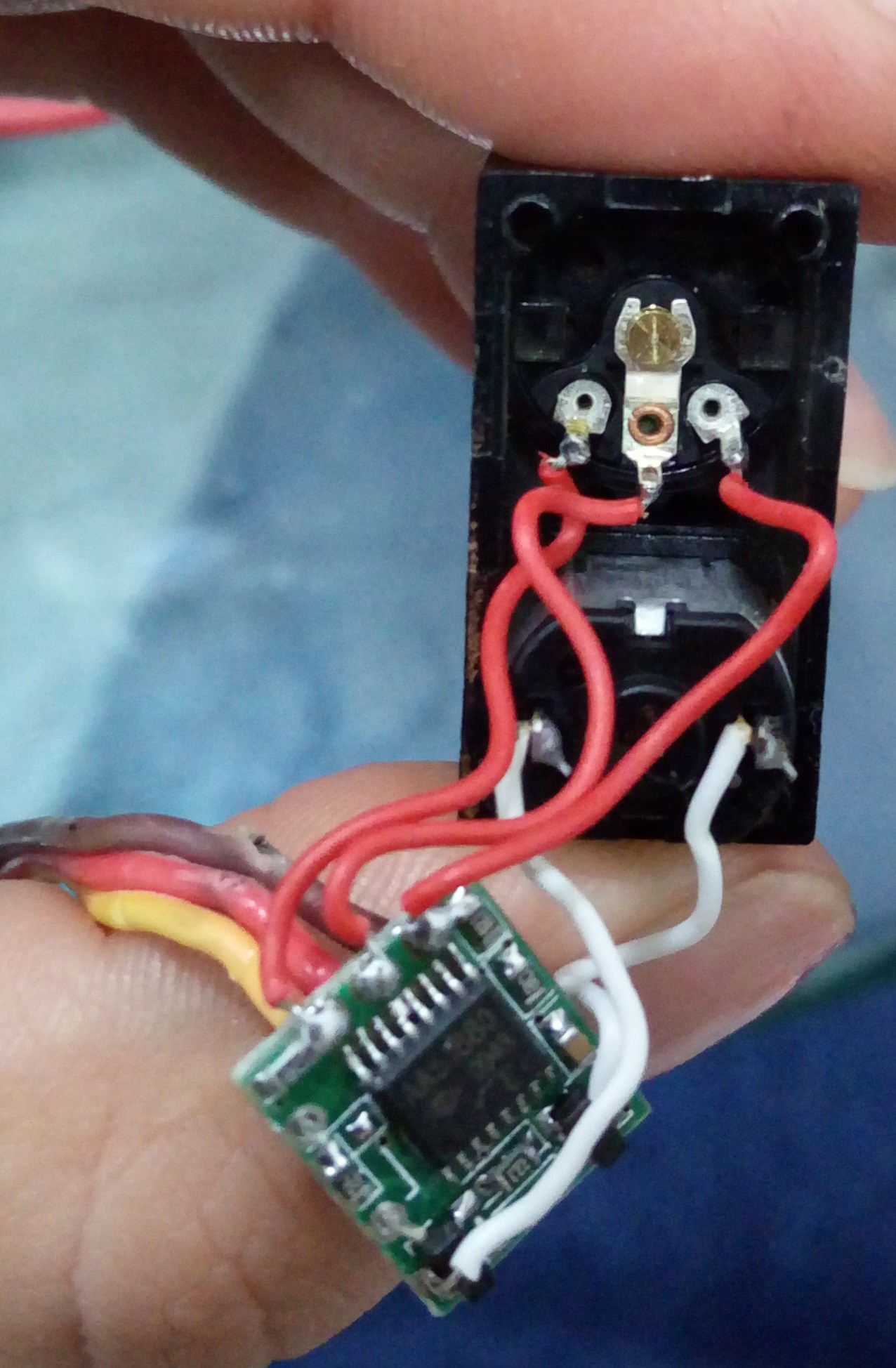

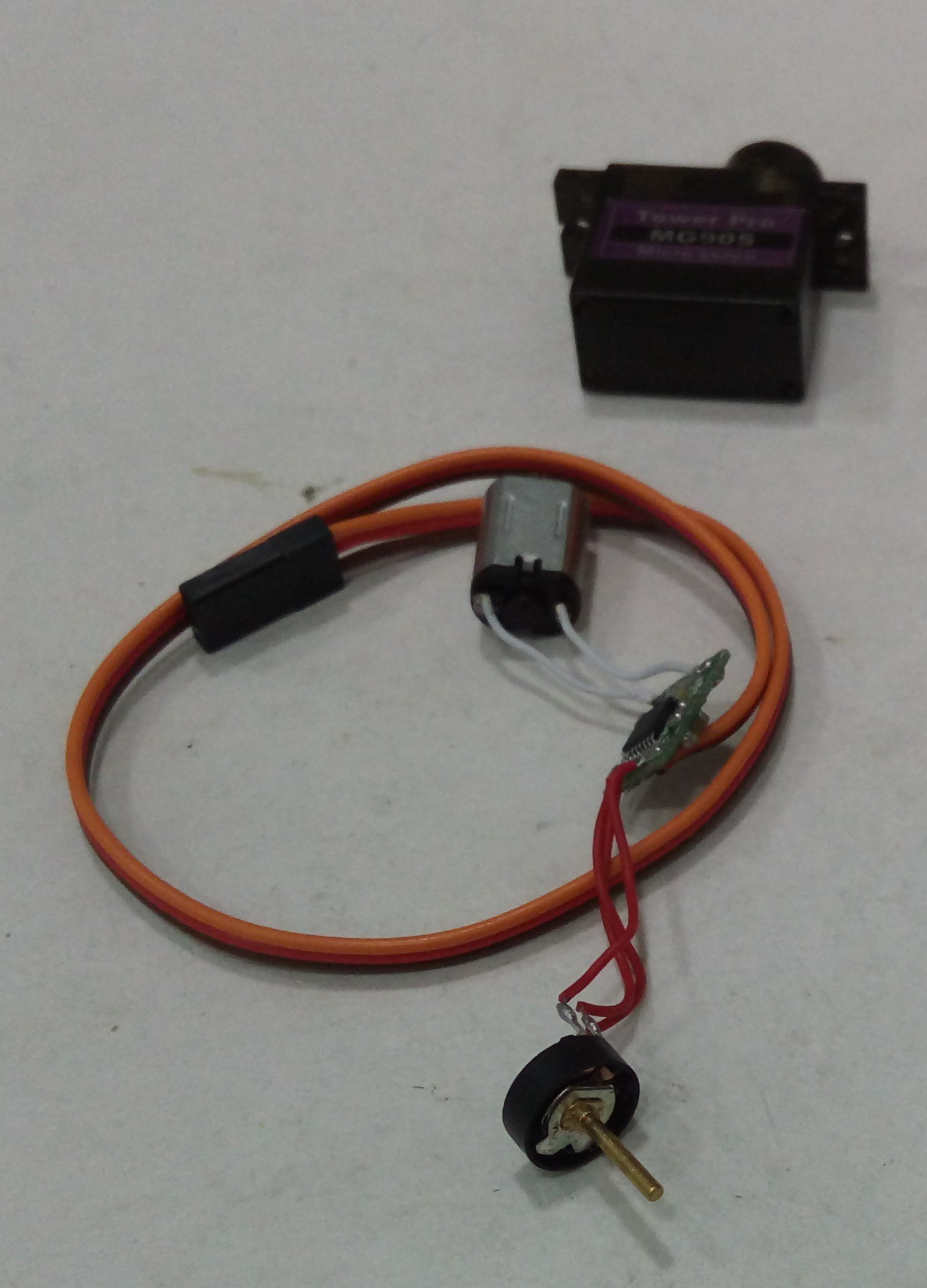

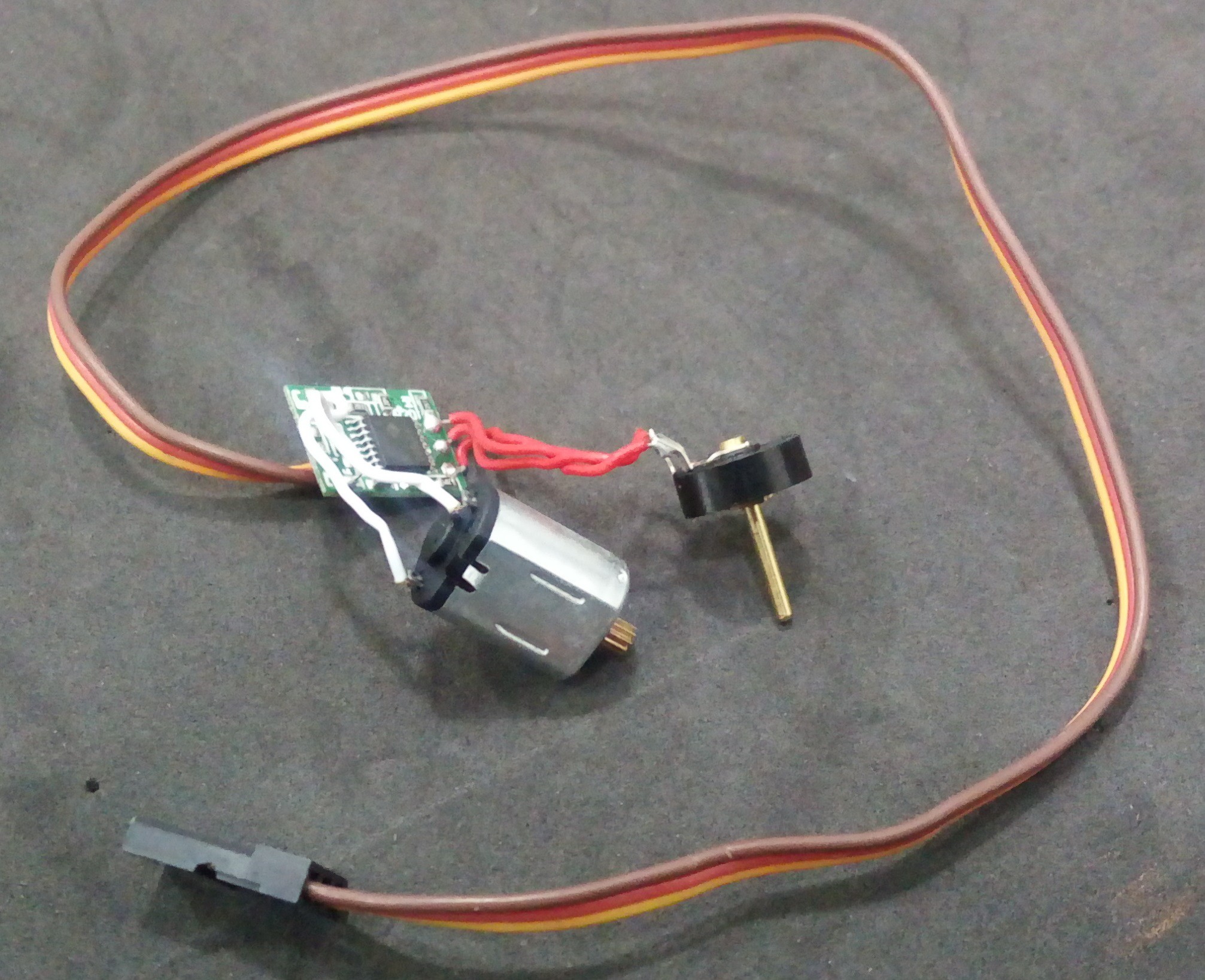

