I will update project logs as I try new things. I based my process of the following YouTube video, it was very helpful getting started

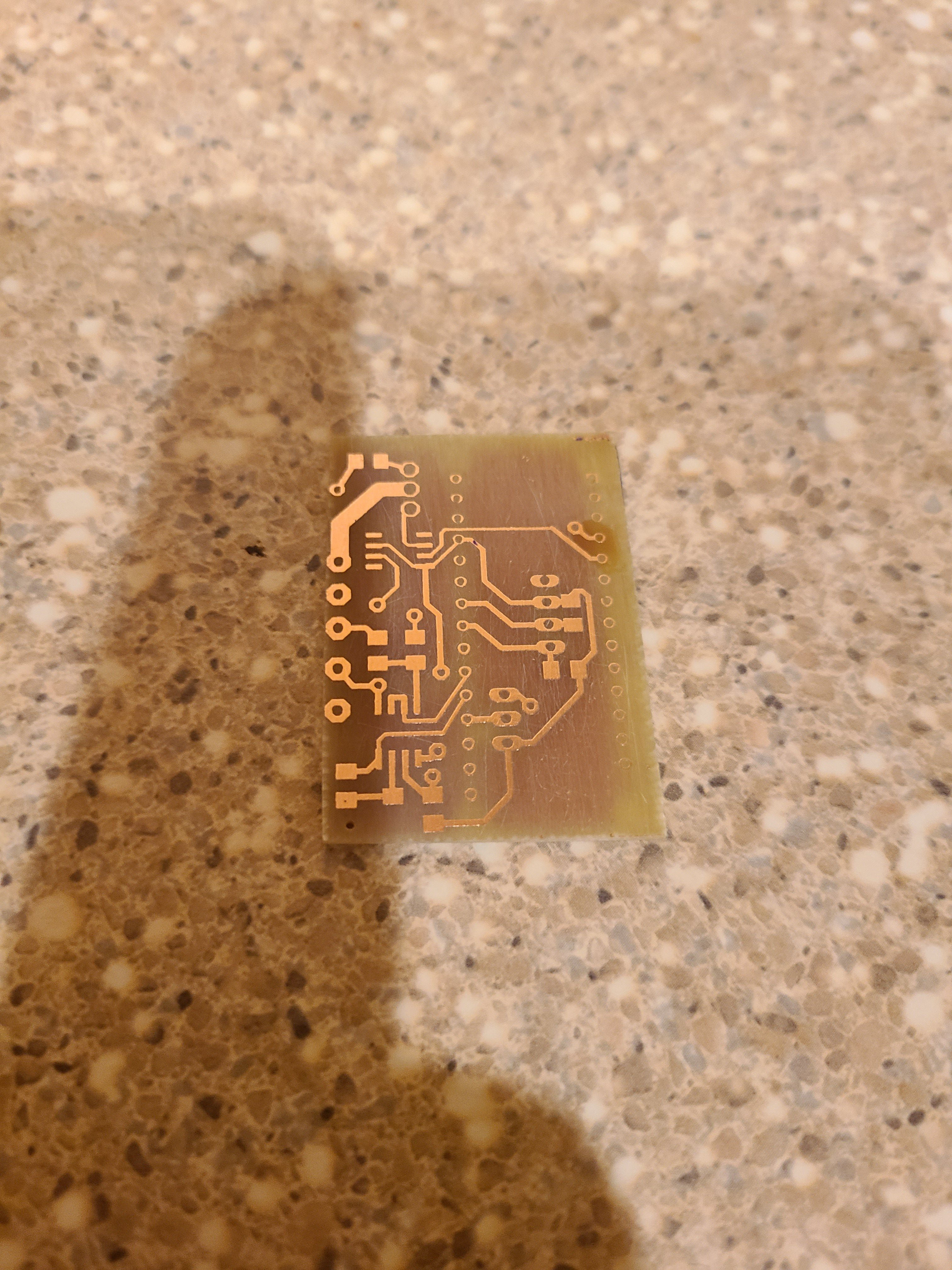

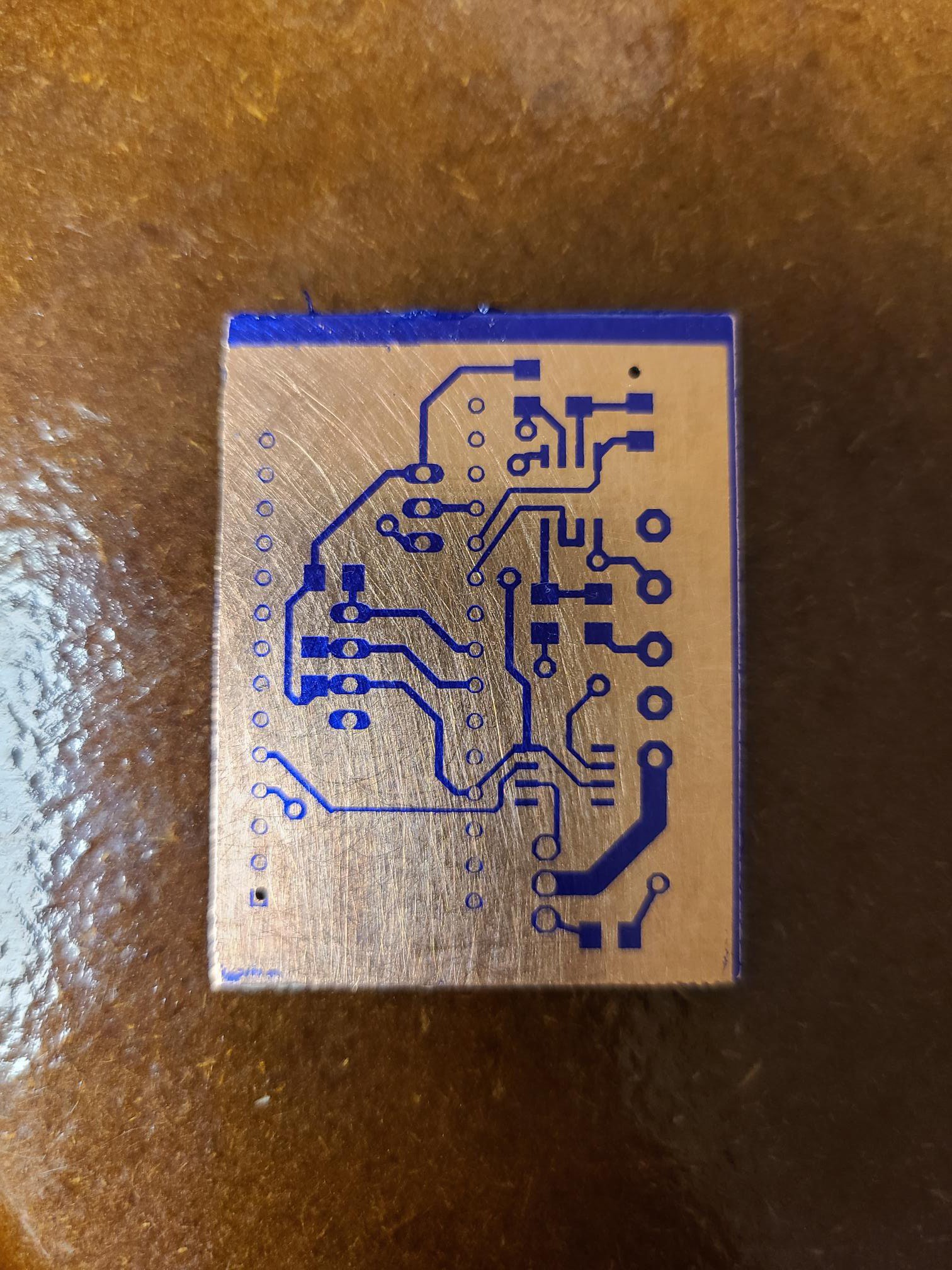

