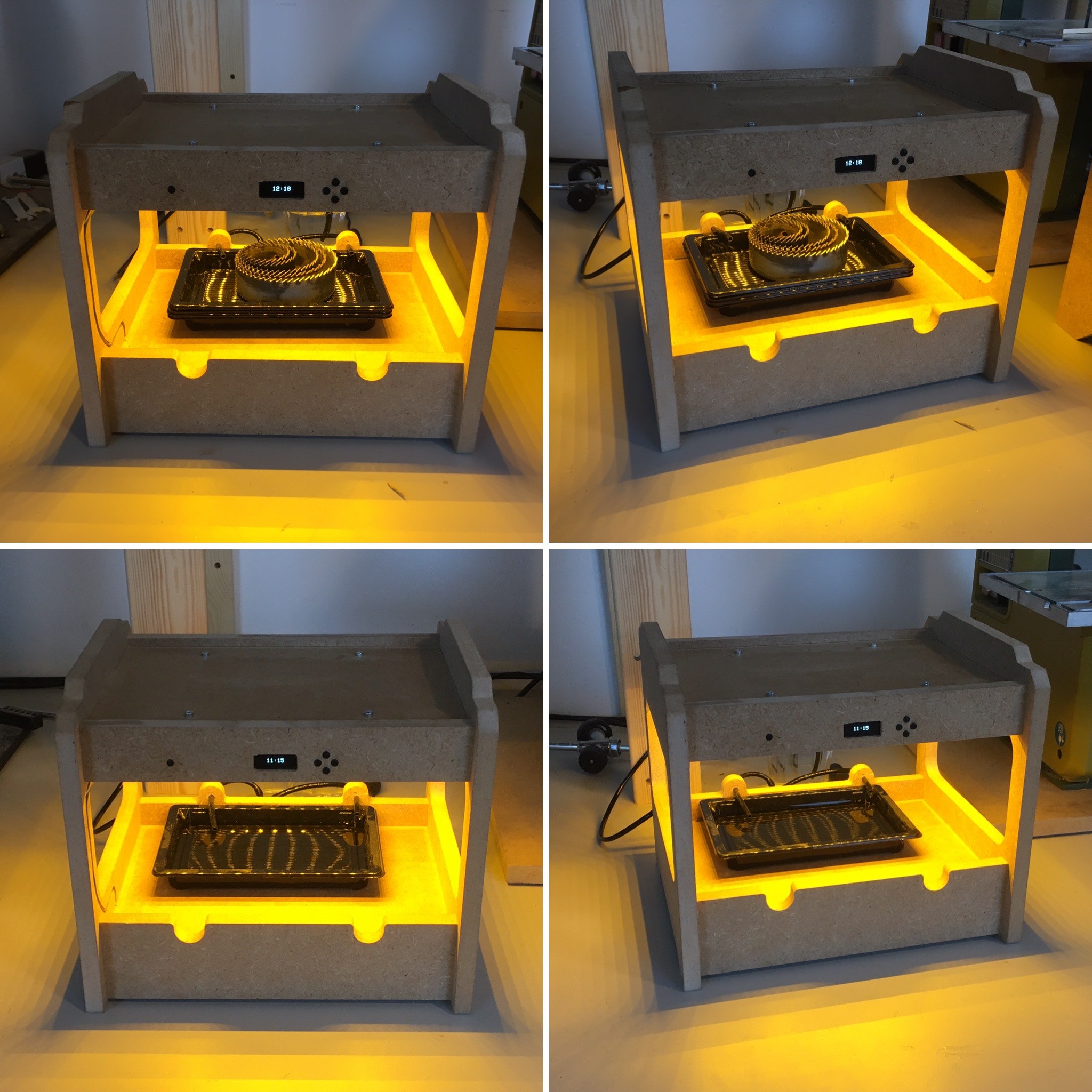

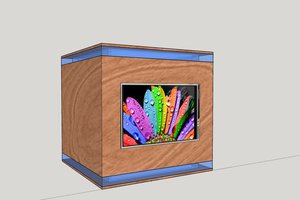

The goal with Microwth to help you grow microgreens, salad greens and herbs indoors with the help of automation. There's a pump installed to keep the grow medium moist, lighting to provide enough light to grow them as quick as possible, and an user interface with internet connectivity to create custom grow cycles with notifications when there are any actions you need to take.

