After watching the talk on diffractive optics from the HaD Superconference a while back I started thinking about some next gen VR display stuffs. The usual pondering. I was looking around the interweb and seeing what sort of ideas people may have about this tech and I found Applied Science's video (opens in new tab) where he mounted an LED inside of a contact lense and then wirelessly powered it. Obviously it wasn't going to be feasible for the sci-fi HUD that we all someday dream of having, but at least it was a start. Of course, that video was made more with the idea of eye-mounted displays in mind i.e. shining light into your looking spheres. That got me thinking, what if you had light that came out of your eyeballs.

Chris

Chris

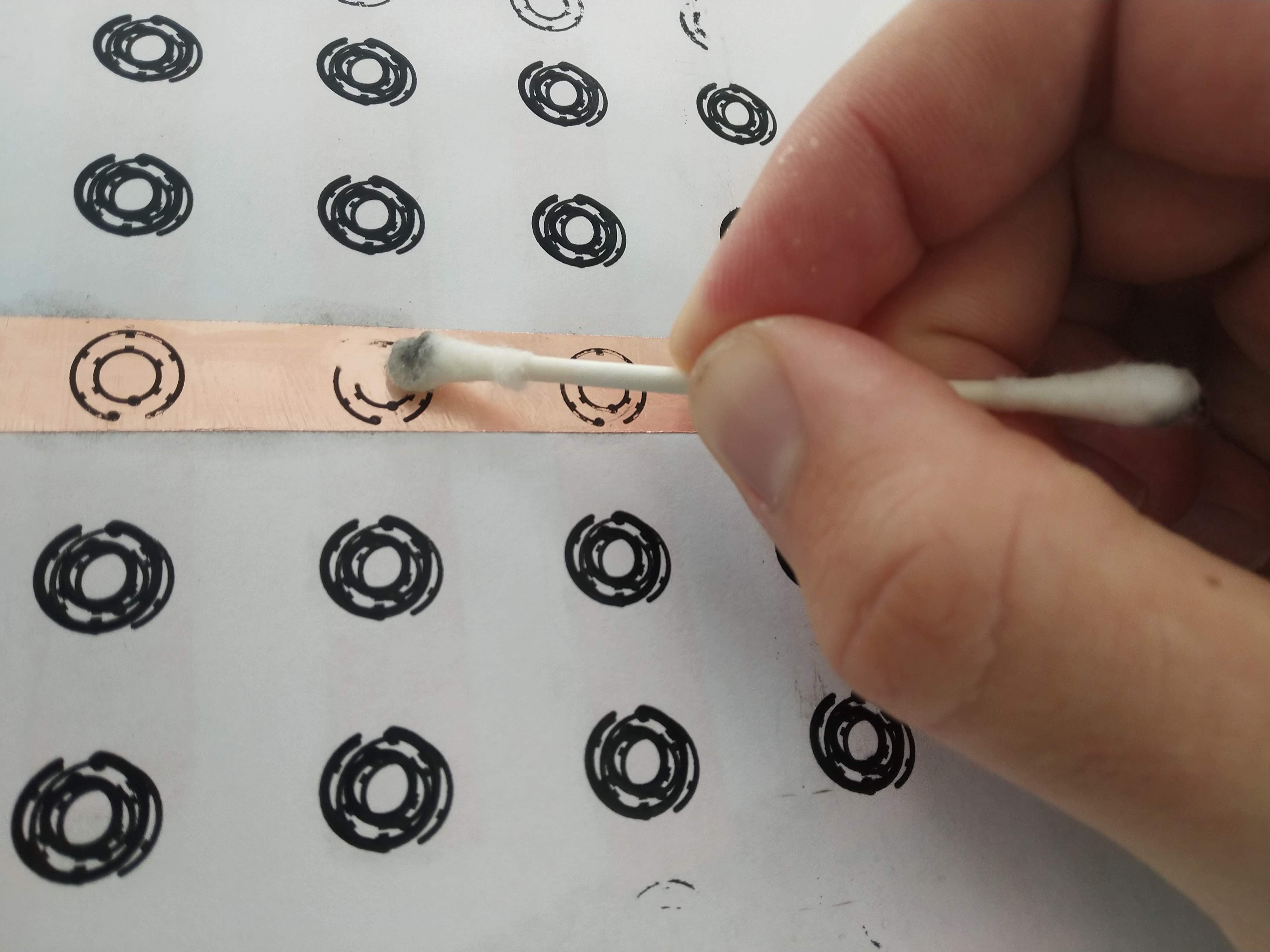

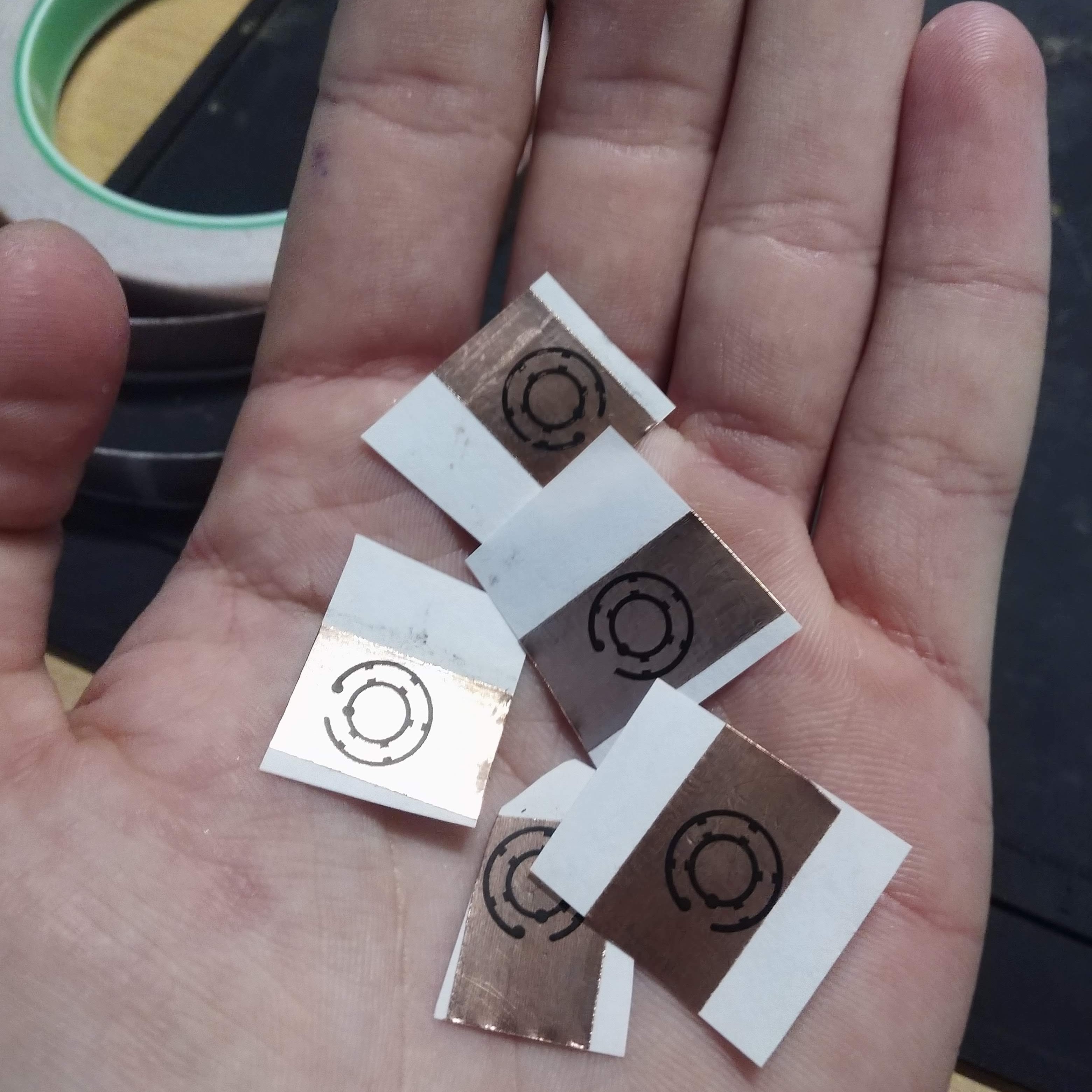

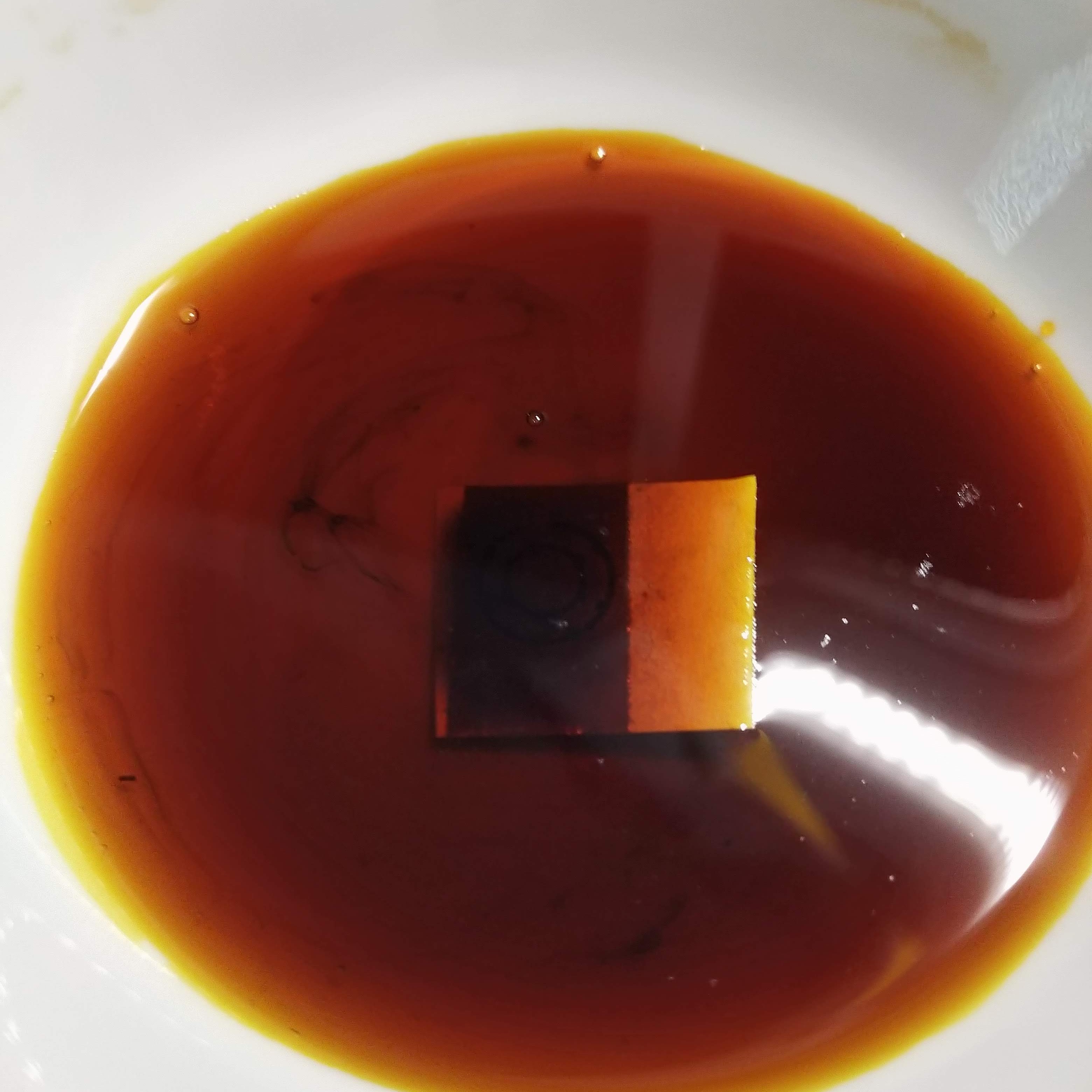

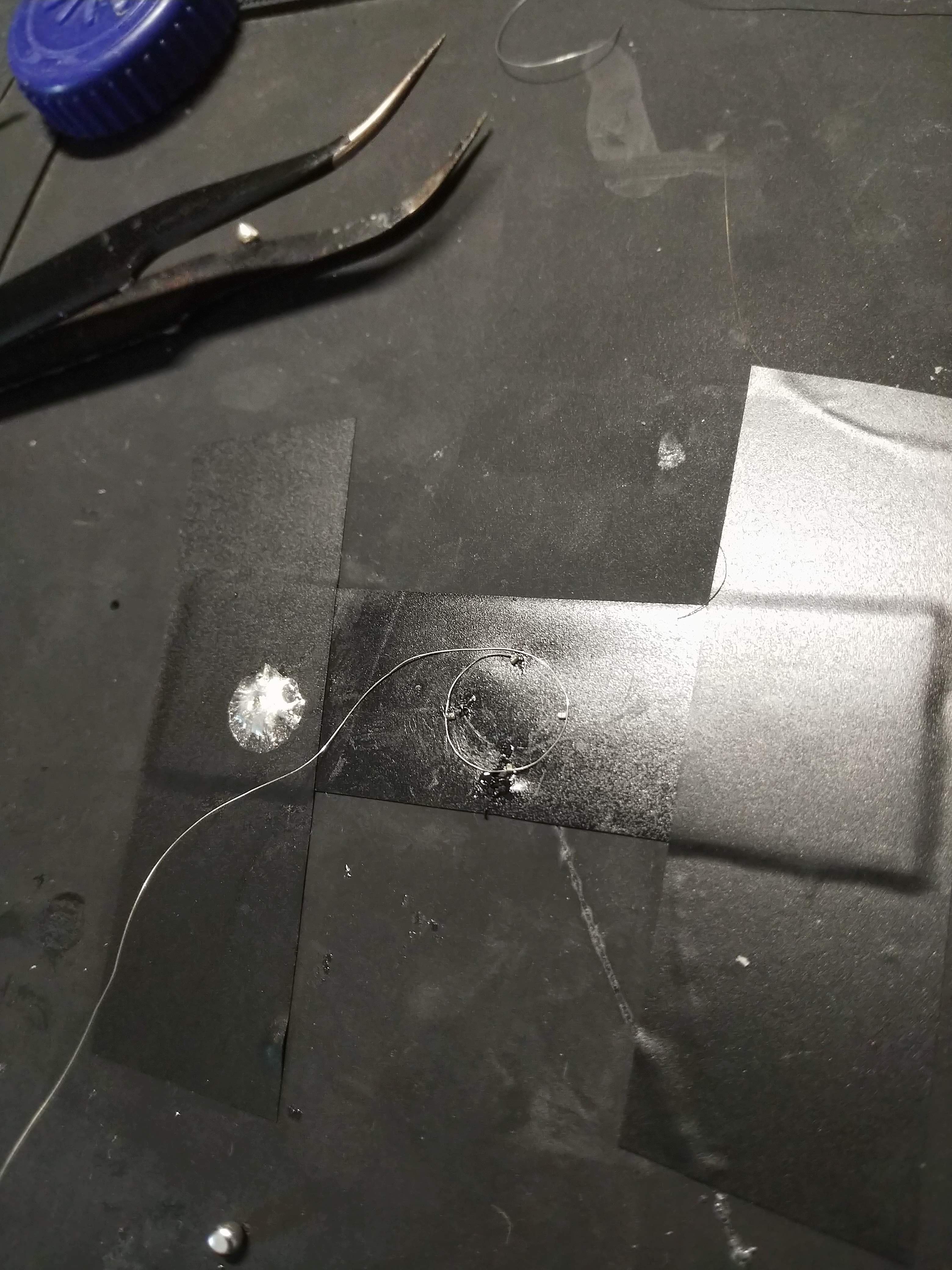

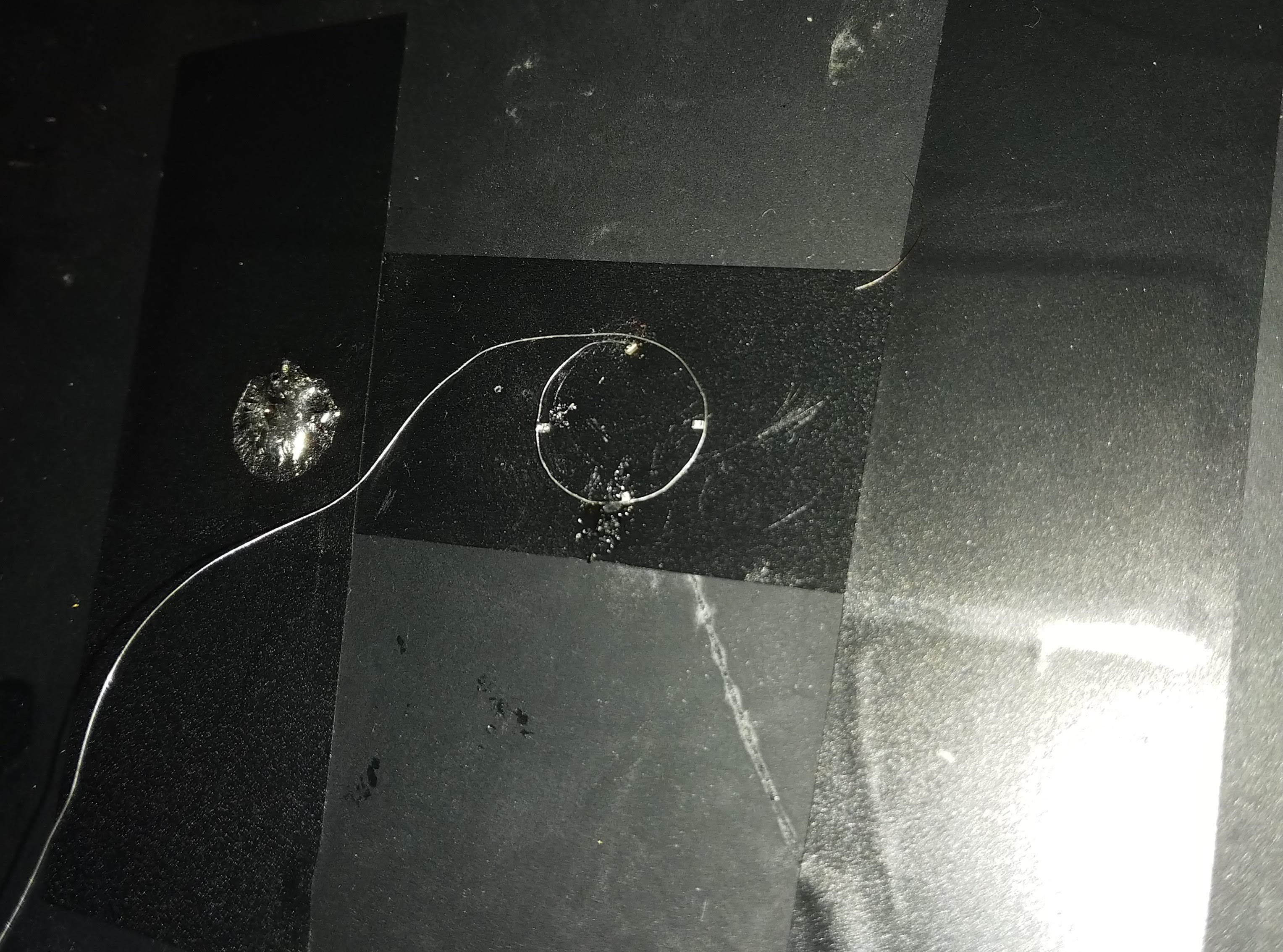

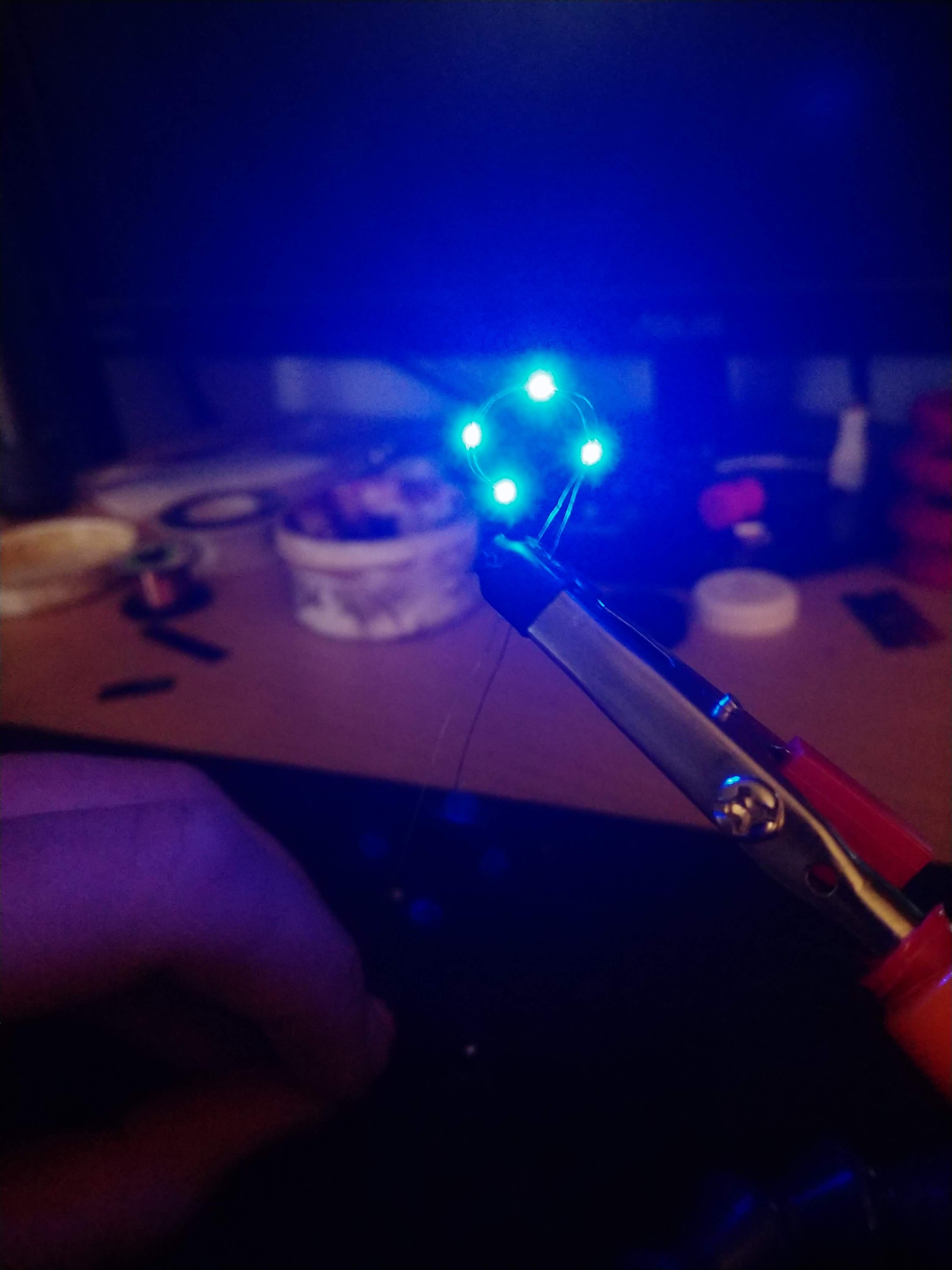

