Fuses are ones of the simplest overcurrent protection devices available. When current passing through them becomes higher than a certain threshold, the wires inside the fuse melt and the circuit opens, stopping any extra current from flowing.

In the context of McGill Formula Electric, we strive to keep our car safe, reliable and performant. Our low-voltage electronics systems are powered by a 24V battery, and to ensure current draws do not exceed the battery and the electrical harness capabilities, we use fuses to protect them.

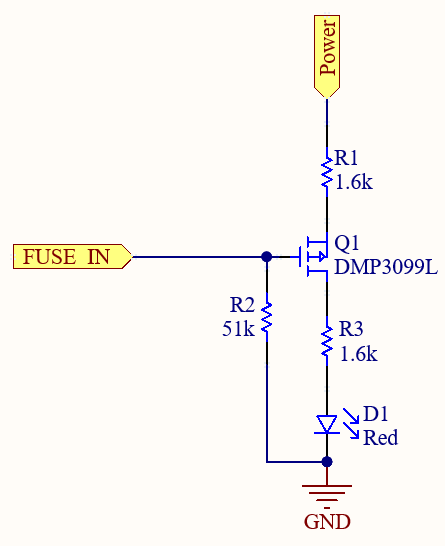

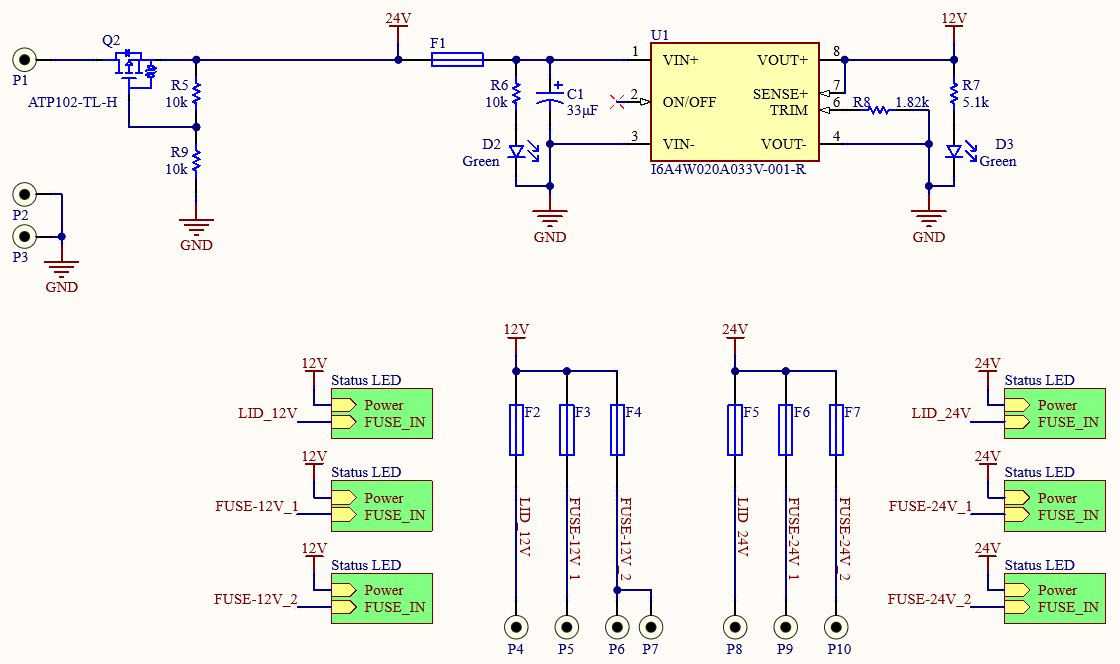

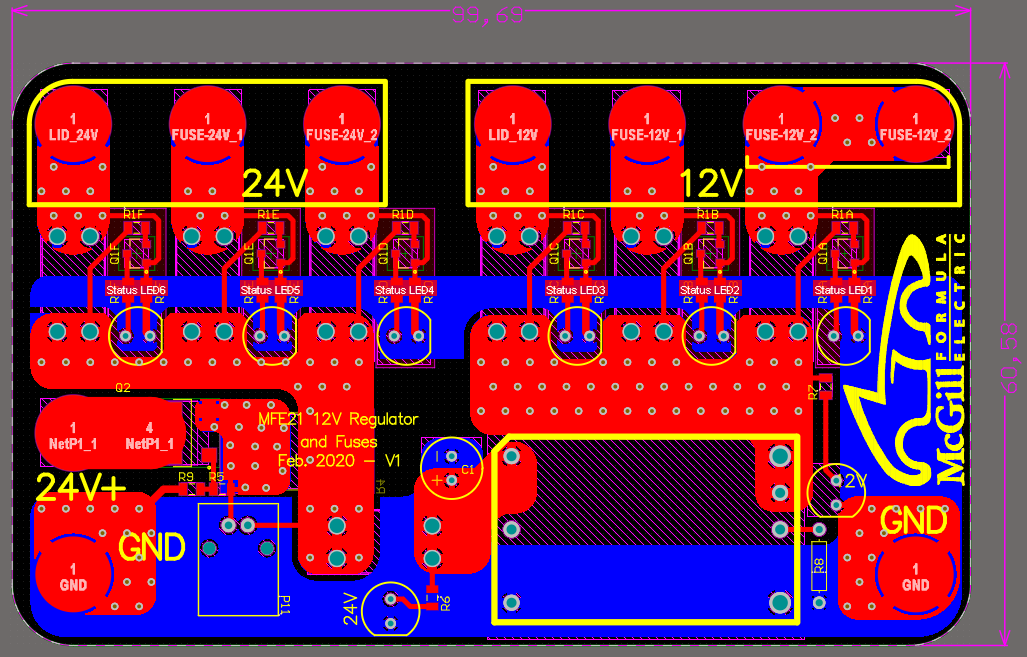

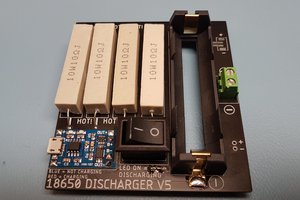

And here comes our custom fuse board. In addition to providing a secure mount for the fuses, it contains an off-the-shelf 250W 24V-12V DCDC converter that is used to power other sensors and data acquisition systems, a PMOS transistor to prevent reverse polarity, and LED indicators that light up when fuses are blown or disconnected. This feature was added to help with debugging and servicing the car.

This article is published in collaboration with JLCPCB. With over a decade of experience in PCB manufacturing, JLCPCB provides some of the highest-quality PCBs available at the lowest-cost.

McGill Formula Electric

McGill Formula Electric

Jasper Sikken

Jasper Sikken

Sagar 001

Sagar 001

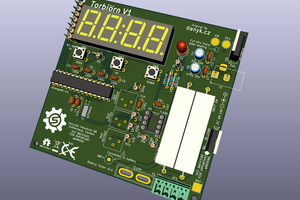

Torbjörn Lindholm

Torbjörn Lindholm