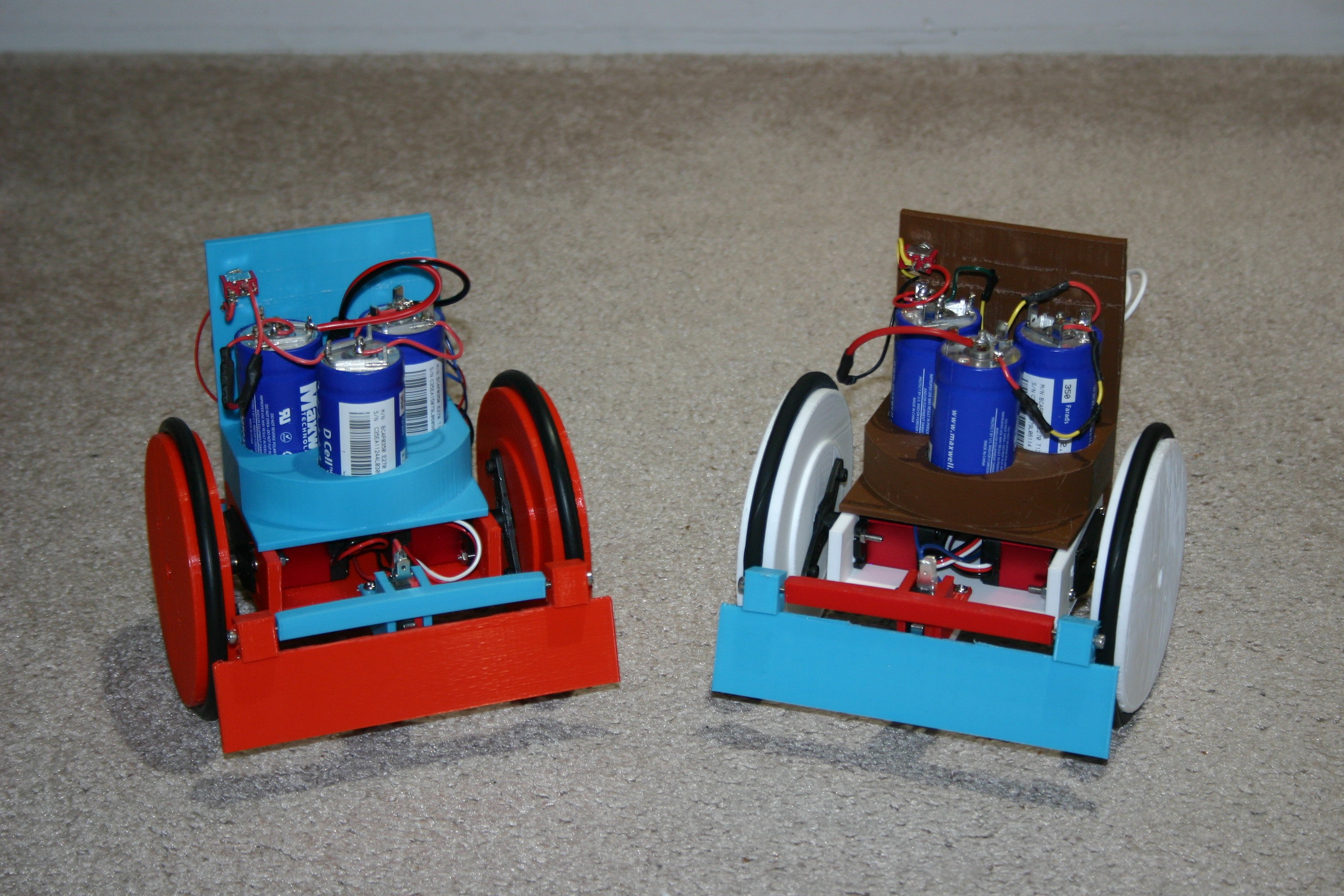

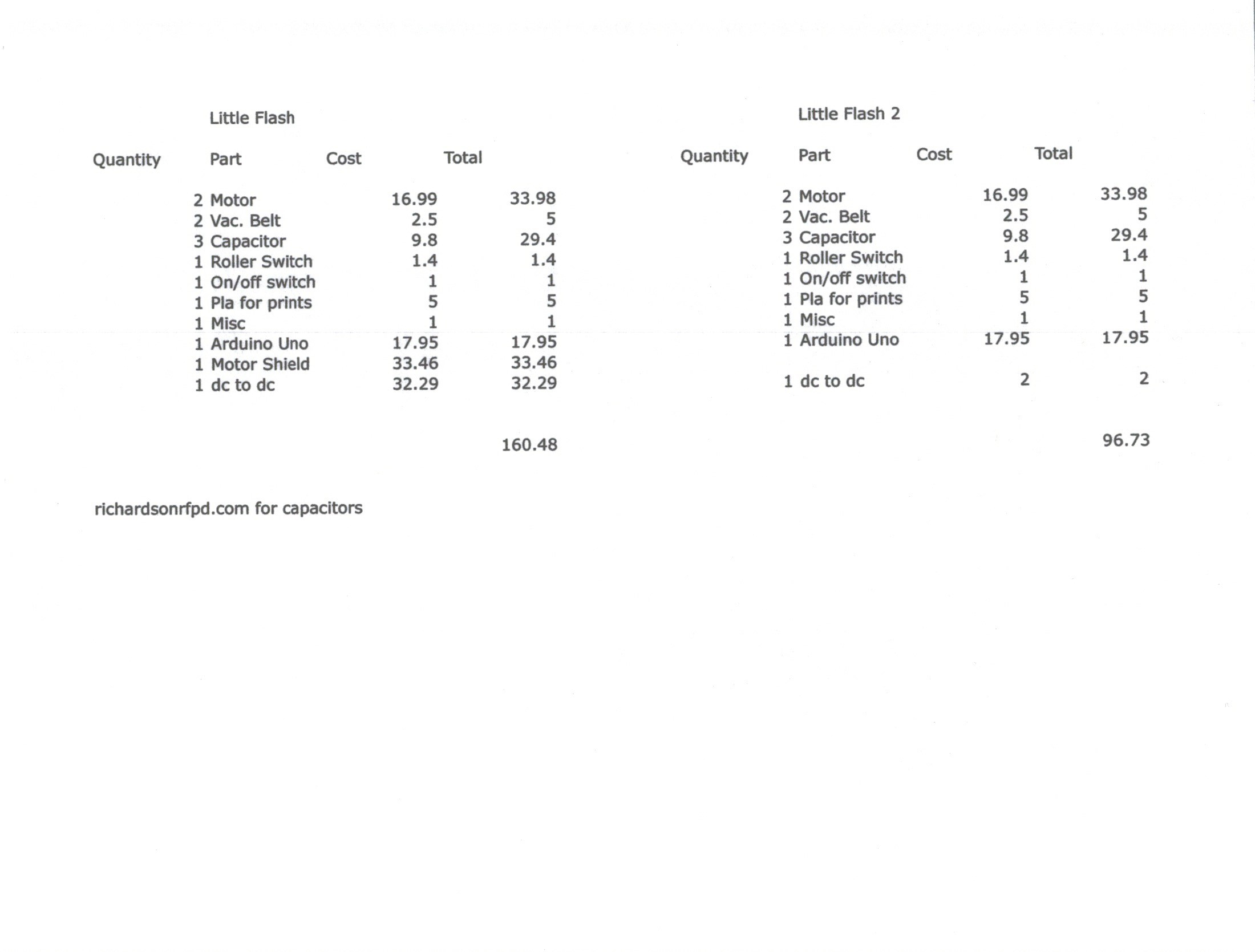

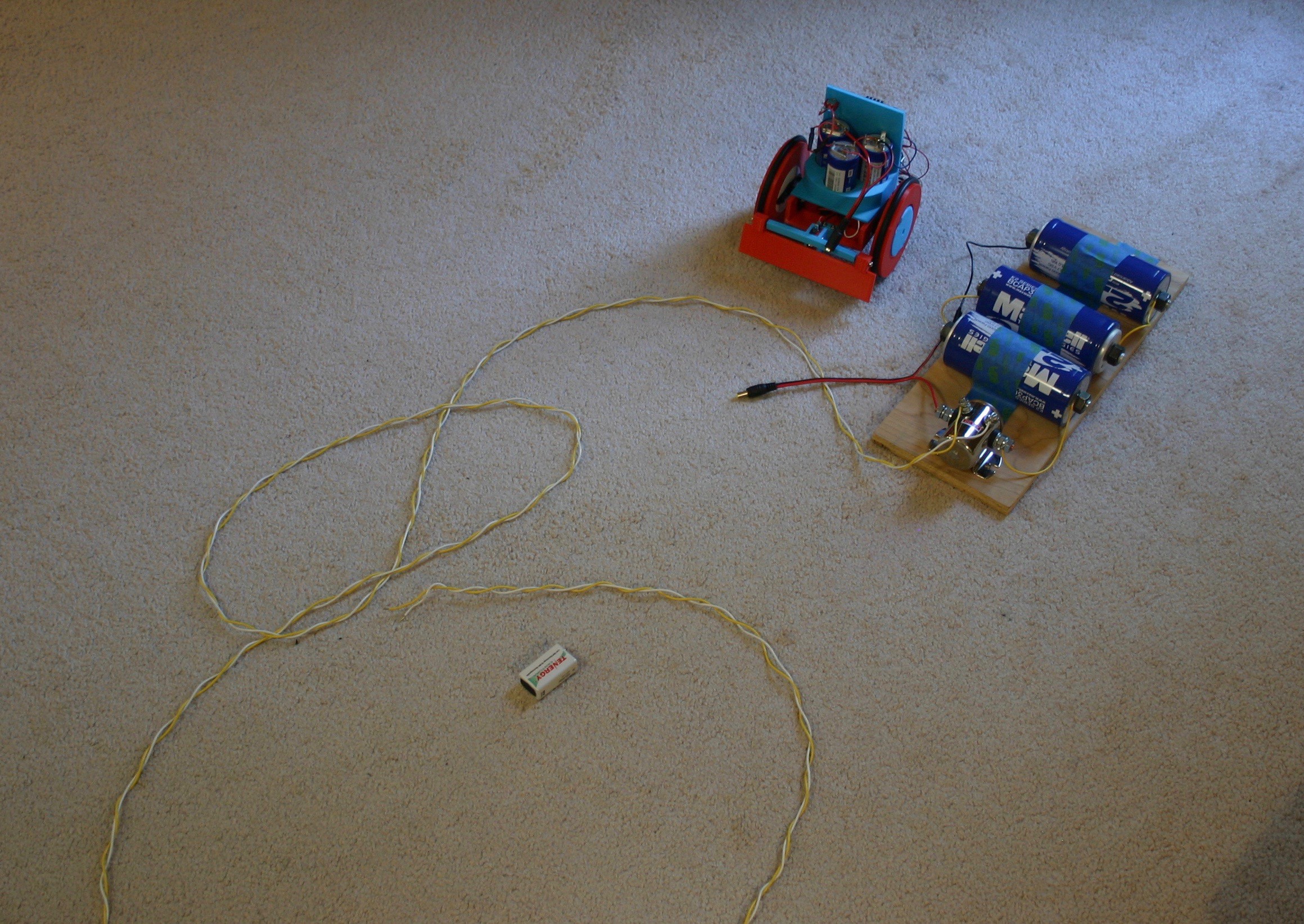

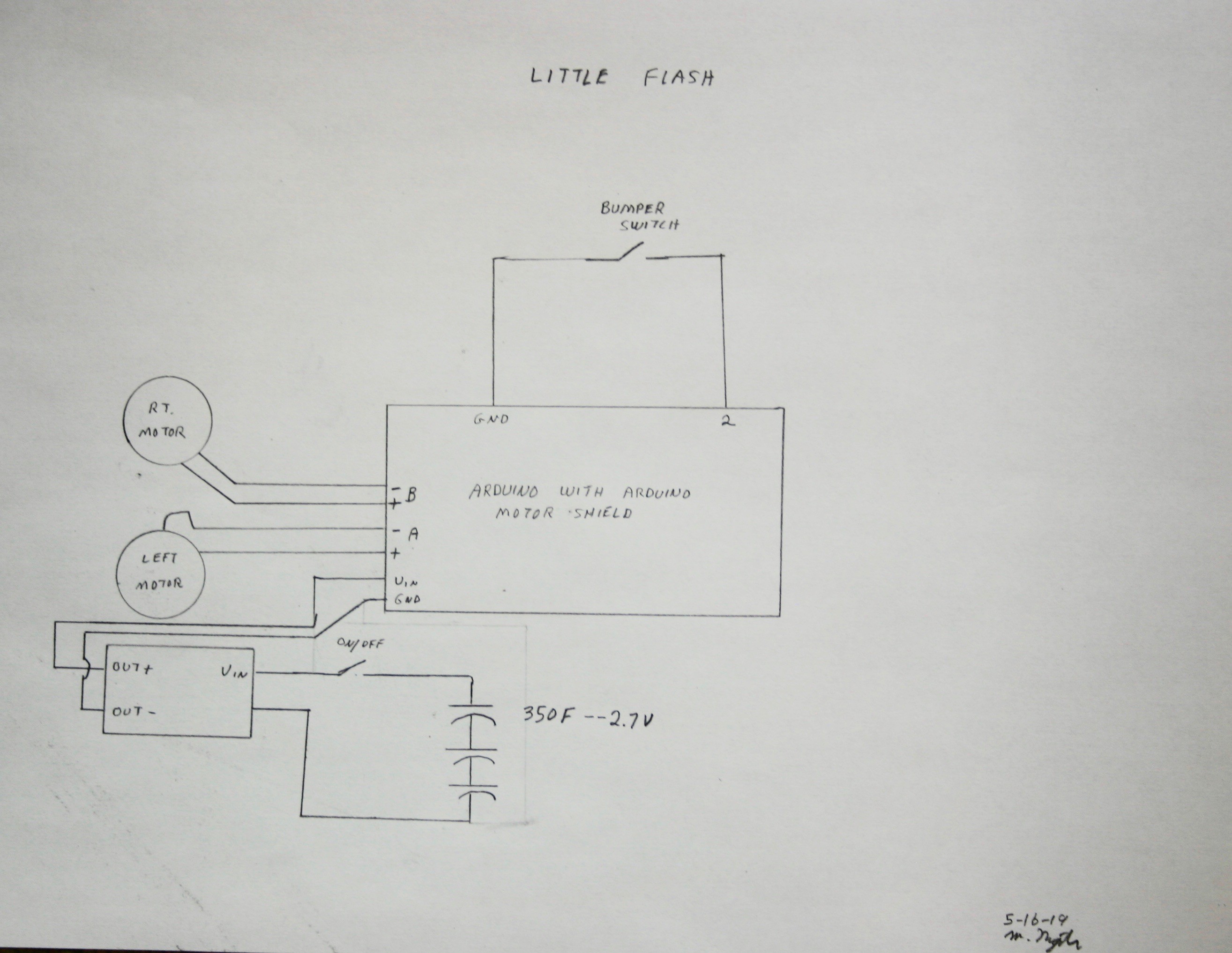

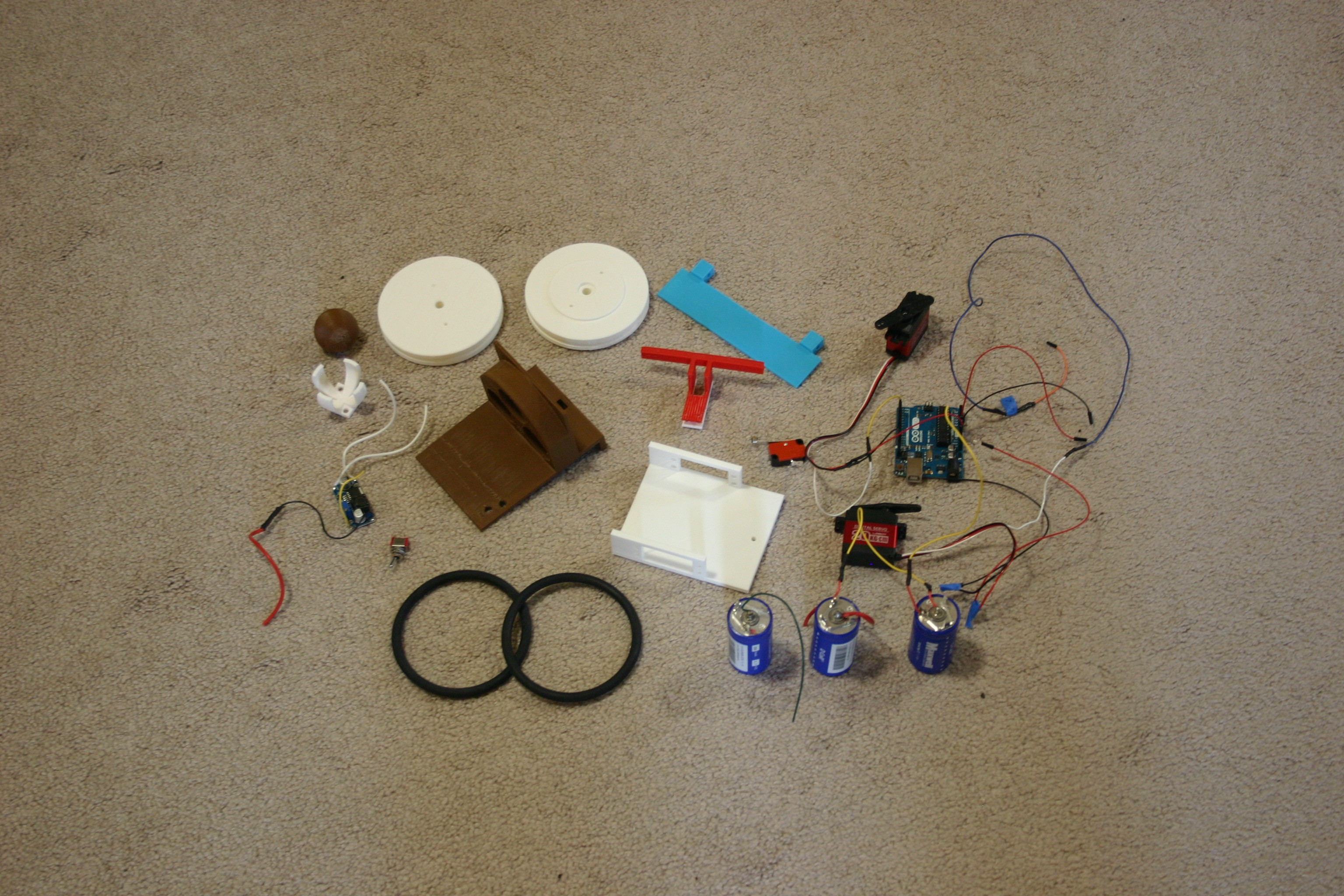

