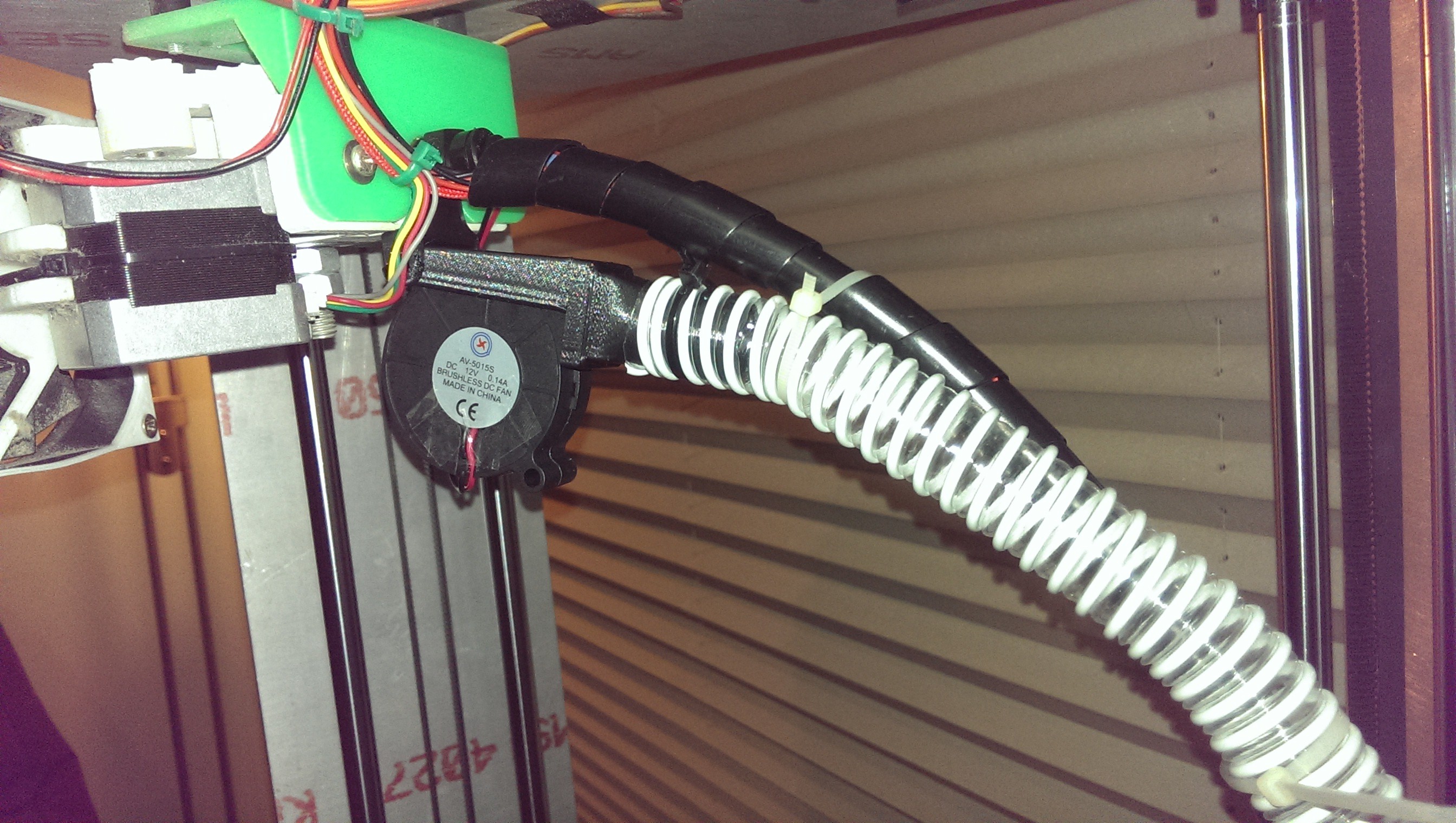

In my never-ending quest to reduce weight on the end effector I tried to think of exactly what was necessary to haul around. The hot end fan couldn’t be removed for obvious reasons and the mechanics were pretty lean already. The only candidate was potentially removing the part cooling fan, but that would obviously reduce print quality. I thought that there must be a way to relocate the fan and deliver the air remotely. The air delivery would have to be low pressure, high volume to provide good cooling. I would need a fairly large diameter tube which would in turn be quite heavy. If the tube was too heavy it would negate the whole concept.

I had a eureka moment while at my local makerspace one day. Two of the guys there have Muscular Dystrophy and require ventilators to help breathe. I noticed they had lightweight, flexible tubes delivering the air to their face masks. This type of tube would be perfect! A few phone calls later I found myself at a CPAP machine distributor. For AUD$25 I got a 2m length of very light, strong and flexible tubing.

This blows!

Heavy part at the top

The concept worked! The blower fan was able to deliver a decent flow and cool well. It also meant that I didn’t have the weight of extra wiring going down the bowden tube. It was very important to get the tension in the tube correct along its length as it had the tendency to be quite springy and exert force on the bowden tube.

I used this setup for a while until I upgraded to magnetic ball joints. Even though the tube was very flexible it would still exert a twisting force on the end effector. Unfortunately, this caused the magnets to disconnect quite often so was abandoned.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.