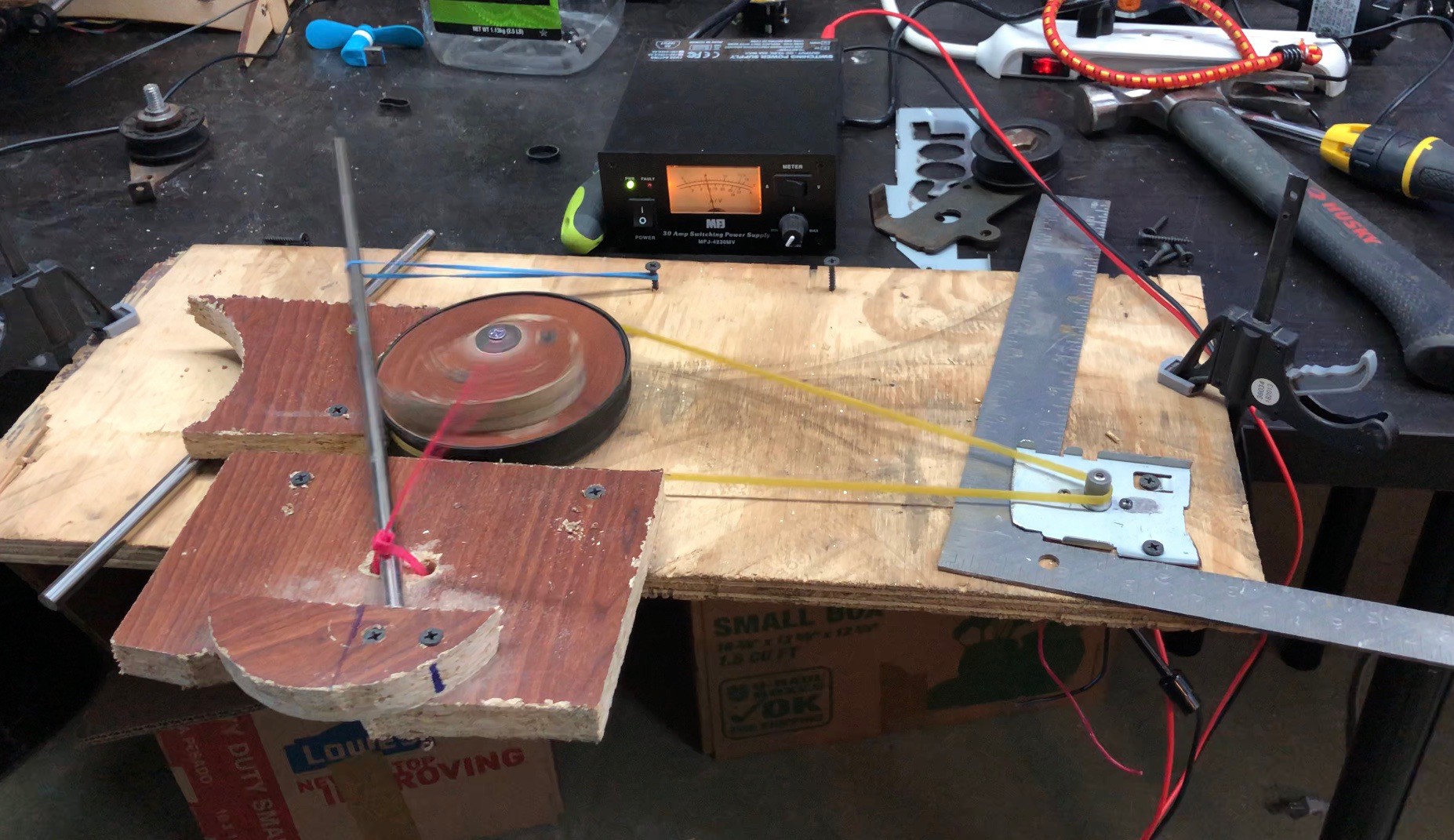

The last log on my machine is about the structure. I didn’t start with a final shape in mind -- I just built it one piece at a time and added on as I went. I started with a scrap piece of plywood and I never intended it to go into the final piece. I had my driver and a box of screws and just screwed things into place where they seemed right. This type of experimentation was refreshing compared to typical electronics work where it’s almost impossible to make a single change and not have it affect something else.

I actually started with the wood flat on the table and when I eventually lifted it up to become more of a display piece, then the mechanism failed to work. I thankfully only needed some adjustments due to the new forces of gravity.

