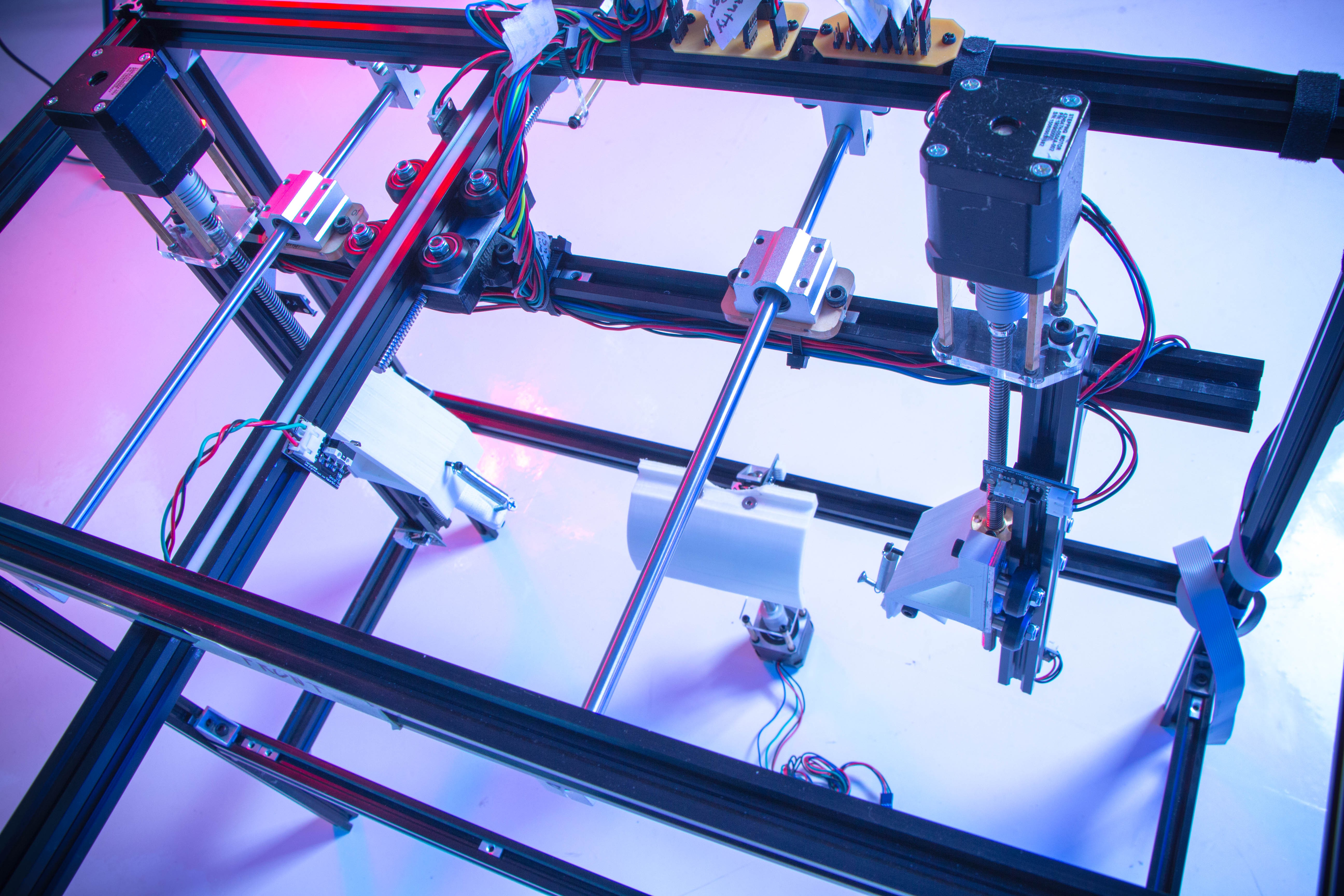

We are creating a system to automate the process of folding boxes

We are creating a system to automate the process of folding boxes

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

No Motors :(