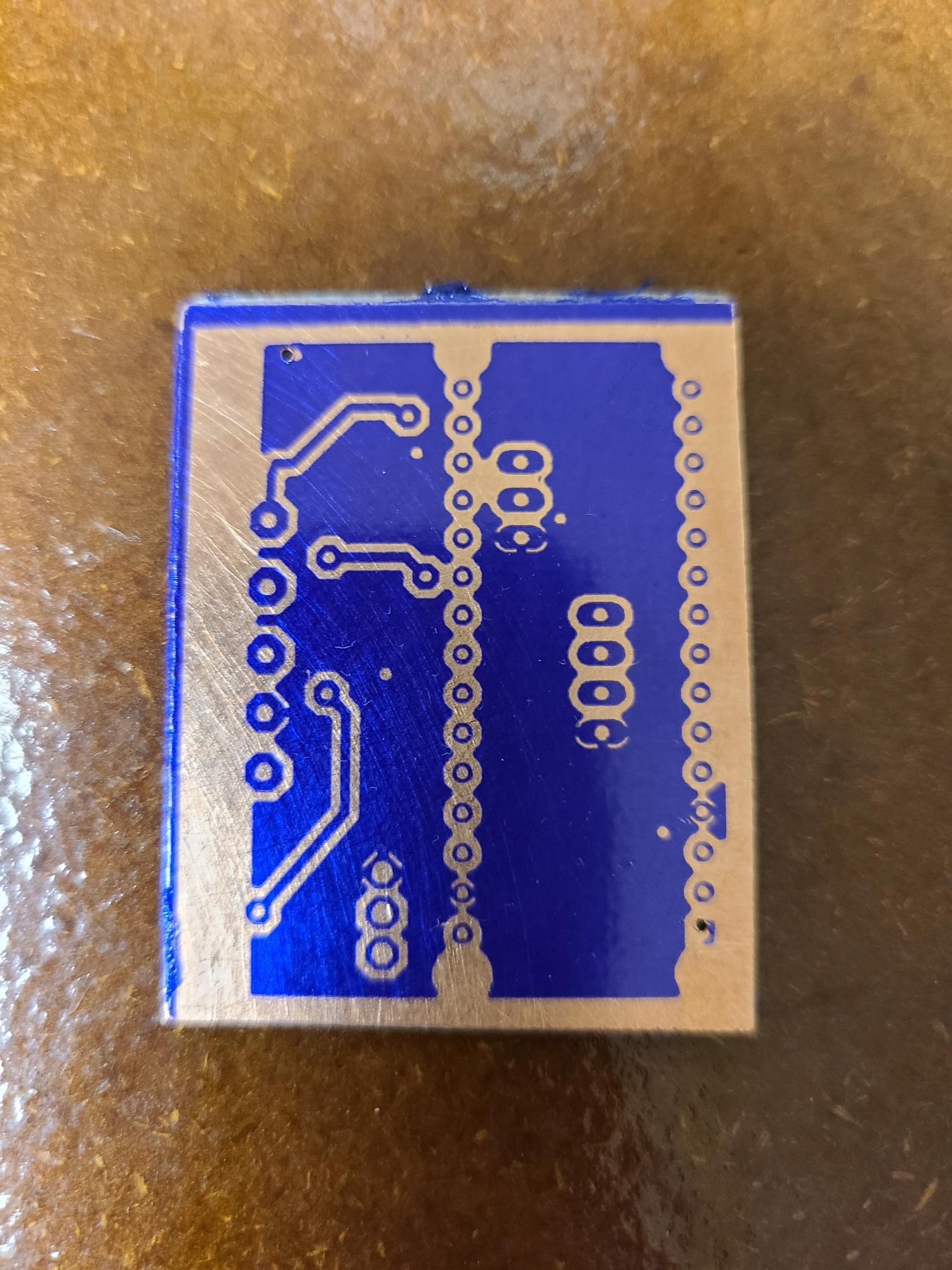

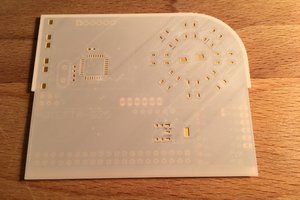

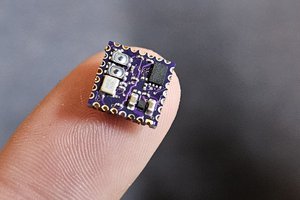

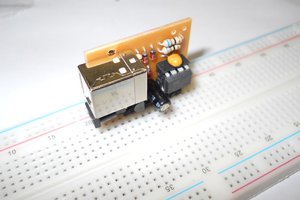

DIY PCB with Photosensitive Film and Etchant

This is a place to keep my notes as I experiment with different processes in making PCBs using photosensitive film

KSUdoubleE

KSUdoubleE

Robert Kirberich

Robert Kirberich

fl@C@

fl@C@

danjovic

danjovic