With this experience shattering the timeline of my actual project, I went into Solidworks and looked at my old design. After years of CAD work, I learned a thing or two and I immediately realized my pretty heavy oversights on the first design. In my defense, I designed this in a day and put it together the next.

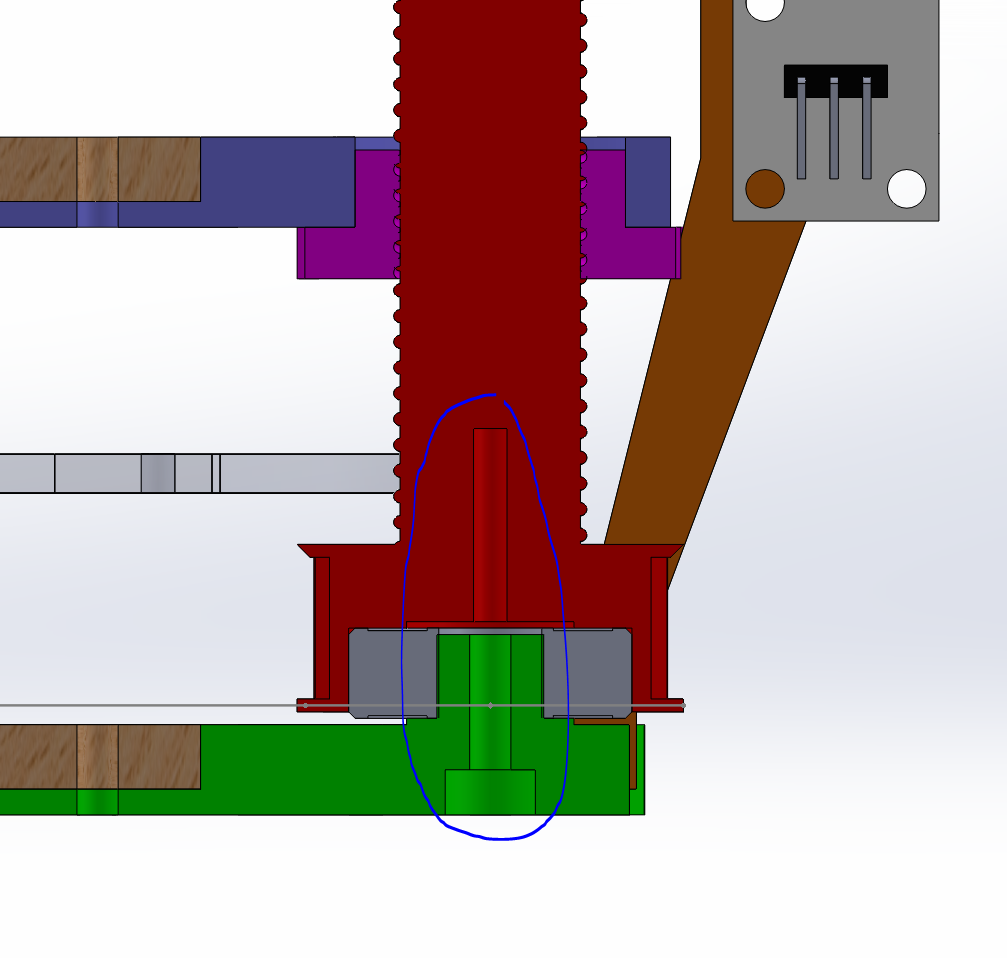

First of all, the spindles were not held by anything. They just has a ball bearing pushed into them from the bottom and shaft of the ball bearing sat on a 3D printed pin. Nothing was stopping it from coming apart. So the first major upgrade was a M3 screw that just holds the spindle down.

It doesn't need to be tight, it's just there, to keep it from falling out. Remember, this table really only needs to hold grams and has no lateral loads to bare whatsoever!