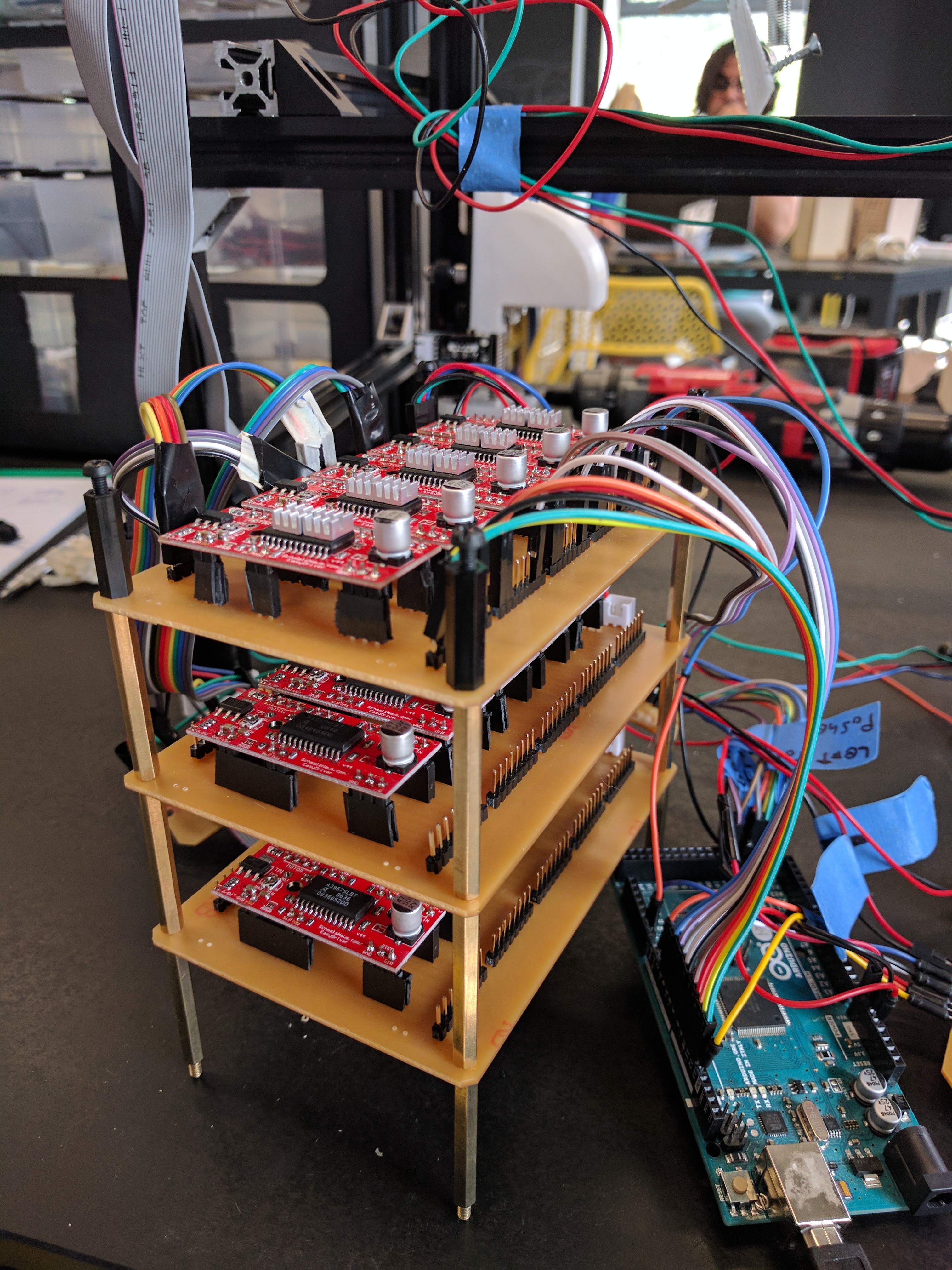

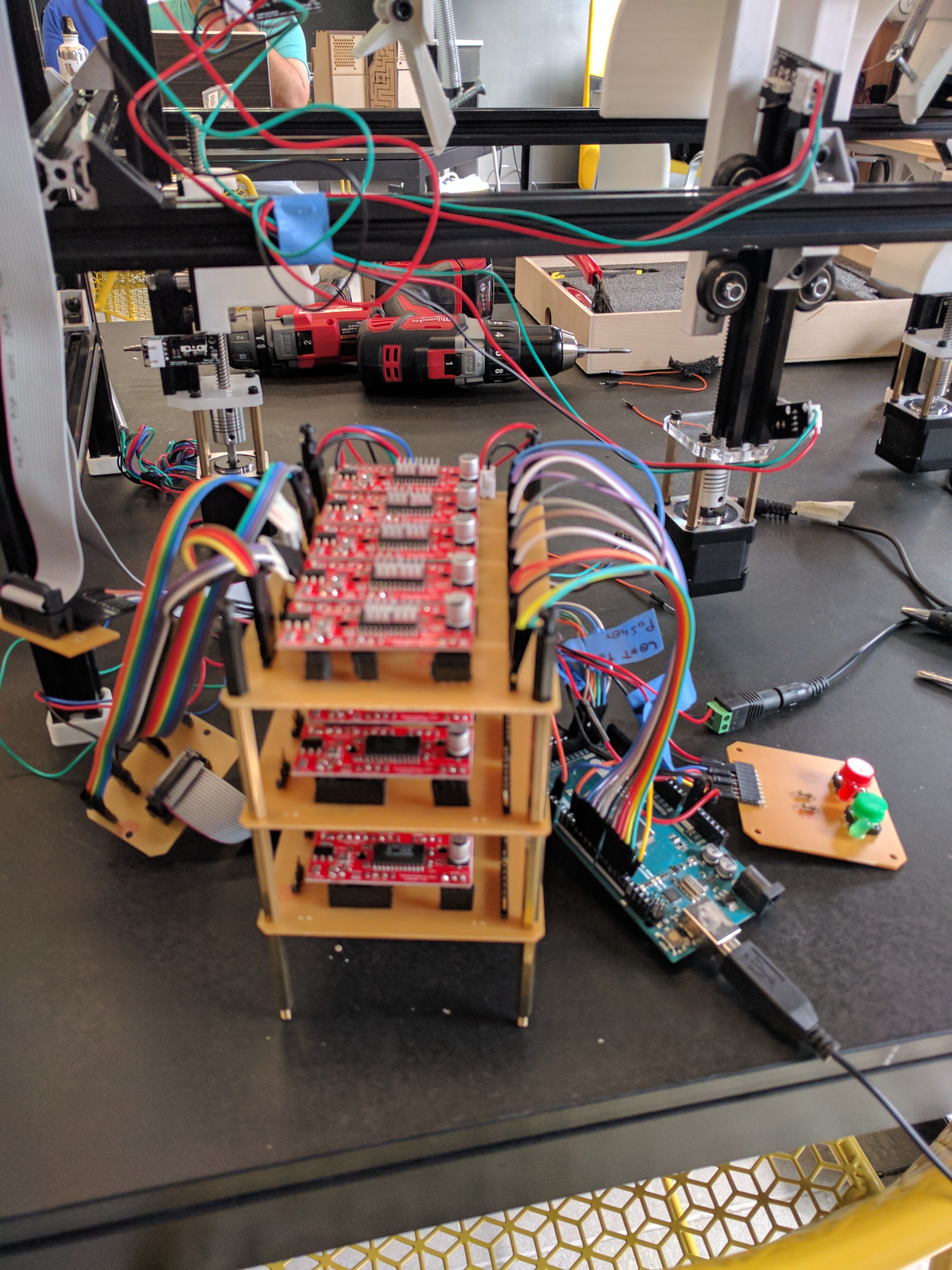

I reduce the motor controller boards down from 5 Big Easy drivers to 4. I also made the 24 volt lines much thicker. Also a special thanks Metal for all his help and the better Quick connectors