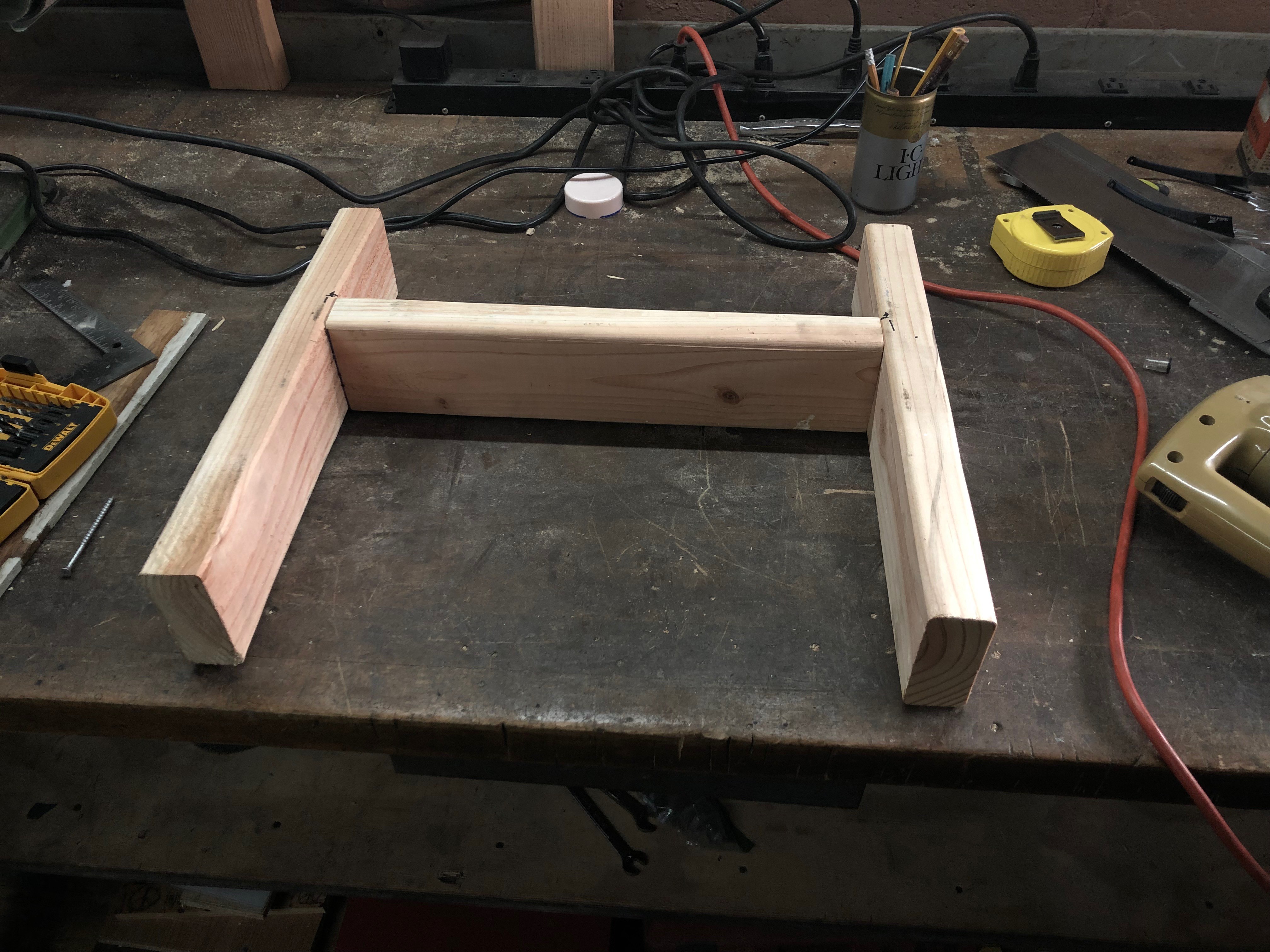

After I got it working while it was standing, I designed an H-shaped frame out of 2x4 to permanently hold it upright.

