The lion kingdom somehow went through college without enduring a lack of ventilation or cigarette smoke, but that all changed in the real world. The 1st night trying to sleep in a microscopic apartment a programmer could afford, with only 1 window, was brutal. Ventilation was an expensive perk.

For the next 3 years, lions relied on small fans in the window to get some minimal air flow, but lions wanted to do better. It was dusty & most neighbors smoked. A key requirement was replacing air in different areas of the apartment rather than just near the window, as common fans tend to do.

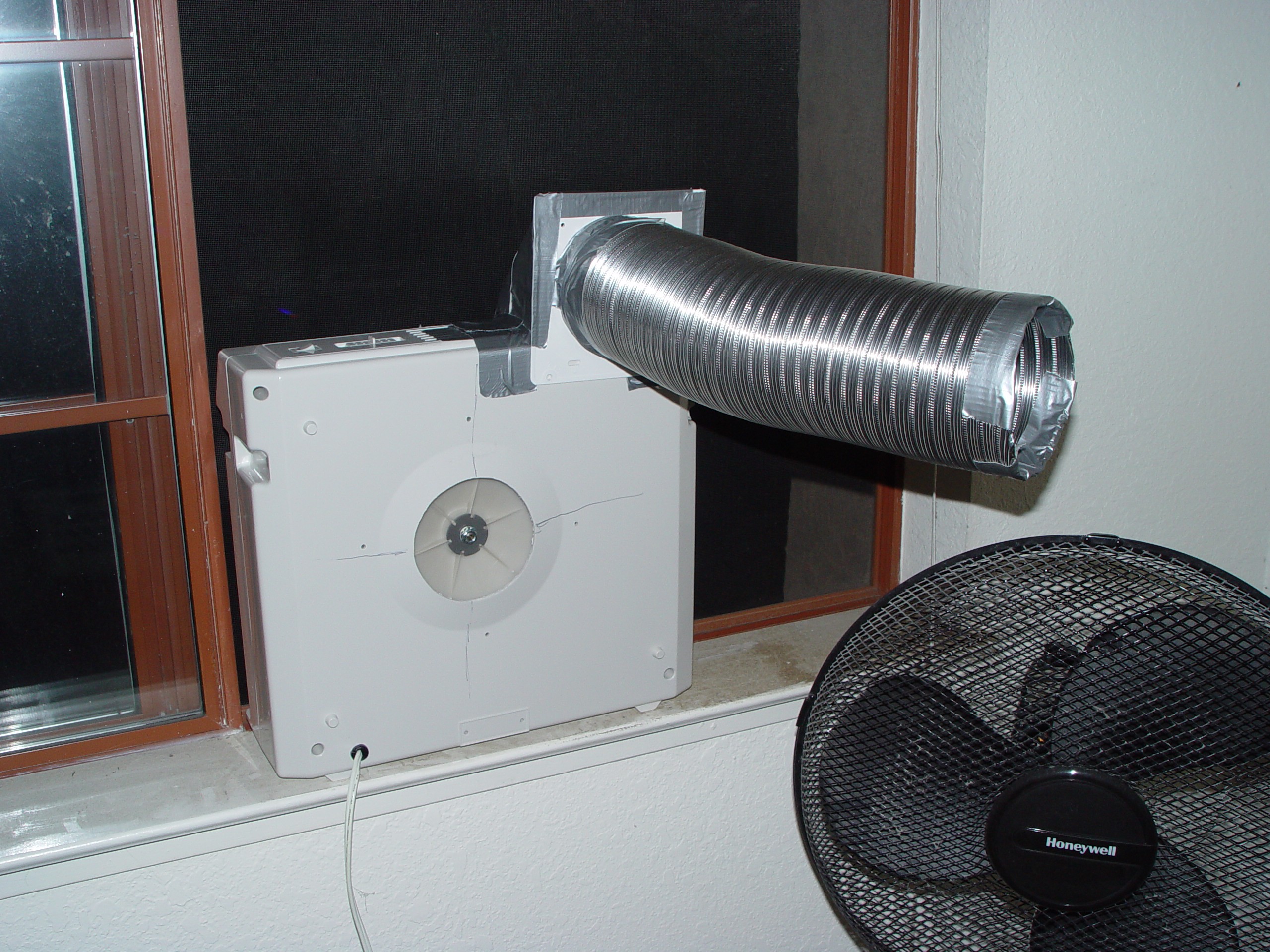

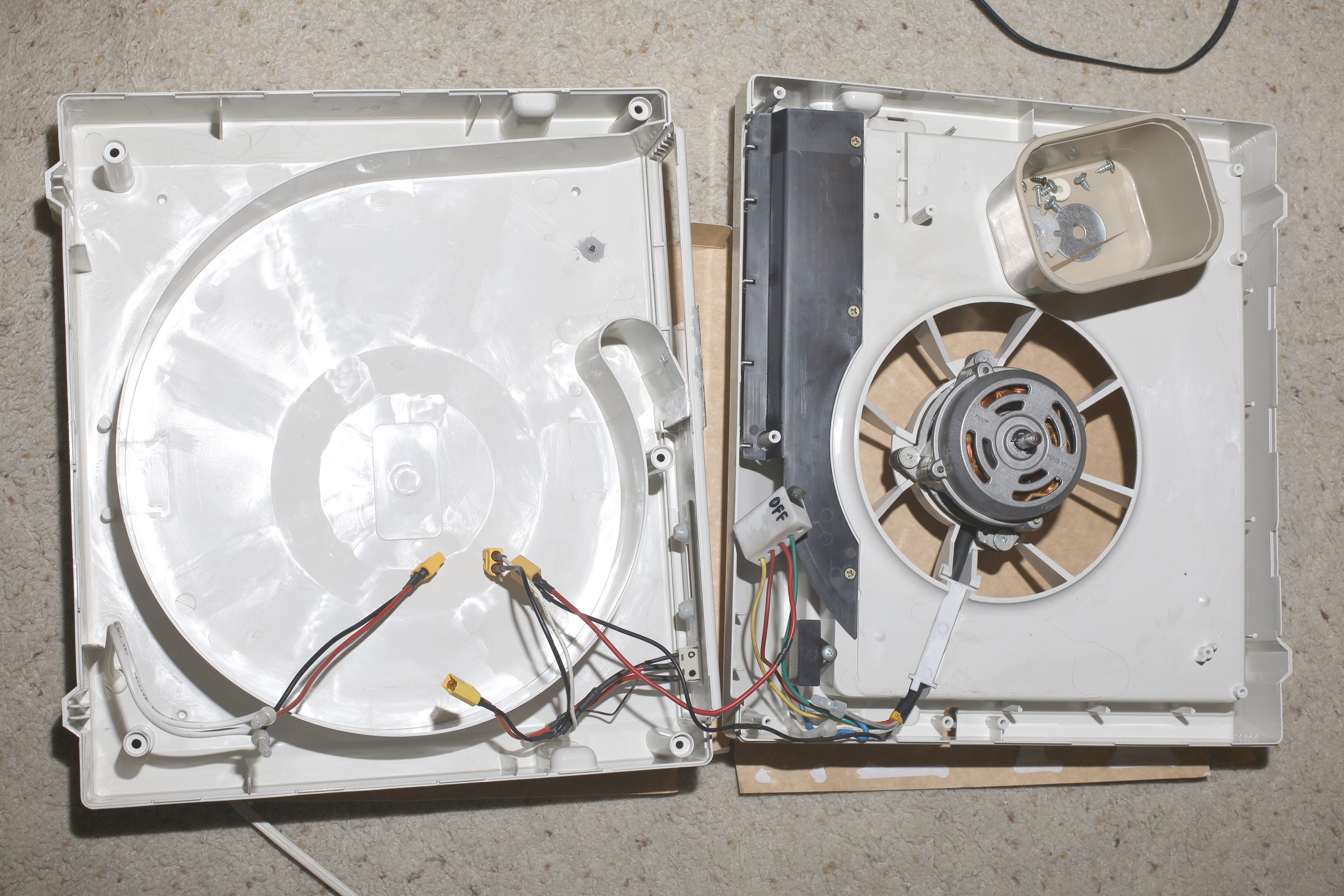

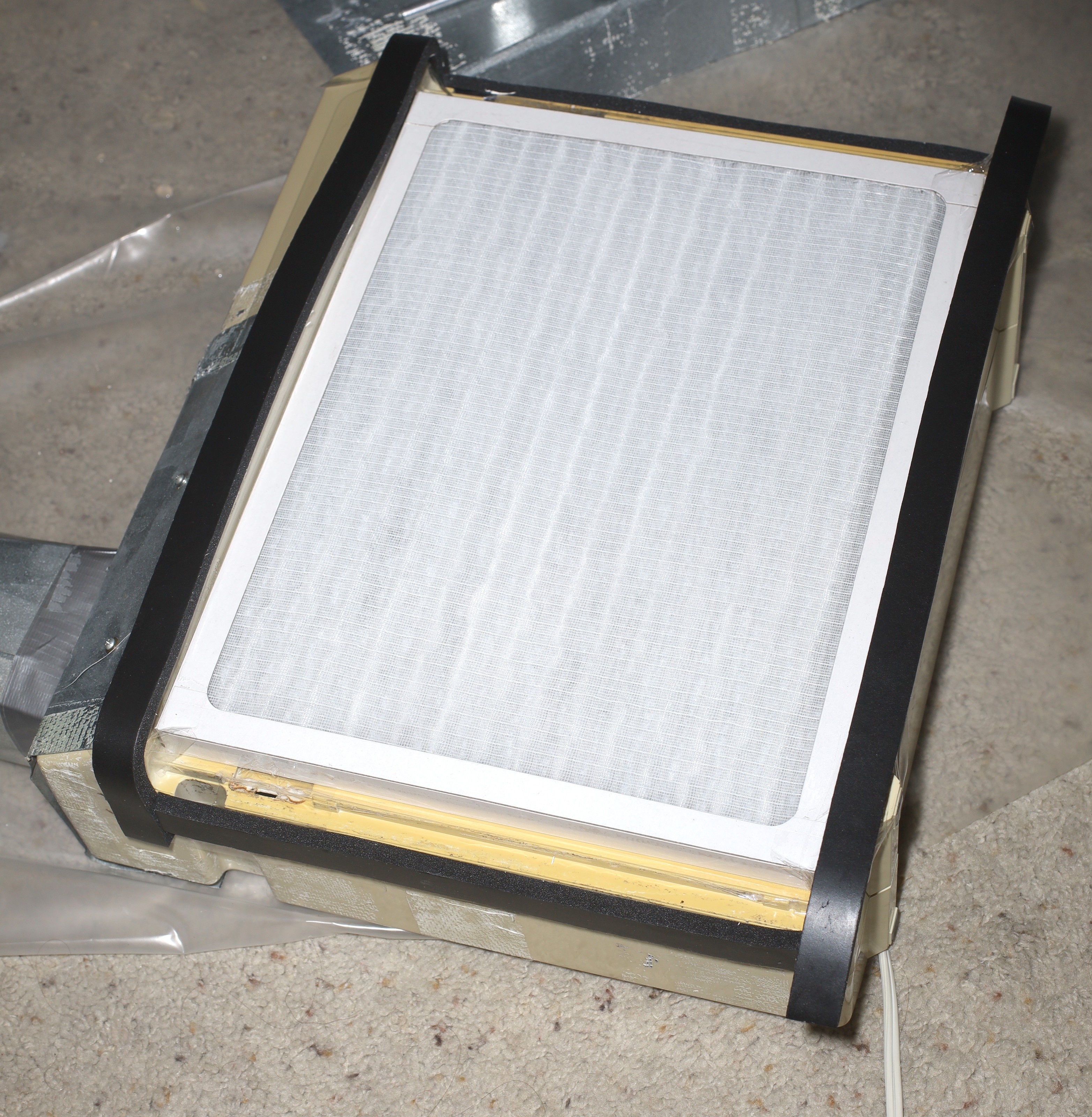

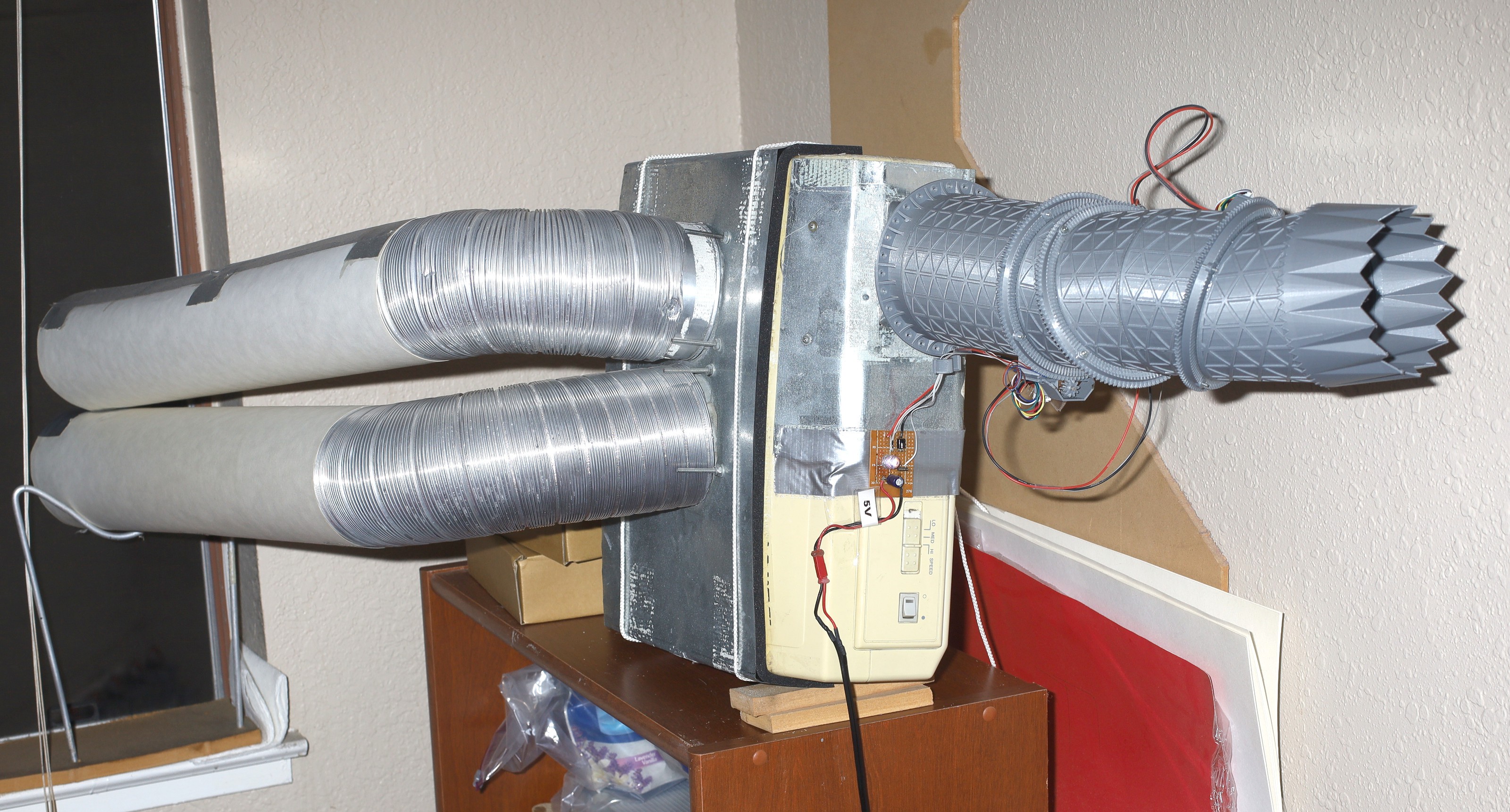

In 2003, the $35 Hunter 30055 arrived. With an air duct made from drying machine parts hacked on, it could blow air in any direction & the filter was easy to substitute with any HVAC filter after cutting it to the right size. It was powerful enough to quickly replace all the air in the apartment. It's no longer made & today's Hunters no longer have a hackable filter.