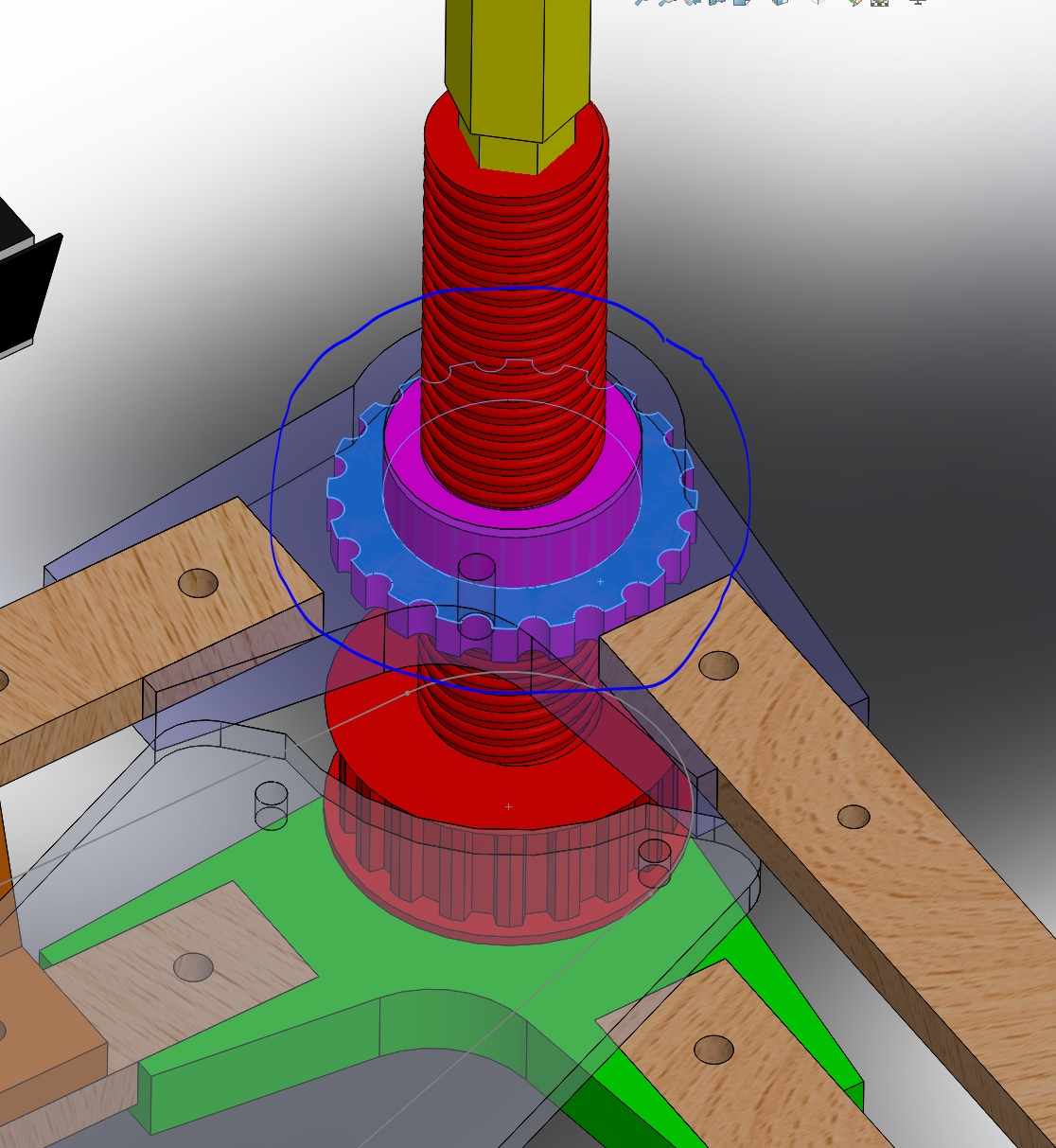

The second major upgrade was adding additional spindle nuts to the design such that I could adjust the table's four corners just by rotating these a little bit.

These nuts are then locked in place simply by adding another M3 screw to the hole in the transparent blue corner module. I cannot stress enough how much easier it is to adjust the height of each corner now. This construction is also just held down by gravity but since I have parts on the table and the honeycomb, too, it's working thus far.

