Why I Stopped

I stopped because I was waiting for 1.2mm diameter end mills for the gear wheel. As they take about six weeks from China fro delivery I went on to other things.

I had moved on by the time the 1.2mm end mills arrived!

I did have a look a the project a month or so ago, made some edits to the design, nothing exciting. The problem remained, the project was complicated and expensive.

So I put it on hold.

Another Approach

While cruising the Internet, I came across the Maslow CNC project:

Okay, it deserves a "WOW". Getting this technology to cut a 4ft x 8ft sheet of plywood is an achievement.

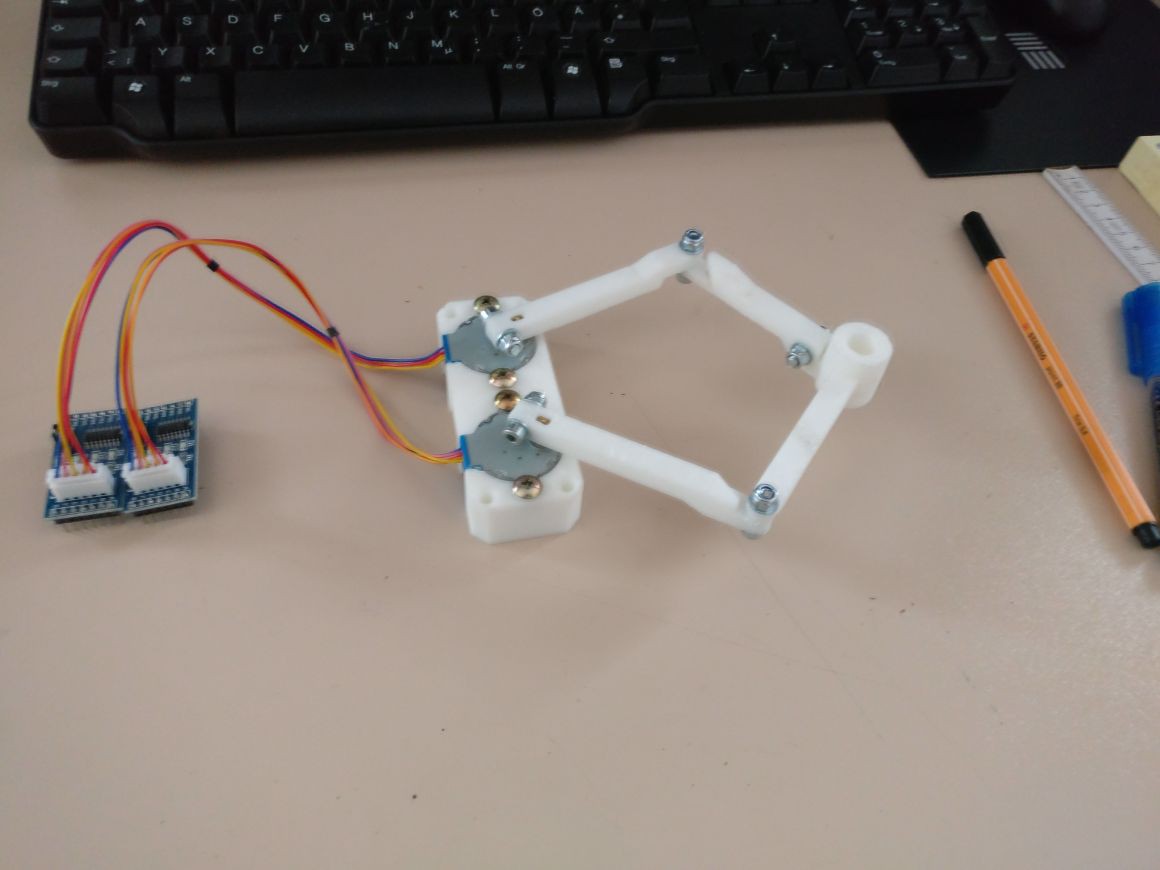

Parallel or 5 Bar SCARA

Okay, if they can get he Maslow CNC project working, I can get a parallel or 5 bar SCARA working (i.e. able to cut plywood). Here is an example of a % bar SCARA (http://fab.academany.org/2018/labs/fablabbottrop/group_week14_15.html):

Why a 5 Bar SCARA?

The main advantages of the 5 bar SCARA are:

- Very simple construction.

- The potential to use domestic hinges for bearings.

- Heavy stepper motors are not on the arms.

The main downside is:

- Not a good design for the application of force.

Possible solutions to the application of force:

- Limit link angle to say 30 to 150 degrees (avoid near "straight" angles).

- Use gearing.

Other problems:

- Need to use an offset laser or cutter if hinges are used.

