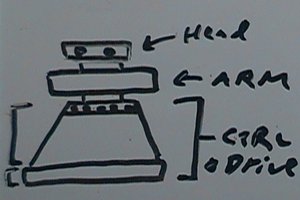

The first few photos in the gallery show a visualization of the image processing steps. Although the TJ logo is just an outline, the edge detection algorithm would find only the most prominent lines and store the simplified image in a matrix. Blank spaces have a null value in this matrix. When painting, the robot would traverse the matrix in real time, moving in a serpentine pattern and dispensing paint accordingly.

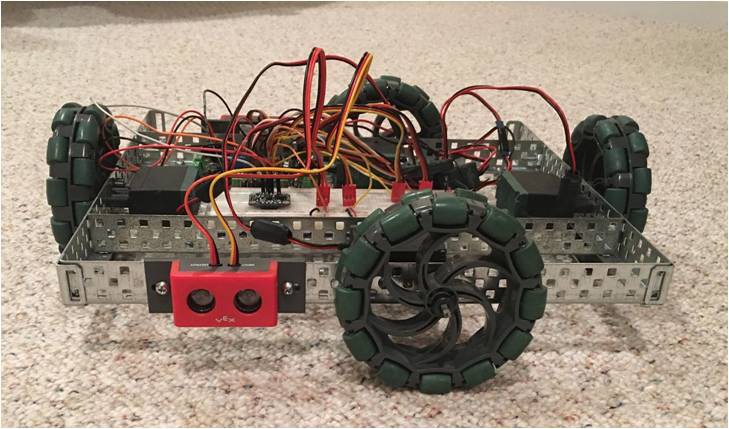

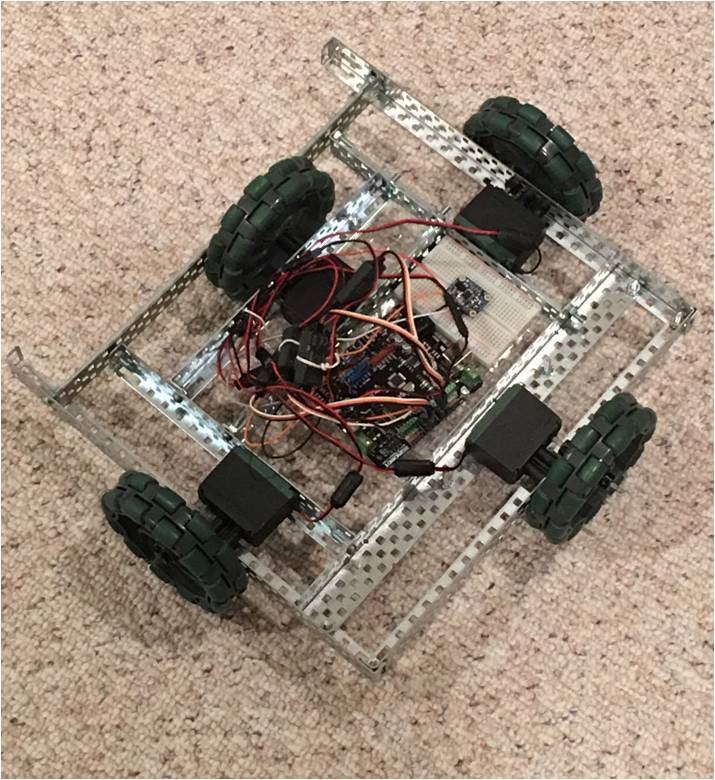

The next few photos in the gallery show the platform we built to test movement. It is equipped with omniwheels to allow for flexible movement as well as VEX ultrasonic rangefinders to pause the robot if something is obstructing its path.

jvsalatino

jvsalatino

Ricardo Daniel de Paula

Ricardo Daniel de Paula

VPugliese323

VPugliese323

tommytwoeyes

tommytwoeyes

While we experienced difficulties in integrating the desired painting mechanism with the robot chassis/movement, we were able to develop a working testing platform that could autonomously and accurately traverse the instantiated grid of movement. We hope that in the future, this research can be expanded and a more efficient and accurate method of painting from this robot can be implemented.