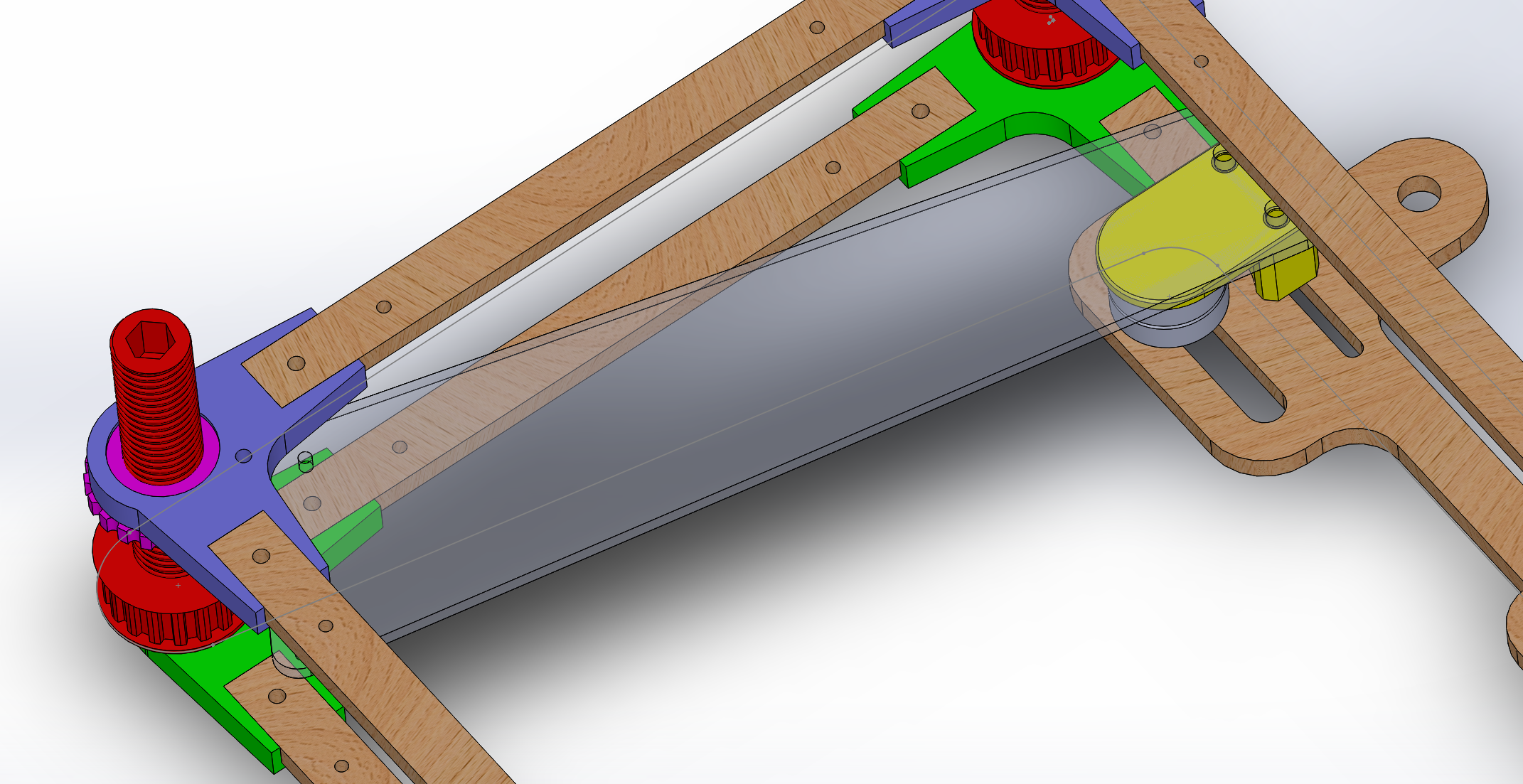

The next bit was to make the table work with my 1440mm belt. TOTALLY the wrong belt for the job, but I had it sitting around and didn't have any other use for it. So it was either throw it away or use it in this contraption (with the massive friction it comes with).

To do that, I added adjustable idler bearings to the opposite side of the table. Yes, the belt goes all the way across. Again, I had it, I knew it is too long for this.

But since that's pretty exposed, I needed to add a shield over the belt to protect it from being burned by the laser during job execution. I did that on both idler bearings and also added a piece of aluminum tape to make the wood immune to laser light.

One last thing I indented to add is an endstop switch to be able to properly calibrate the laser focus automatically each time the thing fires up. There are two problems with that: First, the laser is easy to adjust manually once you have Z-Axis control and a template to get the focus right, and second the mechanical switch I have lying around has too much force to allow me to drive the "gravity held together table" against it from the top by moving the table downwards reliably. Mounting the switch above the table and driving the table up is still... well, on the table, but for now, this works great.

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.