The first step(no photos) was to remove the original insulation from the hotbed as well as the insulation I added.

I scraped it away with a plastic scraper to not damage the original heater in case I ever wanted to use it again. That left some adhesive residue which mostly came off after soaking it with water+dish soap and letting it sit, and scraping, and repeating. I removed the original thermistor and its kapton tape and removed a couple small remaining adhesive spots with Goo Gone adhesive remover.

Once that was done I removed the silicone with the scraper from around the power wires then desoldered those. I used a butane iron as it was able to get hotter than my normal iron. I melted some evil Lead solder into the existing solder on the board to reduce its melting point and as I was able to melt it I used a solder sucker to remove it. Eventually got the wires off and then used some desoldering braid to reduce the remaining solder. Then used the iron to make sure what was left was smooth.

Then cleaned the whole surface thoroughly with dish soap and water and then alcohol.

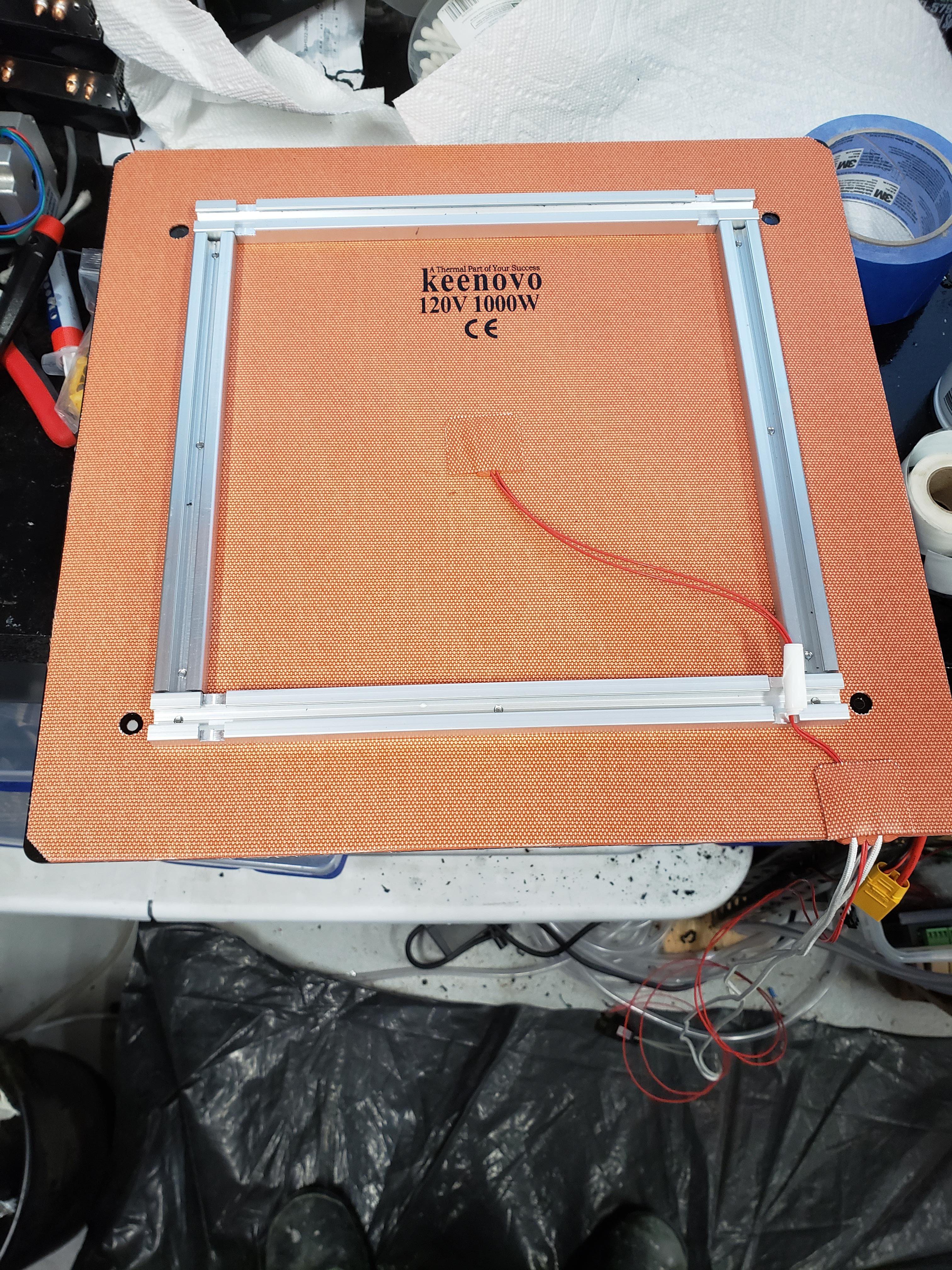

I folded back about 1" of the covering of the adhesive on the new heater and carefully lined it up with the screw holes and applied it, then while lifting the heater slowly removed the rest of the covering of the adhesive while pressing the heater onto the bed being careful to not get any bubbles.

Then I left heavy things on it over night.

Then I put the metal crossbars back on and tightened them loosely.

Then I briefly heated the bed and tightened the cross bars some more.

Then I put a connector on the thermistor and matching the existing connector and set it on the printer. I hooked up an SSR(details to follow) and recompiled the firmware on the printer for a Type 11 thermistor which looks correct. I also took this time to upgrade to a 170 max bed temp.

I then ran it up to 150C and carefully finished tightening the screws and let it cool and removed it to insulate and ground. The white bit is self fusing silicone to prevent the thermistor wires from chafing on the aluminium.

I pushed a little slack in the thermistor wires and slid the aluminium bracket under them rather than smashing them.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.