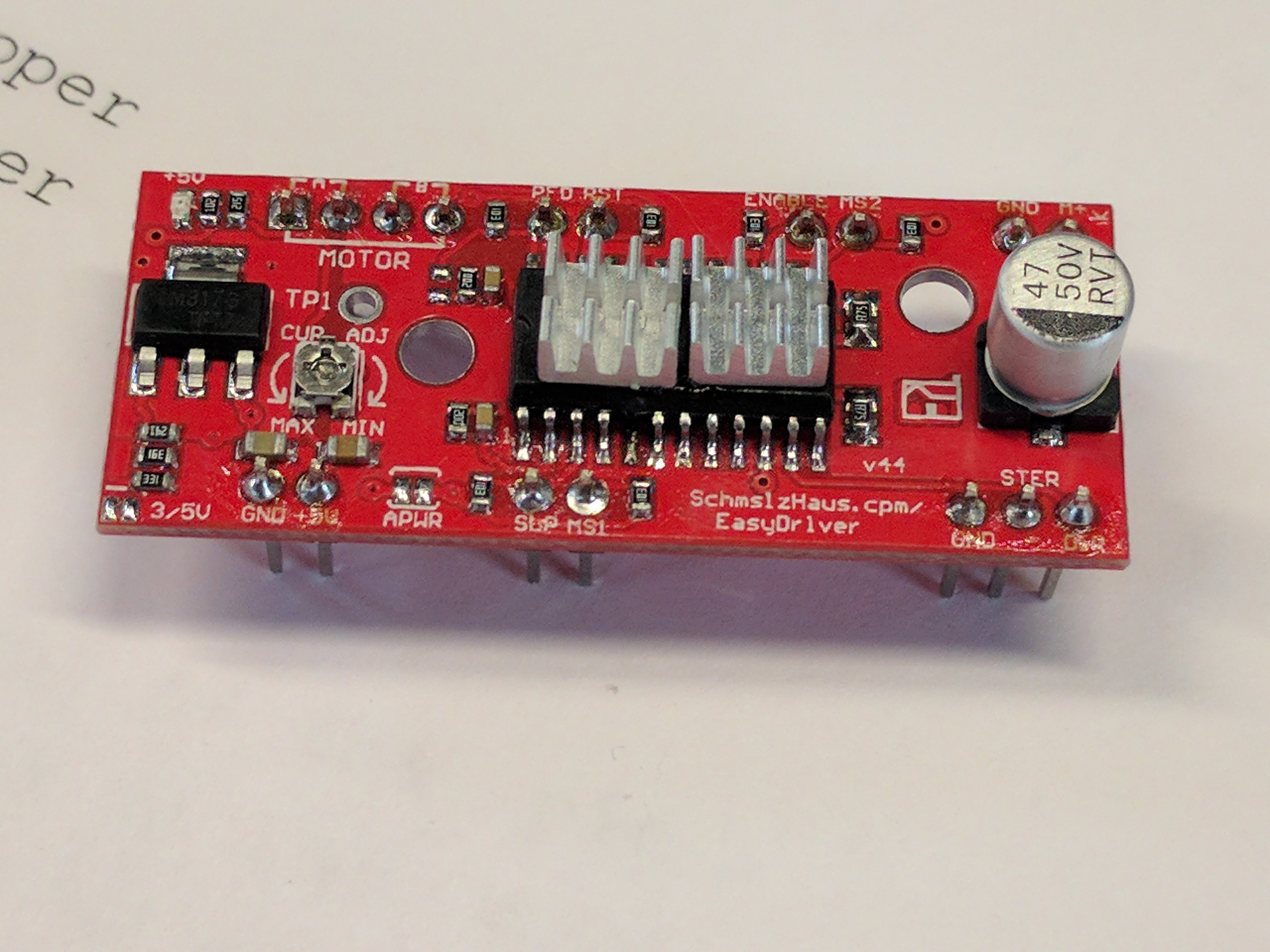

I blew up chips on our Motor controllers

if you look at the pins below the heat sink you will see one is missing, that is because it got fried.

I have fried 3 like this so far :(

One was because of bad stepper motors. The steppers also destroyed the internals of 4 other drivers. They have been sent back and replaced. Thank you Dan for getting replacements.

One was my fault, I wired a motor to the drive wrong.

The latest time I don't know why it blew. This is of course the one bothers me the most because the unknowns are preventing us from getting more than 5 motors working in sequence.