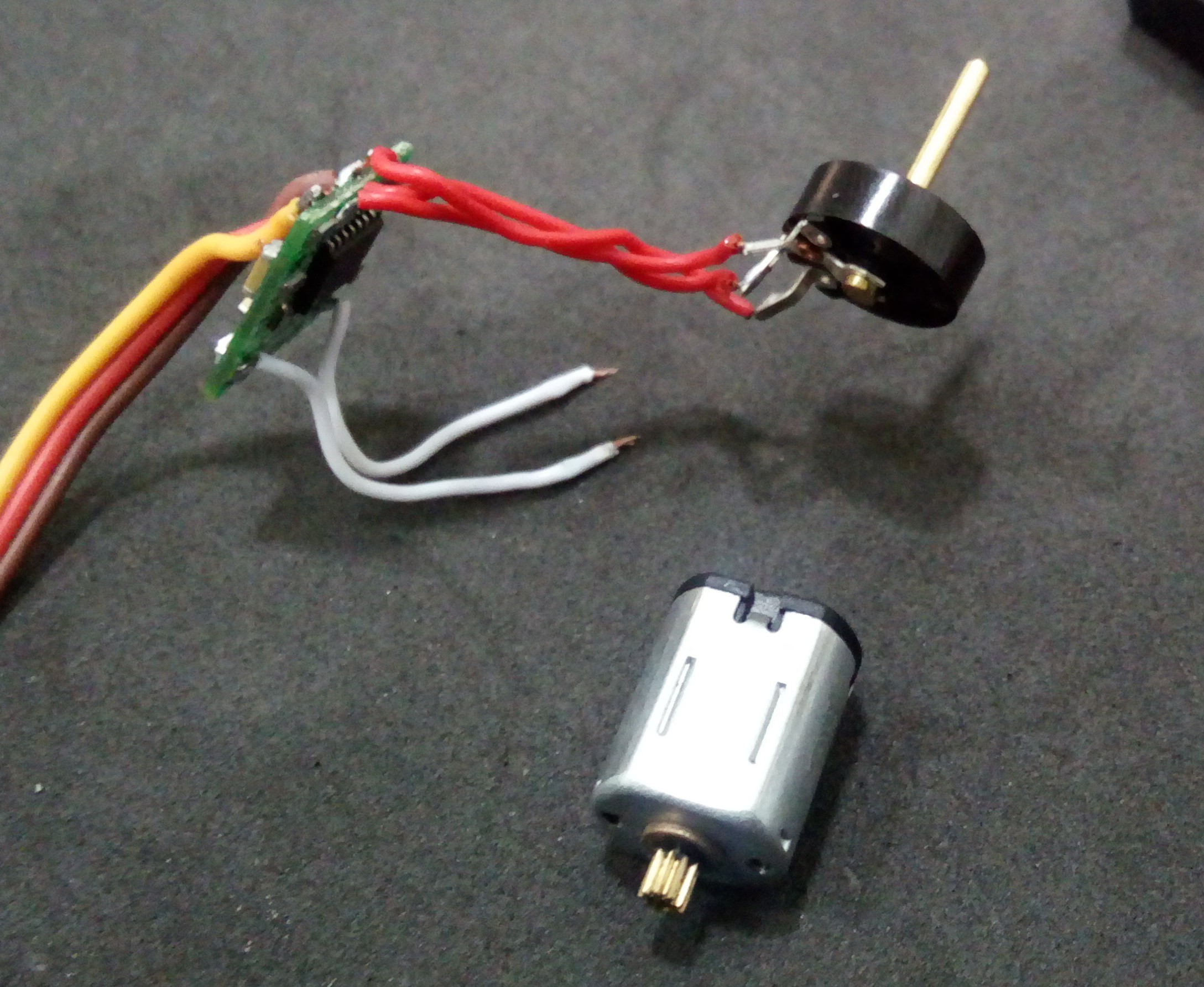

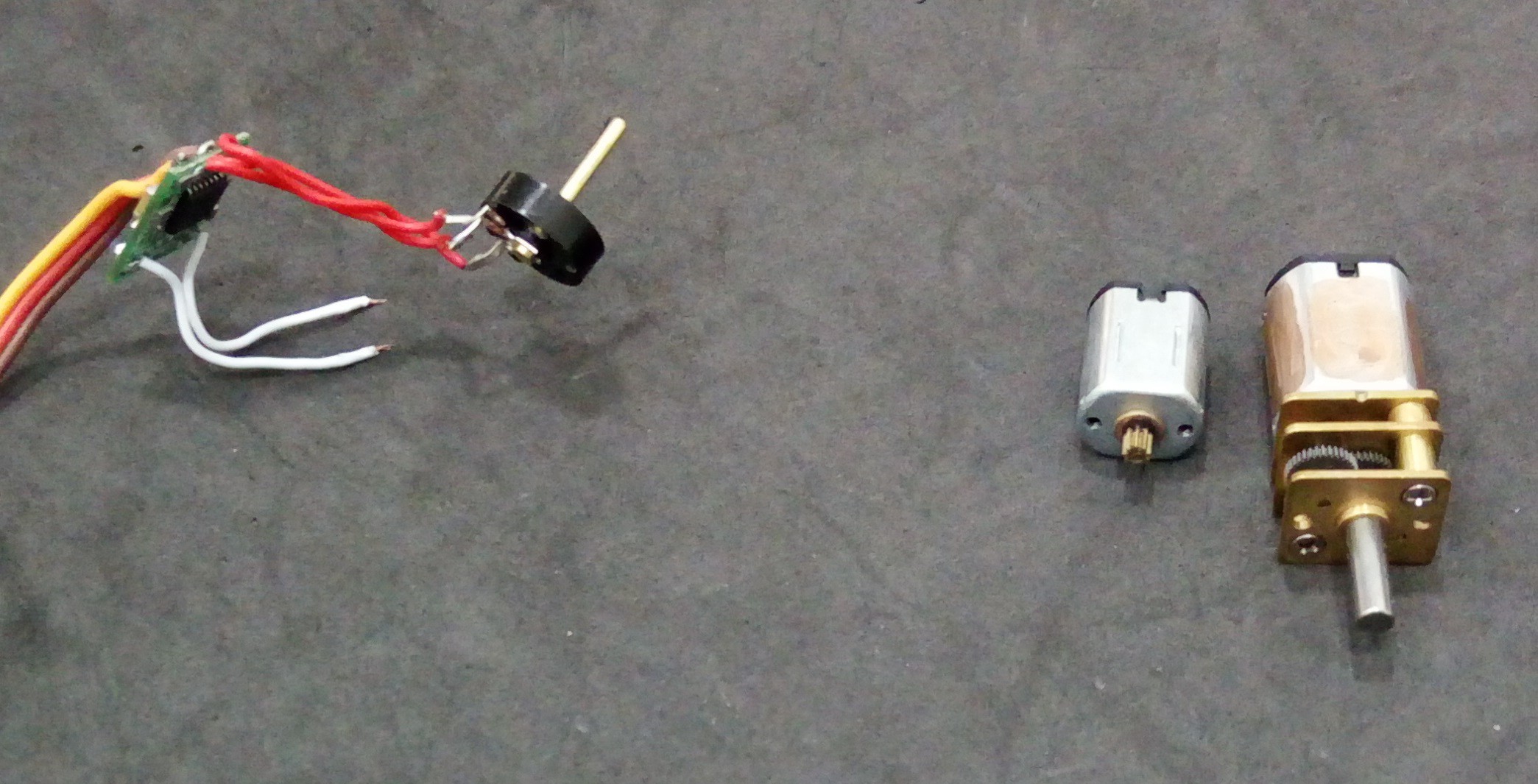

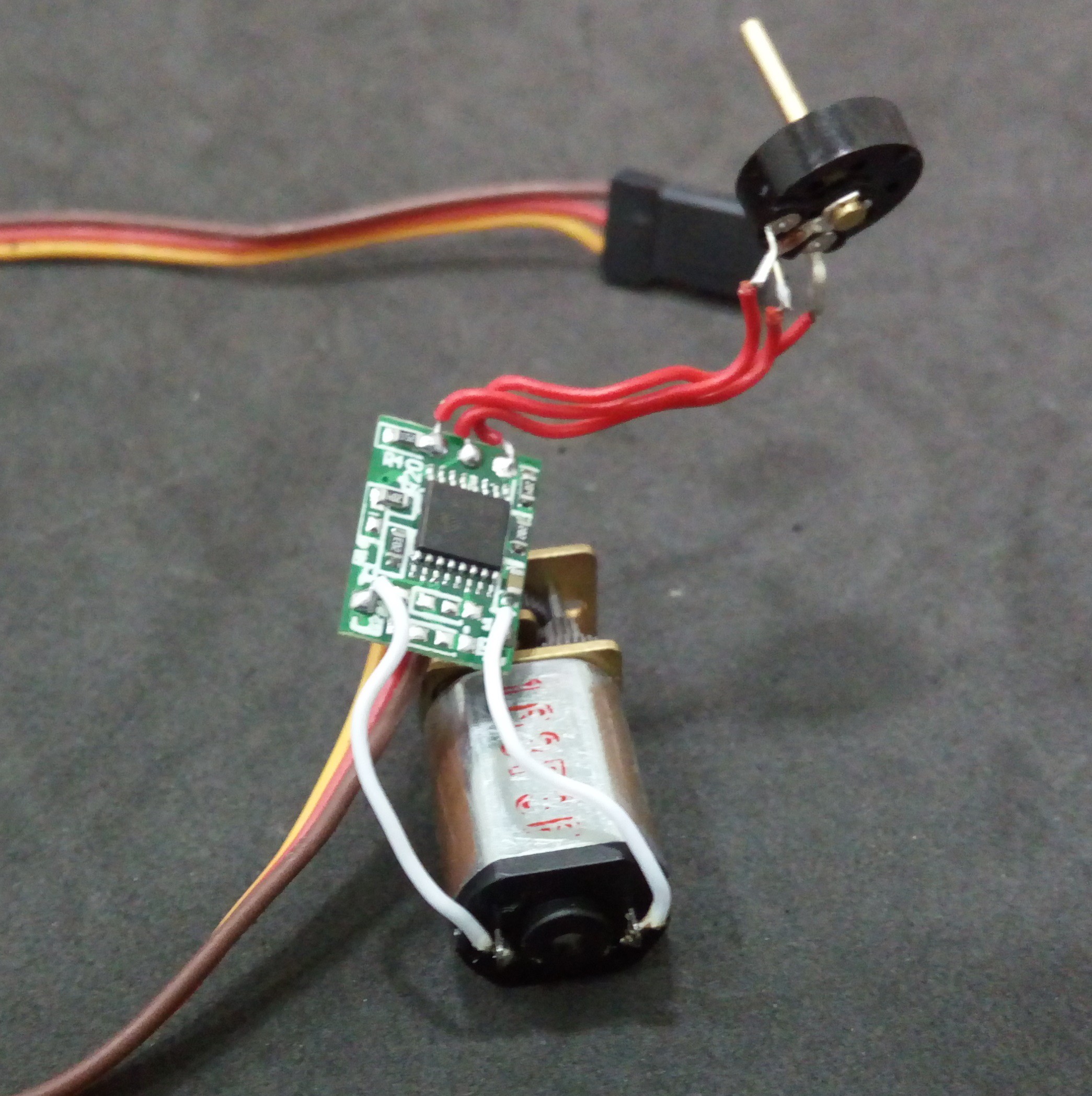

Assembling process

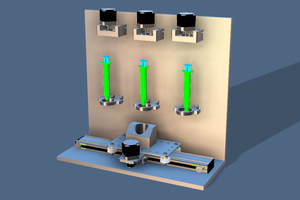

Schematics

Licensing

As everything on Hackaday, all that is published here is for grabs and to make your own. If you plan to sell it, please make it really different or had functionality to it. We know all of that its obvious and already written but we wanted to say it explicitly.

Giovanni Leal

Giovanni Leal

Sam Ettinger

Sam Ettinger

Joan Horvath

Joan Horvath

Hi, do you have files for the hall sensor model ?