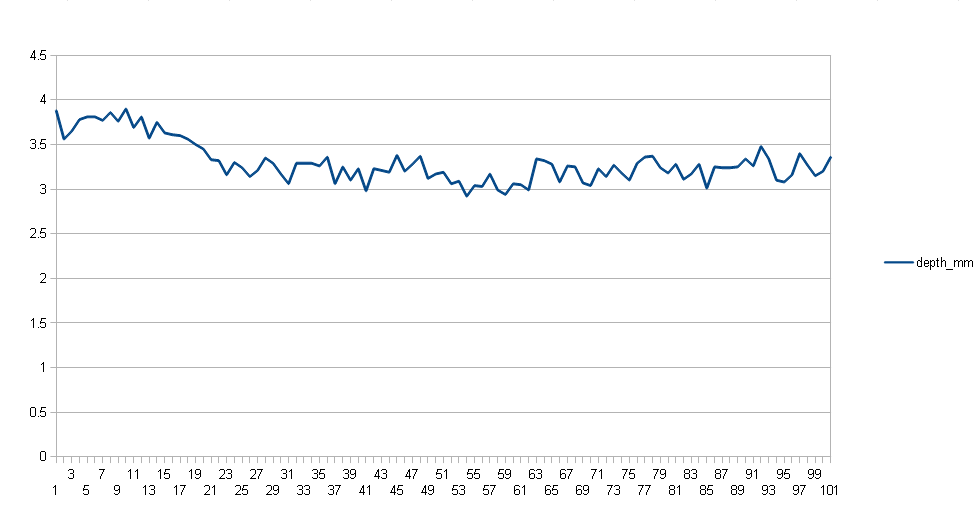

After running my last test I had some unexplained results where running 4 passes cut less deep than 3 passes. This is not the first time this has happened, and I don't think I can blame it on a measurement error. Anyway to try and dig a bit deeper into this I wrote a script to cut a 20 mm line at 100 mm/min and 80% power on my 30 w NEJE laser. The script cuts the same exact line over and over again, each spaced 2 mm apart. By measuring the depth of cut of each line we can see how much variation there is.