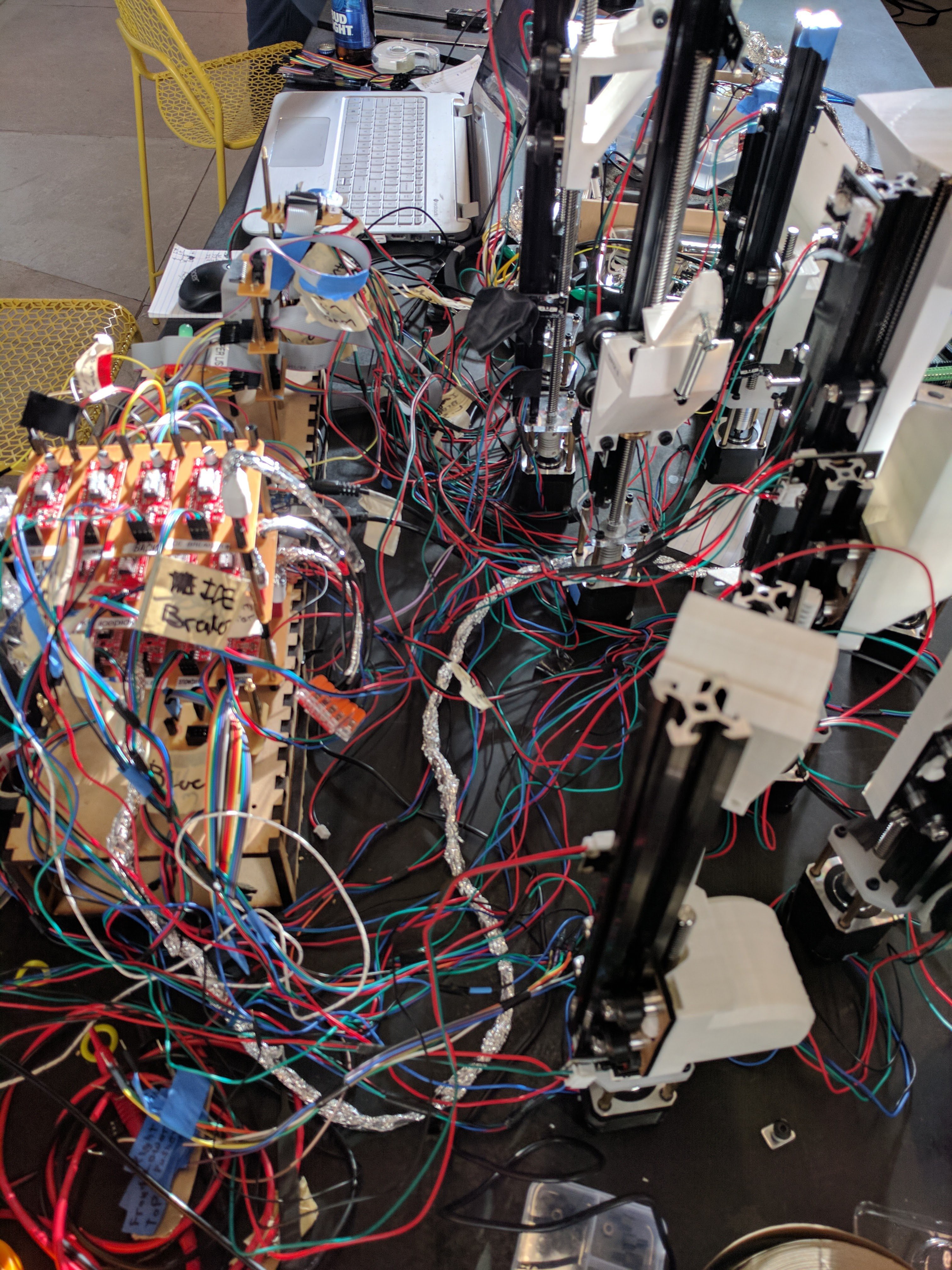

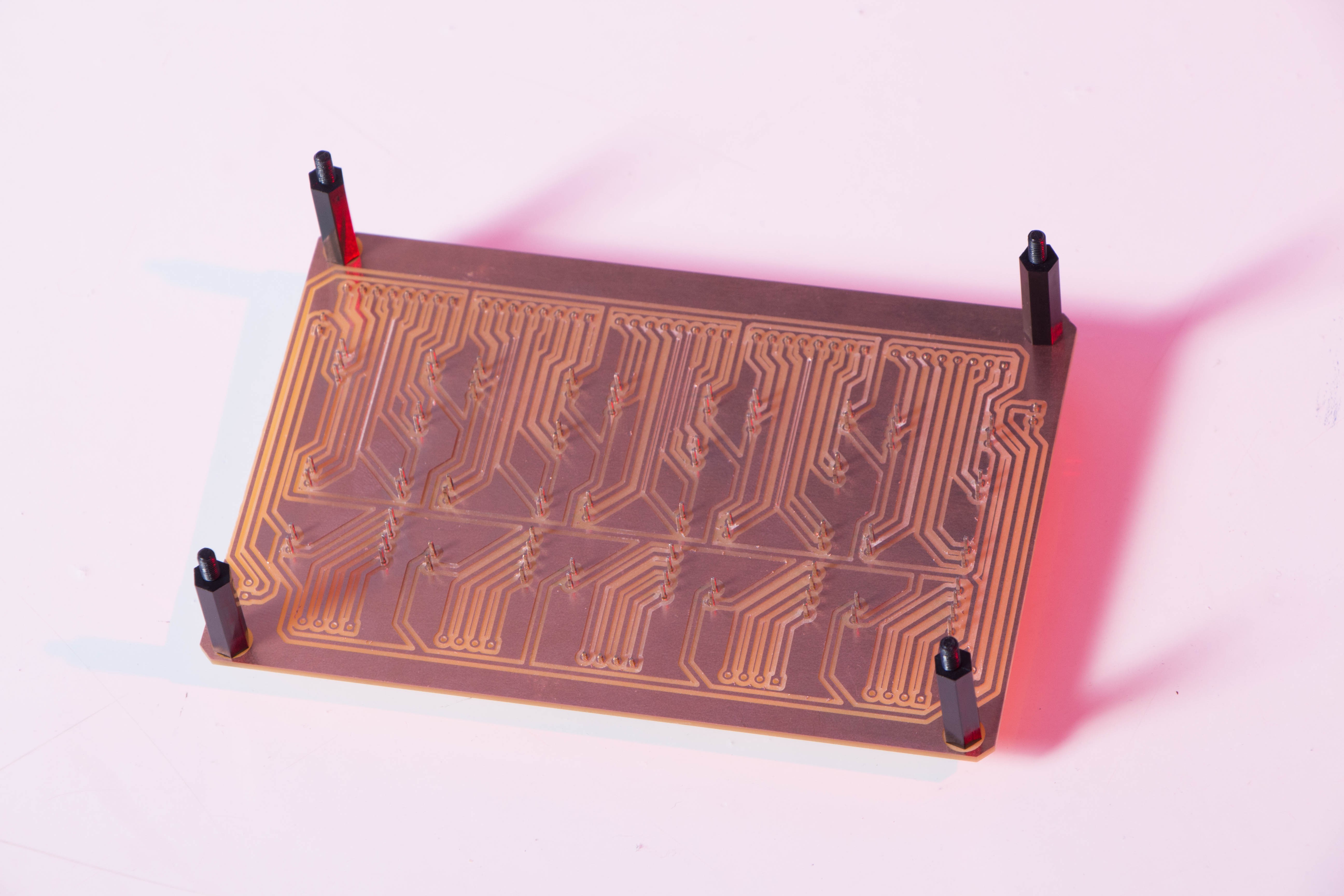

We made the boards for all the motor drivers 15 in one big stack!