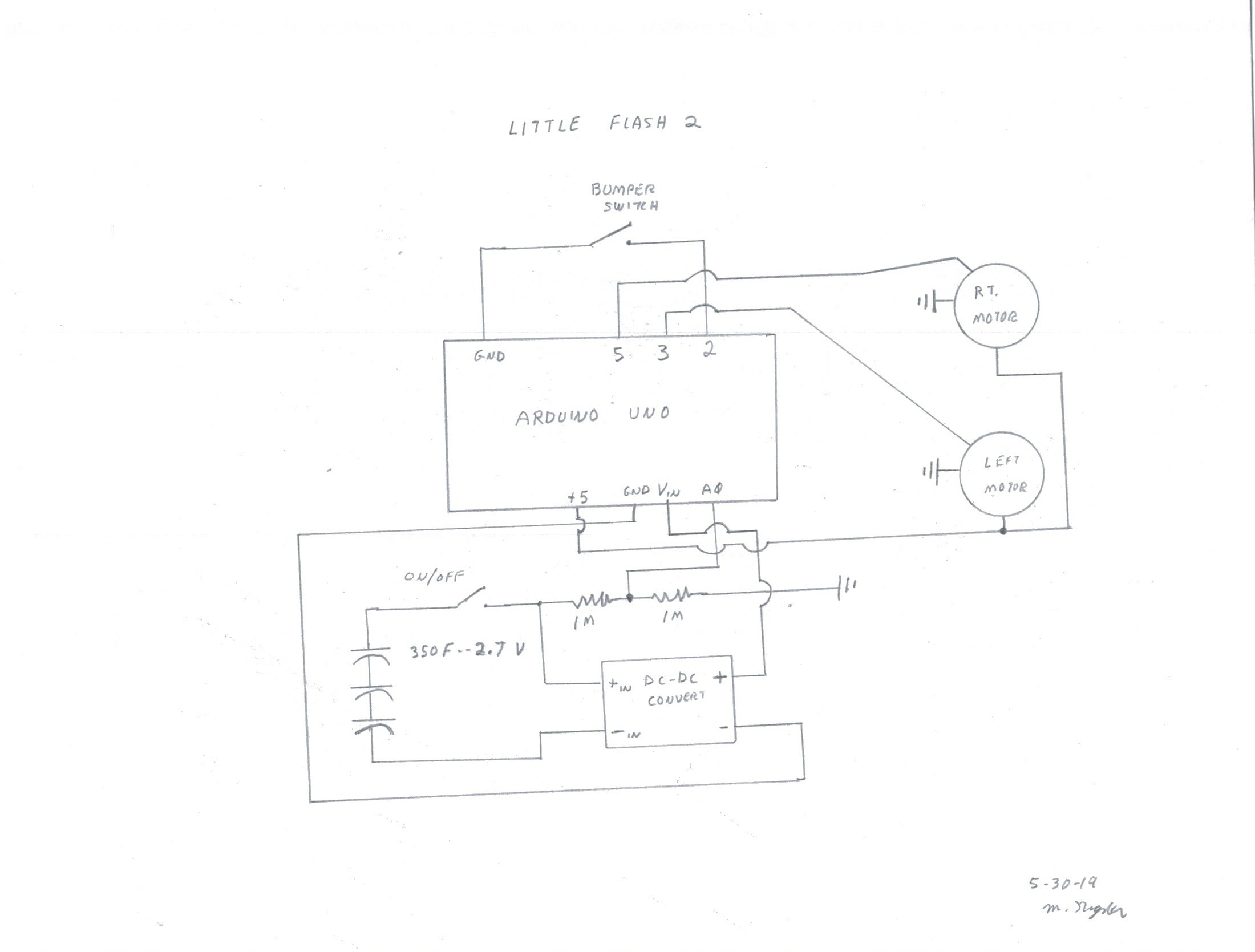

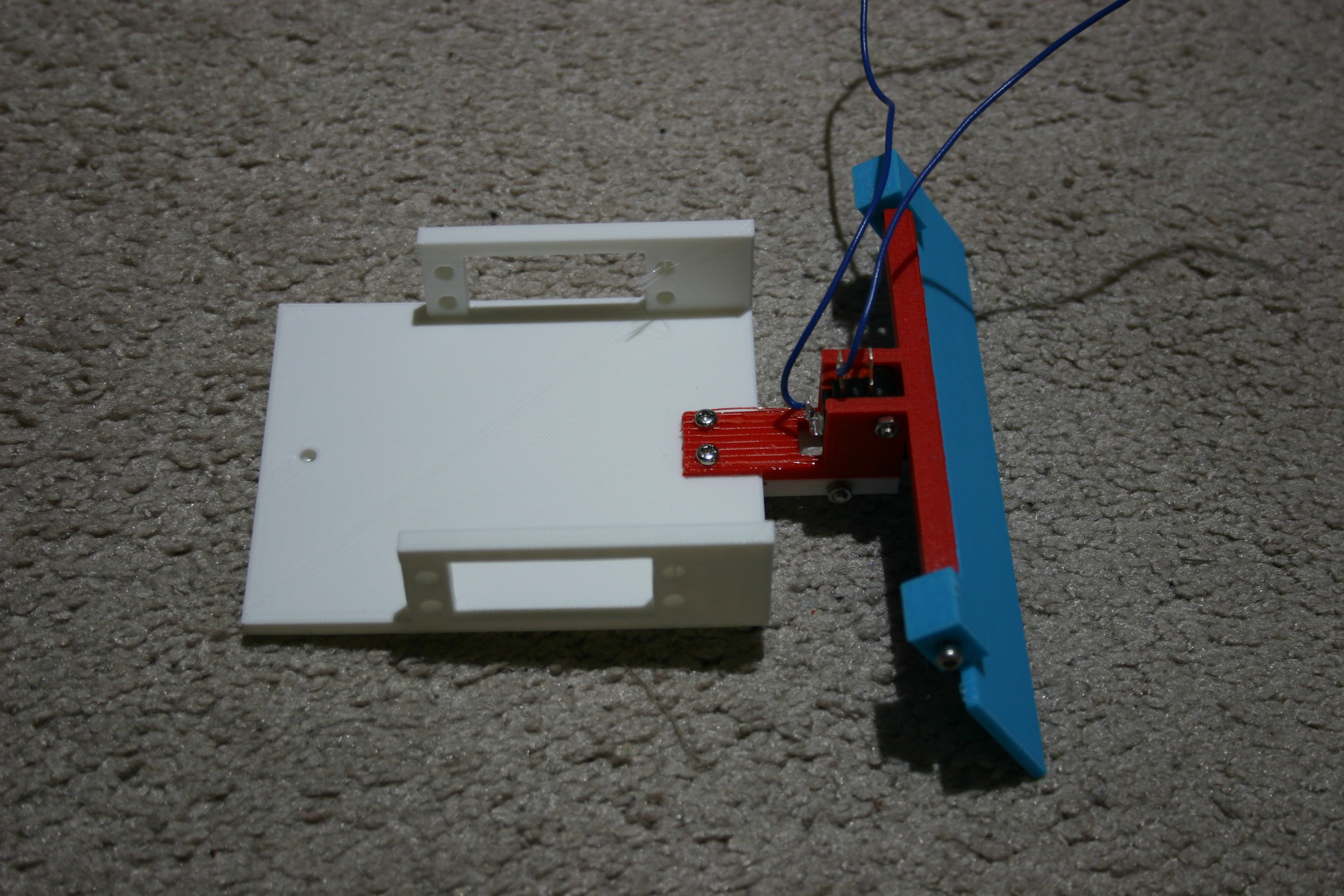

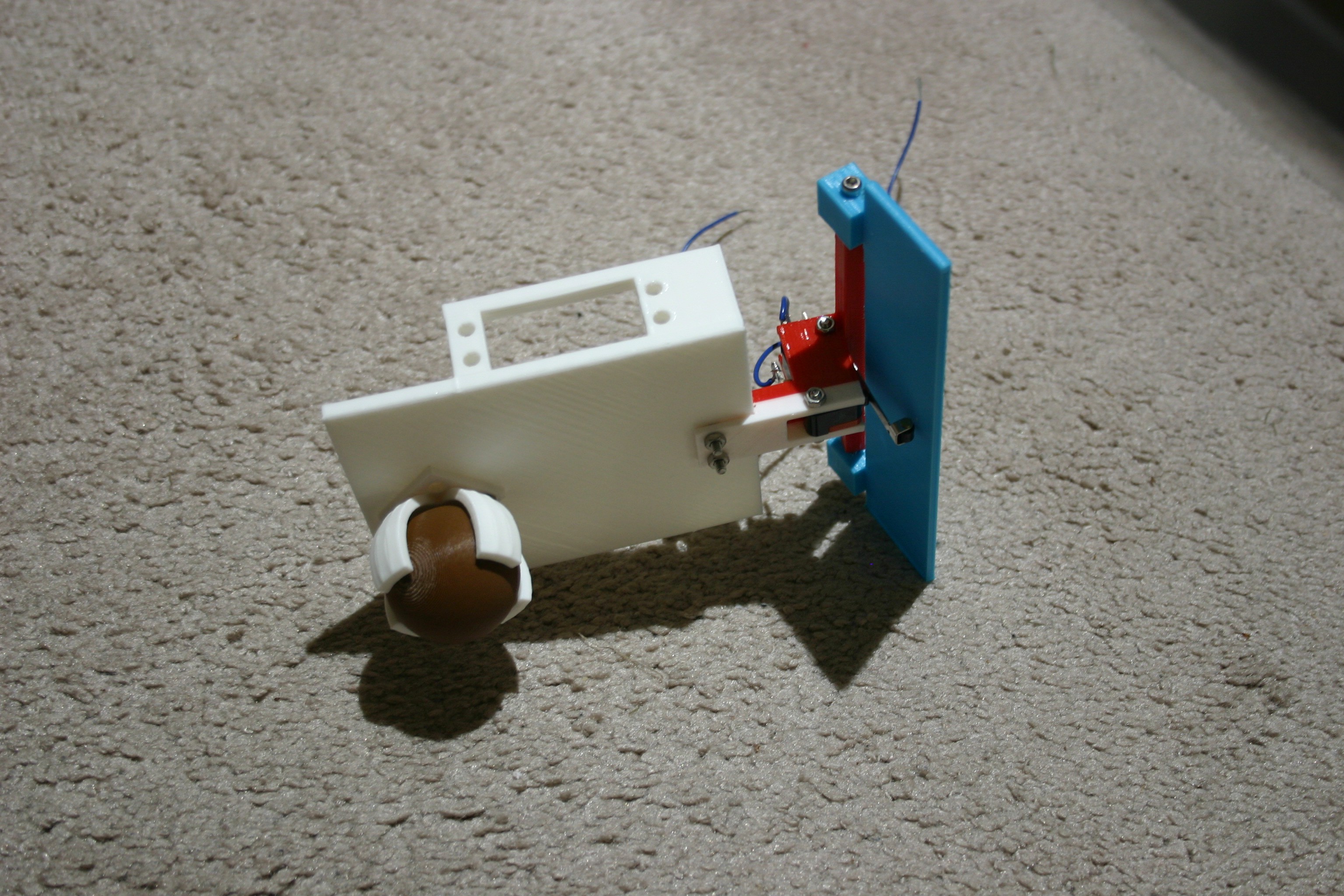

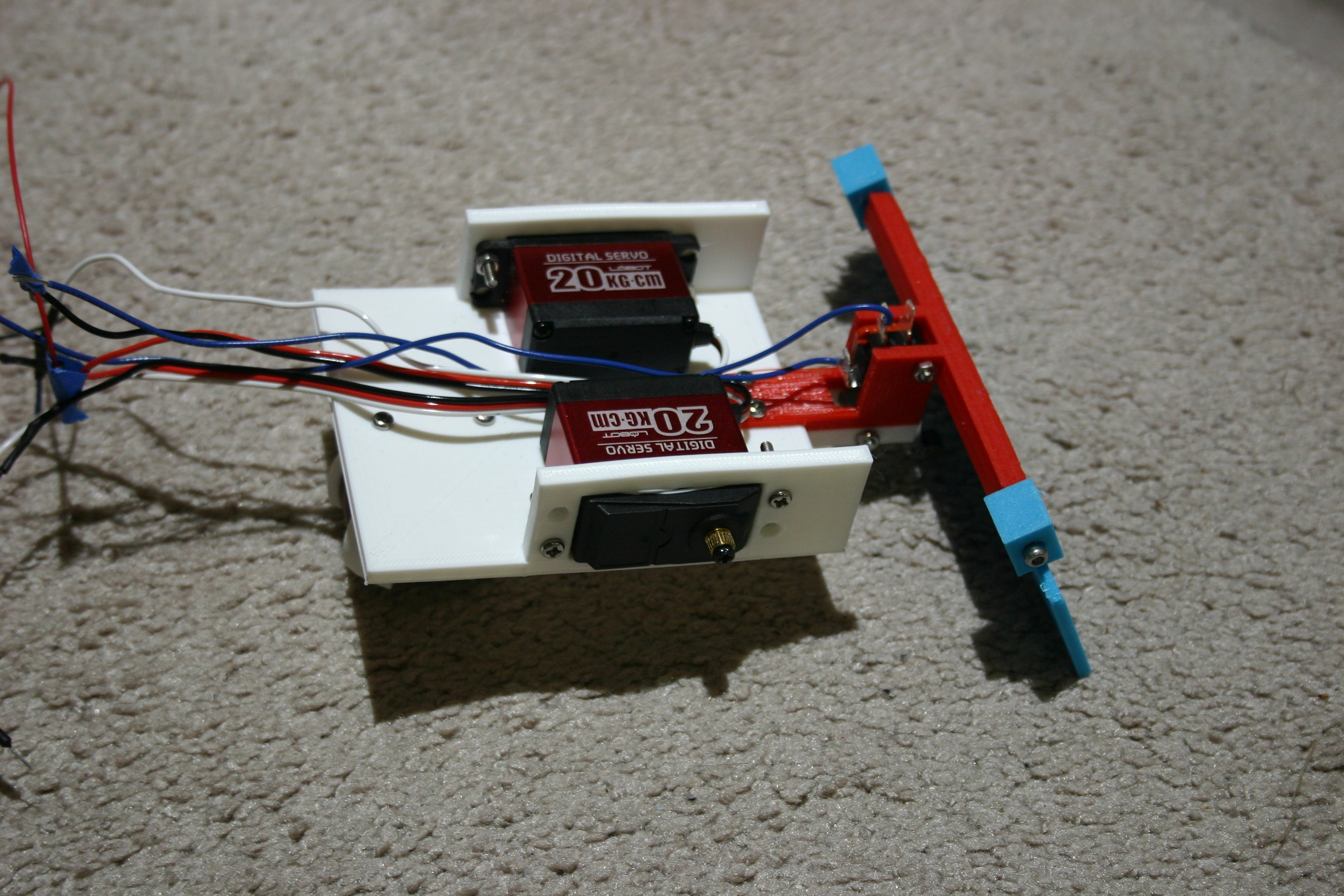

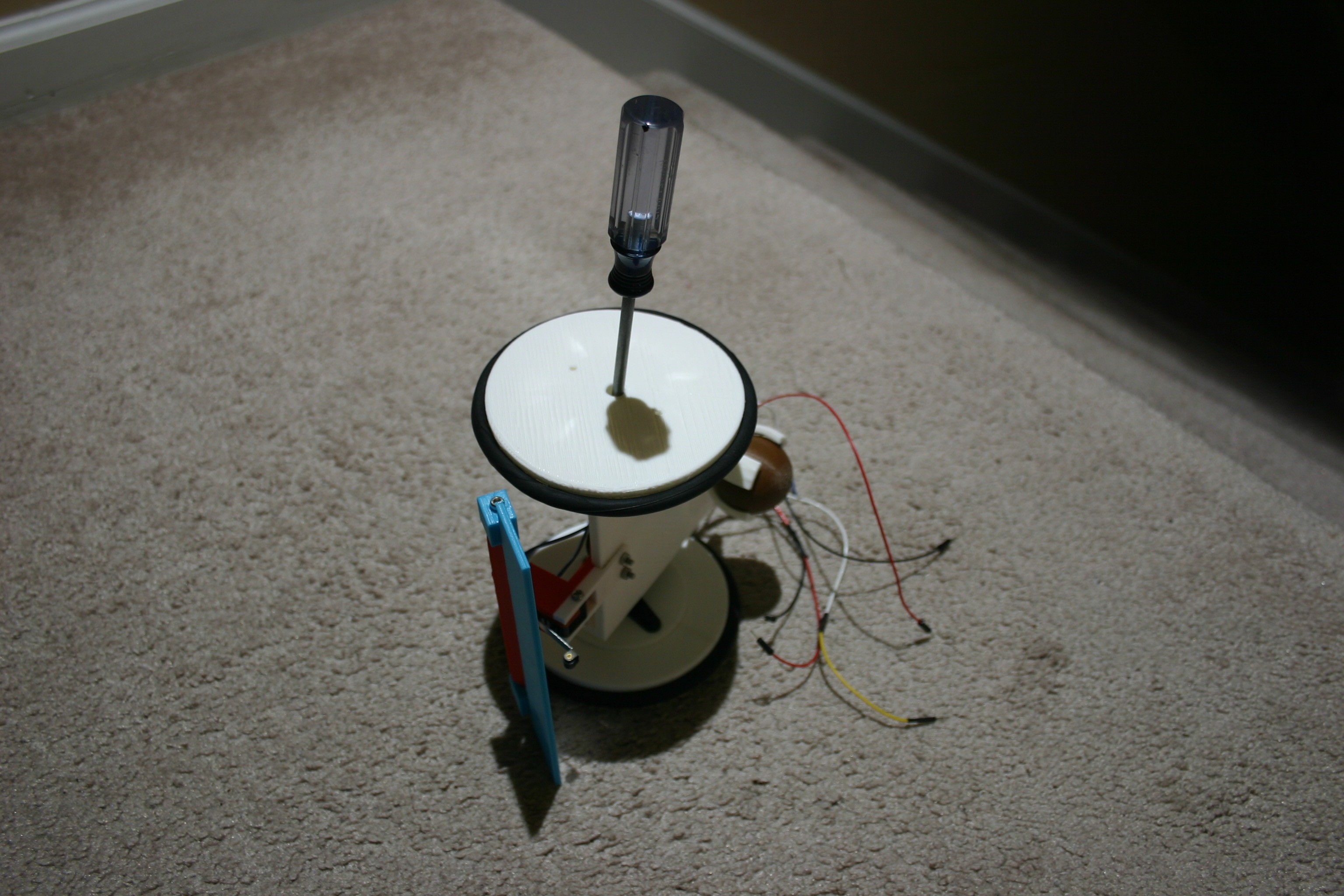

