Introduction

Water condensation on surfaces is a phenomenon that, depending on circumstances and applications, can be a desired or unwanted effect. While psychrometric devices can provide information about the thermodynamic properties of the water vapour-air mixture, few devices are available to detect and quantify the actual build-up of dew droplets on surfaces. Even less are capable to quantify the concentration of liquid water in an aerosol, that is when relative humidity goes beyond 100%.

This sensor addresses this problem providing a way to detect and quantify the amount of liquid water particles in air at proximity of the sensor's sensitive surface, or detect and quantify the amount of fine water droplets deposited on its sensitive surface.

This project has undergo throughly experimentation to test the capabilities of the sensor and particularly of various design and configuration of the electrodes that form the sensitive area of the sensor.

How it works

It works exploiting the well known capacitive effect (self capacitance) when a body is influenced by an electric field. Ultimately it can be seen as a peculiar version of a capacitive sensor. Electric fields are generated providing charges to the electrodes through a current source, and a comparator detects a specific level of voltage calibrated on the limit of the circuit, and removes the charges to start a new measurement cycle.

TL;DR

Basically it is a constant current source that charges a capacitor created on the PCB and designed in a way to magnify the projection of the electric fields, converting the measured capacitance into a variable pulse width signal that is carried through the same line that powers the sensor itself, to an external processor that reads the signal and controls the power cycle of the sensor to limit the risk of self-heating.

It is a pretty simple circuit, you know, often the challange is making things simple and efficient.

Projected fields

Unlike in a typical capacitor, the generated electric fields are projected toward the space above (and below) the sensitive area thanks to the design of the network/grid of electrodes. These projected fields expand the sensitivity to the air above the sensor's sensitive area.

When exposed to air (or any other gas for the matter) the sensitive area projects the electric fields through the air (or gas) and if any solid particle is floating in proximity of the electrodes, it interacts with the electric fields causing a variation in the mutual capacitance composed by the electrodes, the air/gas gap, and the particle. This variation is related to the dielectric permittivity specific of the material of which the particle is made of. Thus in the case of water (liquid, at 25°C) the difference between the relative dielectric permittivity of air and water is about 80 times larger for the latter.

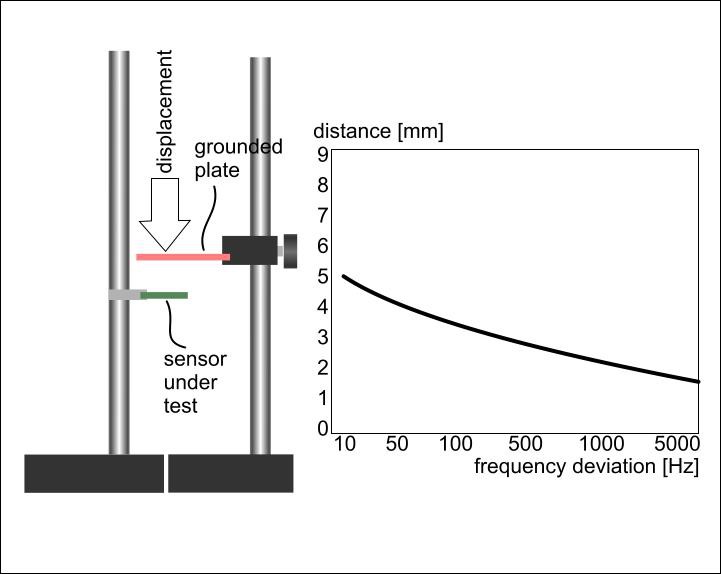

An experiment was made to test how far the fields are projected. As expected, there is no linearity and a cut off distance has been set to discard non significative variations. It was assessed that the sensitivity significantly starts from about 5 mm above the sensitive area.

Effect of droplets build-up

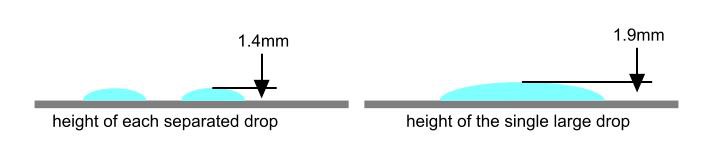

Even the build up of droplets show a limited linearity. In an other experiment aimed to demonstrate this, resulted that a single drop with smaller surface area, but thicker, produces a larger increase in deviation than the thinner drops that in sum cover a larger surface area.

Comparison with other similar technologies

Capacitive sensing is a well known technology in the state of the art. Proximity and touch sensing have been developed using open plate capacitors[1], with circuits that are based upon frequency deviation[2] or upon frequency excitation such as the one integrated in the FDC1004 produced by Texas Instruments[3].

Even though the sensor described in this project has same apparent similarities to the one existing in the prior art, the controlling circuit is based upon a constant supply of charges rather than frequency deviation of an oscillator or amplitude detection through frequency excitation.

It can be considered therefore a novel approach to detect the proximity of particles or even bodies.

Applications

One possible application is the measurement of water condensation on buildings' surfaces, where multiple points can be monitored at the same time at regular intervals. Similarly, can be used to detect the condensation of water in machineries and to prevent rust as actual liquid water particles are the major cause for the development of ferric hydroxides (commonly known as rust).

An other application is to monitor the build-up of condensed water on stocked goods on multiple shelves in warehouses to prevent the growth of molds.

A further application is the control of the amount of liquid water particles suspended in air in industrial processing, such as in some leather and chemical processes where a very fine mist is sprayed, or to prevent the growth of molds and fungi in crop and food storage.

Because a plurality of sensors may be required in some applications, the sensor is designed to be cheap, outputs a robust signal, and requires as little as possibile wirings.

How it's made

Accordingly to the functional diagram that can be seen in the gallery, a source provides the charges that are accumulated on the electrodes that are part of the sensitive area and are represented as a capacitor. A comparator detects the strength of the electric field generated and upon a limit set it starts a pulse generator that provides the discharge of the accumulated charges and an output pulse that, through a transistor, shorts the power supply returning to the controlling unit (based on a microcontroller) the information in time ratio (or in frequency).

To avoid self heating that could interfere with the measurement the microcontroller cycle the power to the sensor and selfcalibrate against a fixed hold time. The arrangement that uses a single wire to provide power and the signal back, allows an easy deployment of multiple sensors with a reduced footprint.

More information

For more information watch the video at my channel Accidental Science following this link:

Also you can read the paper with references and citations:

https://www.accidentalscience.com/docs/water_aerosol_sensor.pdf

Claudio G. Hutte

Claudio G. Hutte