The ARD3 is designed to "drive" up and down the bore hole with flexible tracks that are press-fit or more accurately "squish-fit" against the bore wall, which will double as torque stabilizers and allow standard non-core drilling or core drilling to occur. There are three core-bit strategies, one is 3d printed from stainless steel (or another metal with desirable wear and corrosion resistance properties) and as such could be manufactured on the surface of Mars using a 3d printer located inside of the rover. A powder process machine or a wire-feed welder style machine would both function for this. The other type of "coring module" feature a machined aluminum drill head similar to existing Earth-based drills, with carbide cutter inserts and core dogs. These drill heads would be disposable and can attach to the rest of the coring module in such a way that they can be robotically removed and replaced. This should allow the rest of the coring module to be plastic or fiberglass, which would be easier to fabricate on the surface. The more standard drill head style coring module is not pictured. Means of attachment to the rest of the coring module can vary, but threaded connections as well as a heat-set barbed flange or simple glue joint are all included in the concept. A single piece metal (preferably aluminum) coring module with provisions for replaceable carbide inserts is also included in the concept. The hope in the case of a one-piece metal unit with inserts would be to robotically replace the carbide cutters after each core is taken.

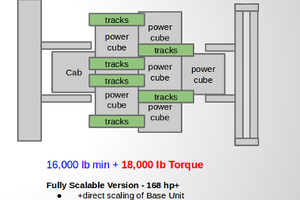

Several ARD3 units could be used to perform deep drilling work in separate bores simultaneously, as well as work bores sequentially. When one unit comes up from the bore, the next can be sent down while the rover services the worn drill, extracts the core from the coring module, charges the batteries etc.

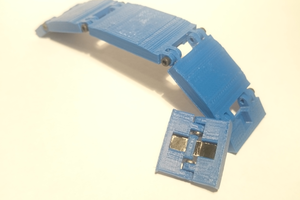

Propulsion is provided by a battery powered motor driven tank-tread system that is unique to this application. A tread design is chosen which also acts as a gear interface to transfer drive power from one tread to the other, which also serves to sync their rotational speeds. These treads are based on the Gear Bearing by Thingiverse user Emmett, and are licensed separately. They are available on Thingiverse at https://www.thingiverse.com/thing:3610134

The Unlicense was used to dedicate this work to the public domain.

Please see the repository for the Fusion 360 Archive and STLs. https://github.com/Shootquinn/ARD3

Drive system test video (Note: the power drill i'm using is noisy!):

Quinn Morley

Quinn Morley

William

William

novirium

novirium

Salim Benbouziyane

Salim Benbouziyane

marcin

marcin