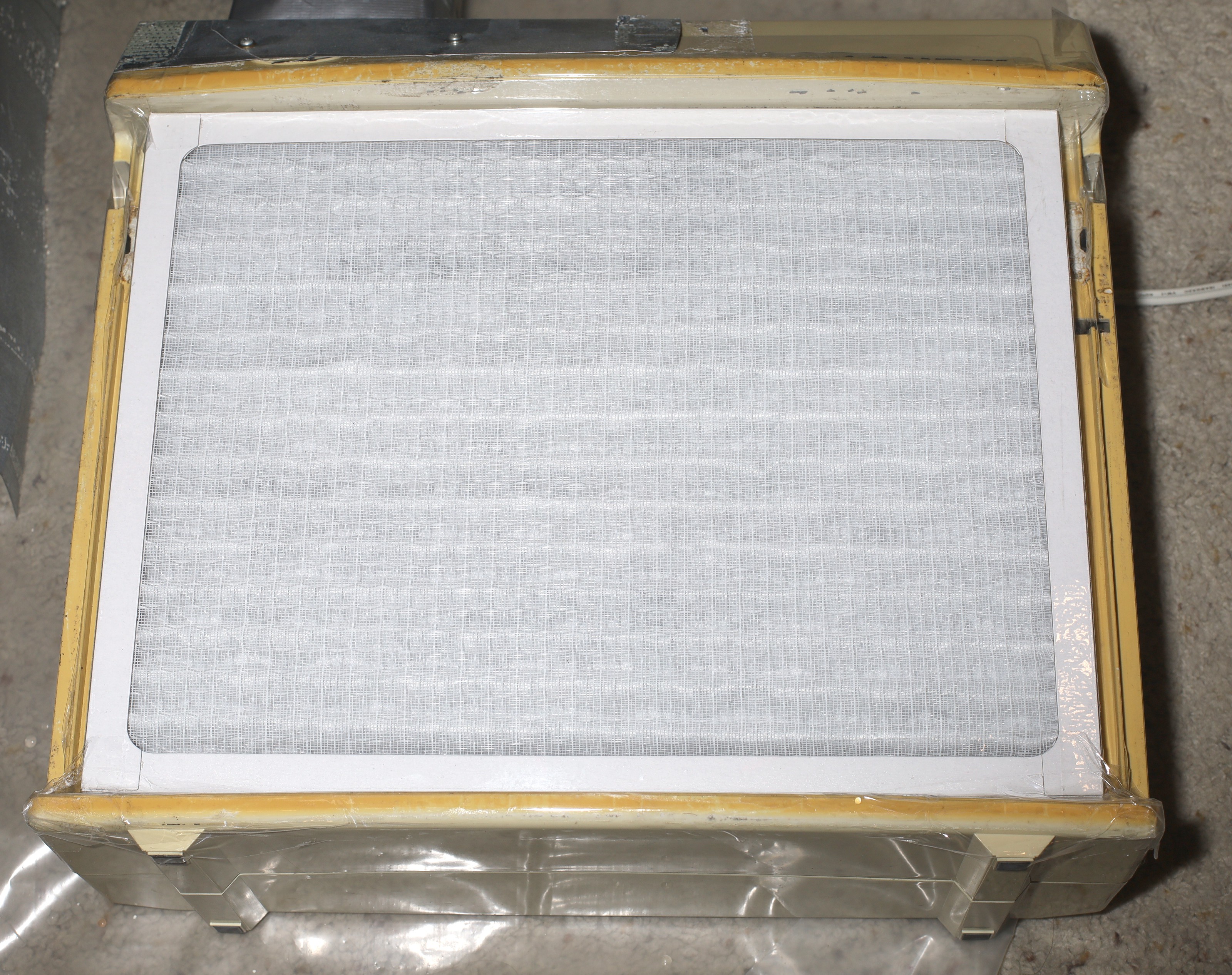

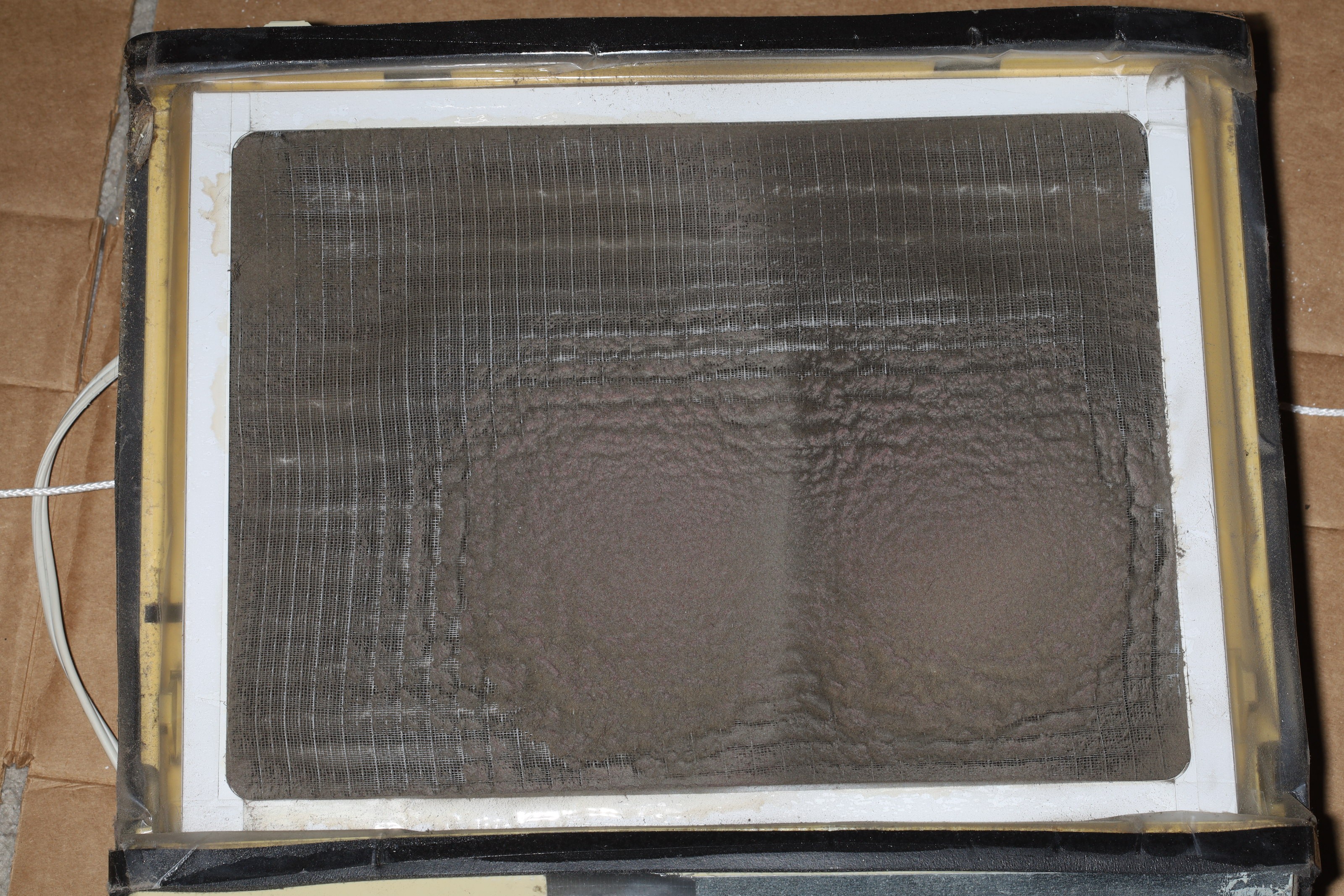

It was used without the filter for many years, before realizing the filter greatly reduced the dust in the apartment & the amount of cleaning of the blower. After resuming filter usage, the lion kingdom made sure to run it as often as possible, to keep dust out of the apartment as well as for ventilation.