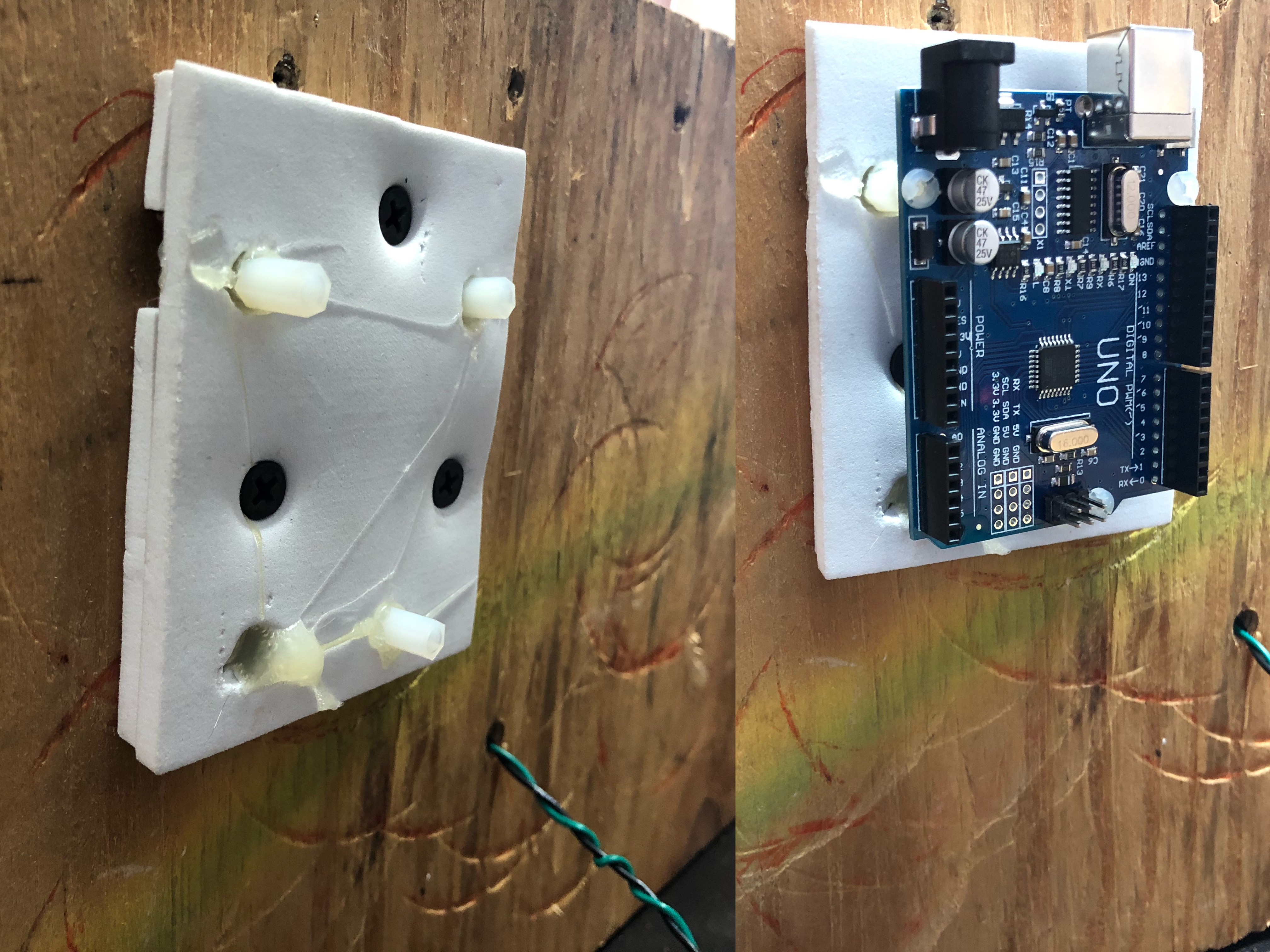

I used a mount that I used for my Arduino in a closet lighting system in my old apartment. The shield mounted to that and I could easily wire into the motor, power supply, lights, and button.

The button holder is a piece of scrap metal from a tool I made. I drilled some holes to mount the button and screw it down. The strength of this piece has been perfect.

I described the wood for the Applause light portion earlier but I cut that so it was the same size as the rest of the machine so it could hide all of the ugly internals. I mounted it to the front of the machine with angle brackets. There’s another piece of 2x4 under that to make the structure more rigid.

This machine is meant to be seen straight-on from the front so I only spray painted the Applause light and the frame below.

I had fun hacking away at the piece of wood that holds the stationary hand in place. I started with a pretty polished piece but as I went along, I kept needing to move it closer to other objects so I'd saw off a small chunk. Right now there isn't much left to it but it does its job. The hand is screwed in place.

The last modification I made was mounting another piece of 2x4 onto the back that holds the power supply in place. It amazes me that a 1200W power supply is almost the exact size of a piece of 2x4.

Dillon Nichols

Dillon Nichols

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.