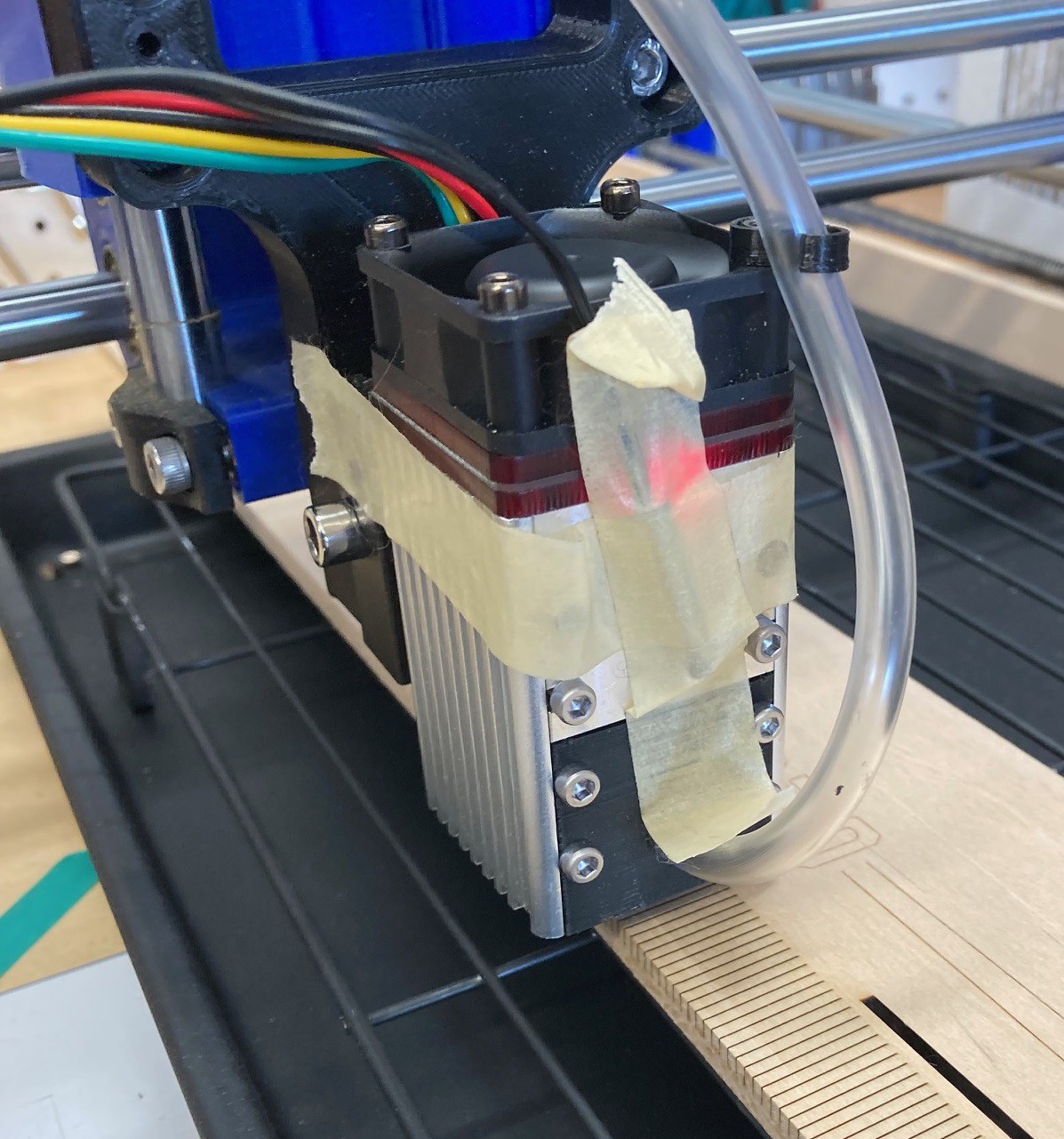

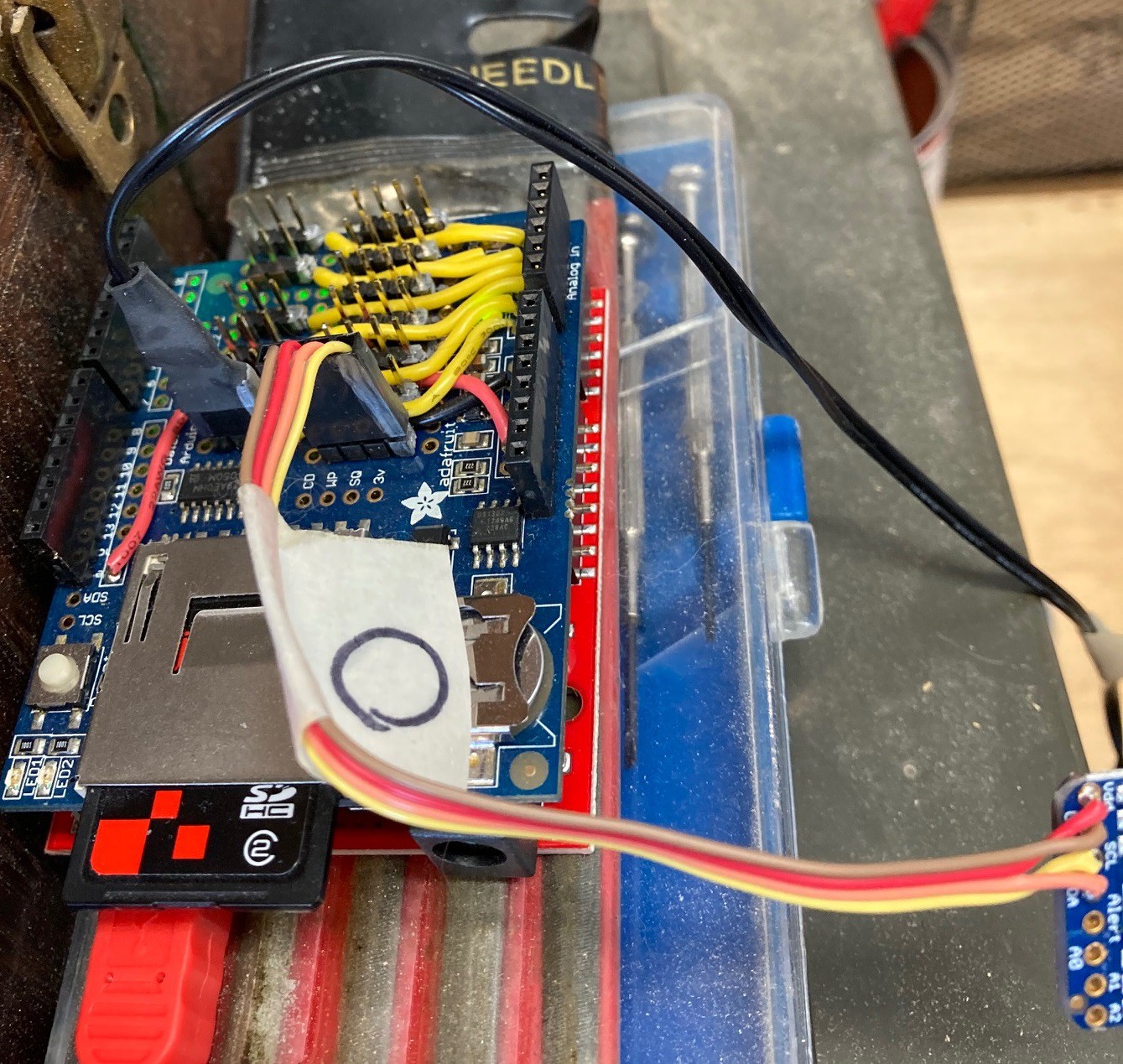

One idea I had was that the laser was heating up and loosing power when running the same cut back to back. I happened to have a temperature data logger that I made from an old Arduino a while ago, so I pulled it out and strapped one of the temperature probes to the front of the laser.

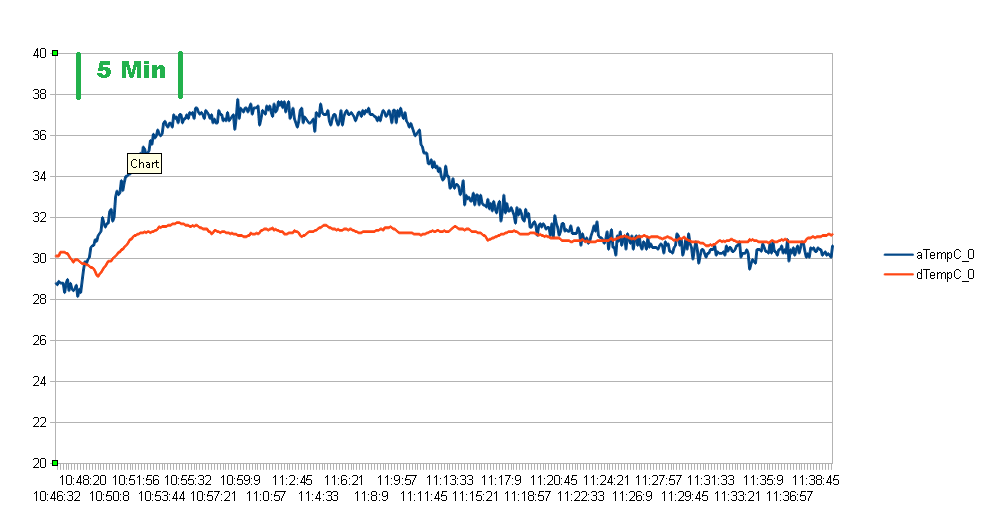

You can see from the above plot that the temperature rises from room temperature (28C or 82F) to 37 C (99F) after 5 minutes of continuous operation. I let the thermometer continue to log after the job finished, it took another 5 minutes or so for the laser to cool back down to something approaching room temperature. It would probably be best to run the fan for at least 5 minutes after finishing a job so the laser can cool down quickly.

I measured the depth of cut of all 100 lines and came up with the results below. The max variance between the deepest and shallowest cut was about 25% and there seems to be an inverse correlation between the temperature of the diode and the depth of cut. It is clear that there is quite a lot of variance between cuts, and that the laser looses power as it heats up, but I don't think it is enough to explain the fact that 3 passes produces a noticeably deeper cut than 4 passes. In some cases the difference was almost 2 mm!

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.