Project goals:

There are a couple of project goals that we have in mind and are listed below:

- Design reliable standalone hardware to control lights and watering

- Good looking design that is easy to produce and functional

- Multiple size for different needs

- Software for offline functionality

- Software for online functionality

- Web app to manage Microwth farm(s) and have greater control over the process

- Create grow cycles for different types of plants

It would also be nice to set up a camera to take pictures periodically ans test if it's possible to identify growth problems, speed and height of the plants.

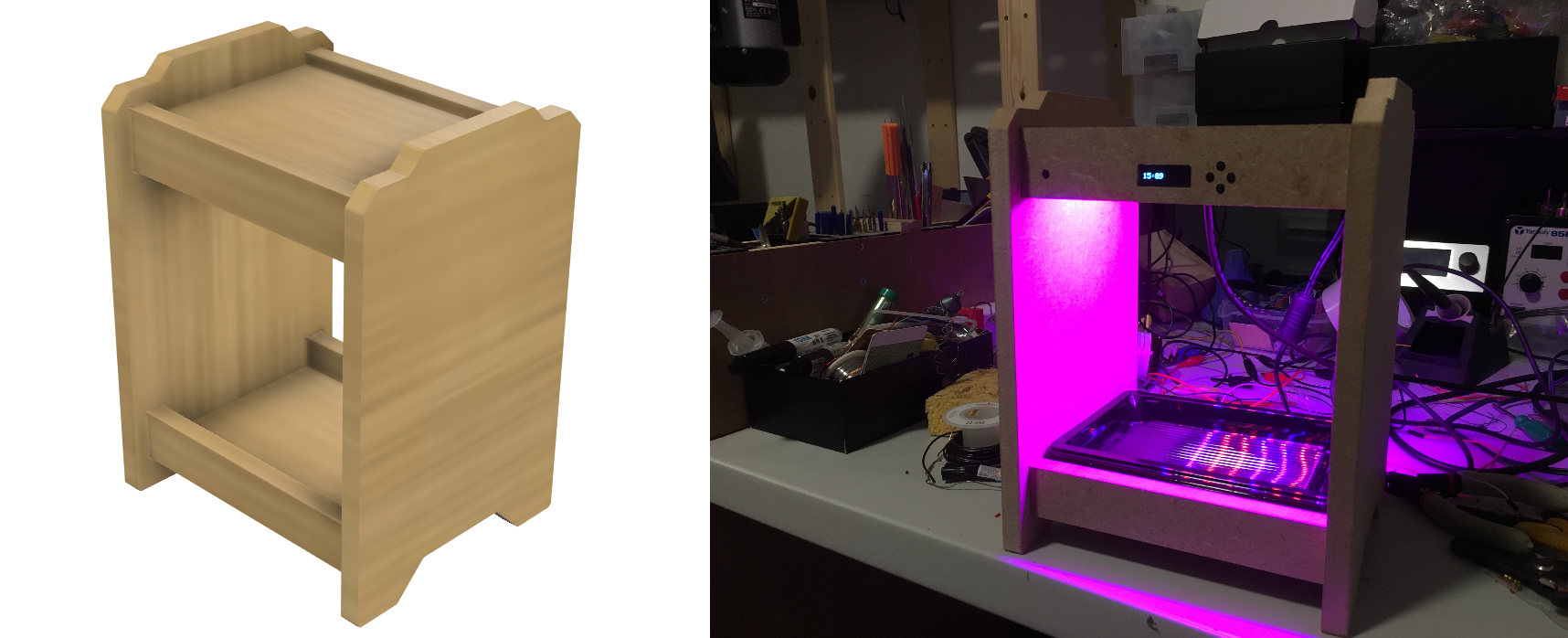

Microwth construction

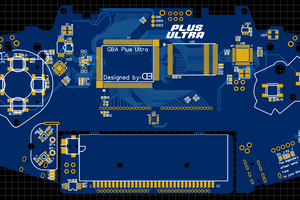

Electronics