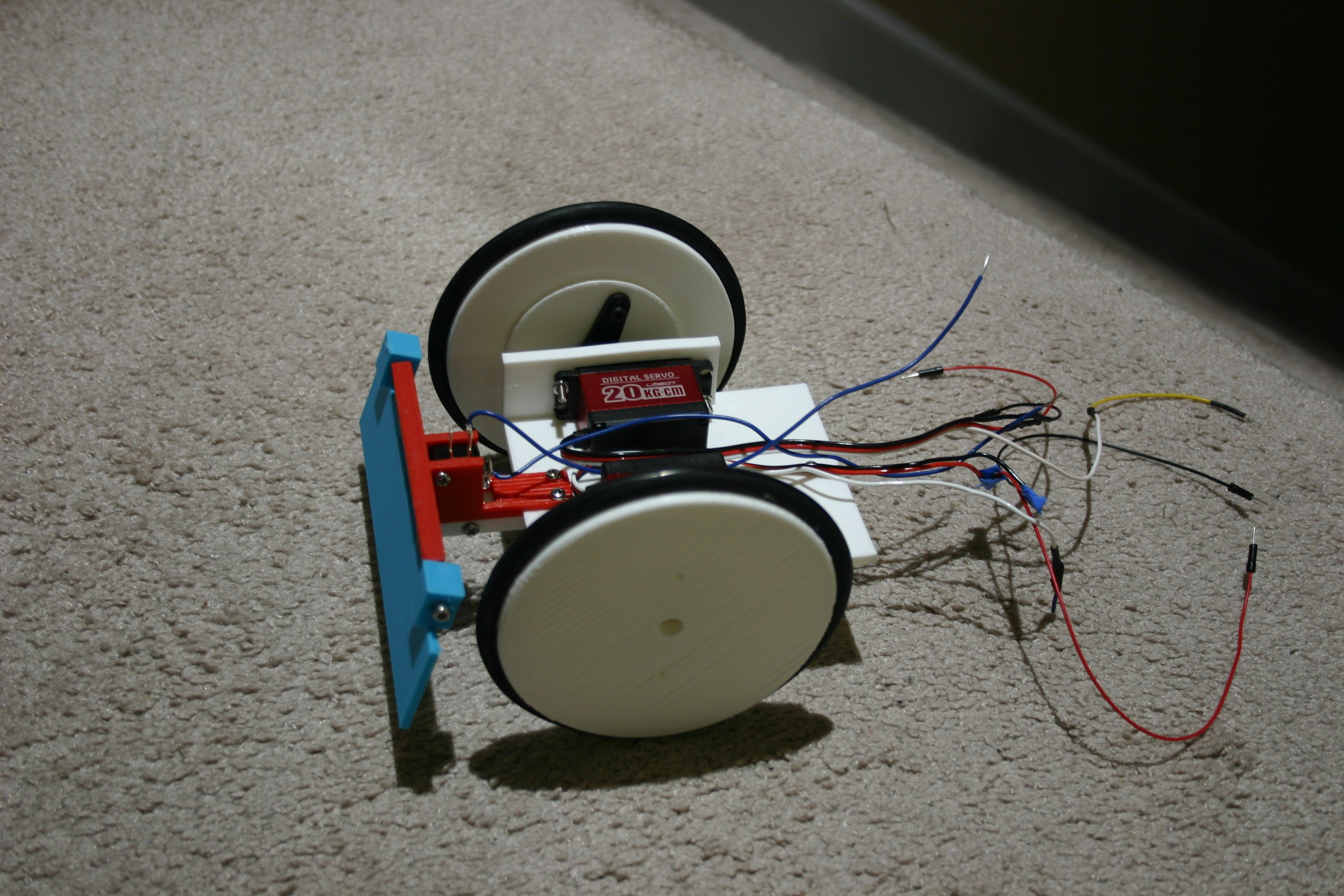

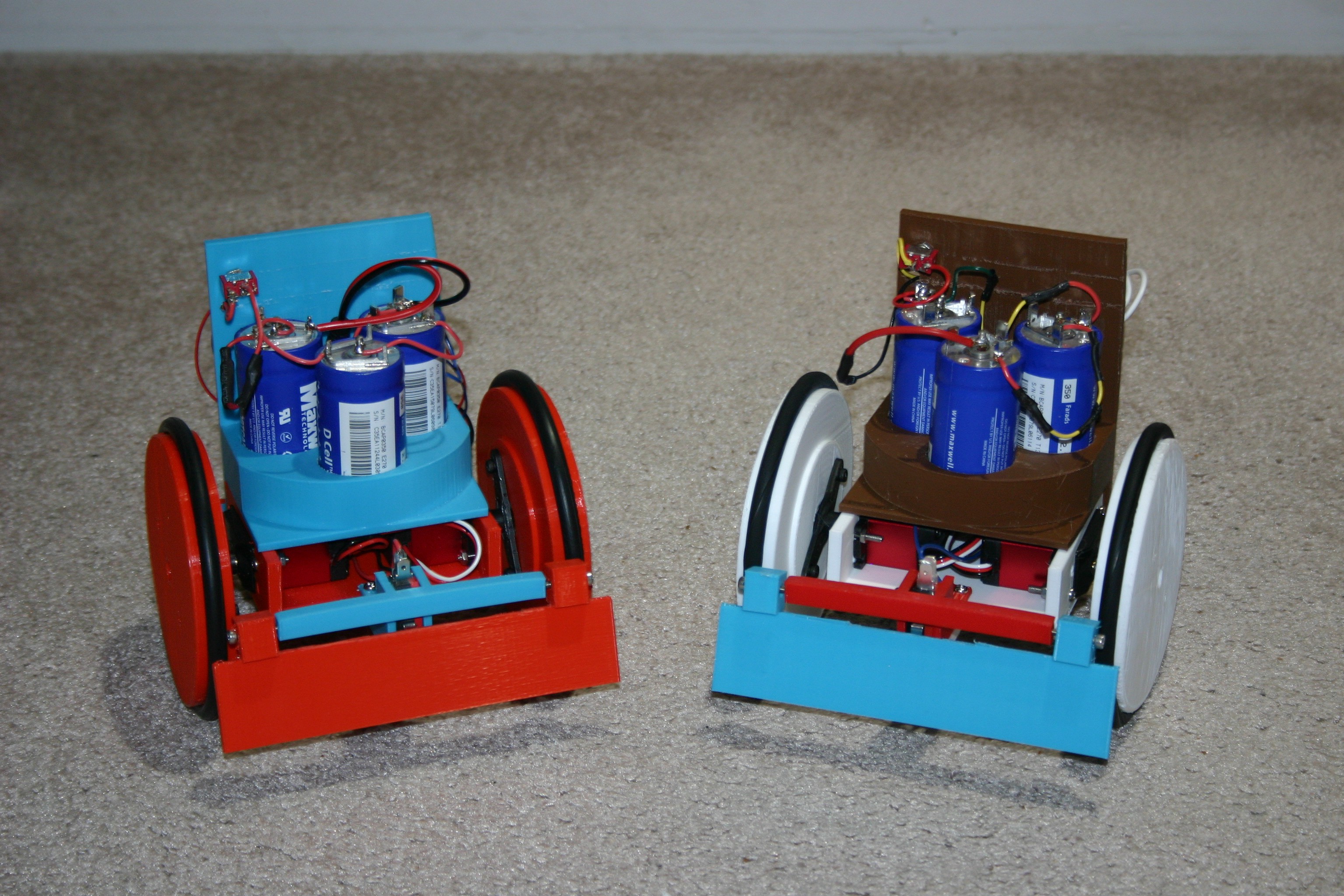

Making a couple of changes to the design allows me to reduce the part cost by forty percent. Here's Little Flash (left) and Little Flash 2 (right).

