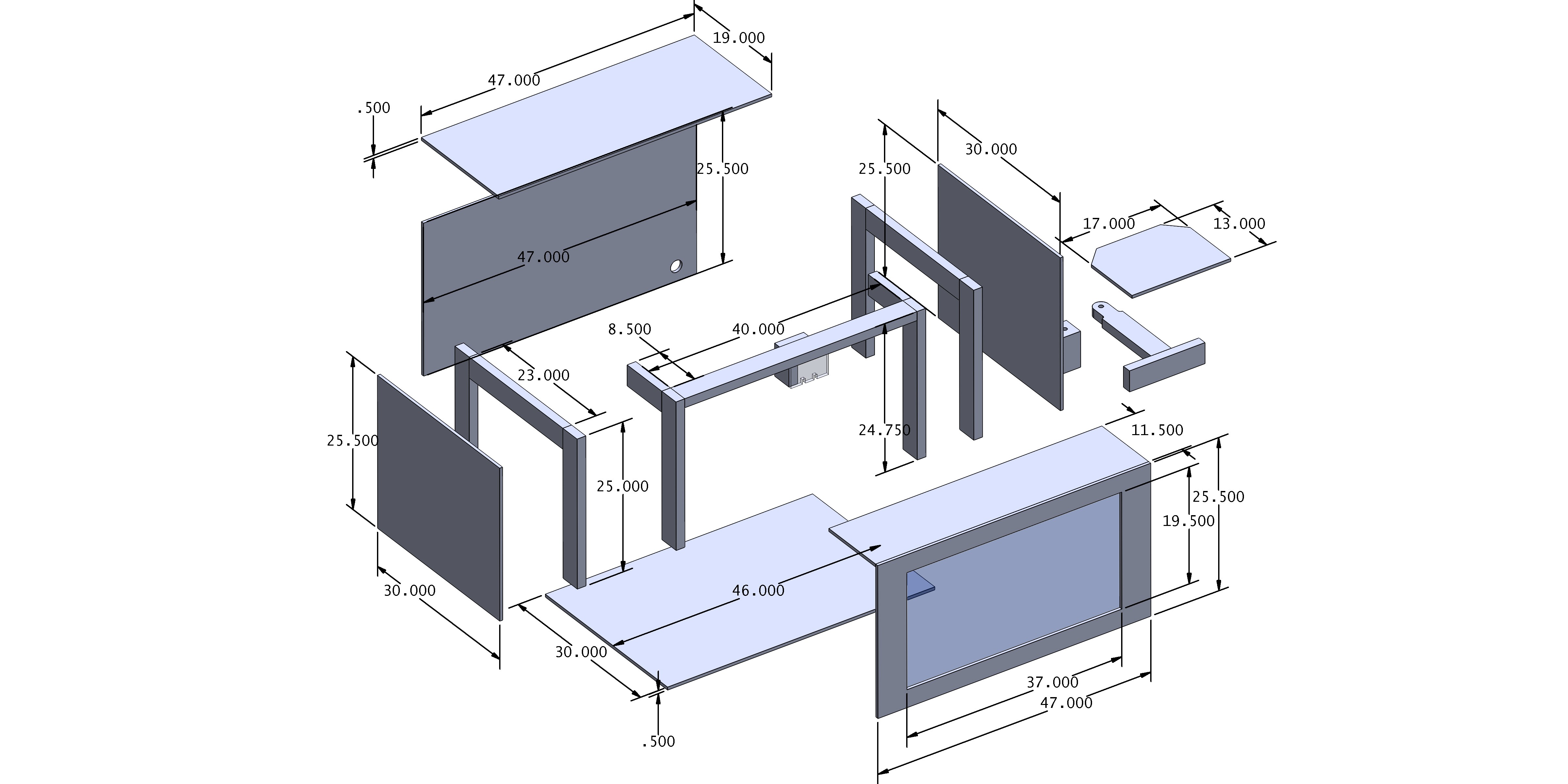

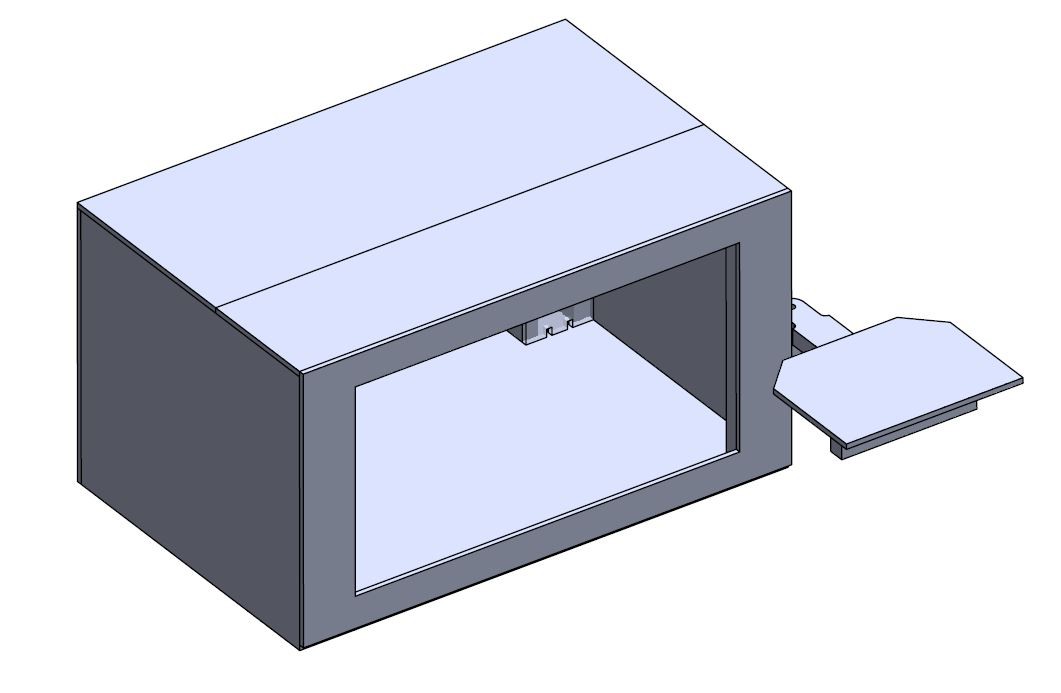

- Big single window made from acrylic (polycarb would be better but much more $$$)