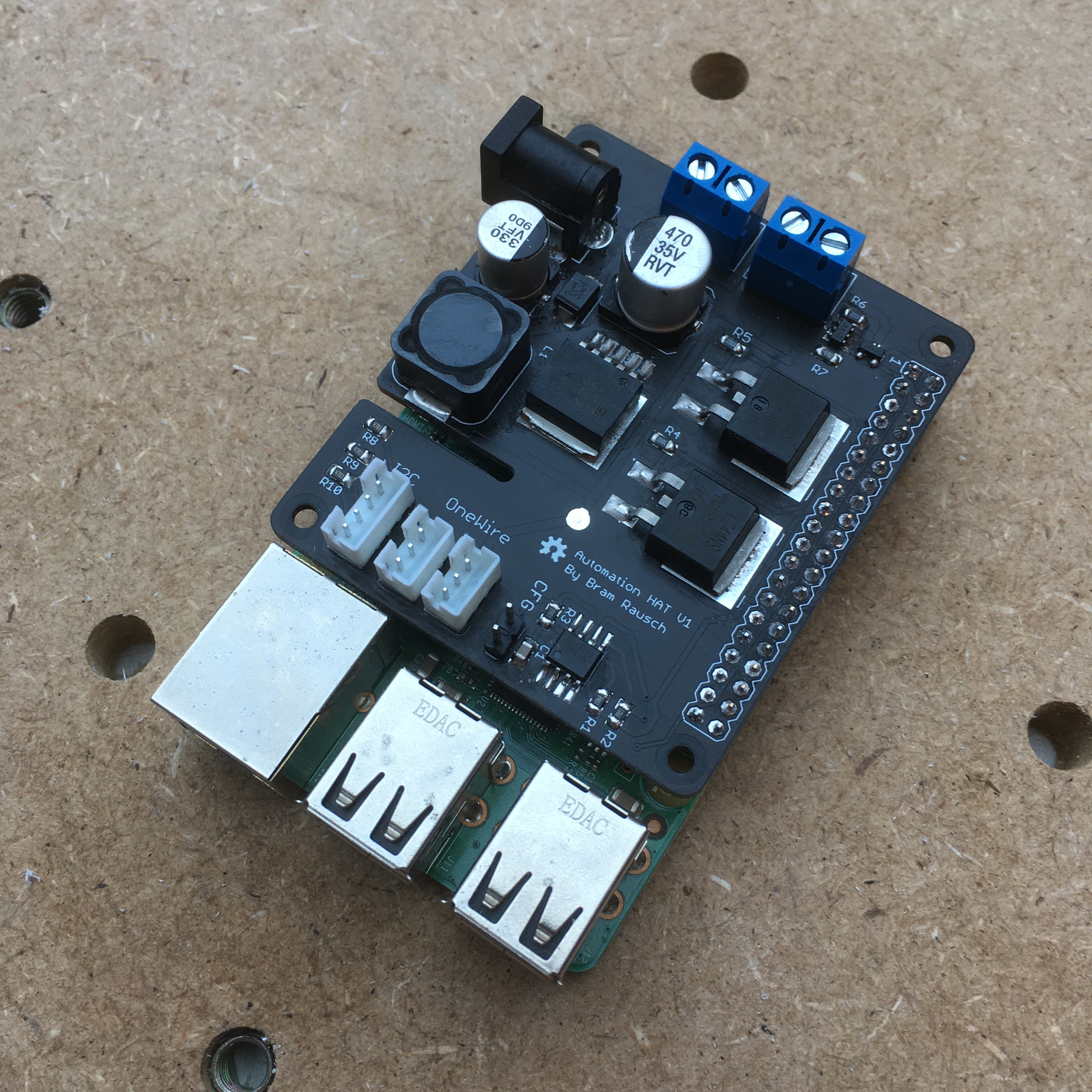

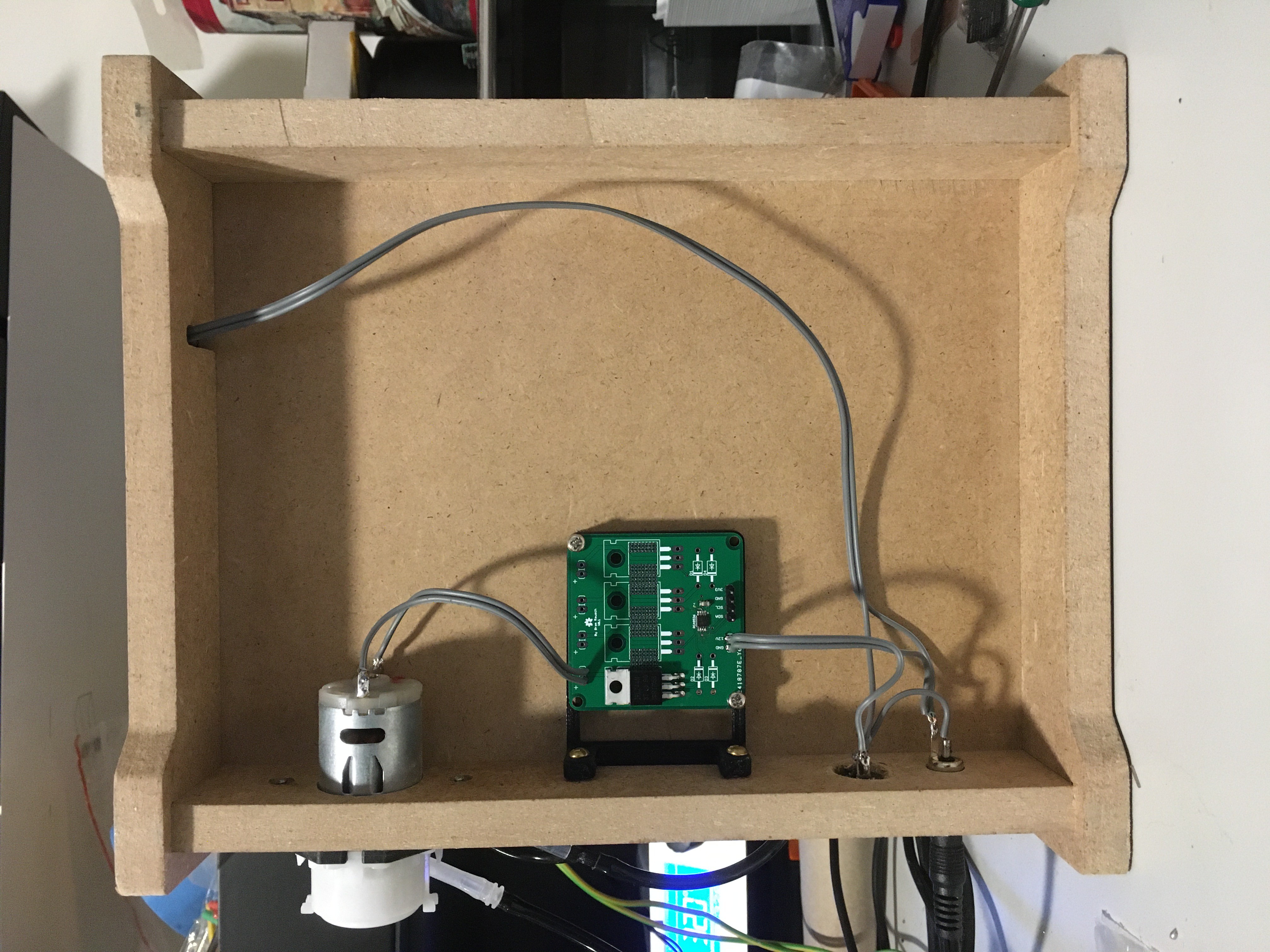

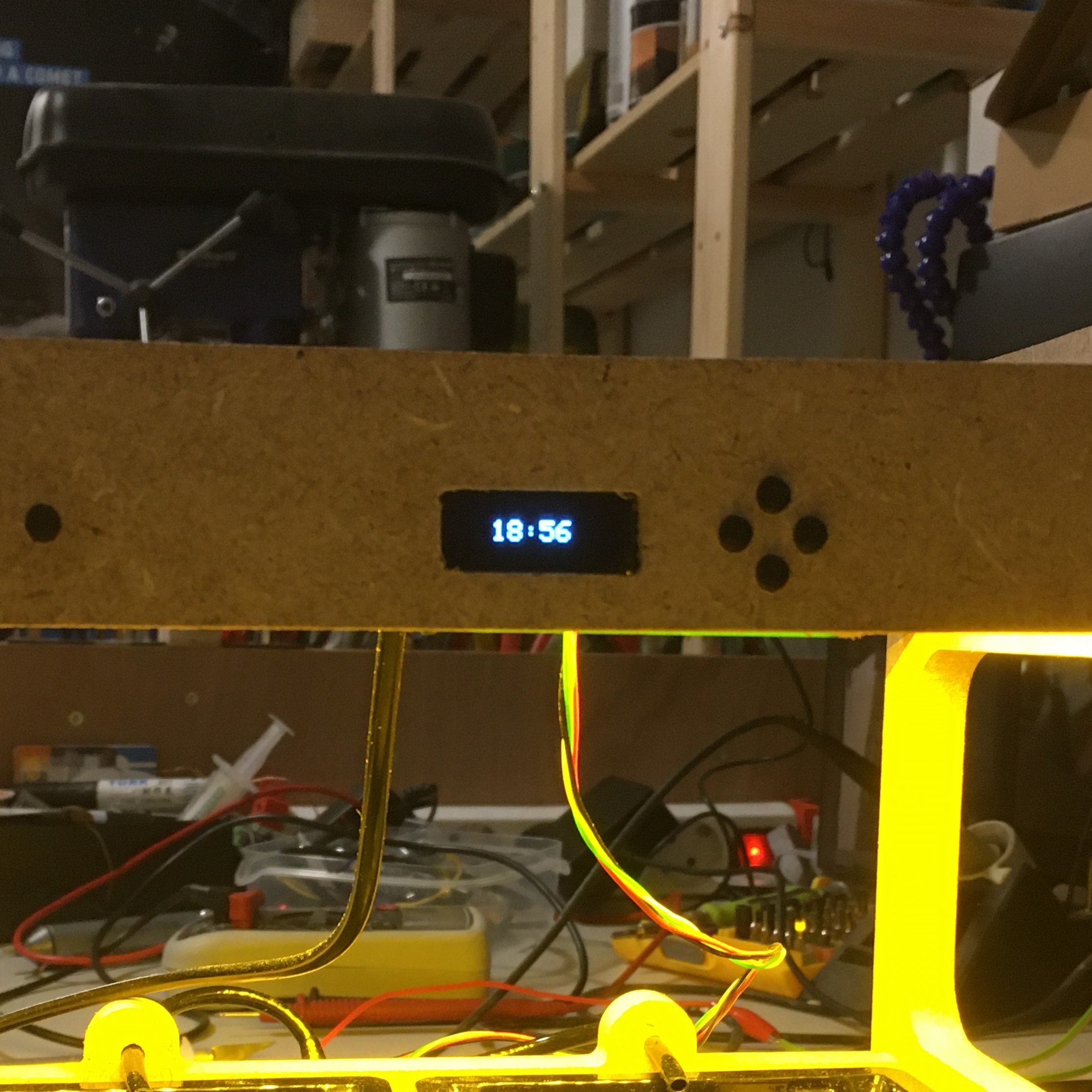

The system is controlled by a Raspberry pi with a custom Garden Automation HAT. This board takes 12V and converts it to the required 5V to supply the RPi. This 12V power is also used to power the lamp and pump and is controllable using the RPi GPIO driving two MOSFETs. The I2C bus available on the 4 pin JST connector can be used to connect a BME280 sensor and an optional HMI board. The three-pin JST connectors are used as a breakout for two OneWire interfaces that can be used for temperature sensors.

Pump

The current design uses a peristaltic pump with a 3x5mm tubing connection and that could approximately pump 90 ml/min at 12V.