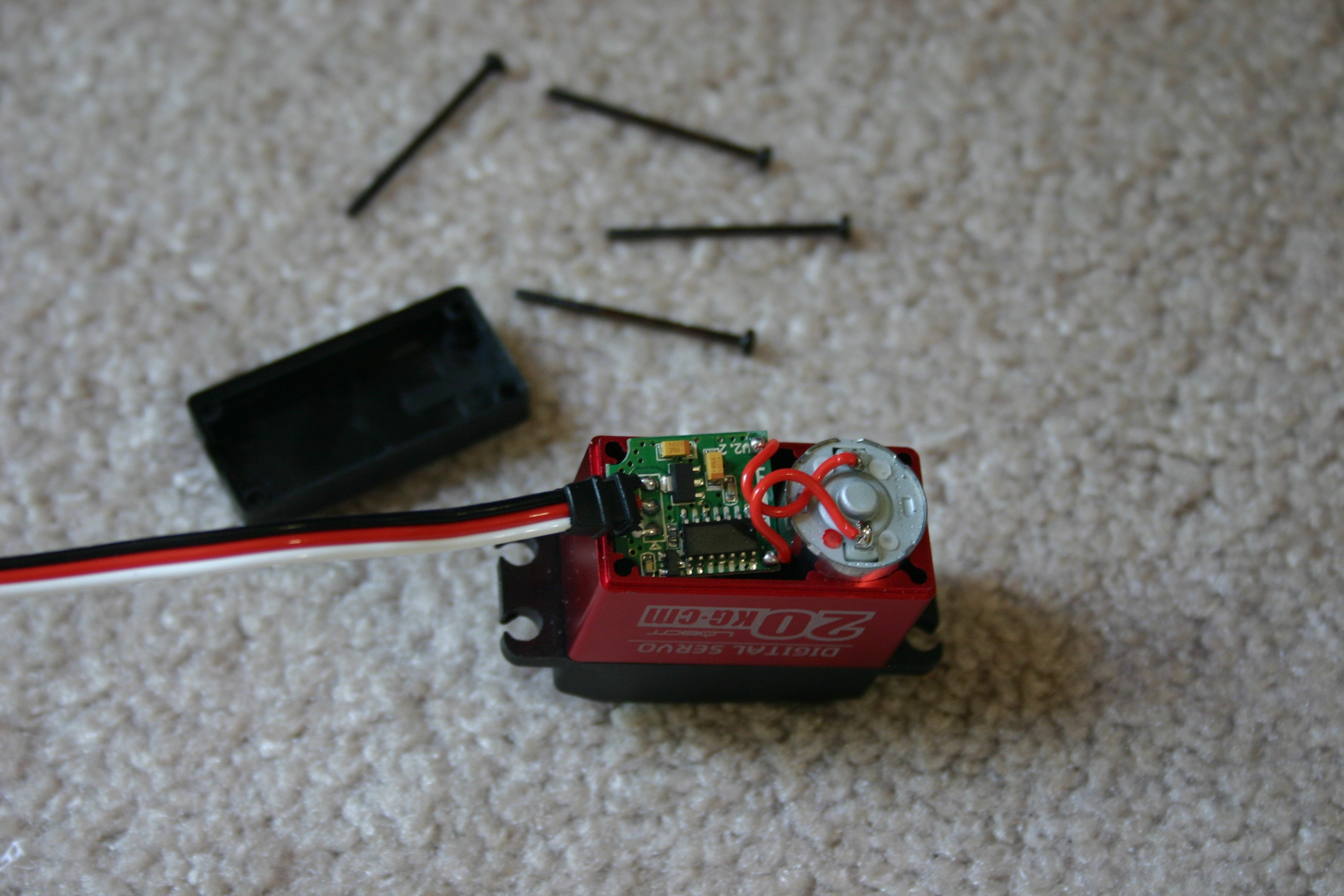

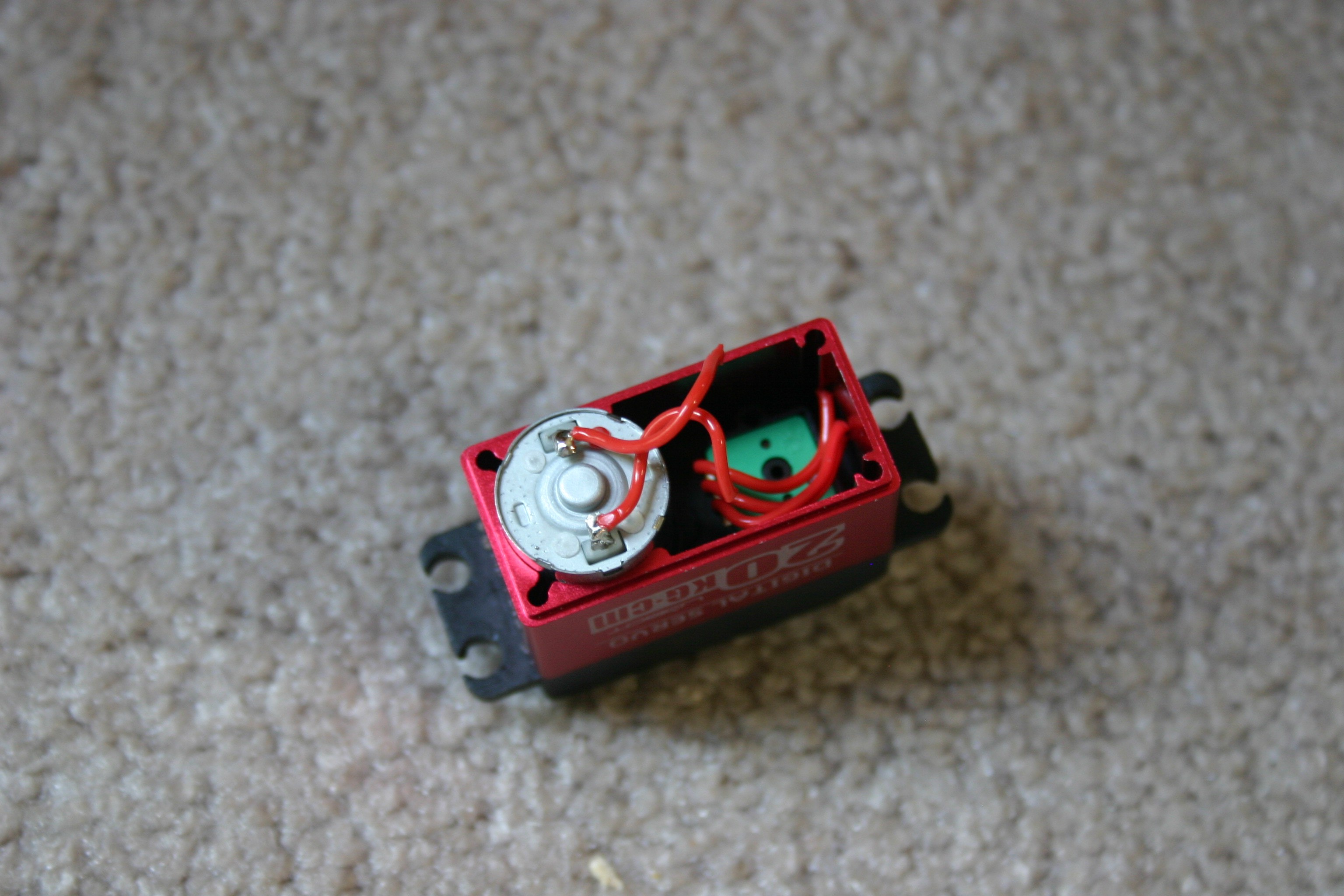

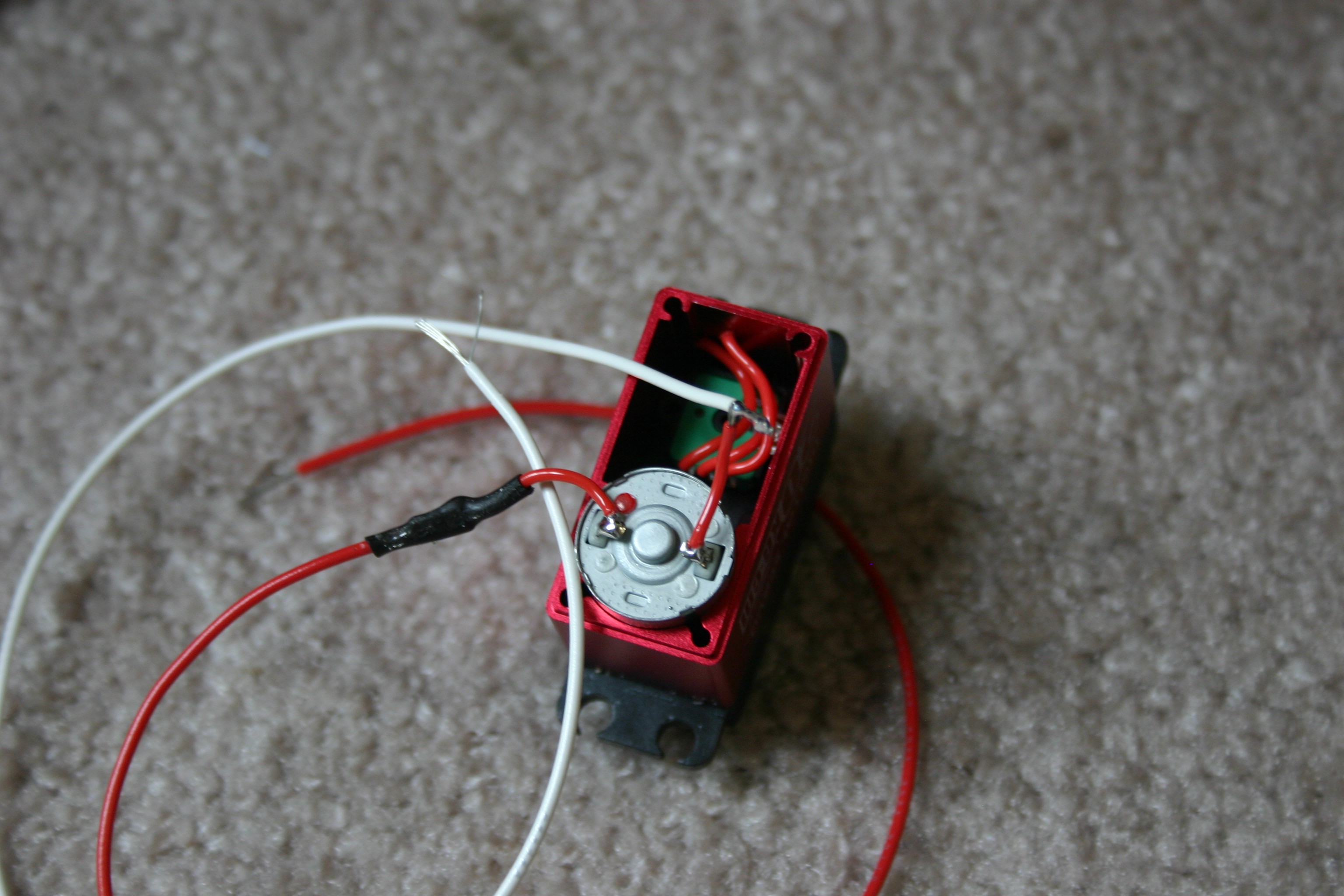

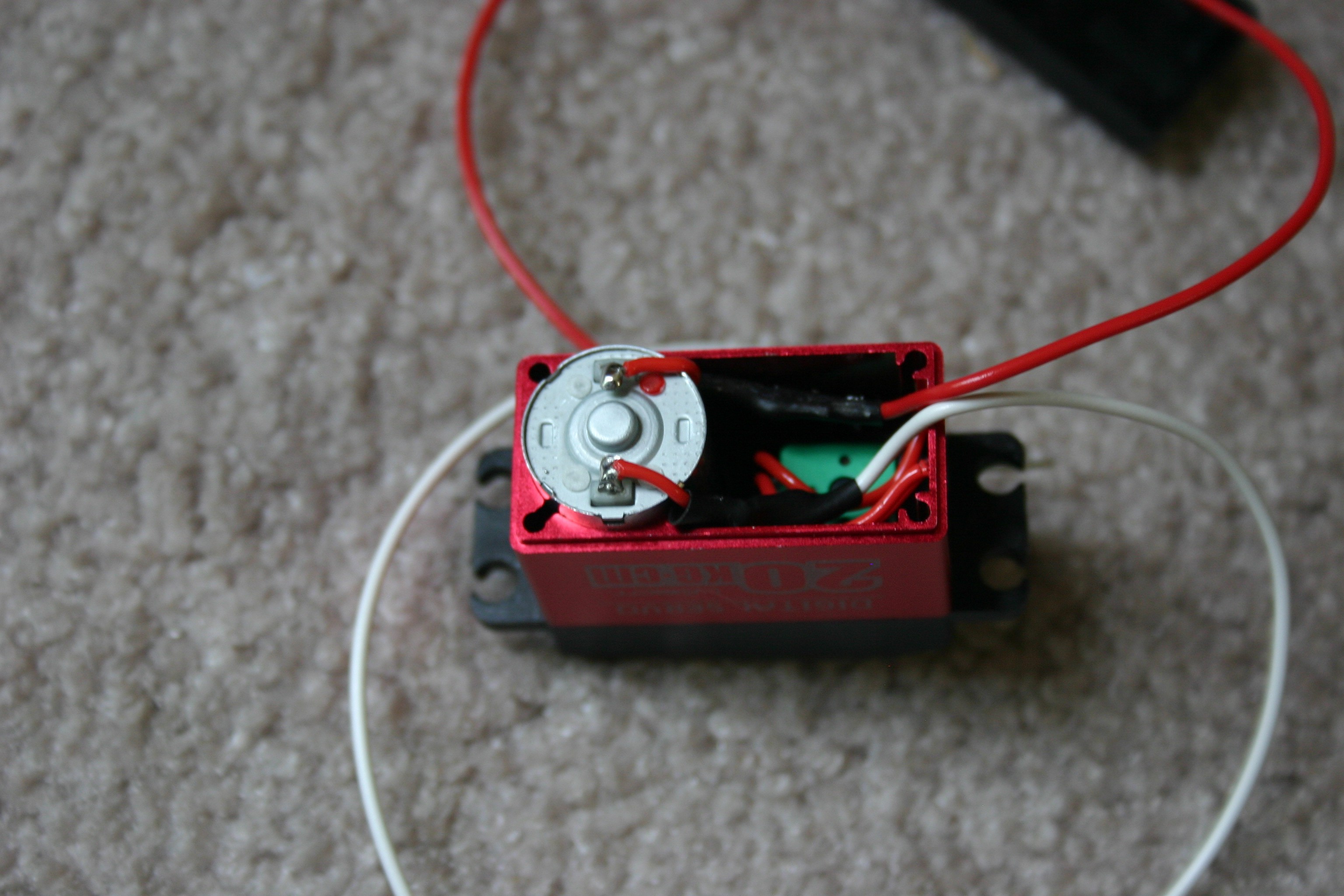

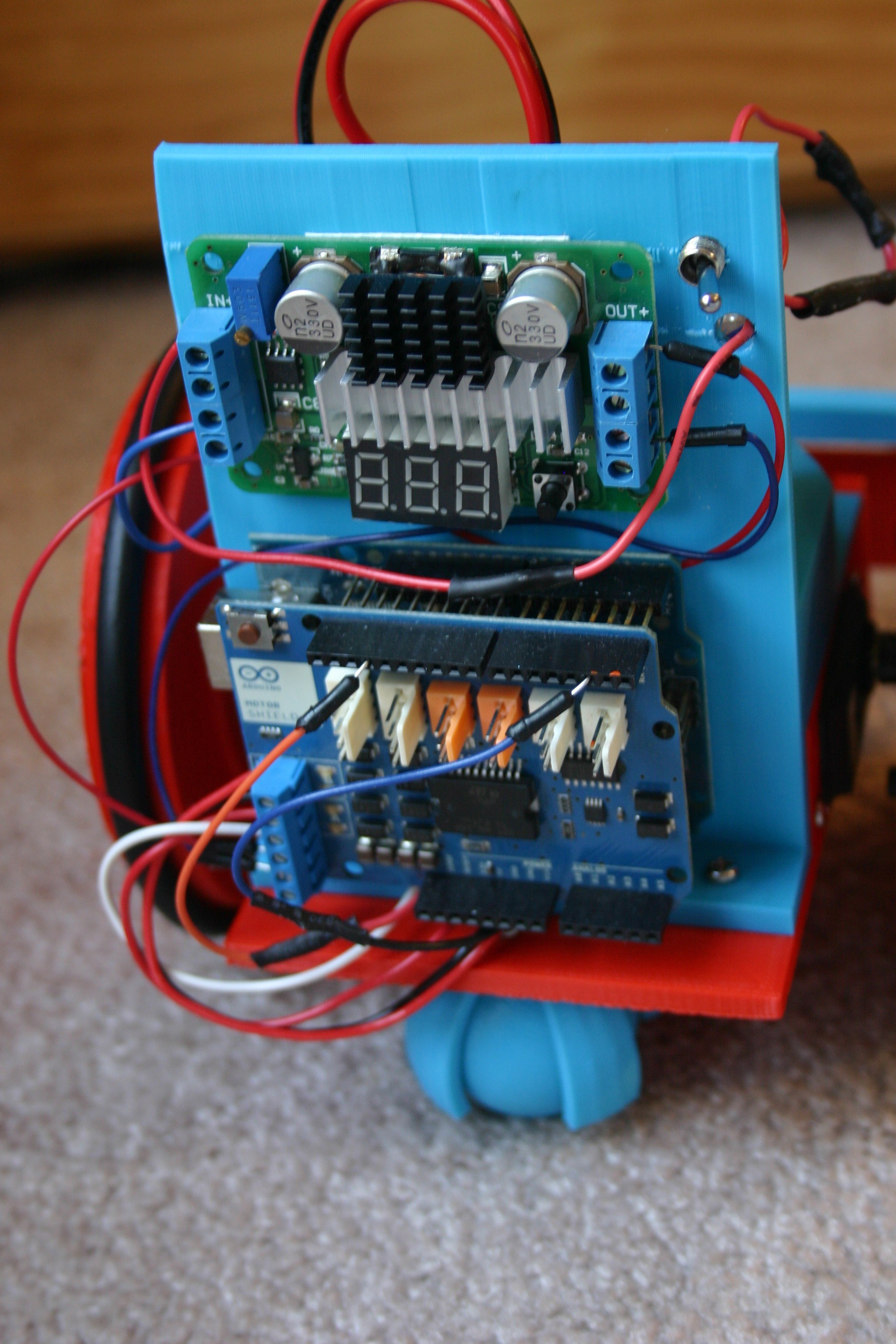

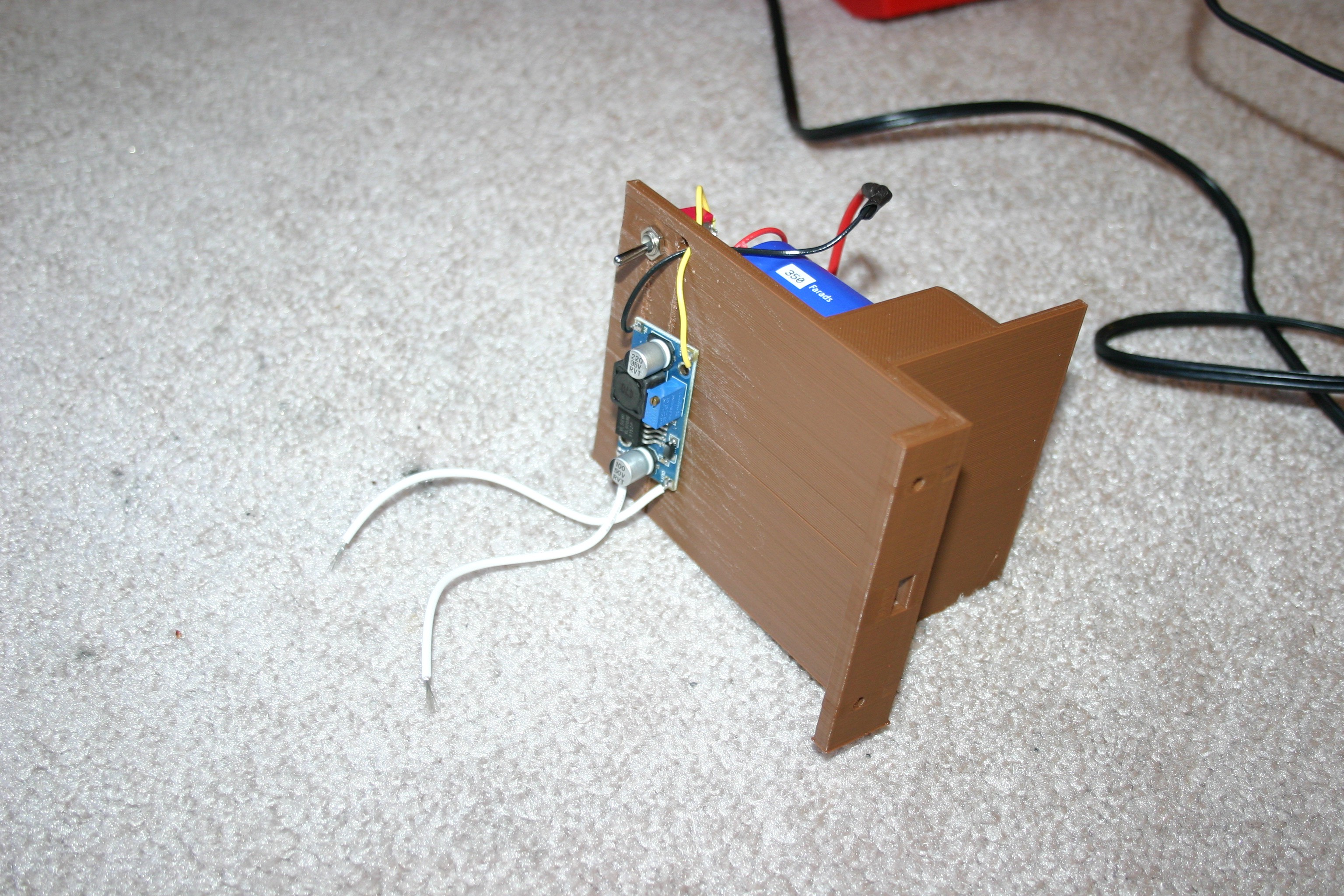

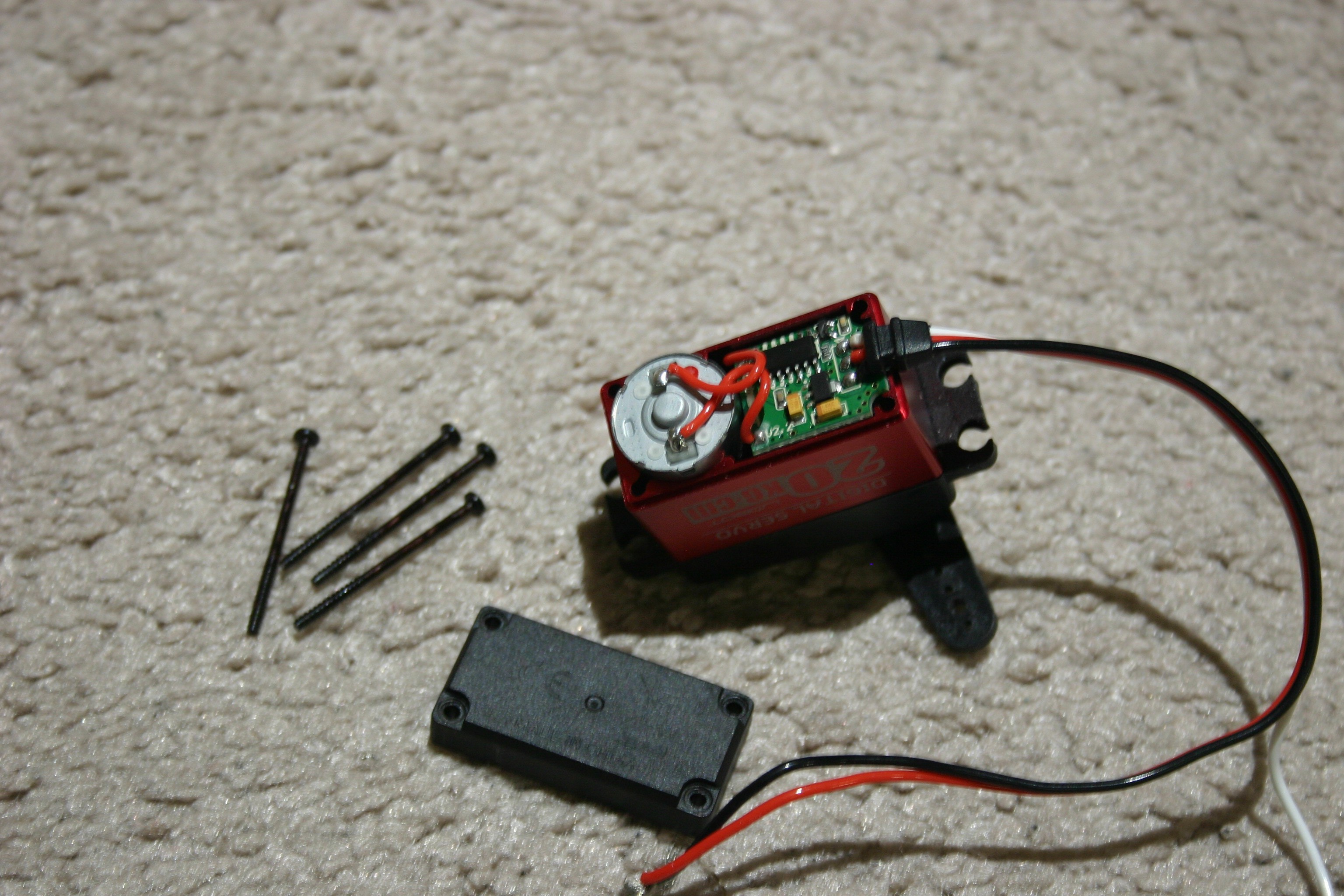

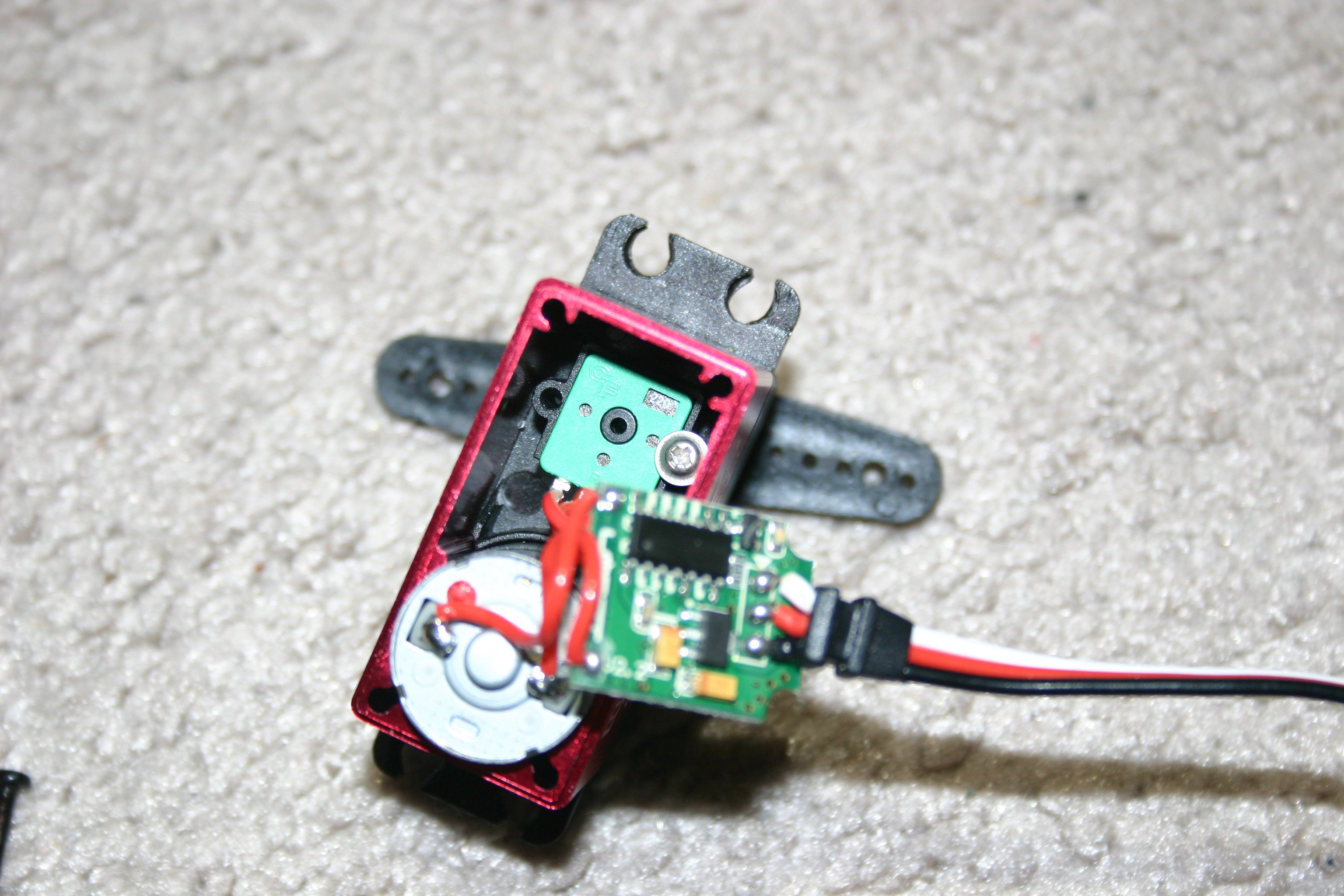

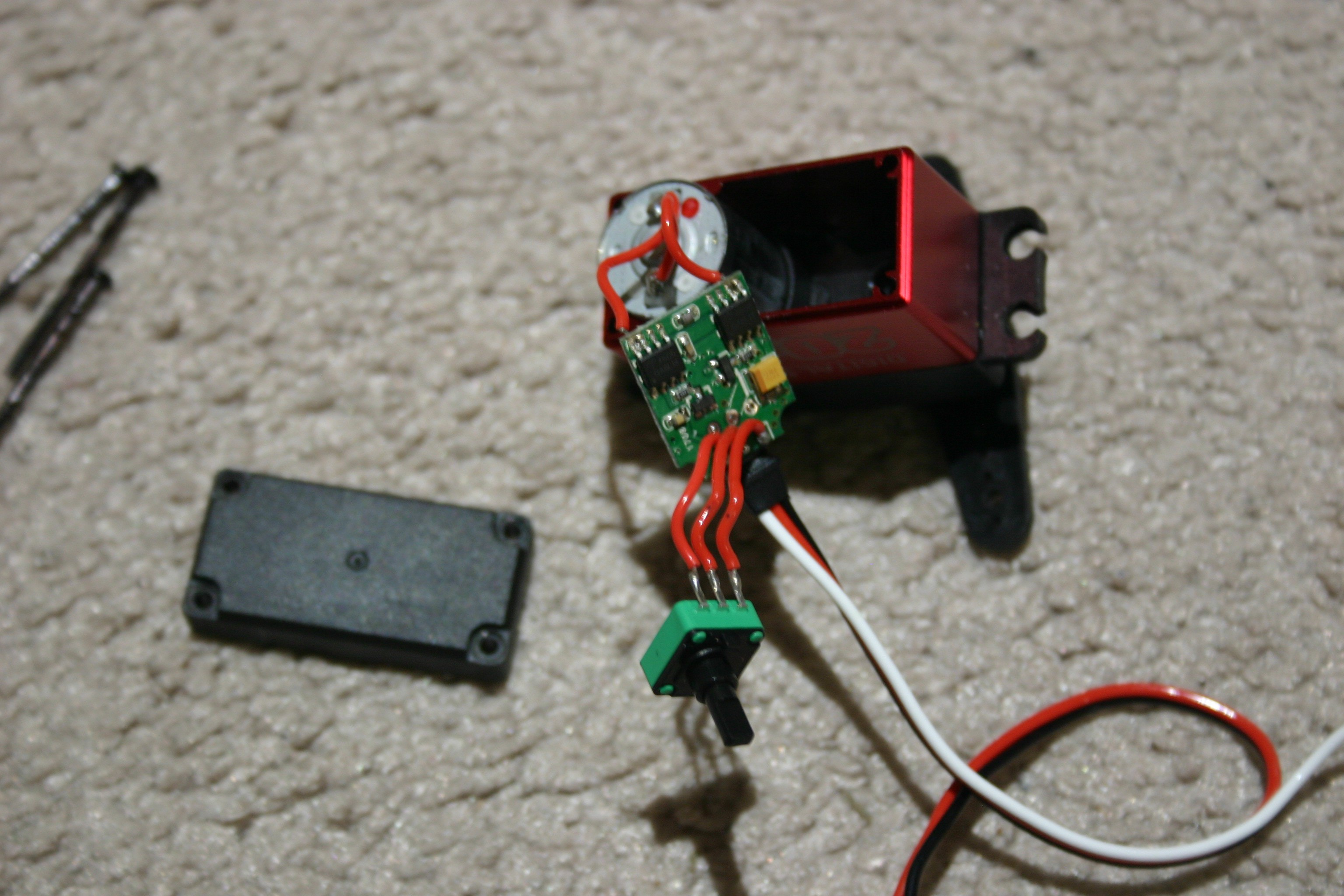