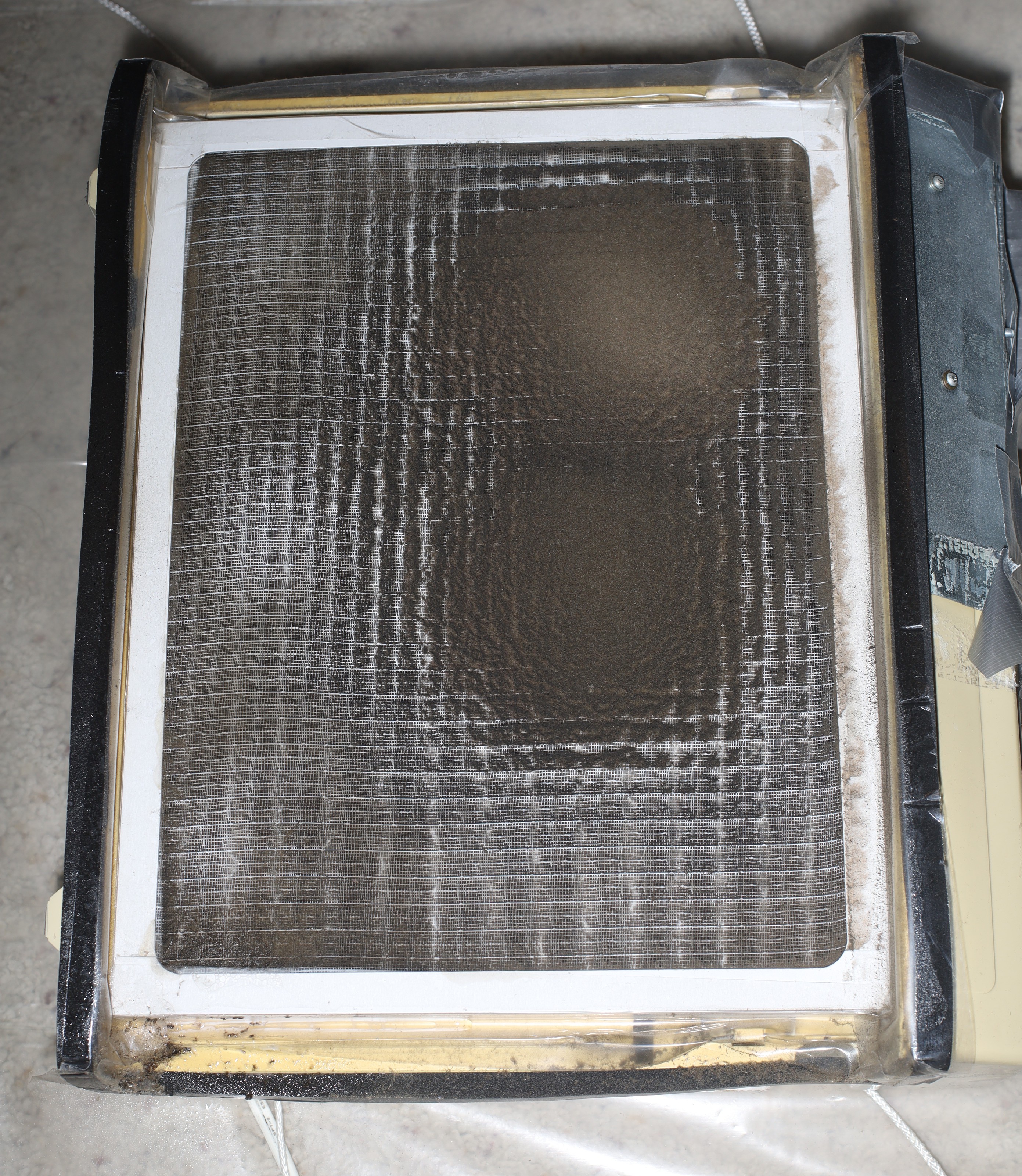

The filters have no effect on cigarette odor, but turn black so they do take out ashes.

In 2006, the decision was made to try to add air ducts from the Hunter to vents in different parts of the room. While fluid dynamics said the pressure from the blower should be at the beginning of a long tube, experience showed the friction inside the long tubes & leaks absorbed all the air movement. The blower was placed at the end of all the ducting originally intended to direct the output & the small vent was returned.

When it was new.

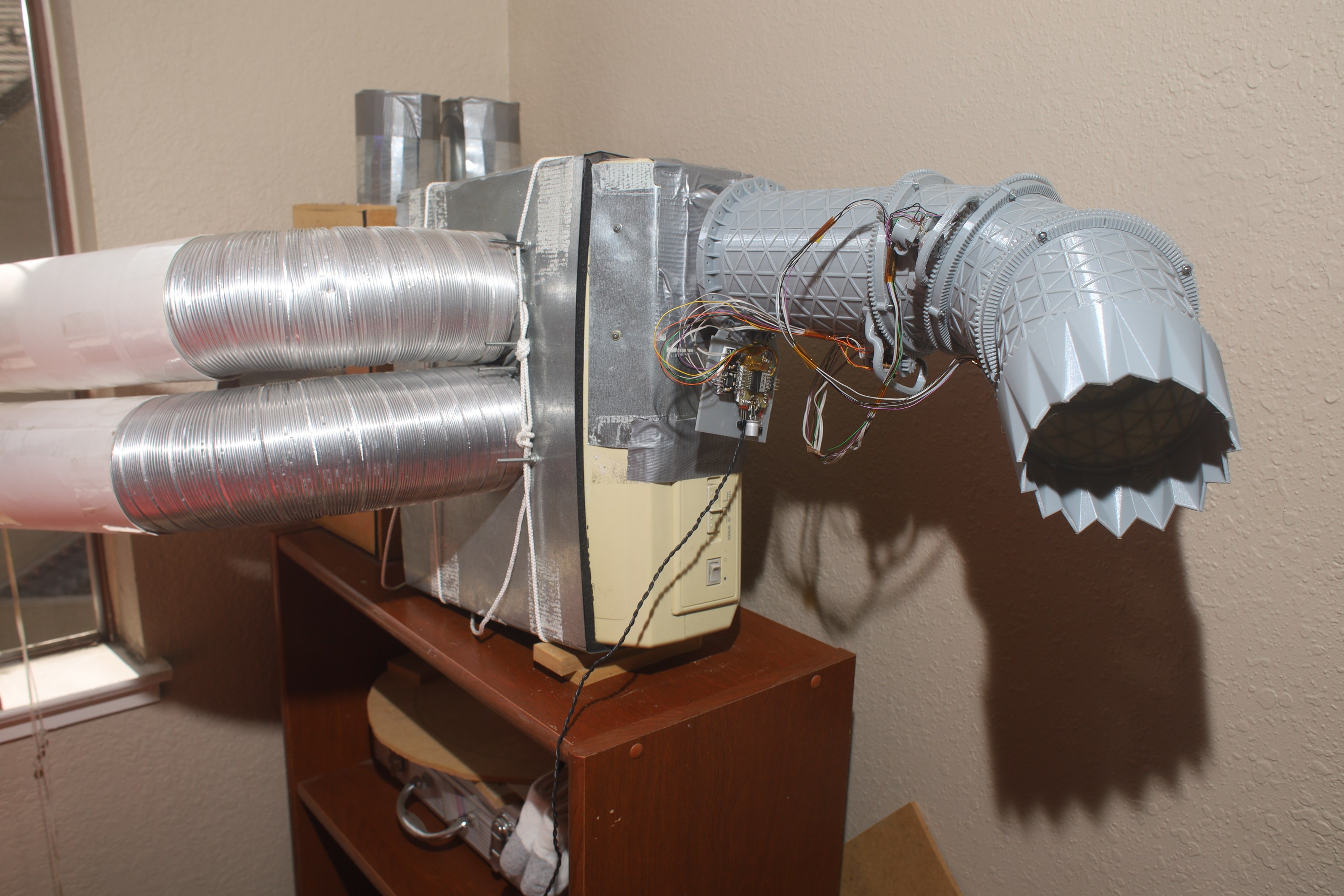

4 years later.

