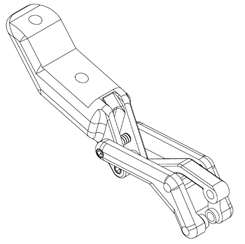

This is the last iteration of the project with 6 DOF.

Printed parts on PLA:

1x Palm

1x Bottom cover

1x Top cover

1x Thumb core

1x Thumb distal phalanx

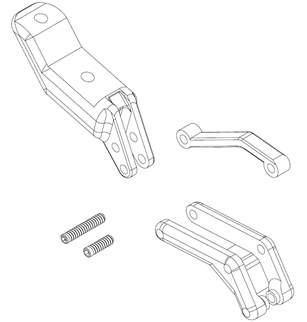

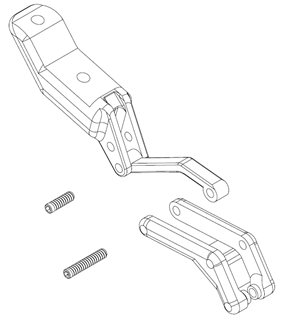

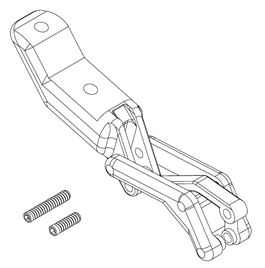

4x Joint

4x Distal Phalanx

4x Proximal Phalanx

The Covers of the fingers can be made with silicone ore rubber using the molds. At least you will need:

1 x Finger mold1

1 x Finger mold2

1 x Thumb mold1

1 x Thumb mold2

1 x Arduino Nano

5 x Actuonix PQ12R

1x Micro servo MG90S

6V Power supply

10 x M3 allen screws 10 mm long

12 x M3 allen screw 16 mm long

1 x M3 allen screw 20 mm long

4 x M2 blade screw 8 mm long

2 x M4 star screw

1 x M10 allens screw 30 mm long

1 x MG90S servo screw

Xavi Cano

Xavi Cano

pcadic

pcadic

agp.cooper

agp.cooper

Timber Rough

Timber Rough

Elite Worm

Elite Worm

Thank you very much! What a nice time in Bucharest! Amazing competition!