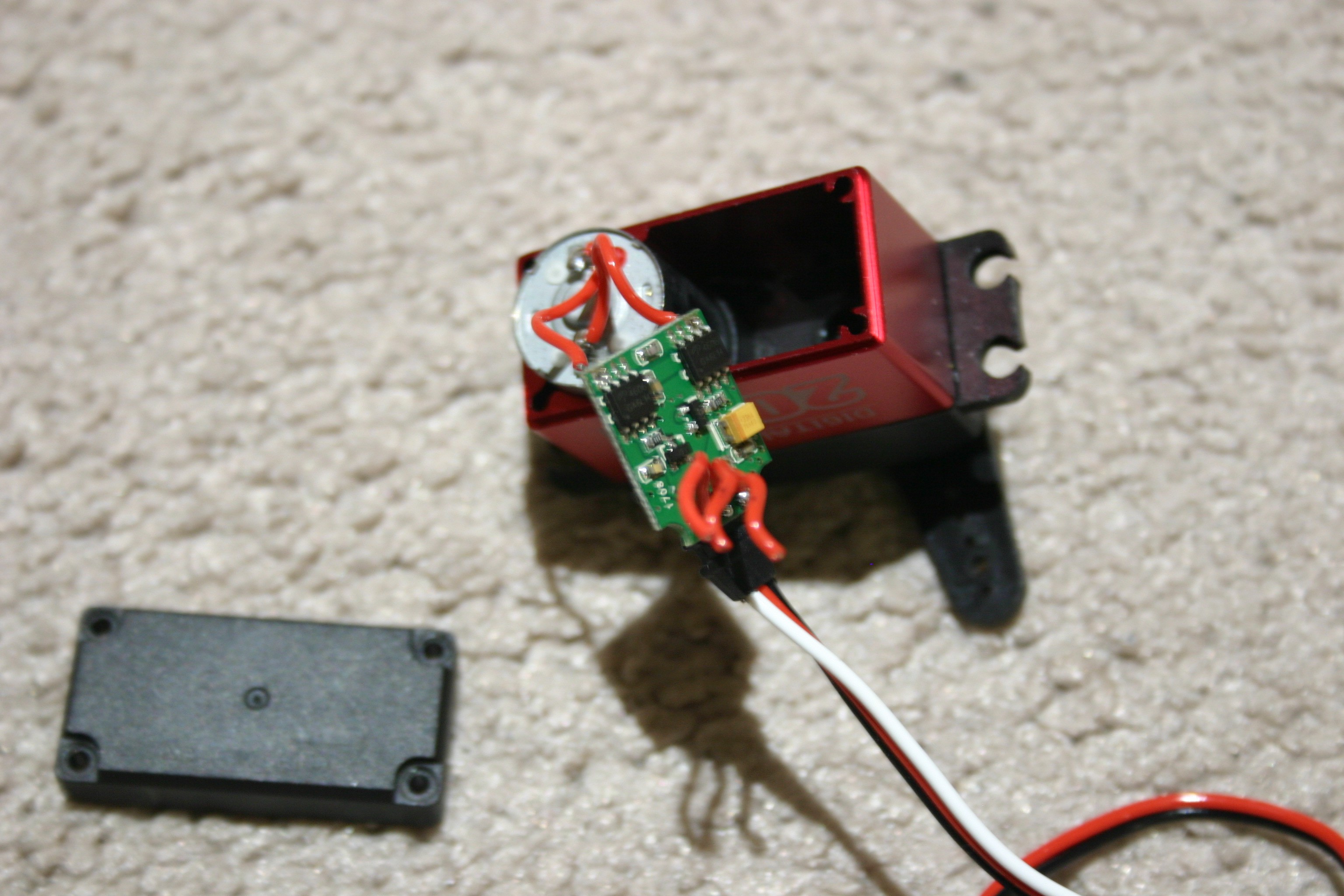

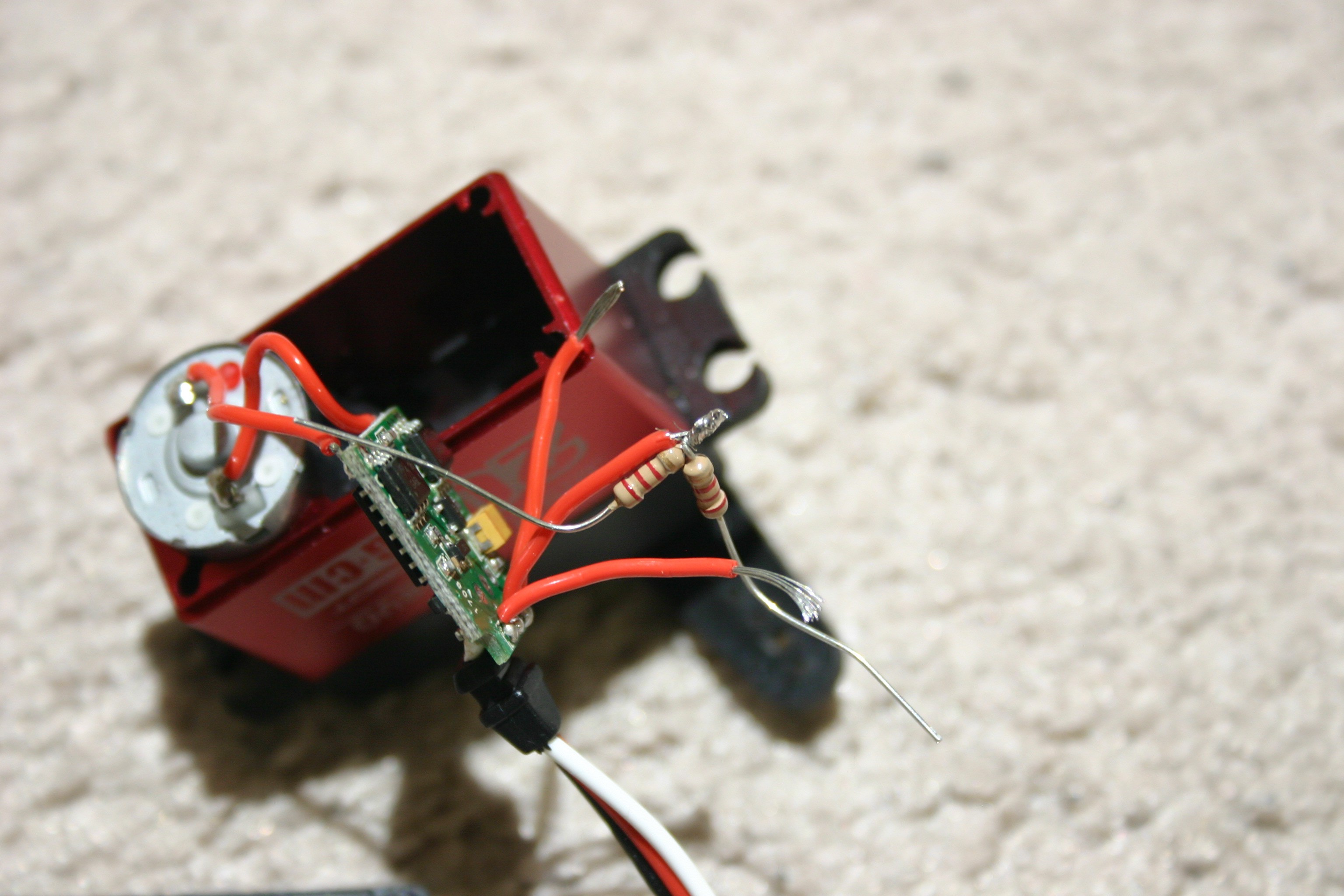

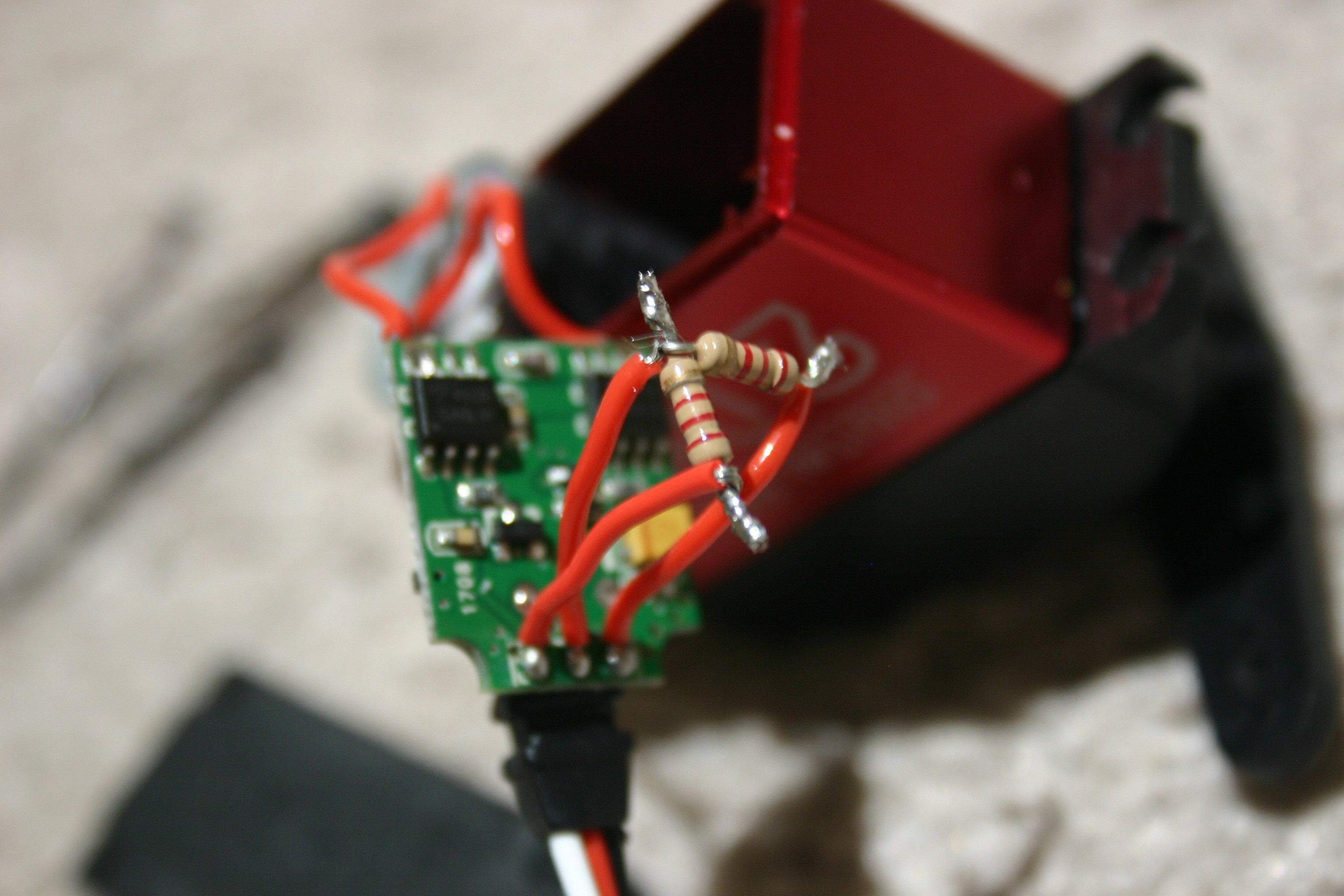

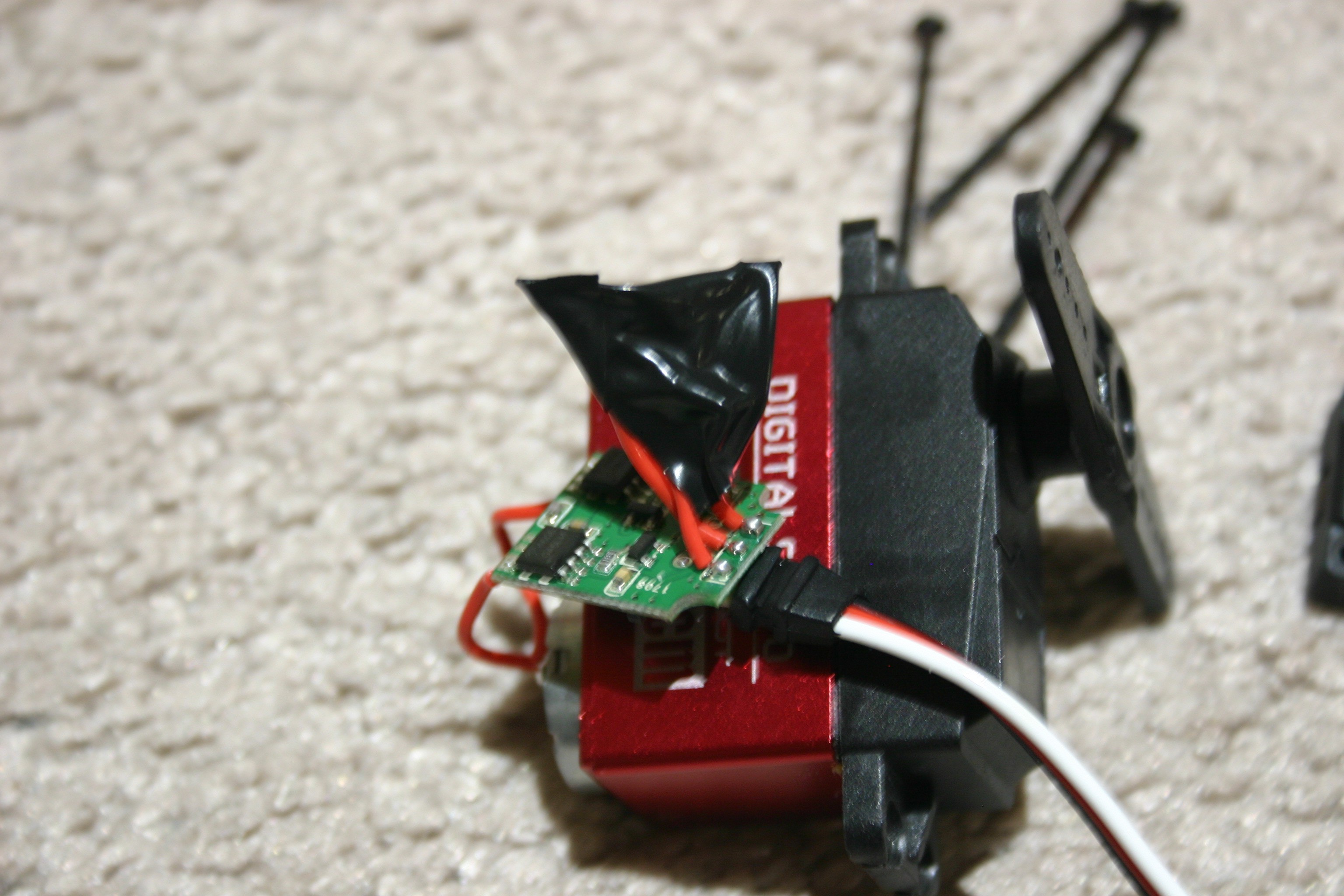

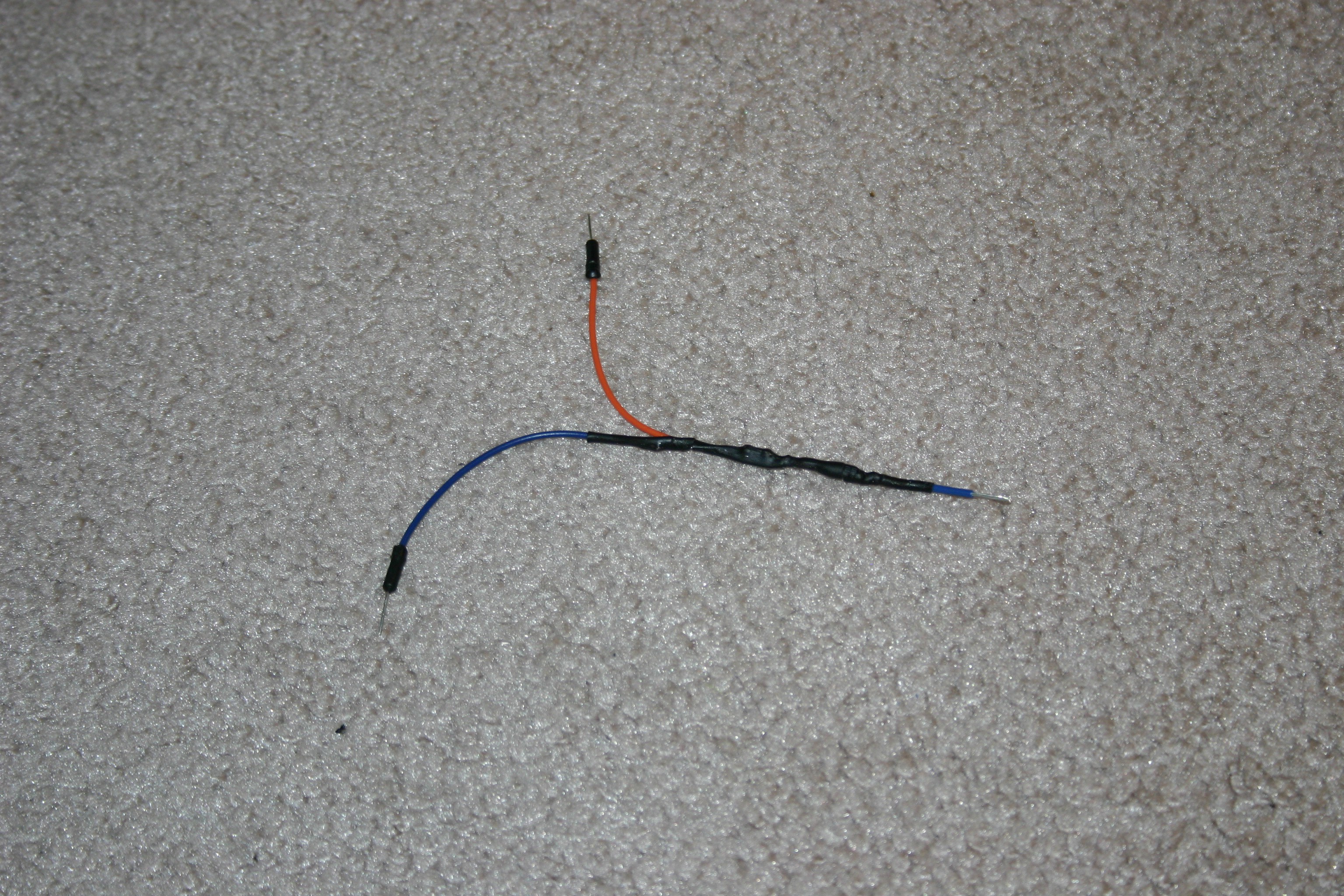

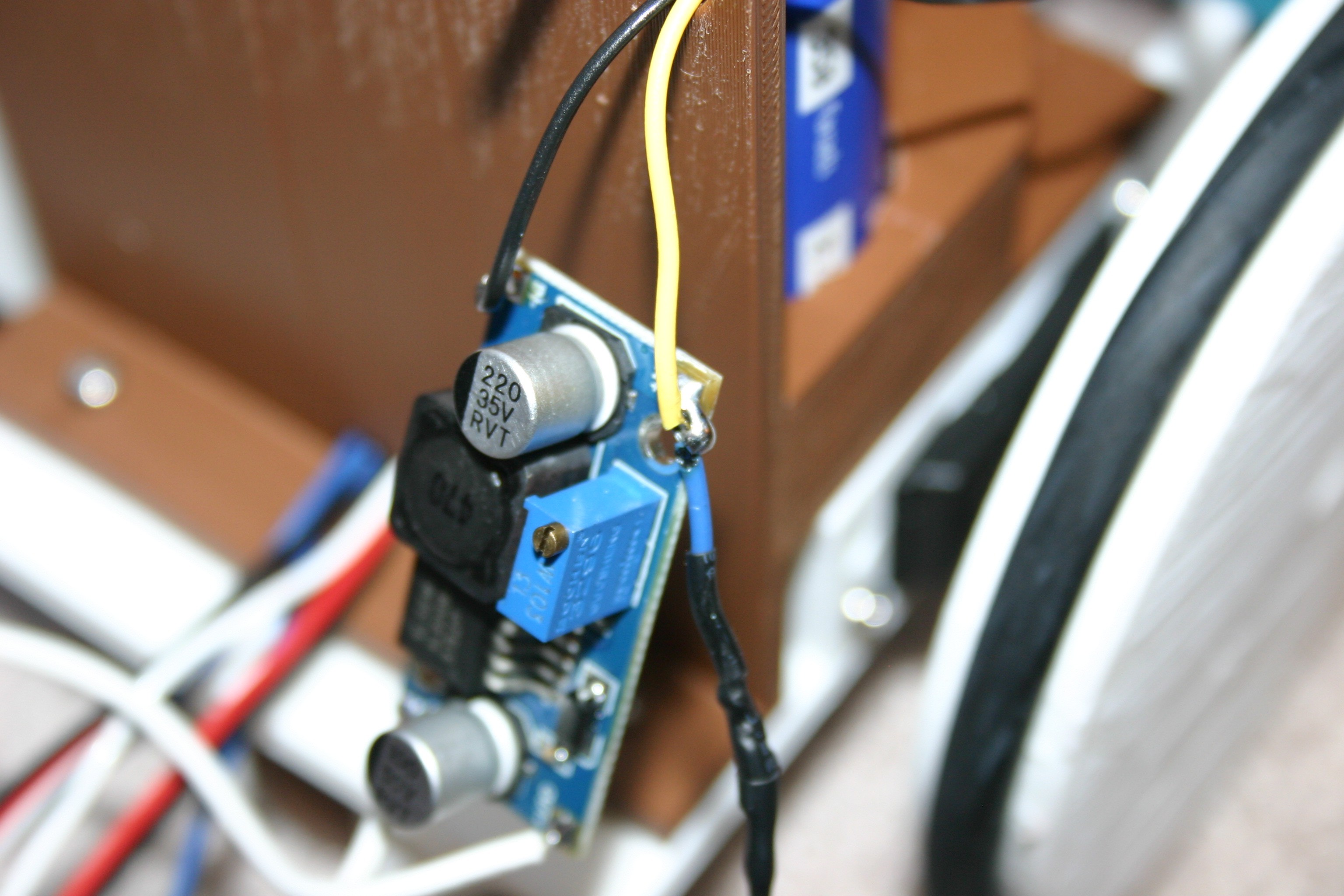

Daren Schwenke suggested a modification to the servo motors that allows me to remove the Arduino motor shield (a costly component). I do lose current detection, but that seems to be insignificant in the scheme of things. Changing the dc to dc converter to a "non metered basic unit" reduces costs further.

This year's competition is about moving toward a market solution for a given device--I thought I would at least try to move toward lower costs while maintaining functionality for Little Flash.