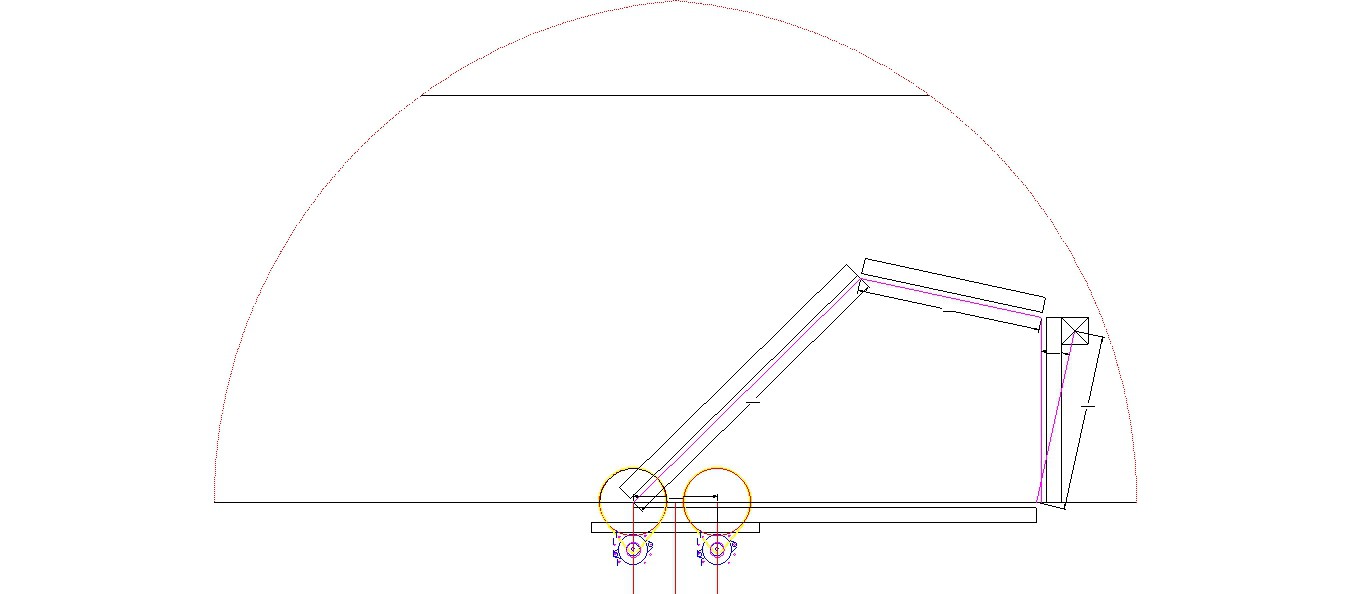

Here is a first drawing:

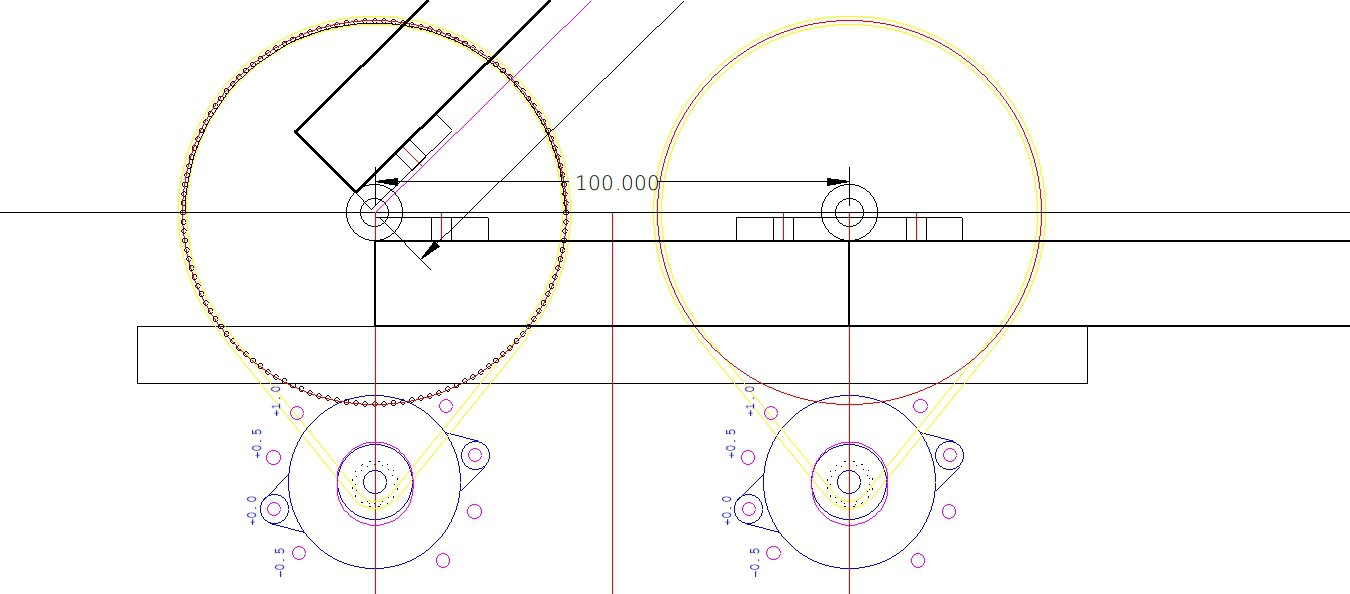

And a close up of the motor gearing and hinges:

Note: The gears are attached to the "near" arms.

SCARA Mathematics

Next is the Mathematics.

Alan Cooper

agp.cooper

agp.cooper

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.