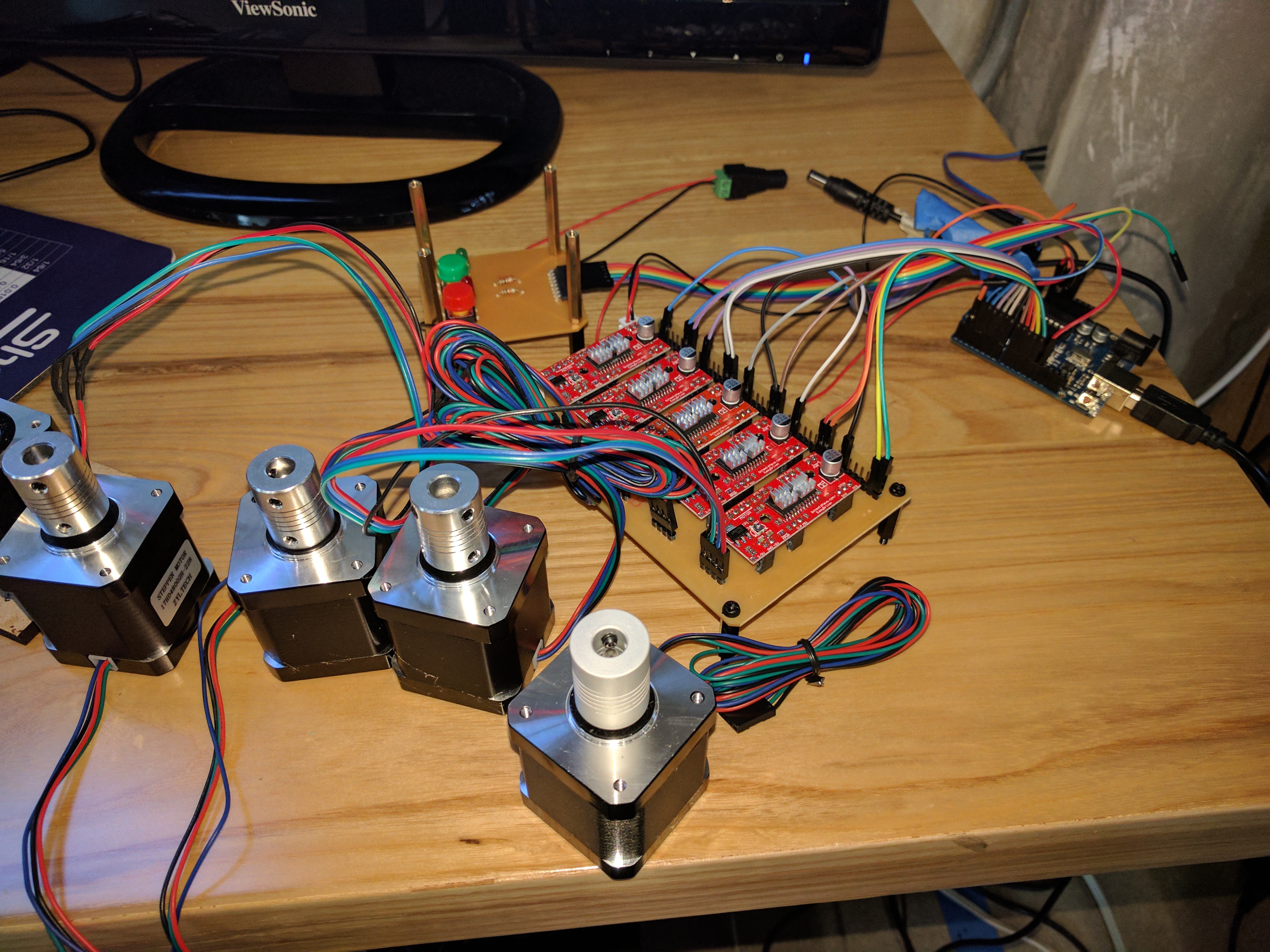

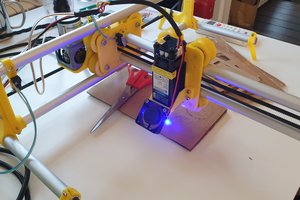

we finally have 4 motors all working together in the correct order

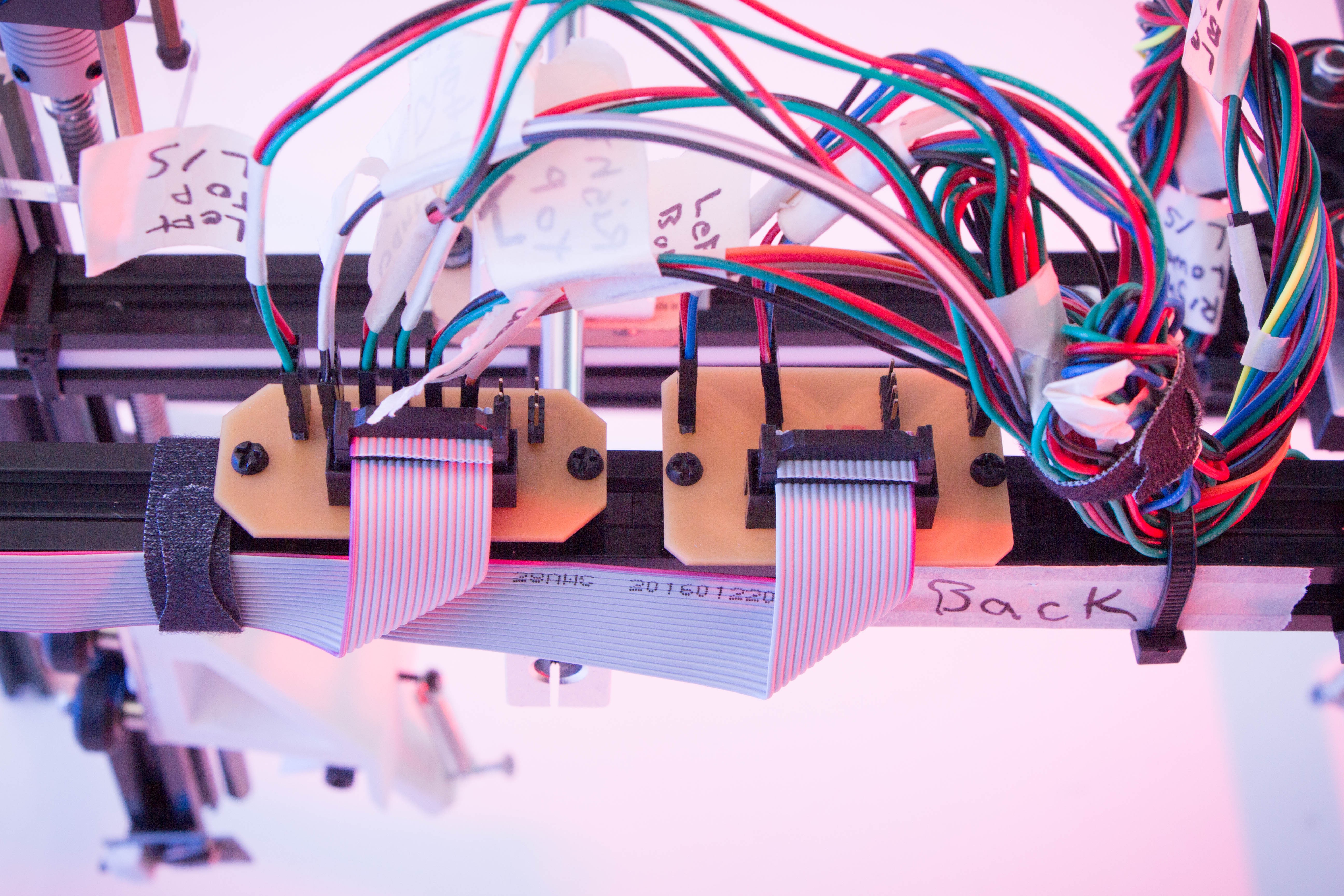

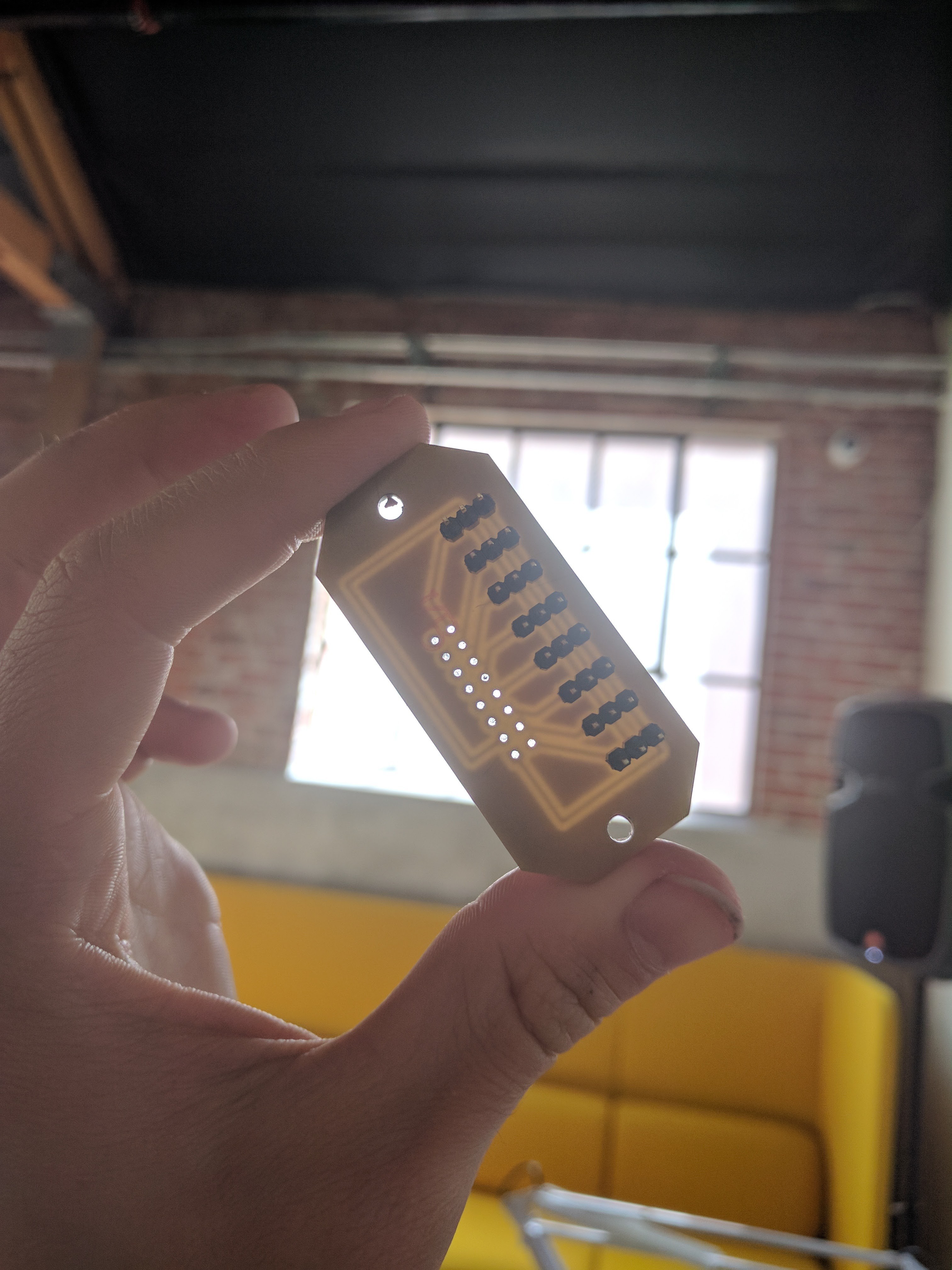

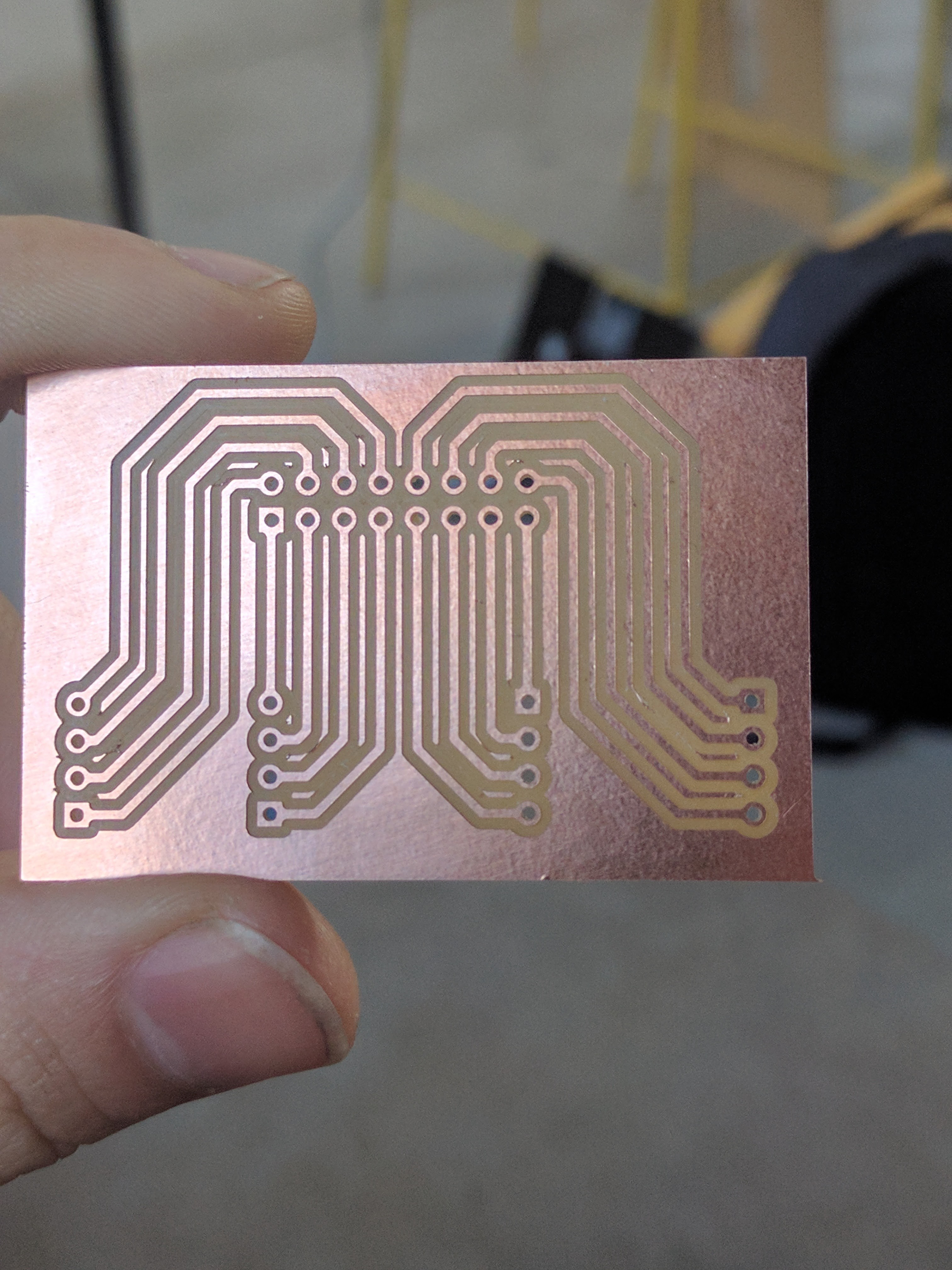

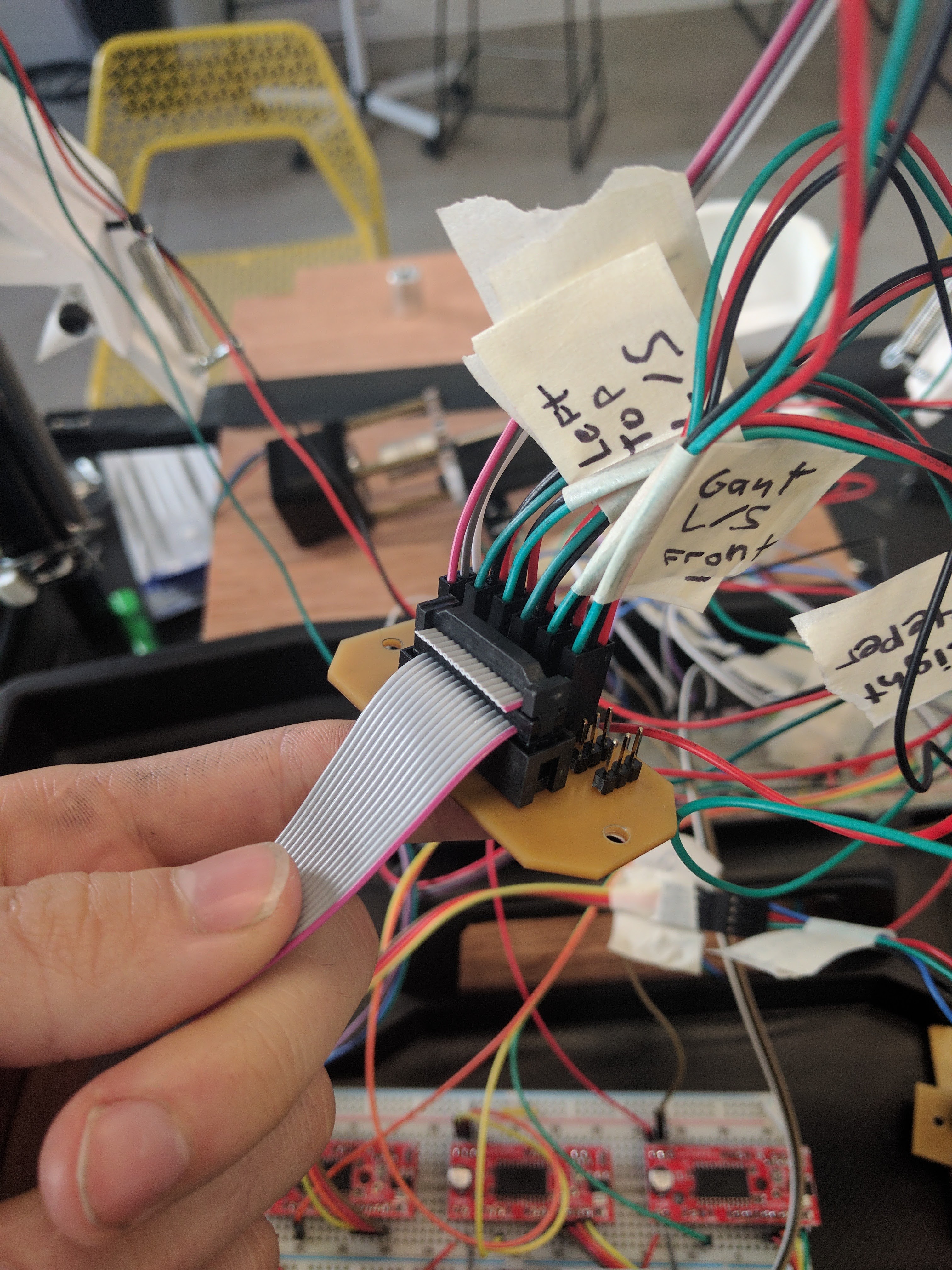

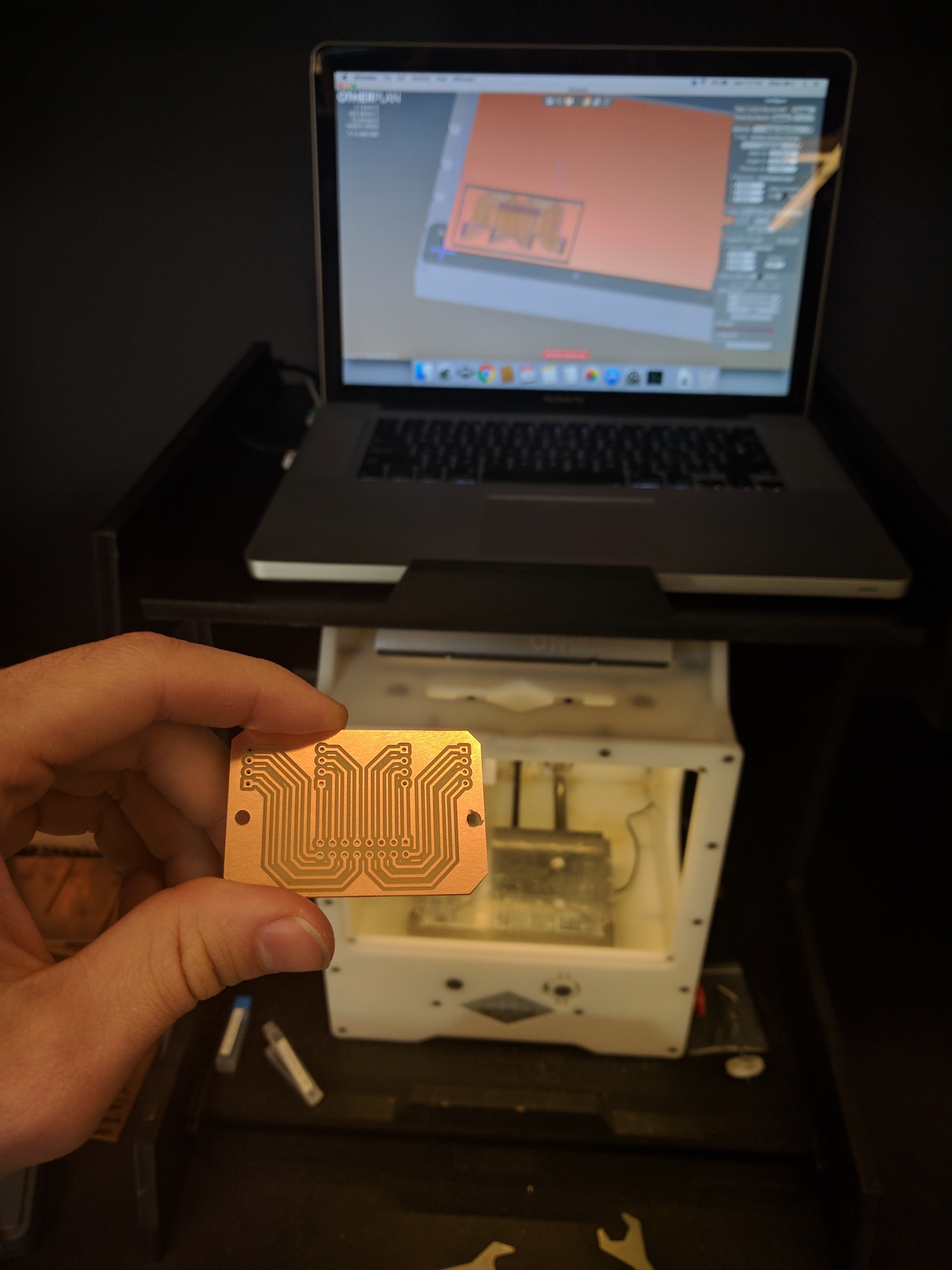

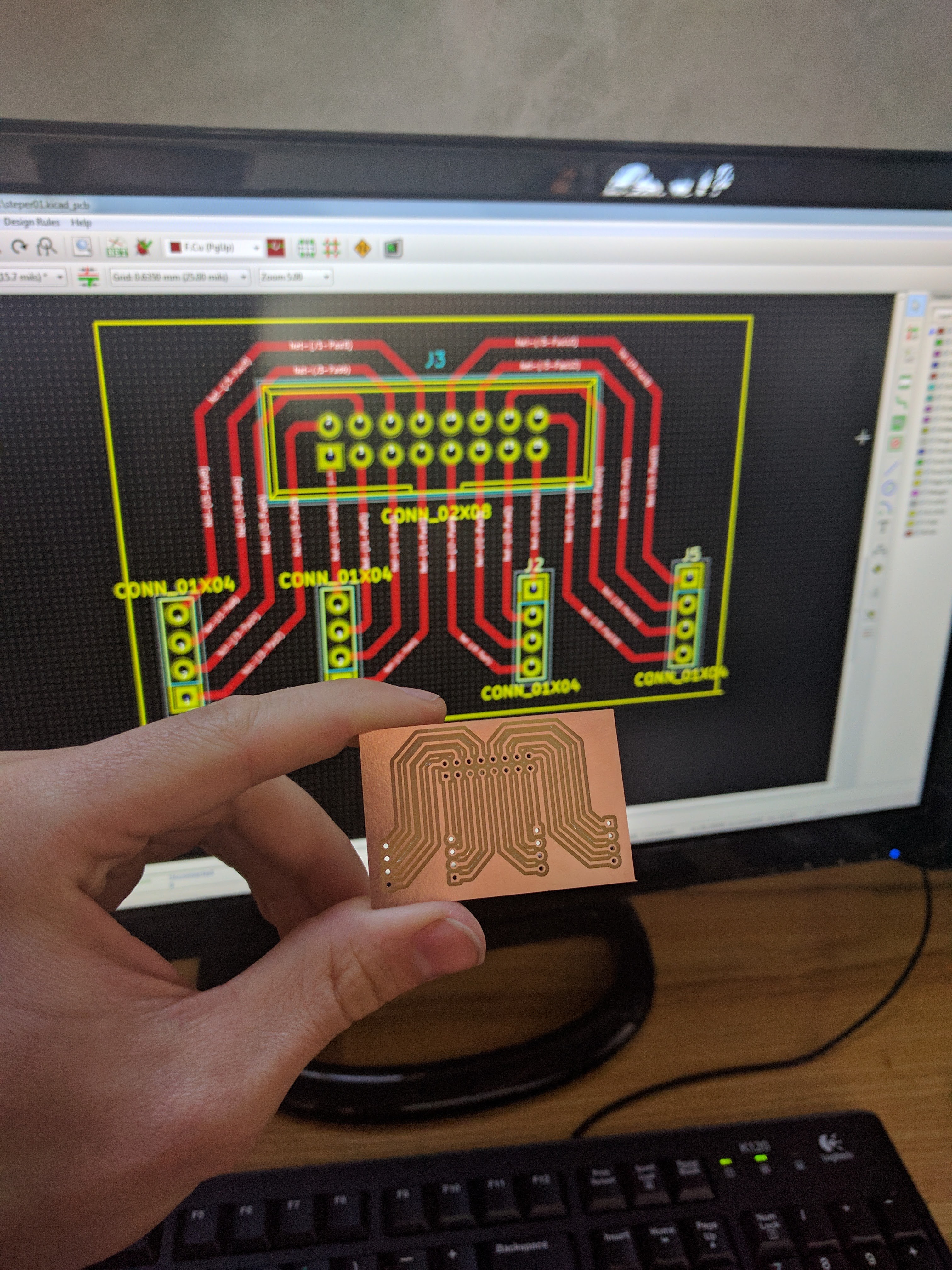

we made some circuit bored or the first time on the other mill. It was very satisfying. Starting we made a beak out bores to connect our 8 limit switches to a IDC 16 pin ribbon cable. We made a 4 stepper to IDC also. we got the tool and made the cable our selves and it was relay fast with no soldering.