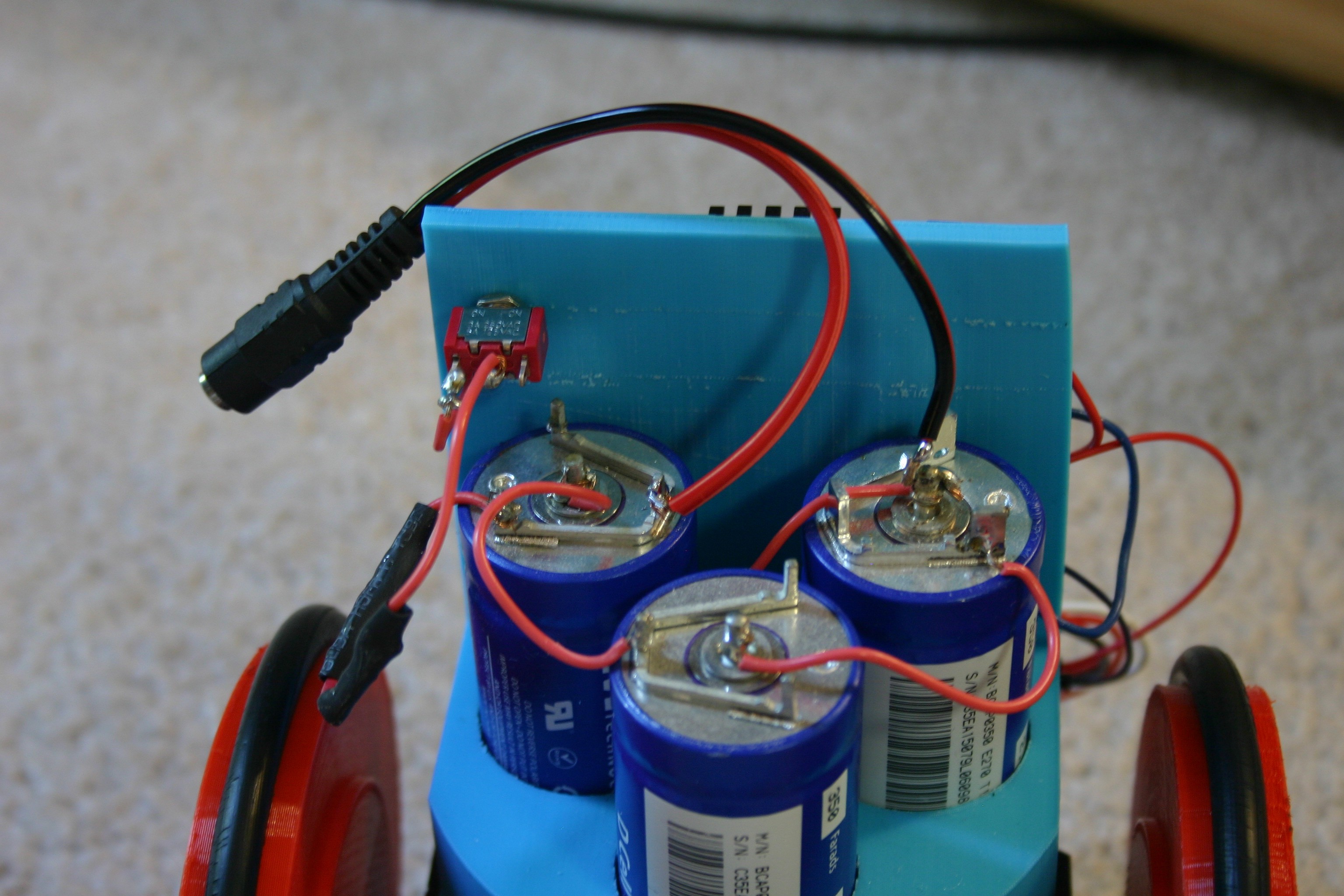

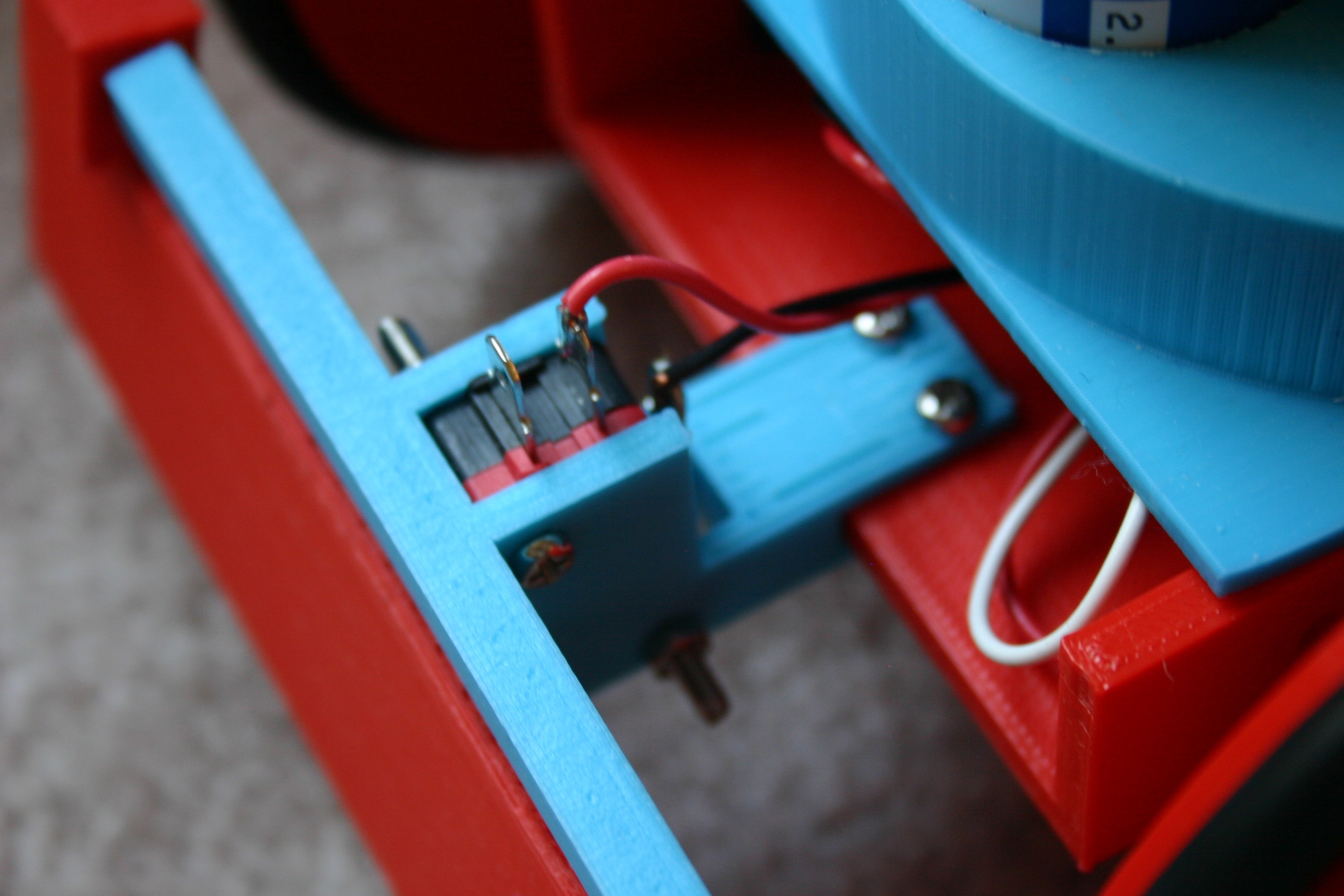

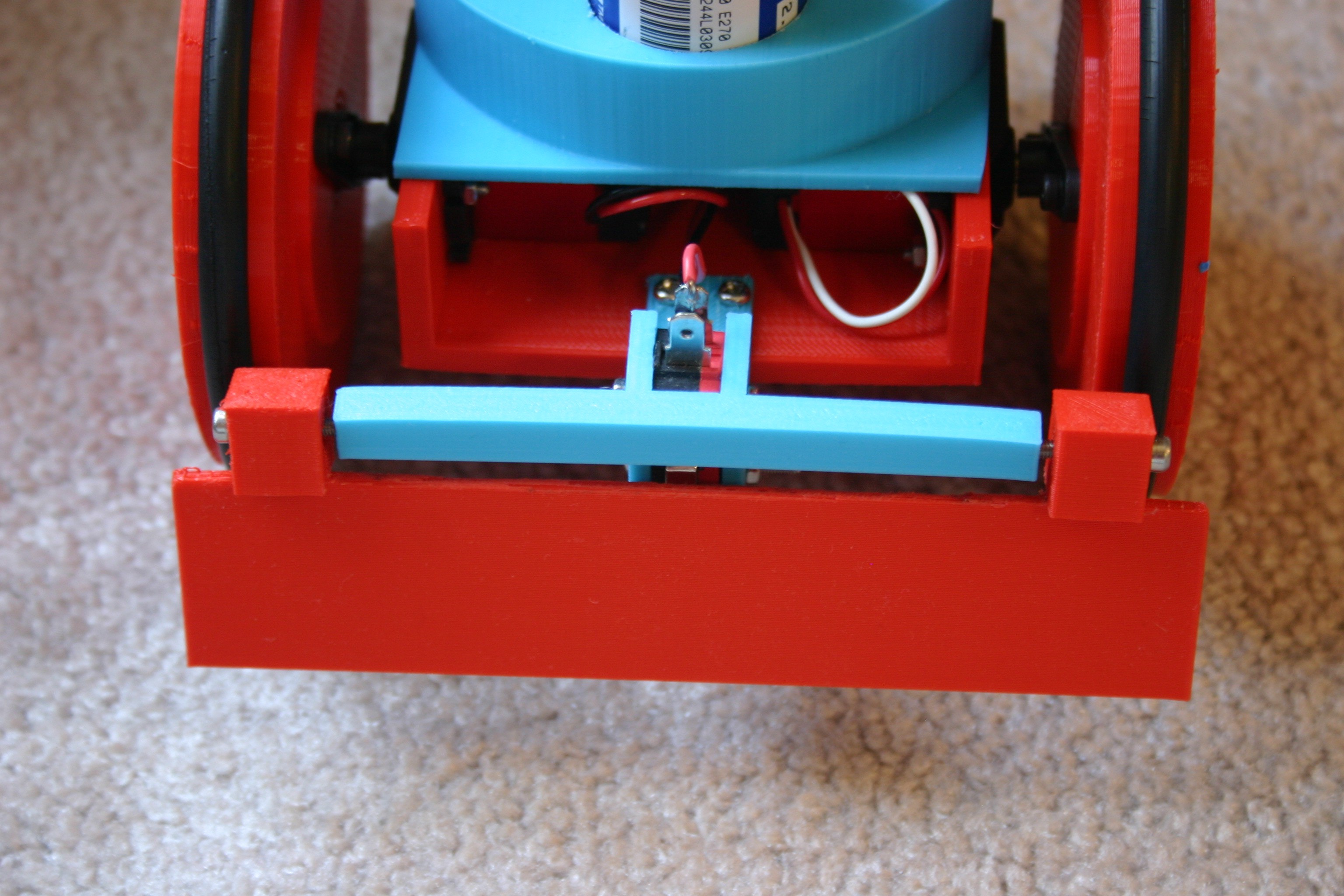

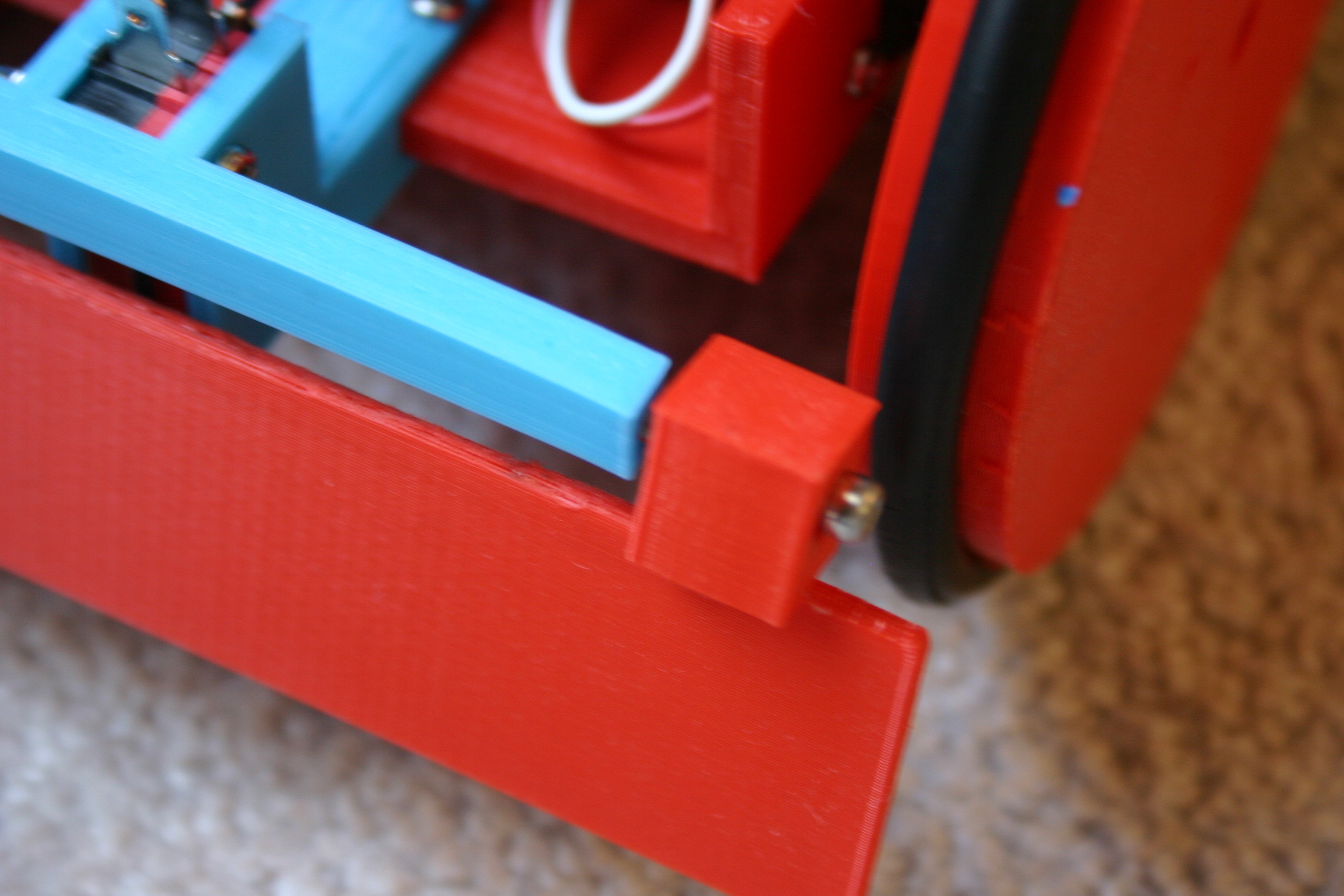

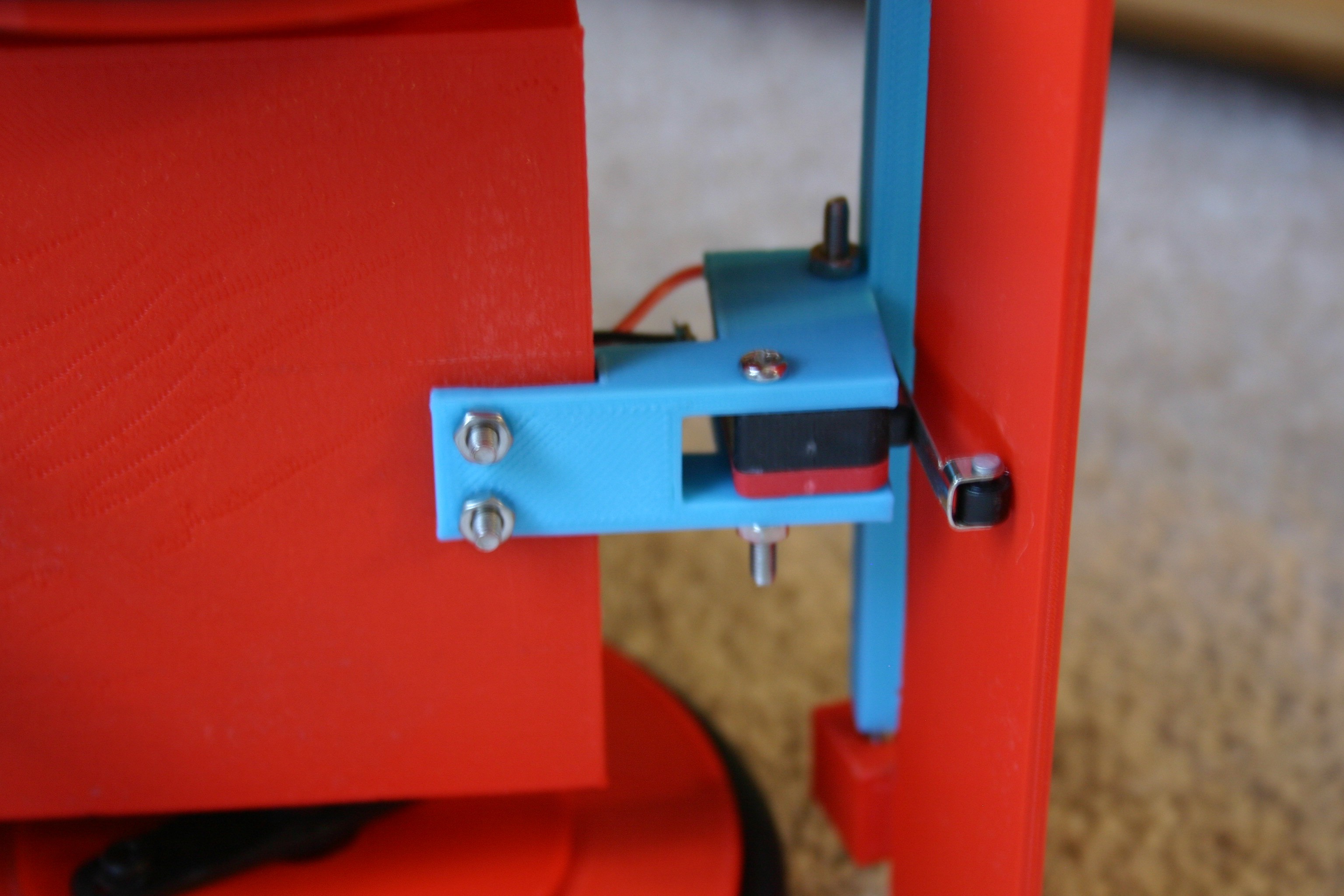

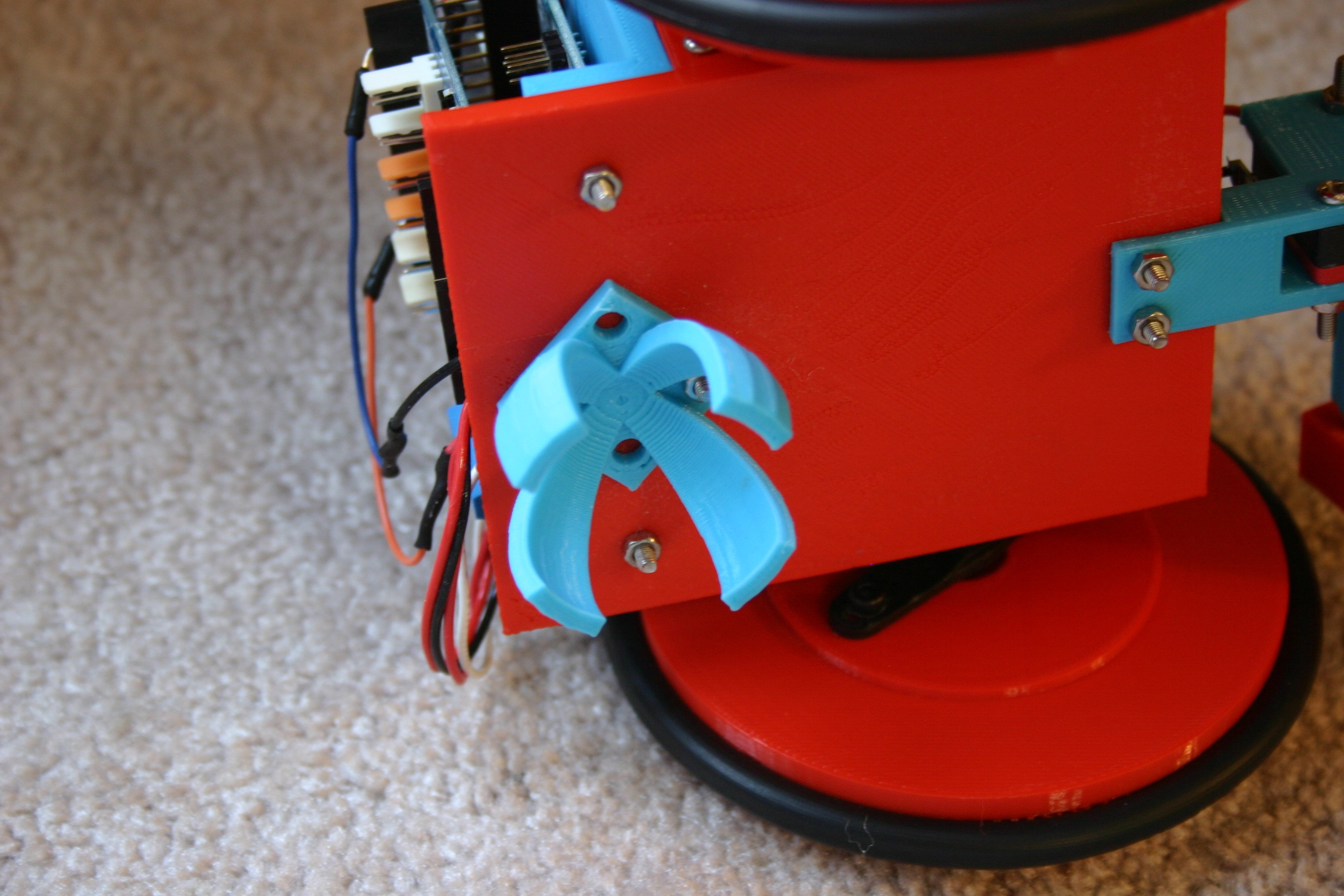

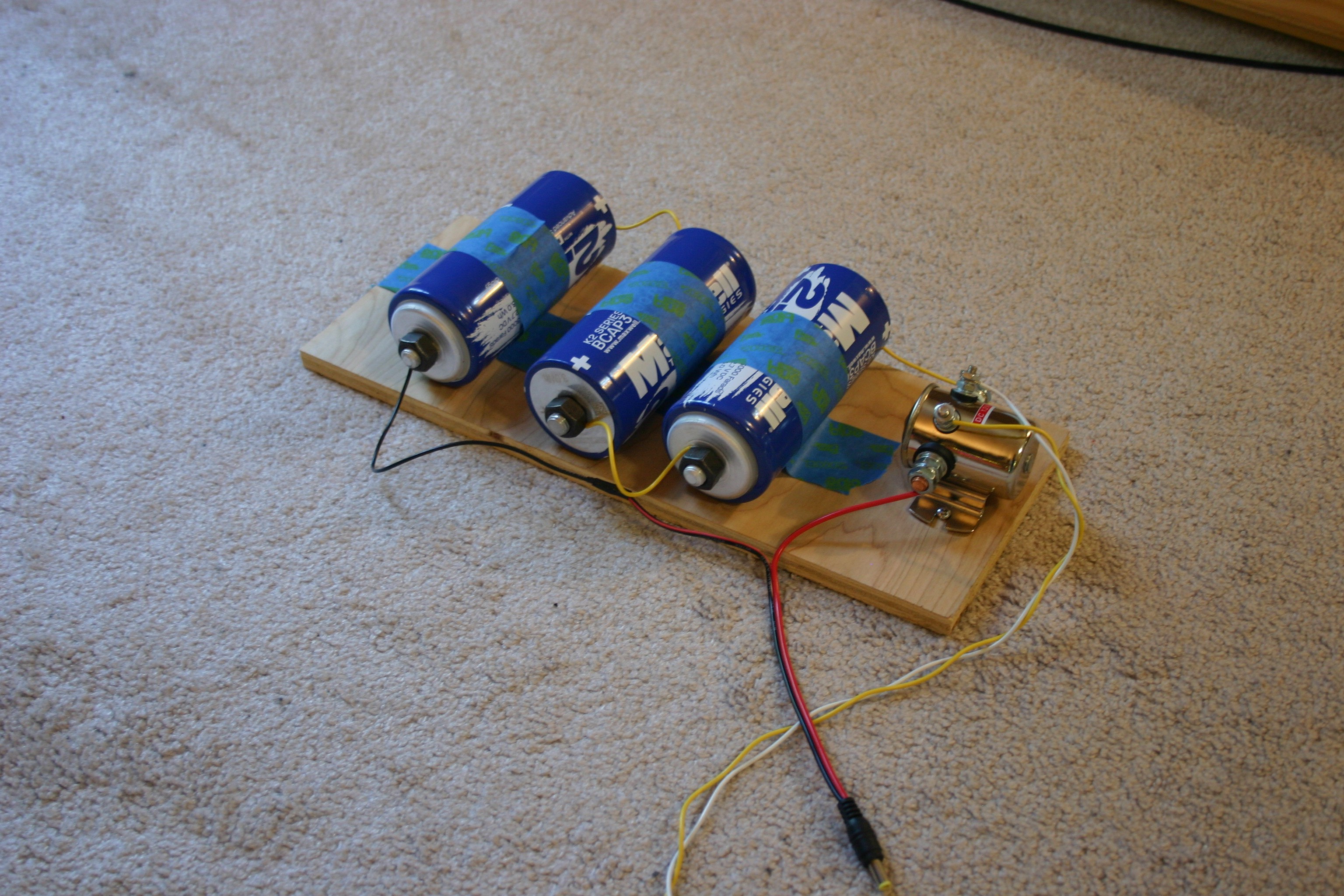

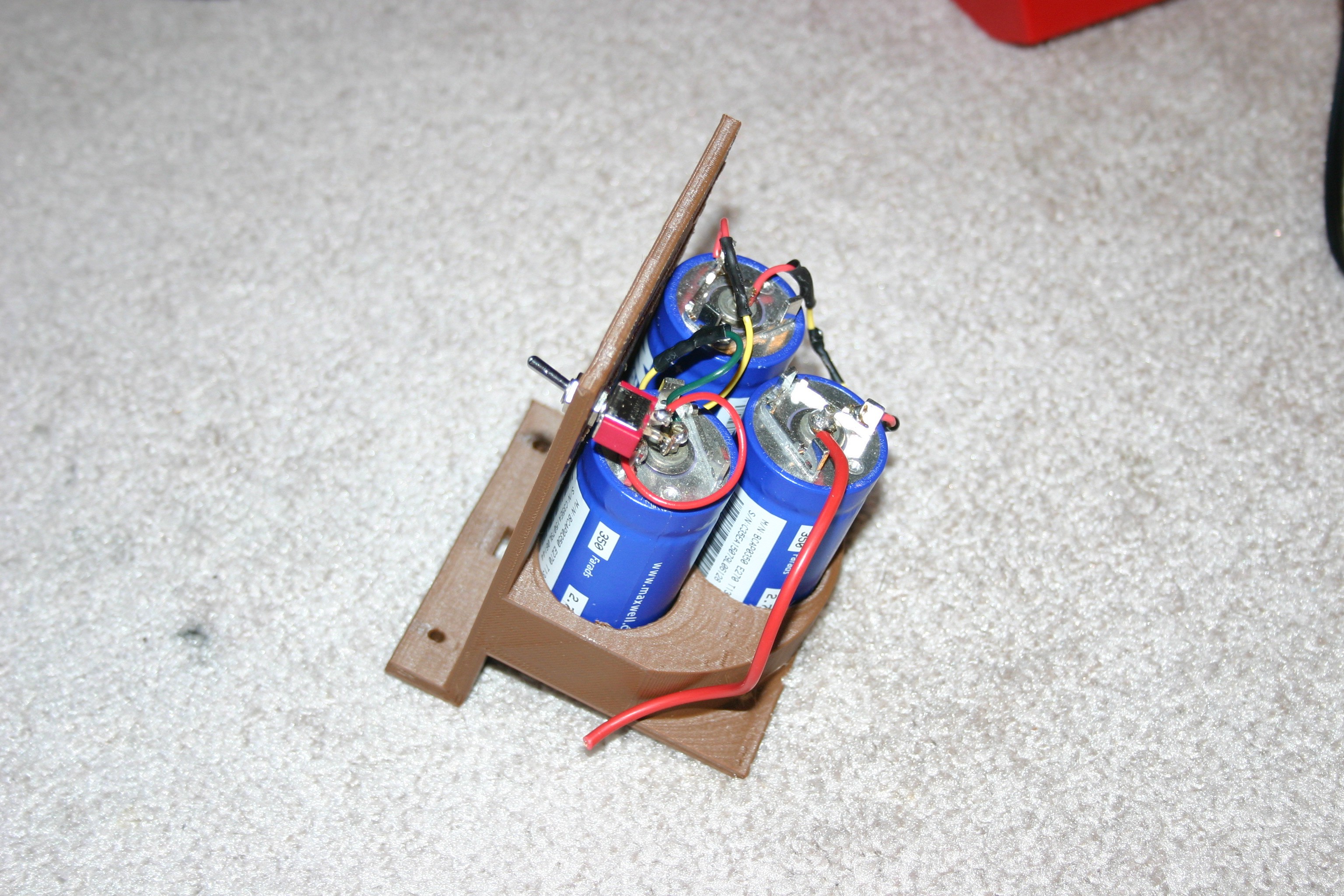

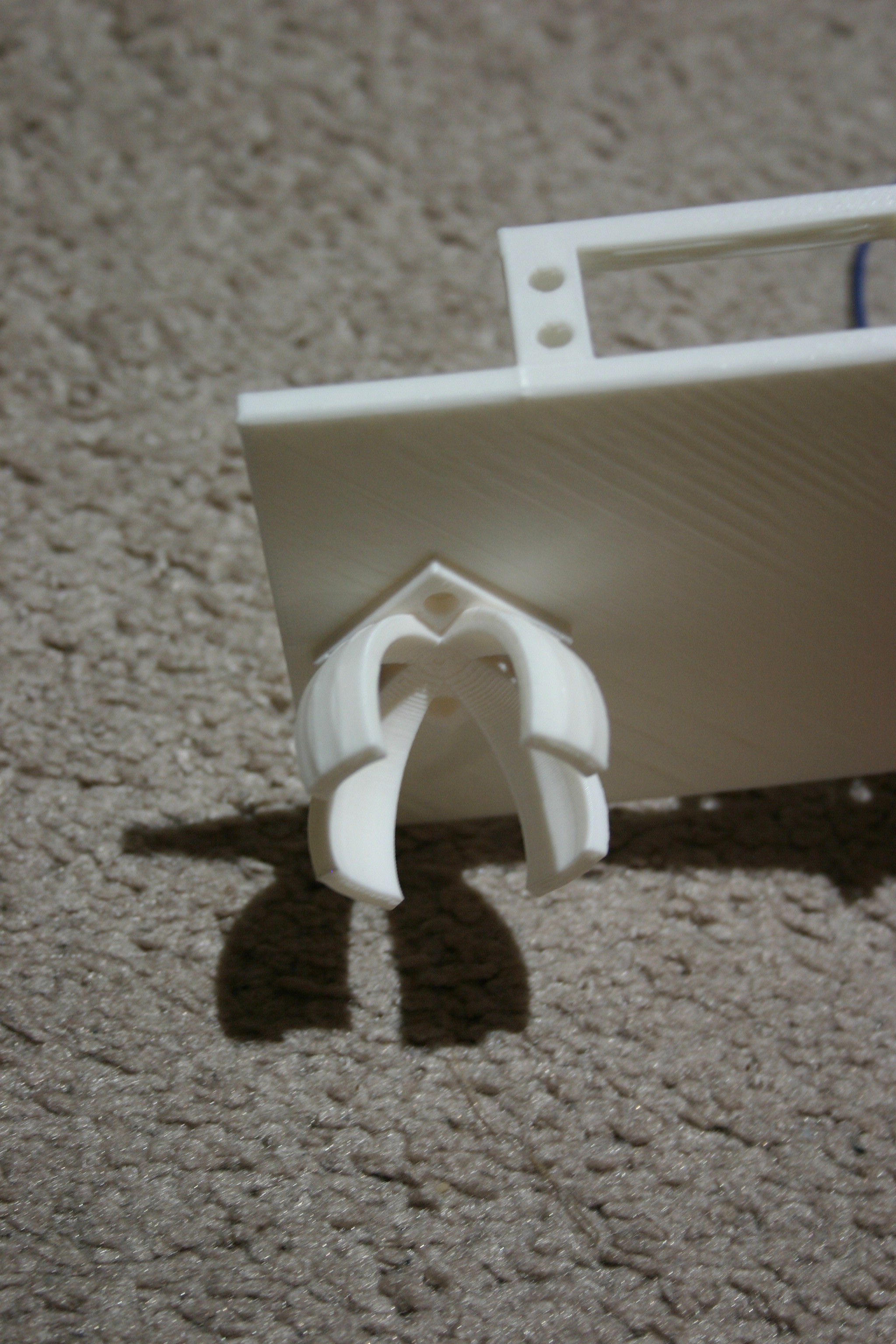

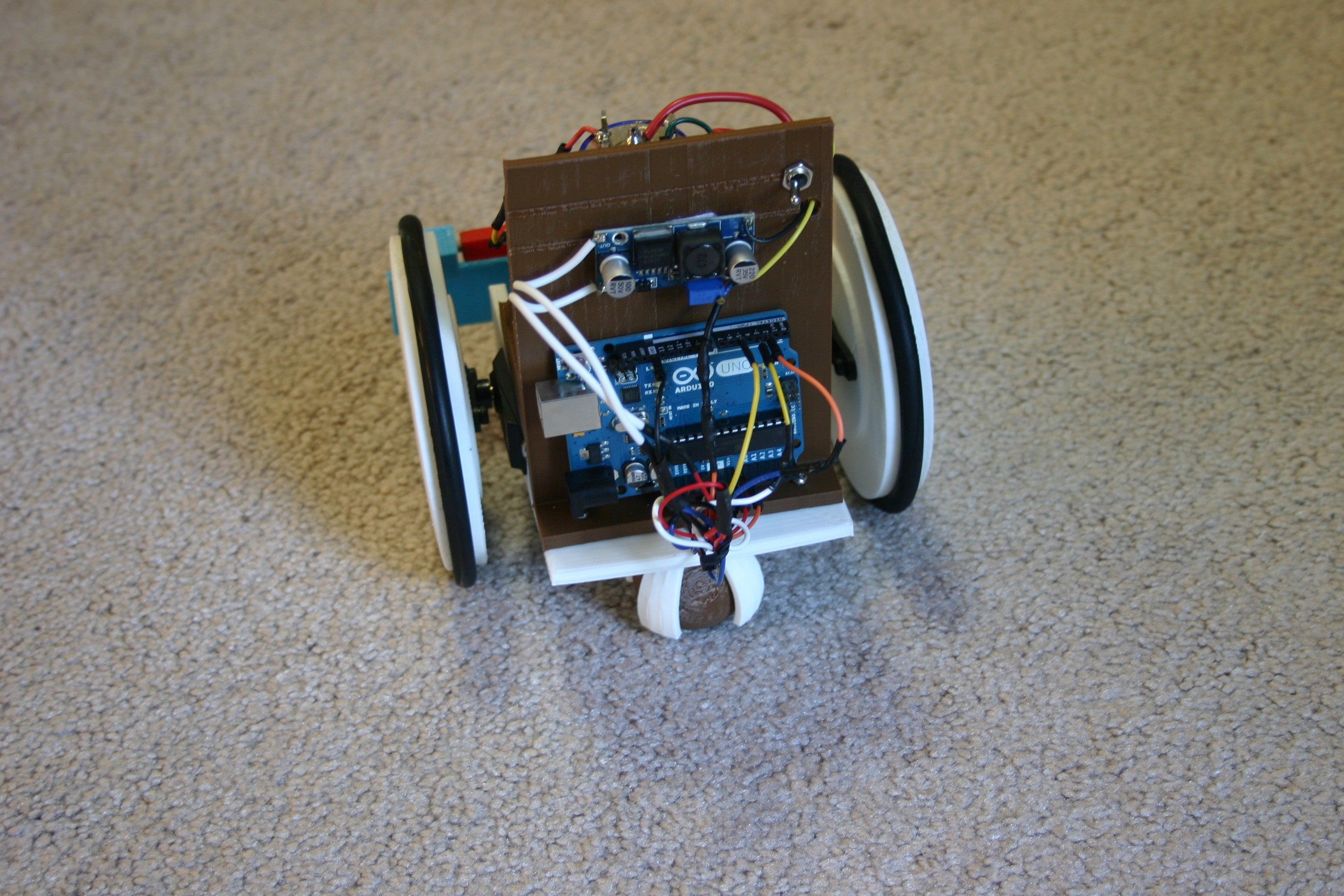

Little Flash is powered using three 350 farad capacitors (in series). Her drive motors are metal gear servos (with electronics and end stops removed).

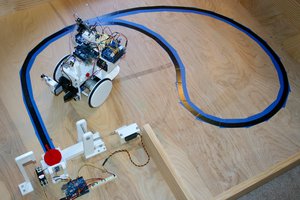

Currently, she runs for over 25 minutes on a single charge and the charge is supplied using a constant current supply (10 amps for 40 seconds).