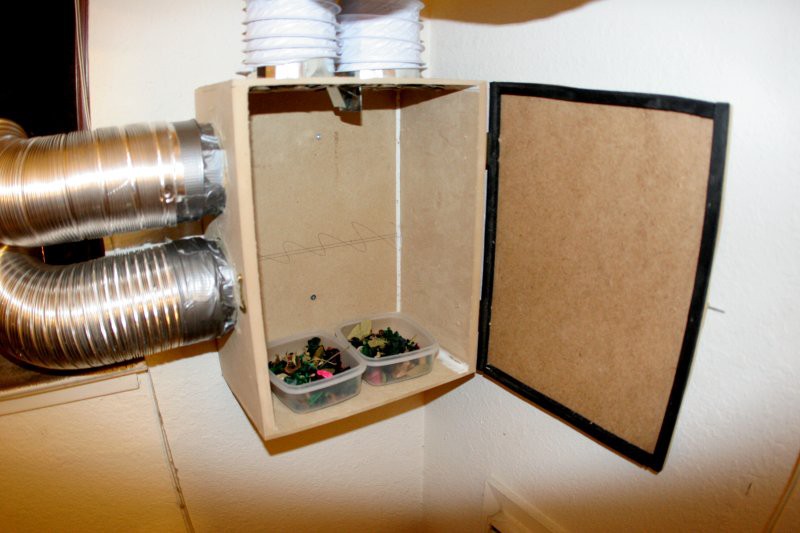

The air ducting could store fragrance, but it manely collected spiders.

This served for 8 years & provided the ideal airflow, a directly vertical blast when sleeping & a horizontal blast into any part of the room during heatwaves. The lion kingdom can't remember ever having trouble sleeping with that airflow. The problem was all that ducting collected dirt, it took a lot of space, & it required drilling a lot of holes into the walls.

The last iteration is simply resting on a shelf for other things to be stored in. The intake ducts are just posterboards rolled into tubes. The airflow is manely horizontal when sleeping, making it less than ideal. It still manages to replace the air in the apartment, but can't directly blow everywhere.

The Hunter 30055 being 17 years old shows signs of age. Eventually, it'll have to be replaced. As simplified as it is from its glory days, every winter involves 6 hours to tear down & clean spiders from every part.