we used KiCad to make the circuit.

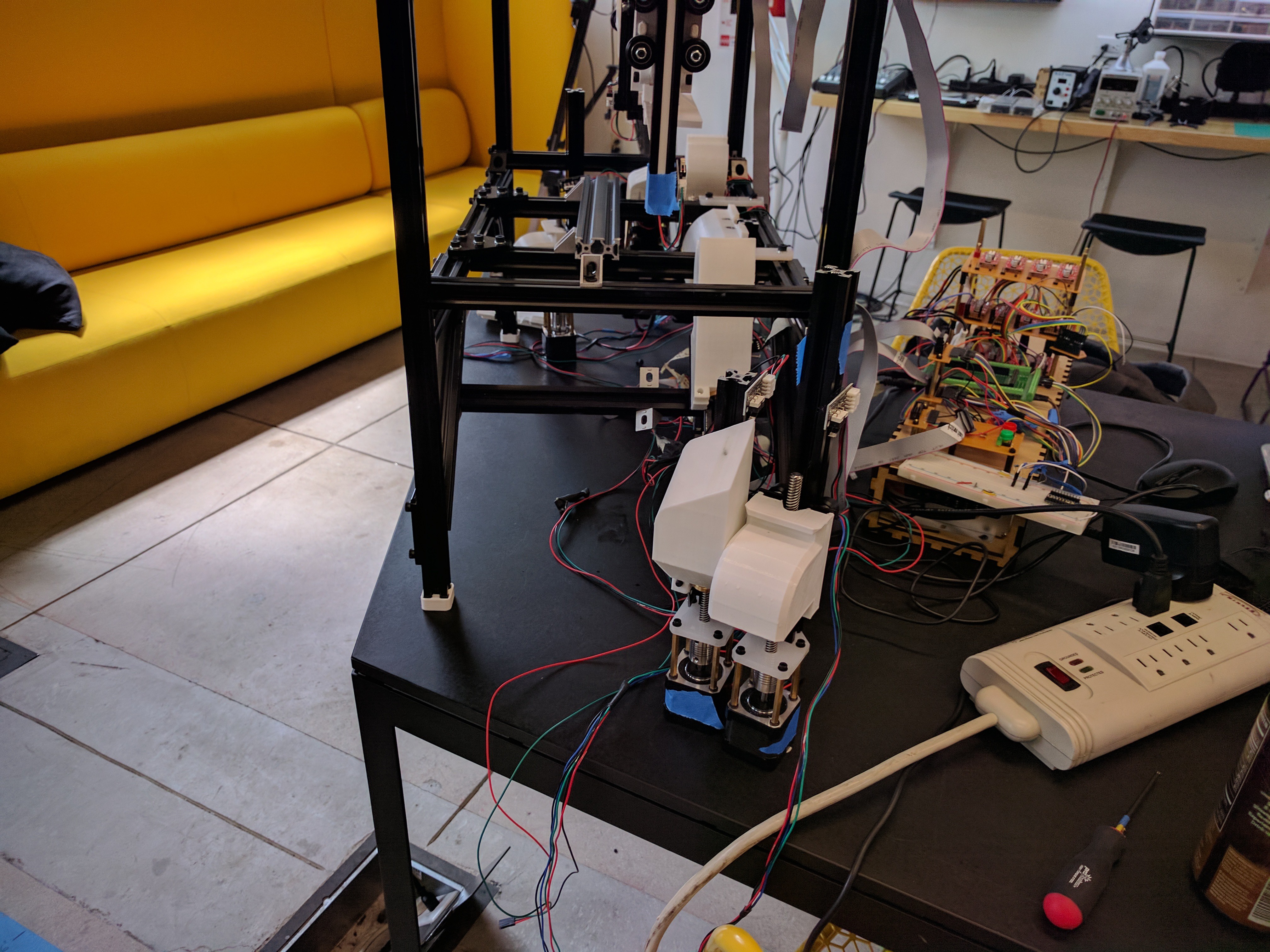

total mess at first.

Create an account to leave a comment. Already have an account? Log In.

What chips are you using for the stepper controllers? I'm currently testing out L6482 's which are SPI controlled so only one wire from the mcu is required.

Nice project! It a really a nice application for my project (AnanasStepper), which is designed to control multi stepper motor at the same time. I think we can cooperate!

Well, servos are made for RC toys. Even the big ones are not really made to drive stuff. The way to go would be a geared DC motor in combination with two end stops. Get something that can put out a two digit wattage. DC motors can go into overdrive for a short time if they get time to cool down afterwards. Something you can easily do in this application.

It kinda bugs me that you are heading for all this high precision CNC gear while you actually need something strong and rugged with comparably low precision.

You could probably get away with some cheap steal rods with wooden carriers directly riding on them with laser cut holes.

Hey I'm in Pasadena and will need to fold a ton of cardboard mailers for my own project in a month or two. When will you all be looking for testers?

Given that you don't need to be extremely precise to fold box panels, I'd go with servos which are geared internally instead of stepper motors. The servos are cheaper, more powerful and easier to drive too.

We are testing both at this time, currently the stepper are winning for most parts.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

Gertlex

Gertlex

Sam Baker

Sam Baker

Maximiliano Palay

Maximiliano Palay

Nathan Peterson

Nathan Peterson

Do you have some problems about motion control ?Maybe AnanasStepper https://hackaday.io/project/20980-ananasstepper-20 is to meet your need!