- Enough space for a small vacuum inside the enclosure

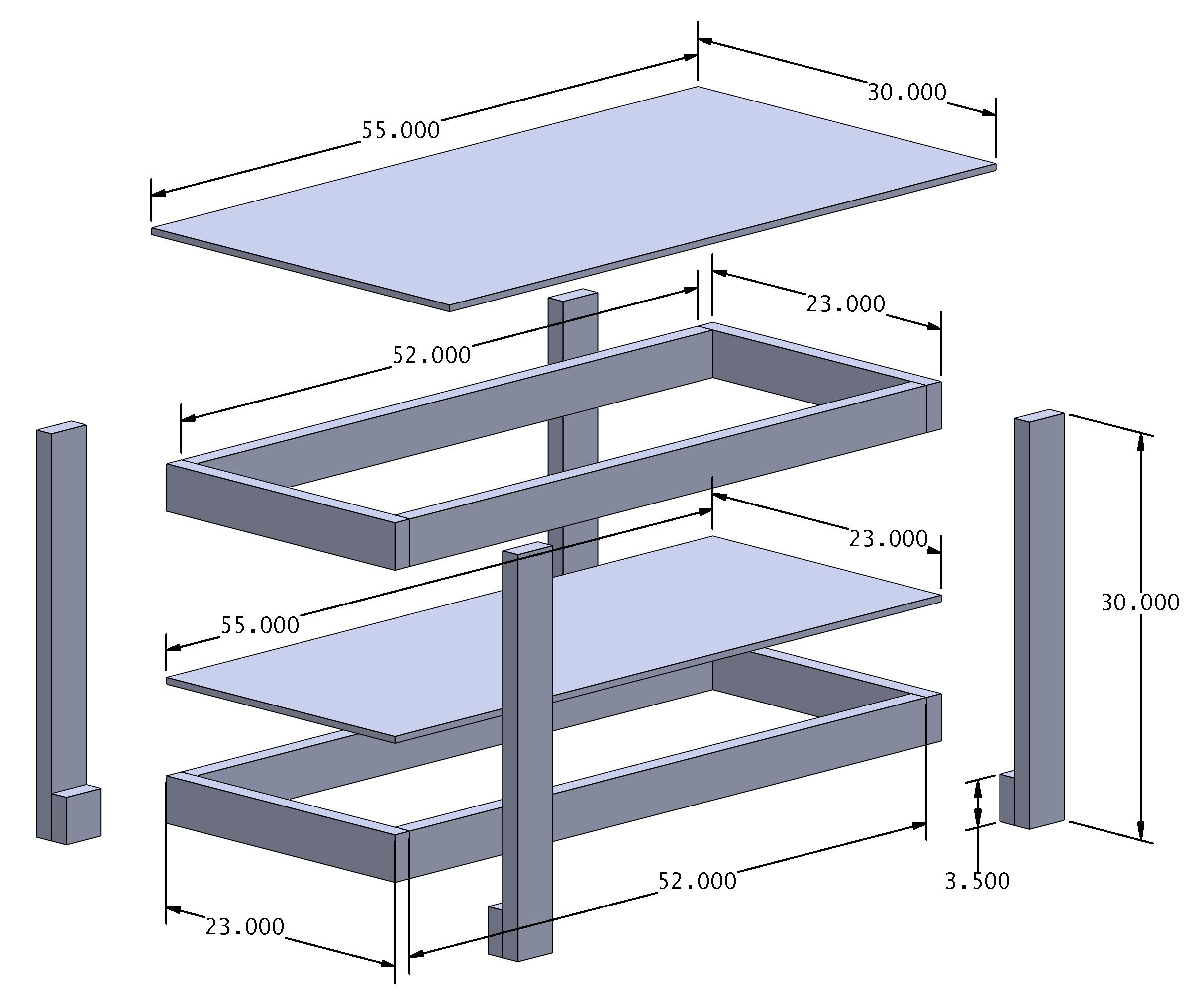

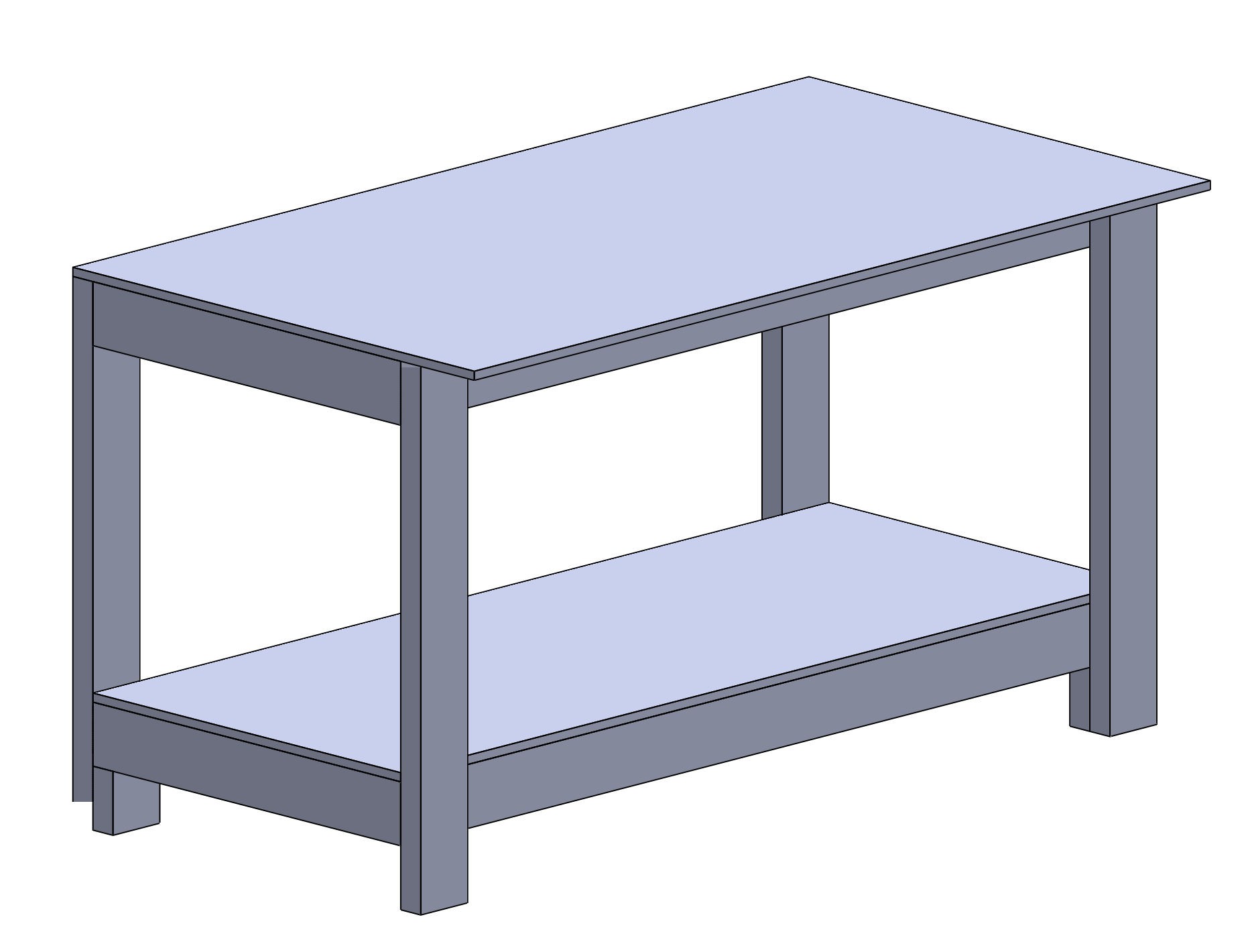

- Laptop stand

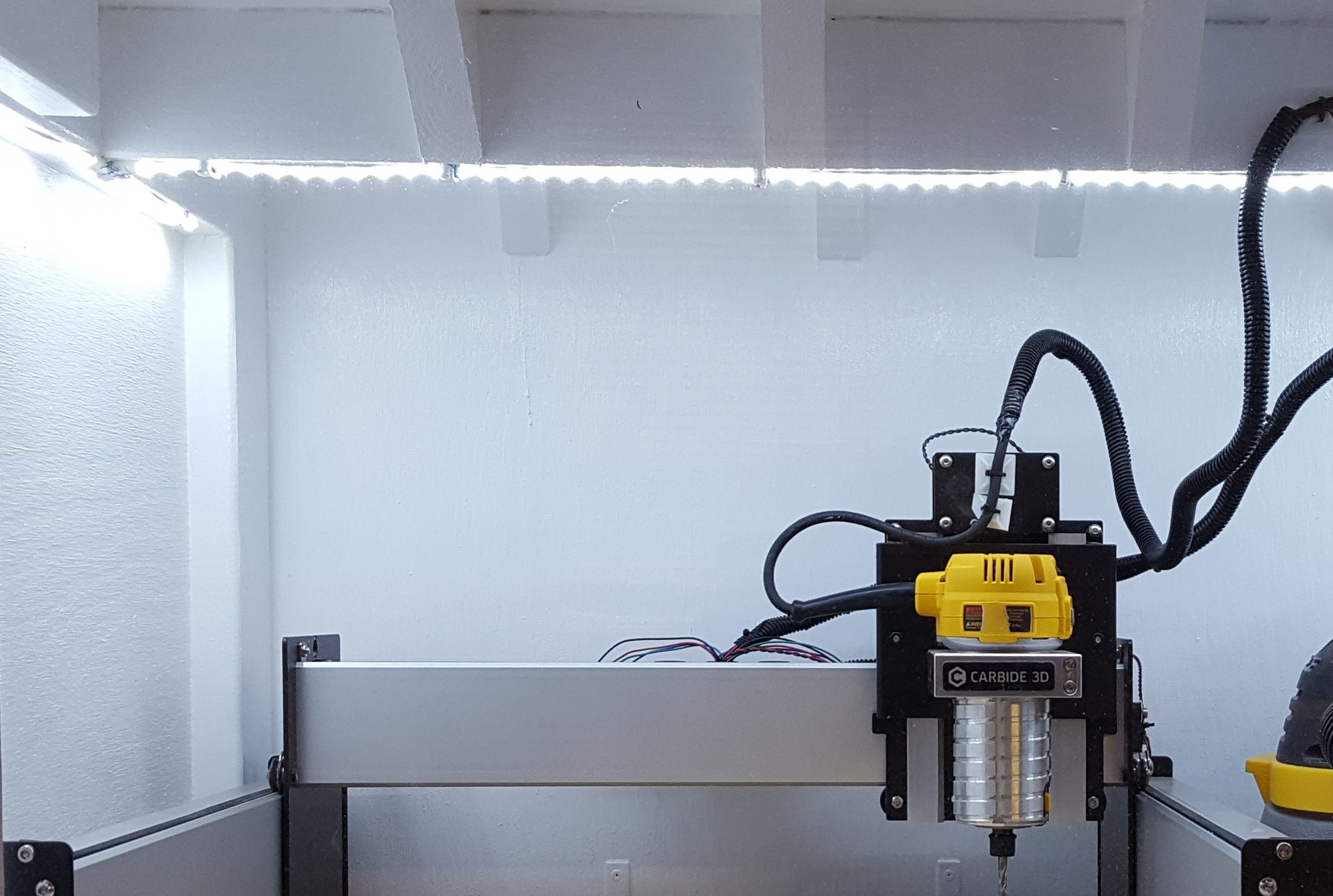

- Painted the interior gloss white to reflect as much light as possible (should I have used mirrors?)

- Exterior is light grey semi-gloss for extra class

- Interior lighting accomplished with LED strips (see component list for a link to connectors, etc.)

Alex Rich

Alex Rich

Steve Pomeroy

Steve Pomeroy

Grayson Schlichting

Grayson Schlichting

Adam Redfern

Adam Redfern

Ian Norton

Ian Norton