I love making perfboard projects, a lot of projects end up not being posted here simply because I had the idea and followed through within a few hours. But one thing that's constantly held me back is the lack of a "good" way to handle lithium-ion batteries. Ideally, for me, adding a lithium ion battery should be a straight forward process and require minimal extra soldering. There are plenty of cheap buck/boost converters available on amazon/ebay but its rare to see a full solution available for a good price (best I've found is by adafruit https://www.adafruit.com/product/2465?gclid=Cj0KCQjw-b7qBRDPARIsADVbUbVzOB_30p-KOXWcoHAI_d4j5mfRYY-gDGzuFvbY4PqwMOjFrPbtUXsaAo9WEALw_wcB but it's $20).

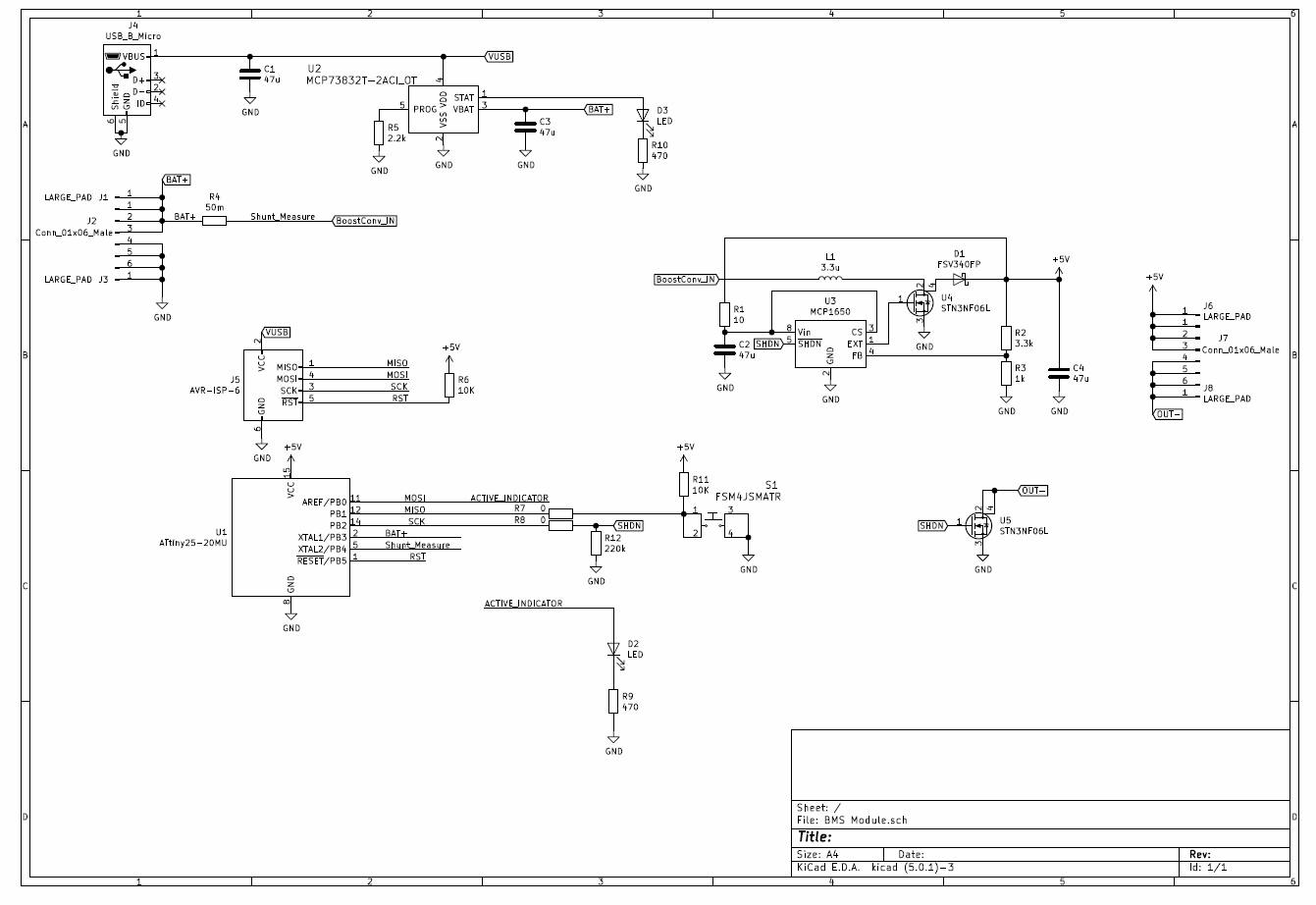

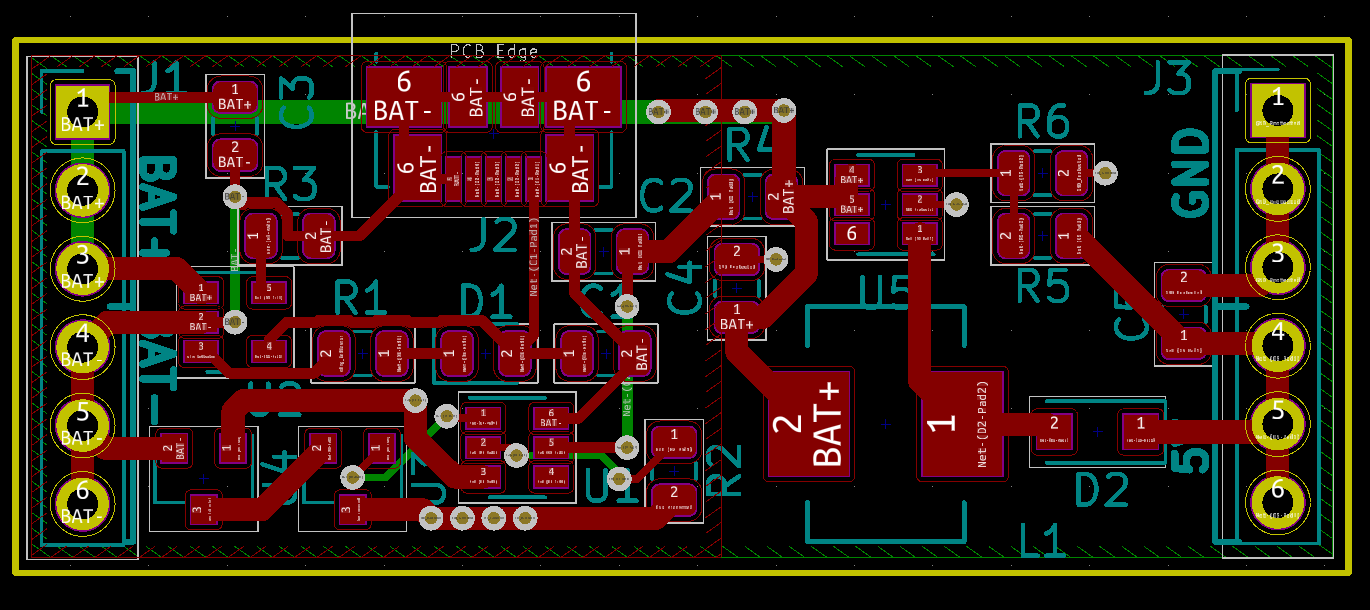

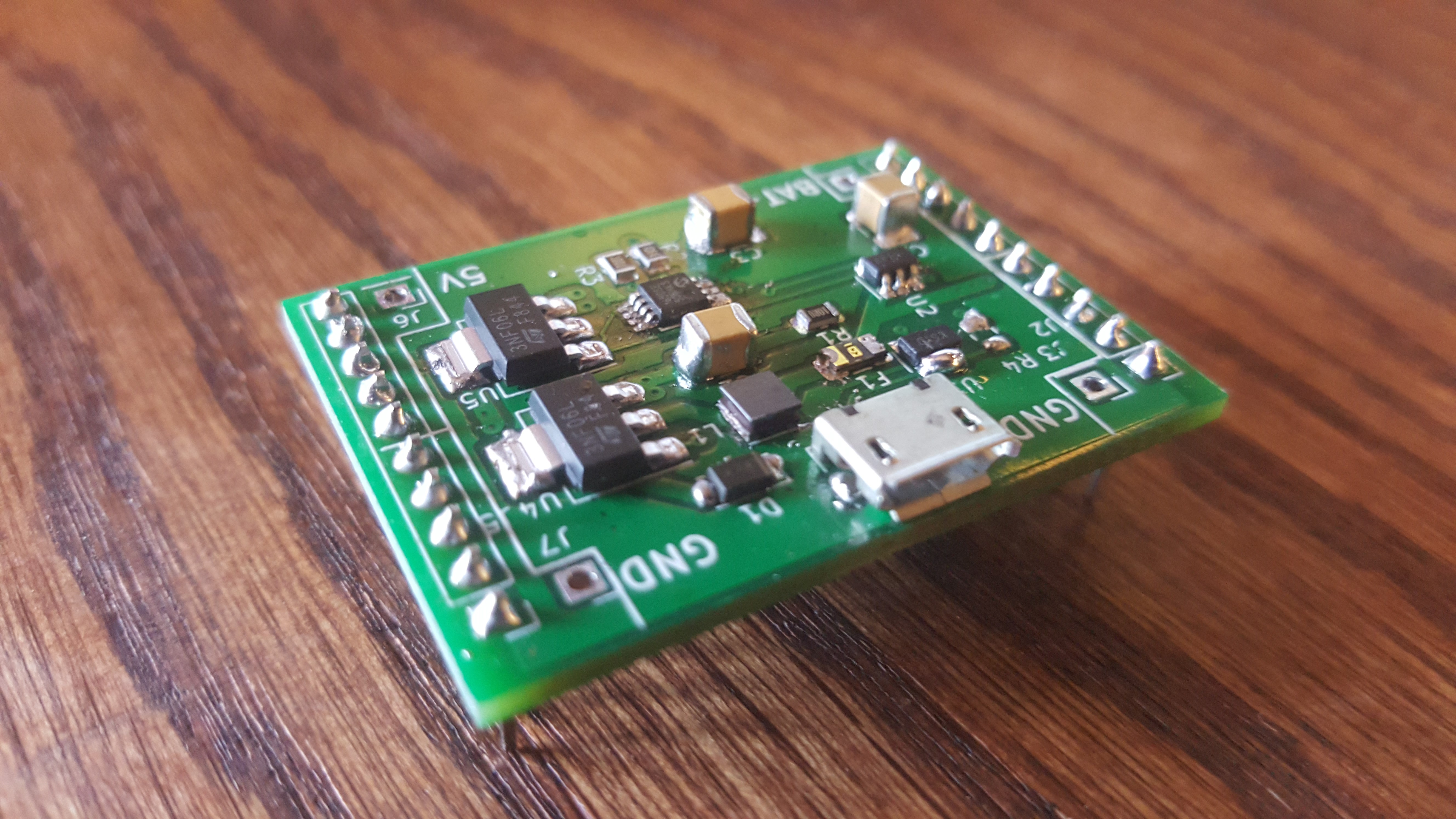

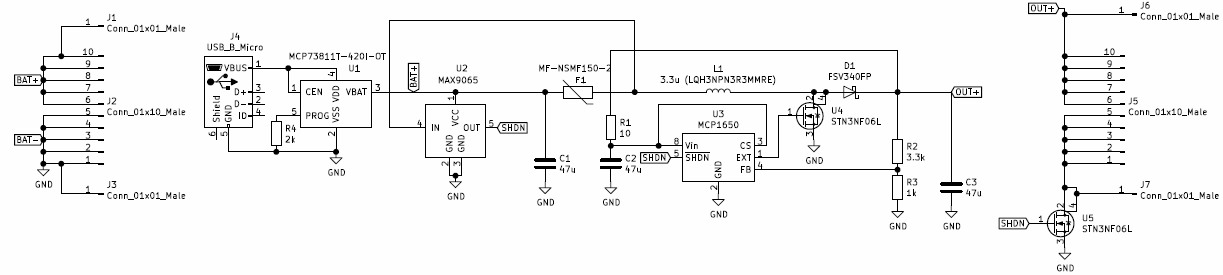

So I figured I'd give it a shot and browse digikey for a few hours to see if I can make my own board(s) at the price point I want.