https://hackaday.io/project/169663/log/183826-f-35-nozzle-air-vent

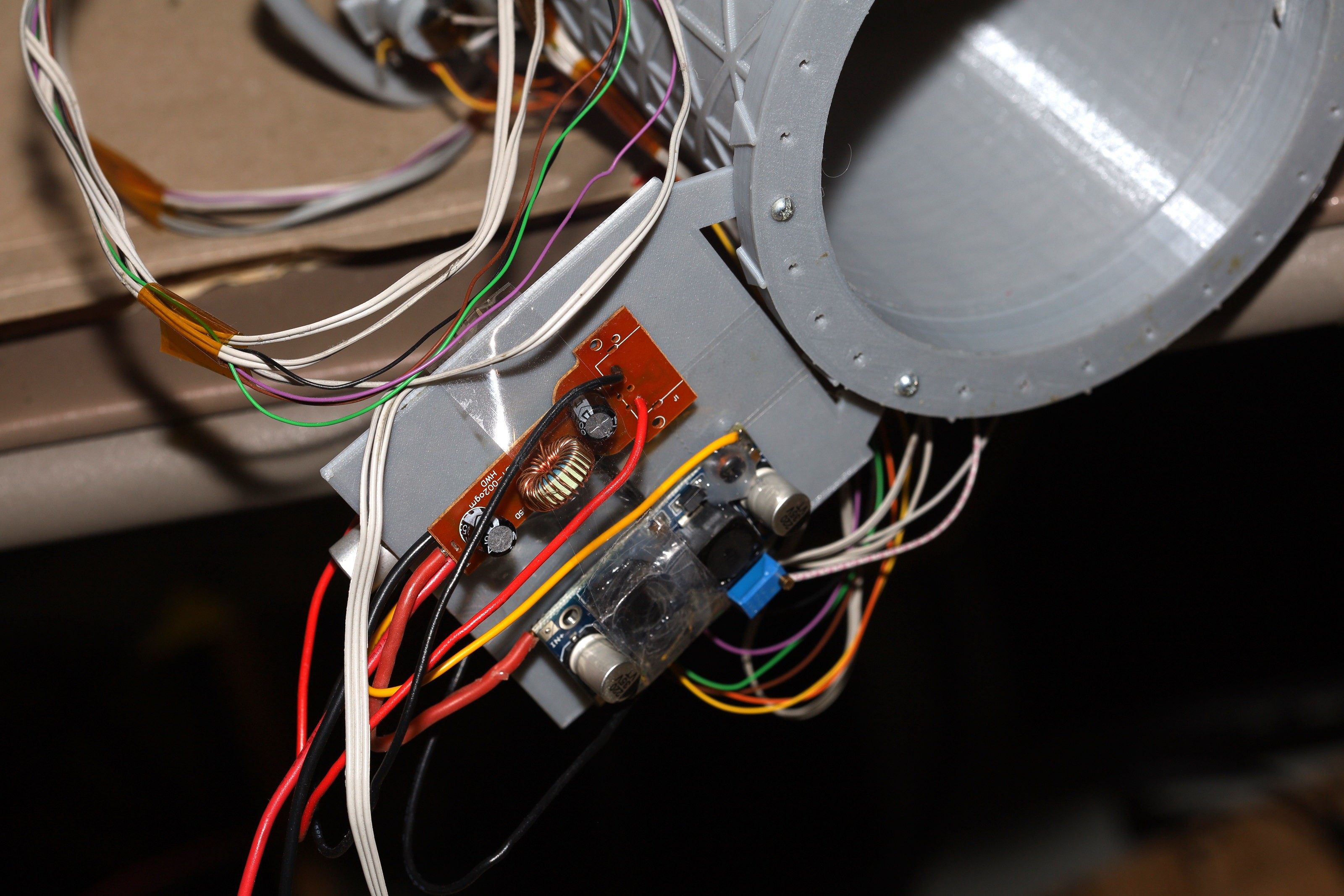

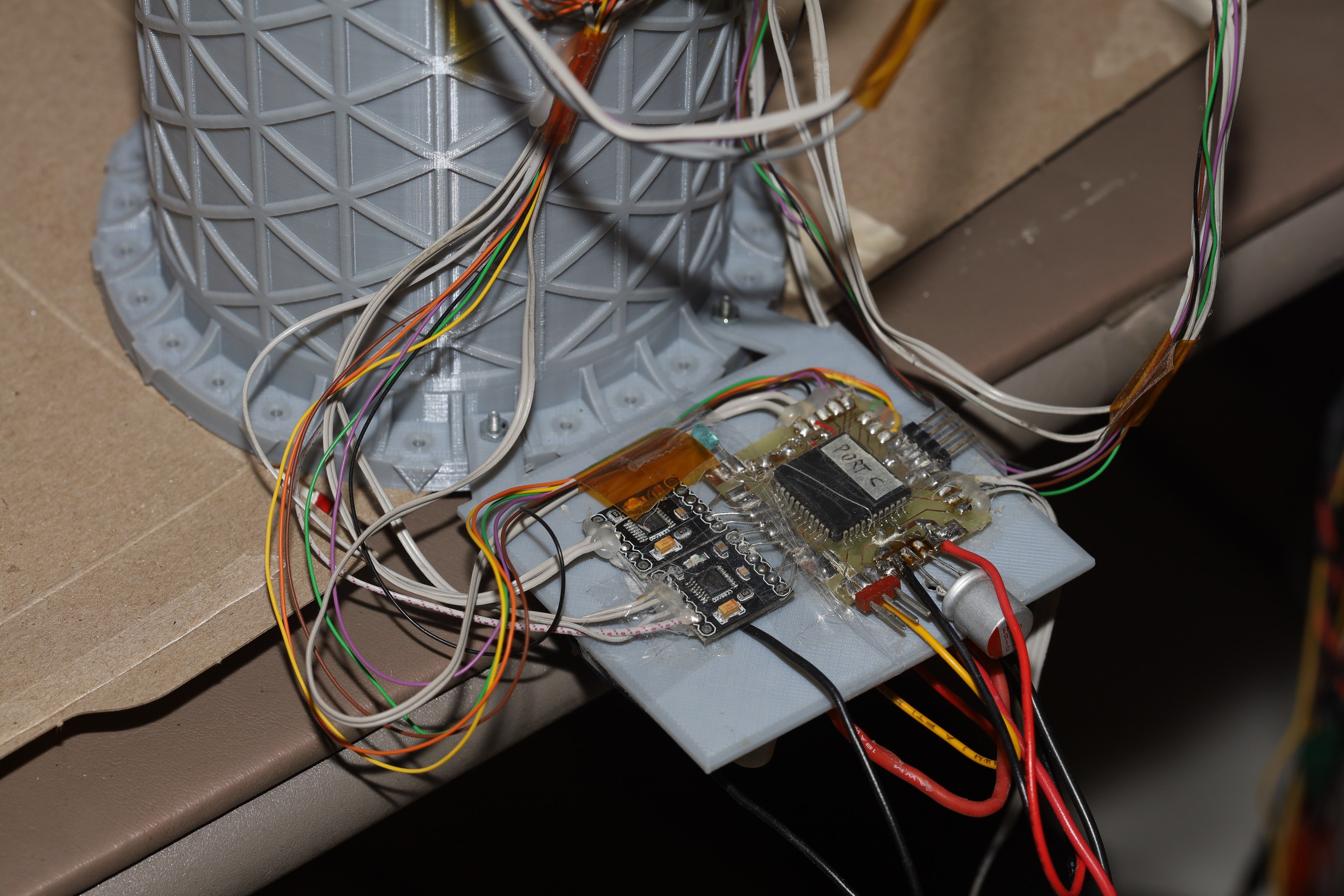

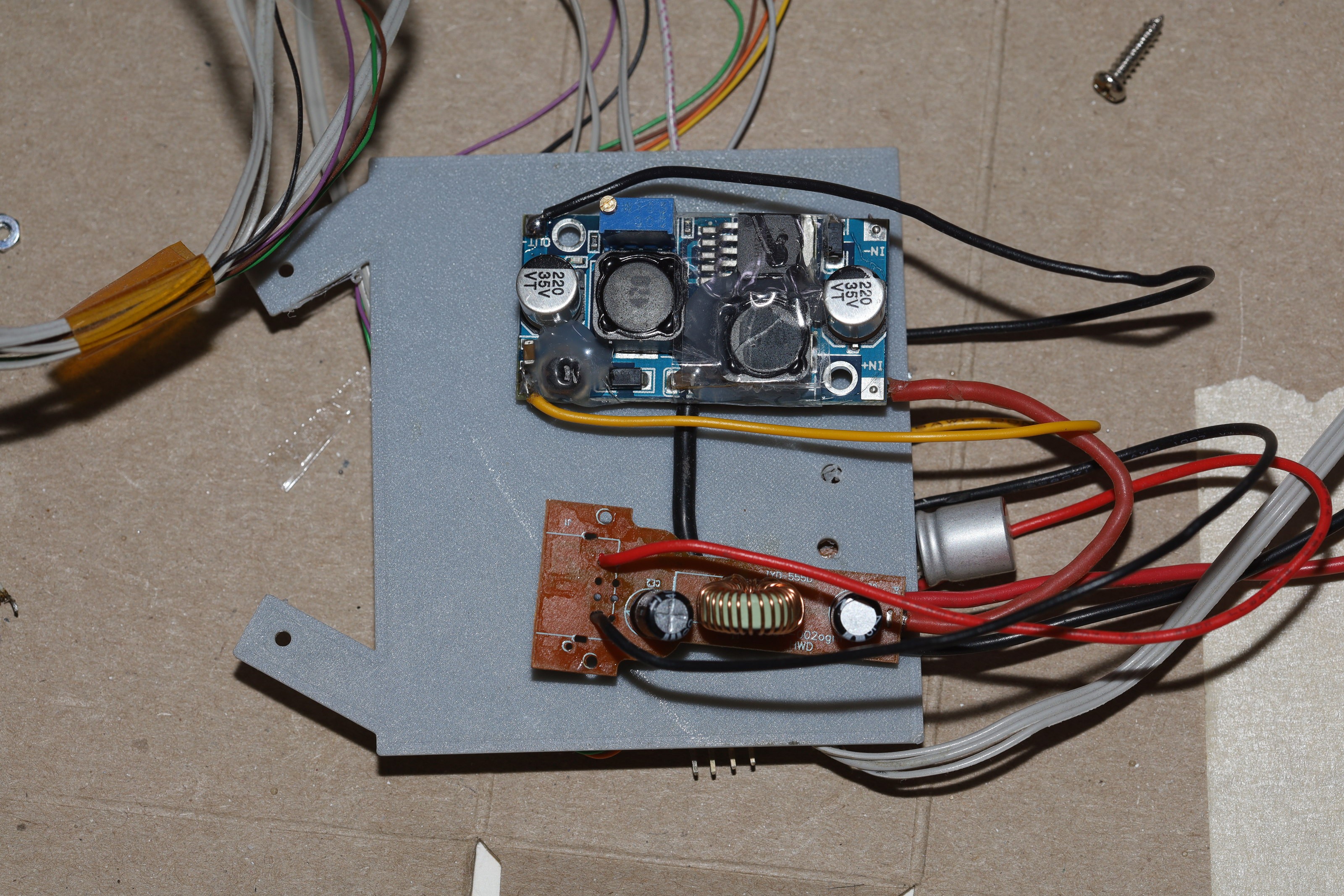

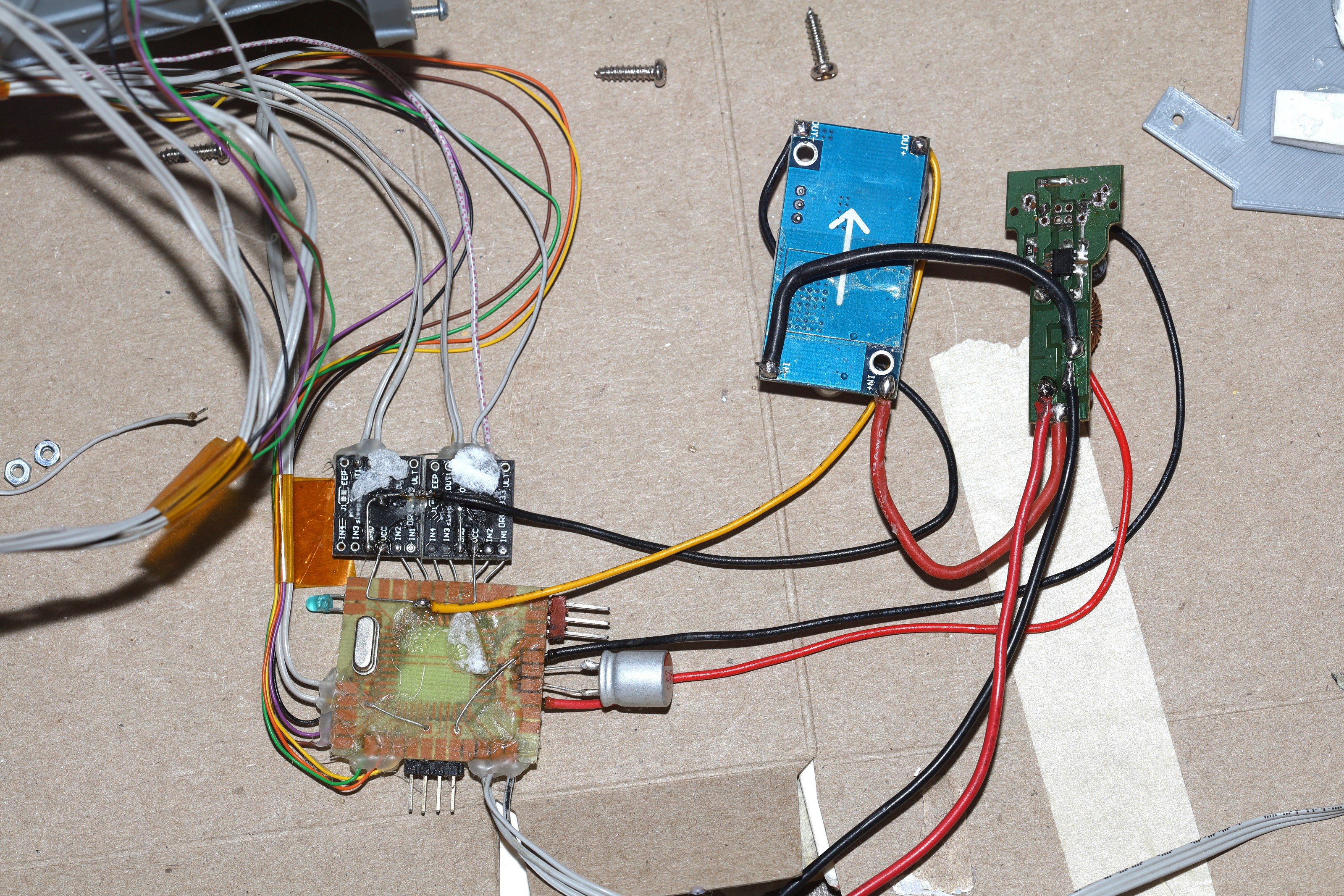

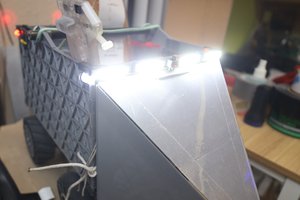

The blower finally got a remote controlled nozzle.

lion mclionhead

lion mclionhead

There is a desire to grind away these fiddly bits, but other problems are the curved areas. There could be attachments for the curved areas to make them straight.

There is a desire to grind away these fiddly bits, but other problems are the curved areas. There could be attachments for the curved areas to make them straight.