The FLAG prototypes are able to light at least 98 LED's wired in series, fluorescent lightbulbs, or any loads that like a high-voltage-low-current output. Wouldn't it be nice to convert the FLAG output to a low-voltage-high-current output for powering electronics, or to trickle charge a small battery? Historically this conversion has been difficult to do efficiently for influence machines.

Just in time, comes the invention of the FSCC (Fractal Switched Capacitor Converter)! This converter circuit was developed at Chongqing University for a different type of generator with a similar output to a FLAG. The FSCC charges capacitors in series, and discharges them in parallel, in such a way that it works like a transformer, at high efficiency (94%), and with minimized voltage drop from the diodes.

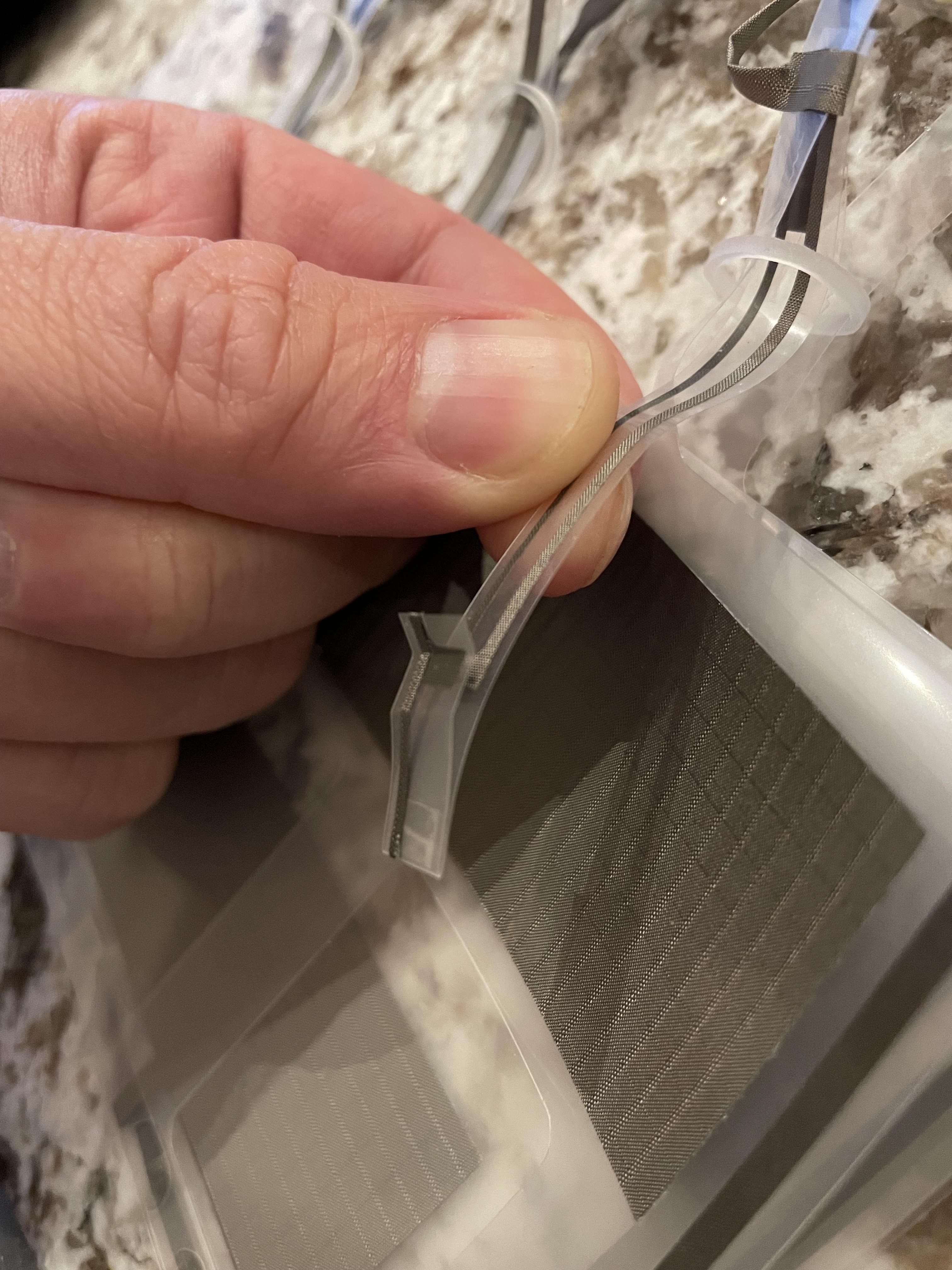

I ordered the diodes (1N4007) and capacitors (22nF) from Digikey, and built the 96 unit FSCC converter circuit from the paper on a breadboard, to give it a try with the FLAG. To operate, the FSCC requires that a switch is contacted on every stroke of the FLAG, so I made a small flat switch that fits inside the FLAG. Ideally, it should be contacted at the moment the inner layer is flat against the outer layer. With all the effort I went through to remove the surface contact switches from the FLAG, I'm not thrilled to add one, but this is just a test to see if this new type of transformer will really work. Below is a picture of the switch- it is folded over and bent with a small kink in it so that it will stay open until the FLAG squeezes it a little each oscillation, closing the circuit.

Before the FSCC, the FLAG could not light any LED's in parallel- it only makes enough current to light a lot of LED's in series. On this first attempt, the FSCC allowed the FLAG to light 17 LED's in parallel including 2 large LEDs (12 shown in the below video). I find this hugely exciting! With a properly designed FSCC, FLAGs will be able to efficiently produce any voltage required, at high efficiency.