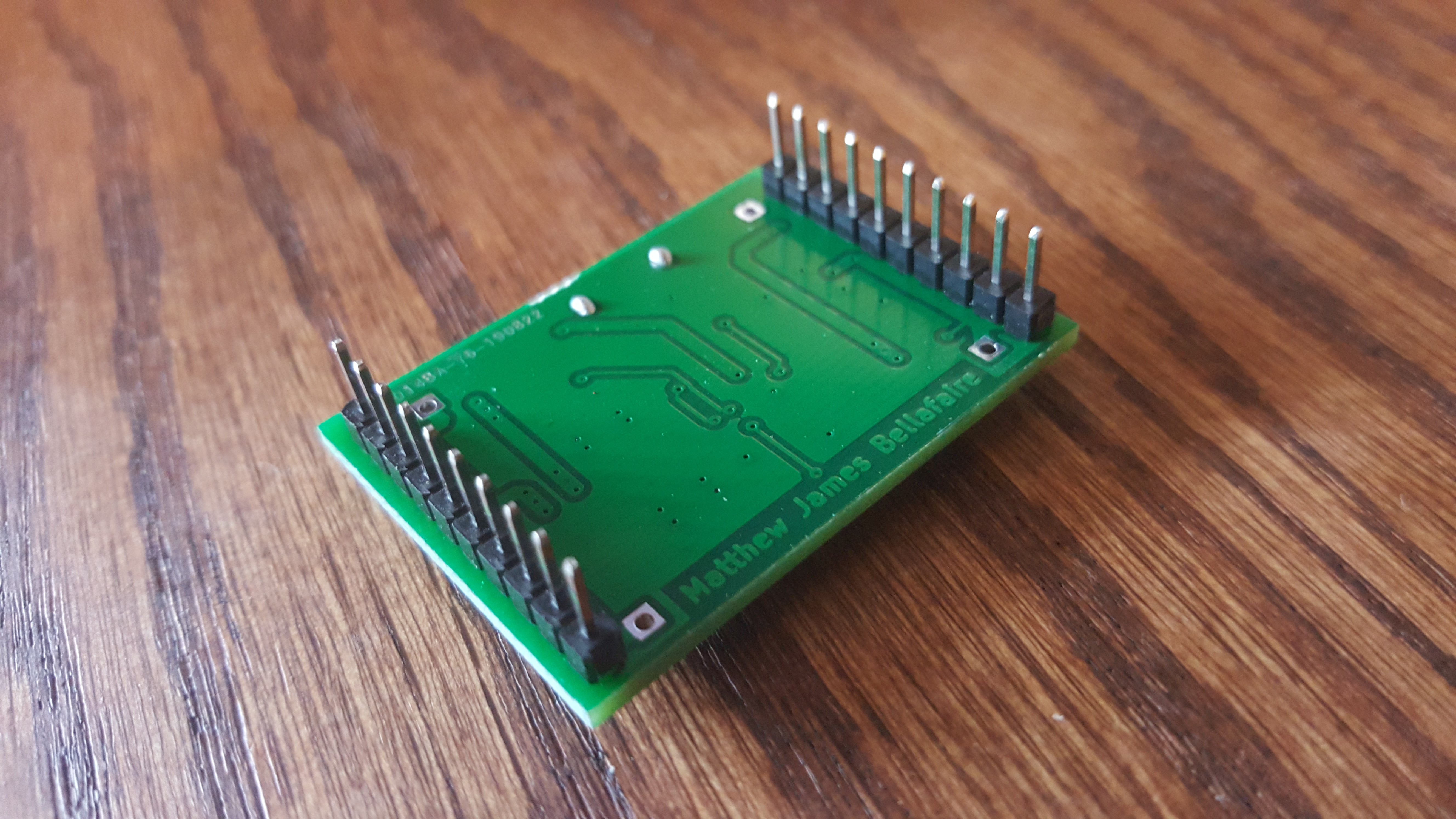

Matthew James Bellafaire

Matthew James Bellafaire

Jan

Jan

AKA

AKA

Paul Andrews

Paul Andrews

Marek

Marek

Take a look at Chinese chip TP4056, available from AliExpress in both modules and bare chips.