This project started by essentially copying Nerdforge's video on Youtube https://www.youtube.com/watch?v=yninmUrl4C0&t=16s.

Kinda got it working although I struggled with the coding side as his code did not work for me. Then I looked around for some more example patterns including some in the Arduino examples directory for the ESP8266. So we were off.

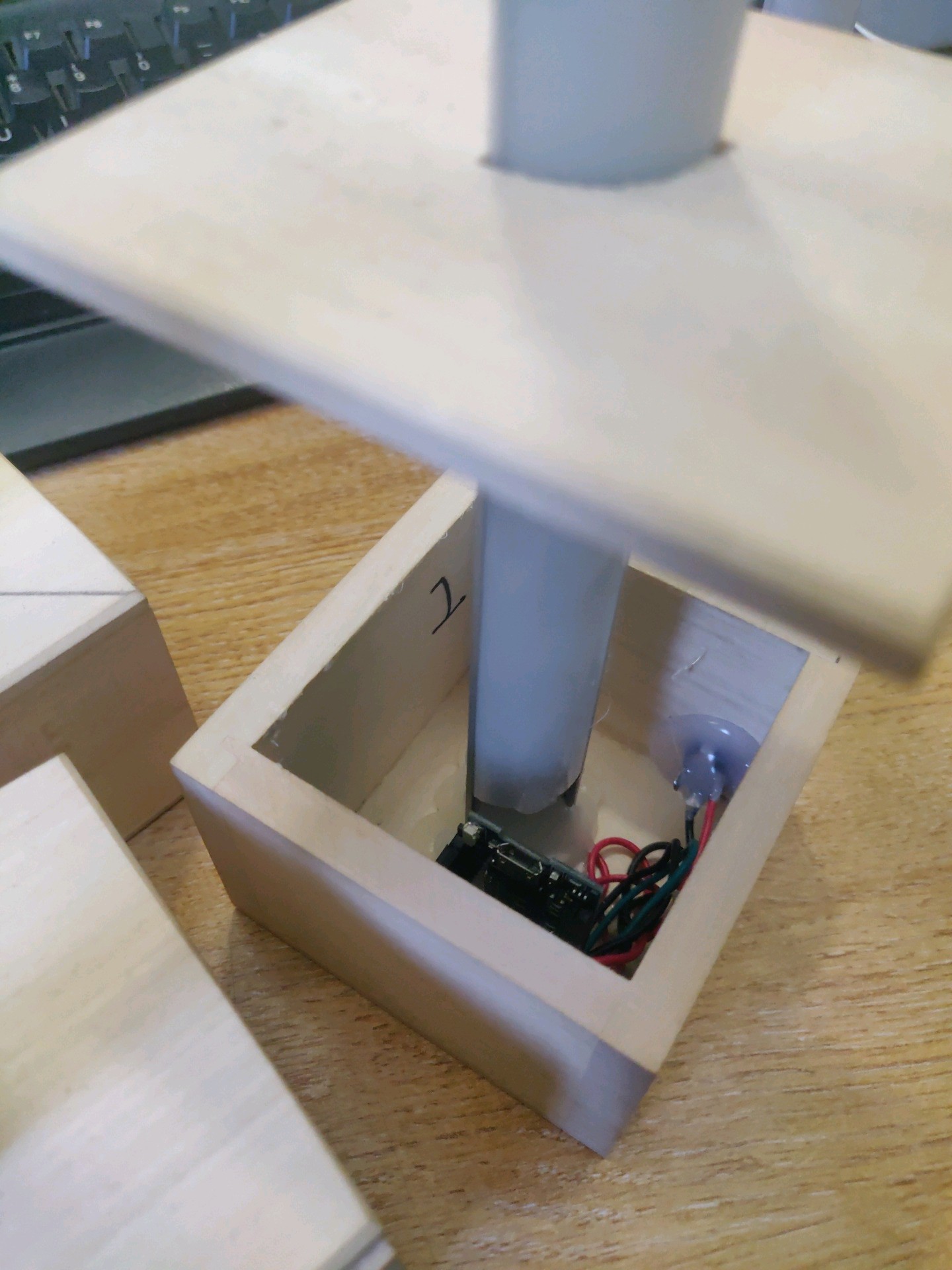

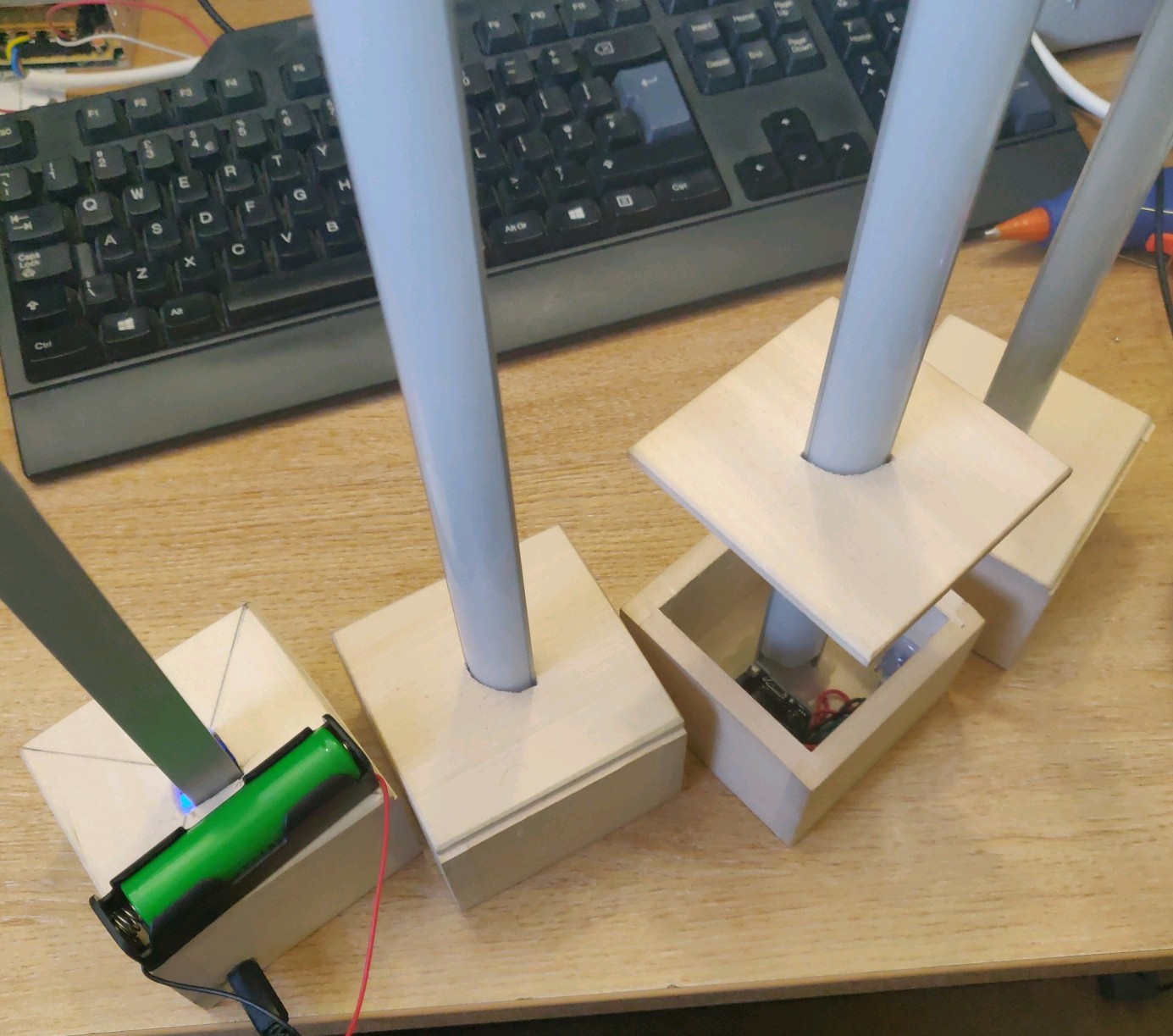

Initially I used a basic pattern library and could select different patterns by clicking a button under the black cloth on the master. There is also a microphone under the fabric listening to sounds. The data received from the microphone was sent via WiFi. All the patterns were stored on the slave units, which is OK. There are some slight differences between the slaves output and they can get out of time with each other as they receive the data from the microphone at slightly different times from the master.

Then, I remembered I had a SP105 LED controller and thought how easy it would be to use that in the master, read the data it was producing and transmit that to the slave units. Then all the slave units needed to do is react to the data it is receiving. Well, I fried the SP105, so, I bought a few SP107E LED controllers as they had sound reactive built in.

This is where I have got to. I am trying, unsuccessfully right now, to read the data from the SP107E and transmit it to the slave units so they react to the output recorded at the master.

If anyone has the experience and can point me in the right direction, please contact me. In the meantime, I will keep exploring the options.

Ron O'Sullivan

Ron O'Sullivan

jeromekelty

jeromekelty

Ben Delarre

Ben Delarre

markwarren.ee

markwarren.ee