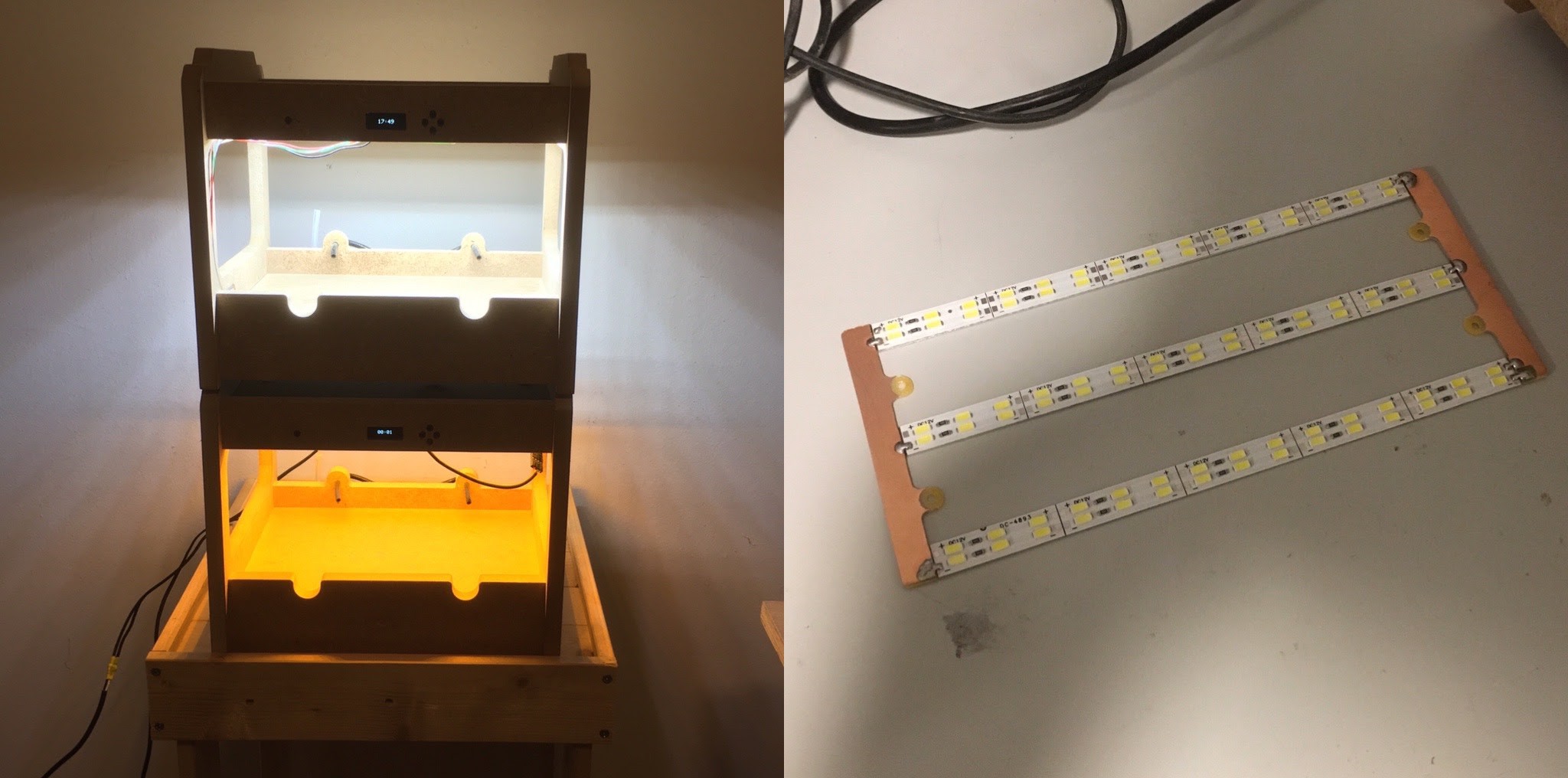

Lighting

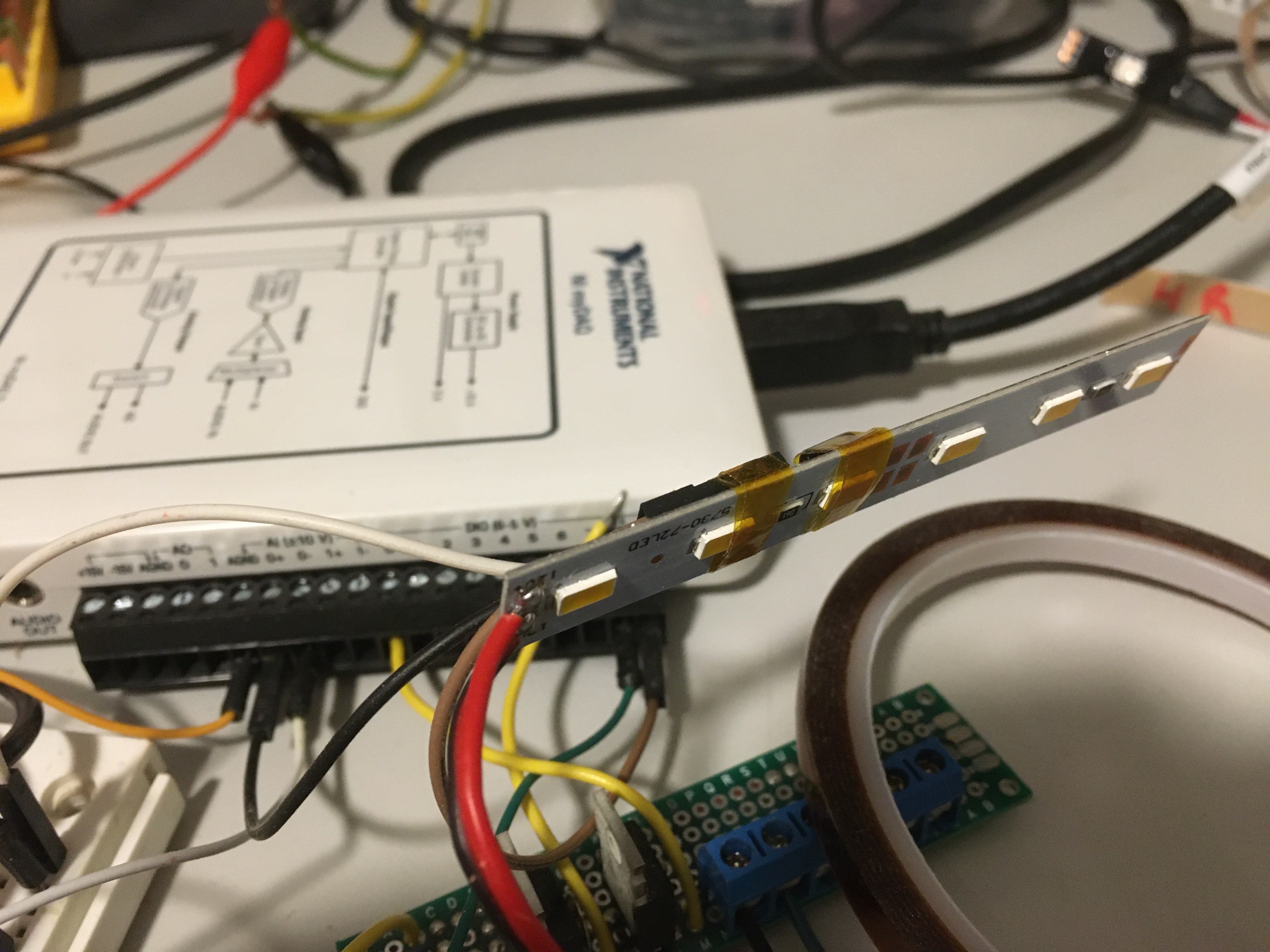

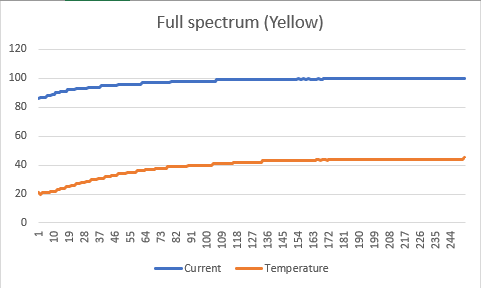

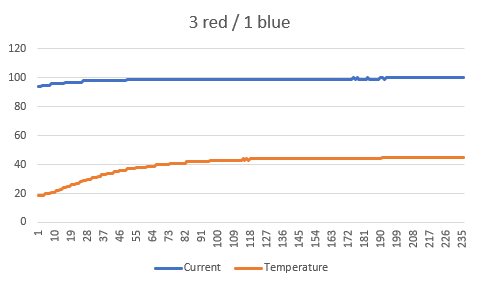

The best lighting options are currently being explored but they will most certainly be assembled in a light unit with passive cooling that is easily mountable.

Plant types

Microgreens

Microgreens are young vegetables with a high nutritional value and a great color and flavor profile. They are often seen as luxury food because they have a short shelve live and should be served fresh. That's why they are generally served in restaurants or shipped in containers without harvesting them. These small plants can be grown from almost all available seeds but a few common ones are sunflowers, broccoli, kale, and arugula.

Salad greens

Salad greens are plants grown for their leafs also called leaf vegetables or leafy greens. These plants can be used in salads but could also be used in stir-fried, steamed or stewed meals and they provide a lot of nutrition. Plants that could be grown under this category are endive, arugula, spinach, and etc.

Herbs

The definition of herbs is up to discussion but the use for most of these plants is to provide flavoring for food and drinks. They could be harvested and used fresh or dried, in the Microwth system it should be possible to grow mint, basil, parsley, coriander and hopefully many more.

bram

bram

Dewet

Dewet

Derek F

Derek F

doctek

doctek

Seth Fleming-Alho

Seth Fleming-Alho

I am very interested in agricultural automation production. After you release all the information, I will make one. What chip did you use? I have no experience in burning STM and other chips