I could see in this test, it was important for the switch to open and close at the correct time and with good contact, which was affected by the angle and amount of kink that I put into it. When I gave the switch too much kink, the LED brightness would decrease. Ideally the switch should be removed completely and replaced with a solid-state solution. In my attempts to make adjustments to the switch, I unfortunately damaged it before I could make any measurements, but that leaves something fun for next time.

Even the tiniest movements of the film caused the LED's to light, which is also exciting for future developments. The first FLAG attempts operated at very high frequency and were held under some tension, with more of a vibration like motion at approximately 50Hz and only moving a couple of millimeters. I can see how operating the FLAG under tension like that would increase the power output- perhaps by a factor of 5, since that would be the relative increase in oscillation frequency. The shorter stroke would also mean that more layers could be fit into the same volume (another multiplier for power output per unit volume). Higher frequency designs seem well suited for kites, which by their nature are held in tension.

As this FSCC was not custom designed to match the FLAG output, I'm sure the efficiency could be improved. It should also have two switches, one for each of the two end positions of the center layer of film. That means the LED's in this test were blinking half as often as they would with two switches. In the future, I would like to try this again with two better designed switches, and a slightly smaller FSCC.

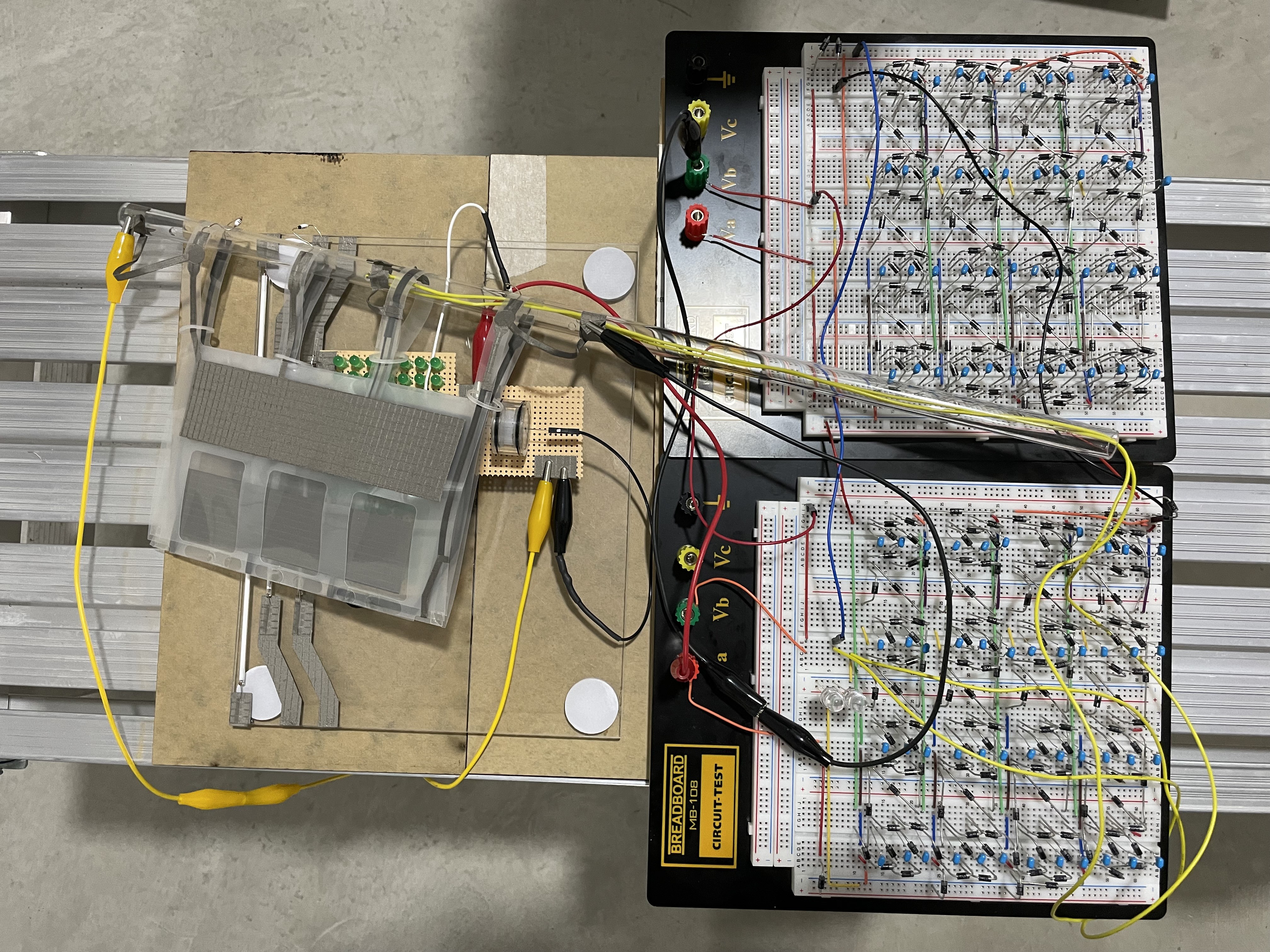

Below is an image of the apparatus from this test. You can see the 96 unit FSCC took two poorly-planned breadboards, although Chongqing University fit the same circuit onto one relatively small PCB. The FLAG has been mounted onto an acrylic tube, and the two small yellow switch wires were run through the tube, and connected to the FSCC. The FLAG outputs are connected to a small spark gap and the FSCC through the alligator clips. A couple of the large blue LED's that were blinking in the video can be seen in the bottom breadboard. The FLAG was then exposed to approximately 20km/h air from a nearby blower to energize the FSCC circuit.

Stuart MacKenzie

Stuart MacKenzie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.