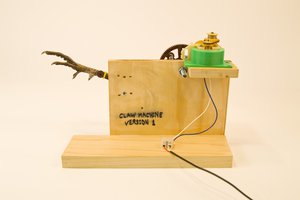

Precise Wire Bending Machine

Open-source wire bending CNC machine for wires at 1mm and less in diameter.

Open-source wire bending CNC machine for wires at 1mm and less in diameter.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Don't miss a chance to build your own wire bending machine!

Detailed instructions how to build one can be found here https://www.instructables.com/id/Spring-Making-Wire-Bending-Machine/

All STL files are now available in a git repository on GitHub. Feel free to download and print. I will post instructions on how to build the whole machines shortly.

Yes, it can make springs. Totally satisfying to watch. The precision is incredible. I am really proud of this machine.

My Wire Bending Machine Finally Works! And it is incredibly precise!

Few hex made by the machine. They are identical. Two sizes.

New wire feeding gears assembly is ready. Using welder machine feeder gear. It's incredible, works like a charm. I will share the overall progress tomorrow.

The first successful bend. A lot of scrapped wire was made in the process. Still, the biggest problem is insufficient adhesion of drive gears.

The new assembly is ready, will test it tomorrow. I will upload all the STL files if it works.

Today I am printing new version of drive gears assembly and bending tool. It should improve it significantly.

Create an account to leave a comment. Already have an account? Log In.

this is really interesting, I saw in the comments you wanted to make the pin retractable, was wondering, why not put the nema motor with the bender on a rail, add a rack and use another motor to retract the whole nema motor and bender then to allow you to reposition the bender on the other side, then move it back forward,

hola desde el primer día que vi la máquina me sorprendió

que ya tengo todos los componentes para armar bender

dudas ¿puedes trabajar con mach3 ???

cuál sería la forma más fácil de operar una máquina de doblar para un novato

Gracias

This is lovely, and I very much want to build one.

Questions!

Are you sending it G-Code to make the pattern, or some other control language?

Is there a wirebender CAD program?

Have you considered adding a rotary axis to make more complex forms?

Thanks!

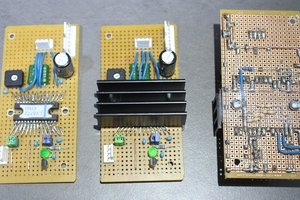

Yeas, G-Code. I am using cnc.js and GRBL firmware.

I wanted to create the simplest version and improve. So yes I want to make more complex shapes ;)

any chance this could make the worlds smallest solenoid? I would be interested in <100um wire and eventually much less.

That would require all parts to scale down (feeding gear, straightener gears, bending head). But I don't see a trouble in that :)

Perhaps this could be modified to make wire sculpures and make solenoids/transformers, I have actually experimented with machines to make the latter myself (because I don't want to buy solenoids/transformers nor wind wire all day)

It depends whether you can build them with .8mm wire. Isn't that too much?

good point. But like I said, may need modification. Just a thought though

how do you get the wire to form a spring by bending in 3d? should it just continue bending in the same plane and overlap the previous curve? great work ! i am also building a modular wire bender but got stalled because i don't have a reliable feeder. also eventually u will need to add a servo to raise and drop the bending pin if you want to bend in two direction ( left and right )

The pitch is defined by the thickness of the bending plate. The bending plate has a sharp edge to make the wire slip on its top rather than stuck on its edge. But the springs are not the target use case.

Exactly, I want to make the bending head retractable to be able to bend in two directions.

For some reason, a wire sculpture of Bender from "Futurama" does not appear to exist on the Internet. Might I suggest that you should use your wire bender to make a Wire Bender...? ;)

Last year I spent some time developing a machine that will cut insulated electrical wire to various lengths. The main stumbling block was the feed mechanism which, like yours, kept slipping. I used a similar approach of pinching the wire between a stepper-driven, toothed roller and a bearing, but couldn't get it to work reliably. Have you solved the problem in your version 3?

Have you looked at the recent version? He uses a grooved feeding roller which prevents slipping quite well.

That may be not practical when using many different wire diameters like in your approach but it works well here...

This particular feeding roller I user has grove for 1mm and .8mm wires. But many other for different diameters can be found and are simple exchangeable. So it would not be problem to use various wires.

Your work reminded me of this - https://youtu.be/HPQbKTJPsU4

This was source of inspiration as well. But I wanted to make it precise.

Love this simple design. I am often re-bending paperclips into different spring shapes. I have had it in the back of my mind that I would like to automate it. Right now, I 3D print bending fixtures to make repeated parts.

Yeah, I was thinking of that as well. But this was much more challenging :)

Currently, it is an unwanted rotation caused by drive gears. However, I've added the straightening phase and it holds the wire at a still angle. But now the problem is the drive gear which has low adhesion so I am upgrading that one :)

When this 2D bender is done I want to experiment with second axis to create 3D bender.

Nice, sounds like a good plan! See https://youtu.be/5QjVeH2Z57E for your wire bending porn needs :D

No, srsly watch that short film if you haven't yet. It's mesmerizing to say the least...

@Jan that bending porn is perfect. They even colorgraded it to an amazing style.

check thé 90 degree rotation at thé start( where thé wire enters) and thé coil size determins latéral motion. There are other factors innvolved as well. But that la à start :)

Become a member to follow this project and never miss any updates

Pete Prodoehl

Pete Prodoehl

Norbert Heinz

Norbert Heinz

Bu çalışmanız gerçkten harika ama githup dosyaları indiremiyorum?