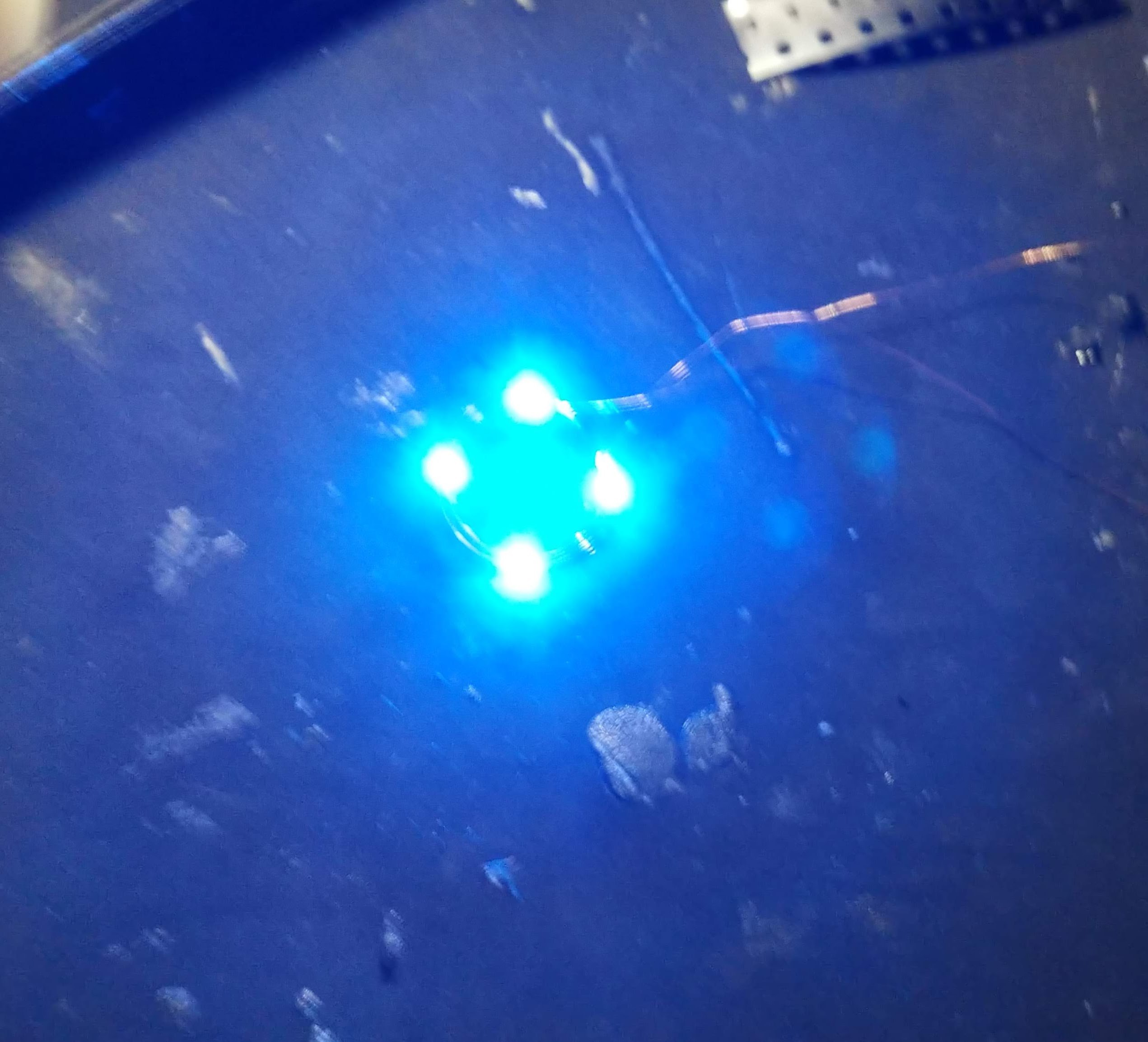

This was using 0603(1608) SMD leds. They were crusty and didn't actually work. For some reason, the solder just wouldn't wick onto the wires, making it near impossible to actually attached the lights. I even made sure to burn off the enamel coating and everything! Once again, for those keeping track, it was a this point where I decided to have the PCB made, which is what you can see in my friend's eyeball featured at the top of this project. The thought of a substrate free design still seemed like the most feasible option though. So I ordered some more leds and decided to give it another shot.

This was using 0603(1608) SMD leds. They were crusty and didn't actually work. For some reason, the solder just wouldn't wick onto the wires, making it near impossible to actually attached the lights. I even made sure to burn off the enamel coating and everything! Once again, for those keeping track, it was a this point where I decided to have the PCB made, which is what you can see in my friend's eyeball featured at the top of this project. The thought of a substrate free design still seemed like the most feasible option though. So I ordered some more leds and decided to give it another shot.

Just use florescent contact lenses and black light, much better effect without losing your eye.