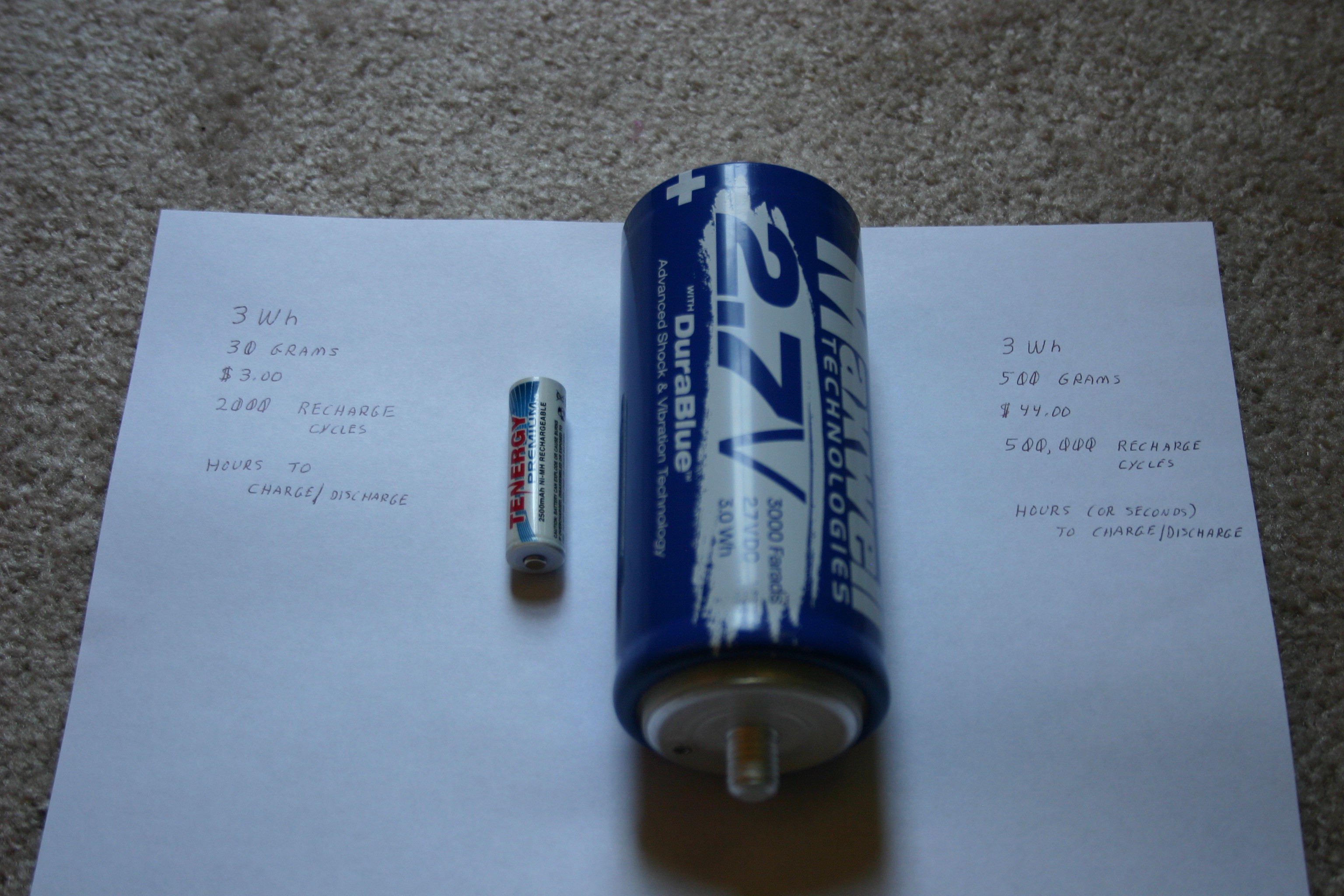

I expect to use three 3000 farad capacitors (in series) to quickly charge Little Flash--this could result in Big Flash; something we'll see in a few days.

Mike Rigsby

Mike Rigsby

Russell Cameron

Russell Cameron

Shawn Chen

Shawn Chen

1/4" soft (or rigid if you like) copper pipe makes pretty good 200A+ buss-bar at a fraction of the cost of real ones. Squish the ends in a vise or with a hammer, drill through, and then you have termination points as well.

Lighter weight could be had by using refrigeration tubing, although it's usually the same price, and for the transfer duration that would probably be fine. On the other end of the spectrum, Type L water pipe can handle 800-1000A.