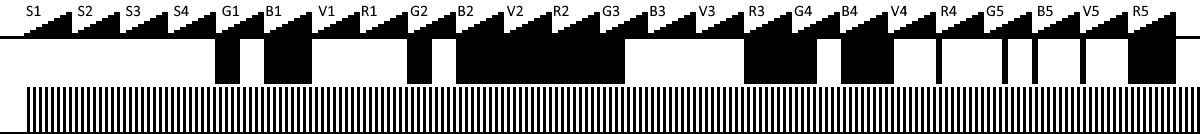

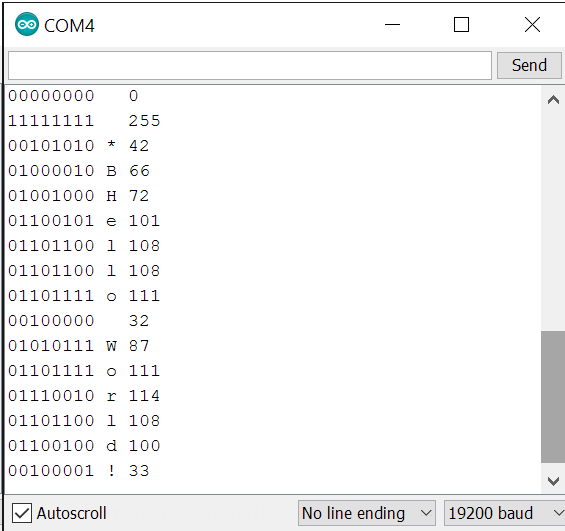

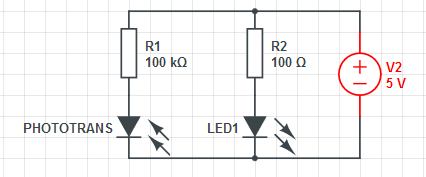

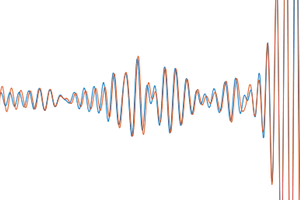

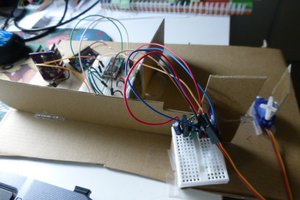

The theory for this project is very simple : have two phototransitors read a strip of paper, generating 0s and 1s to bitbang a data and clock signal to do anything you need.

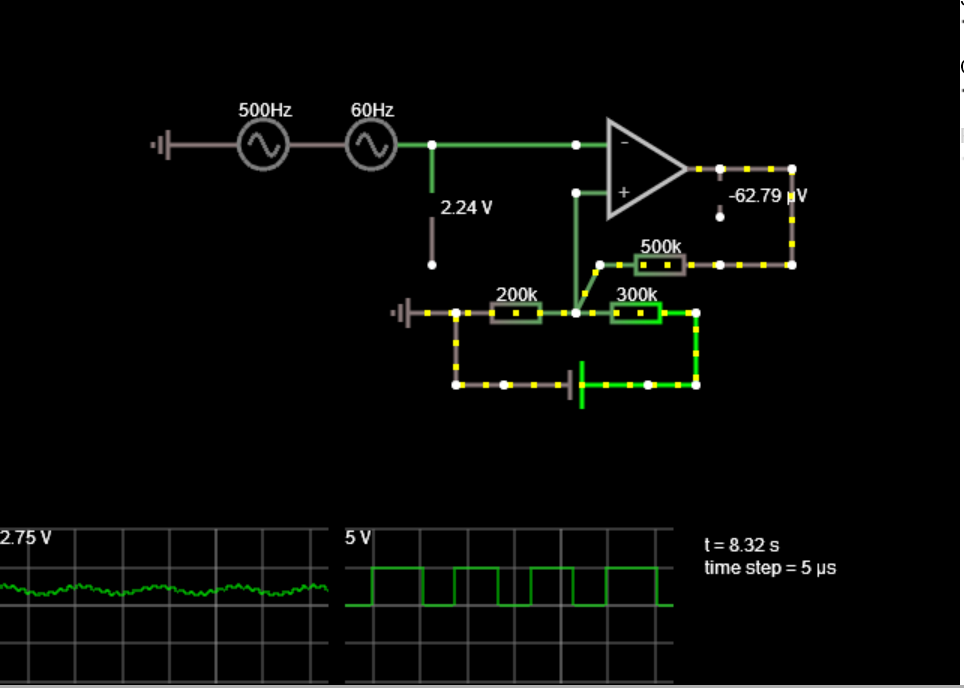

The ouput signal from the phototransistor will be cleaned and amplified to proper levels using an OpAmp. I did'nt knew much about analog electronic when I started this project, but using the OpAmp was easyer than expected.

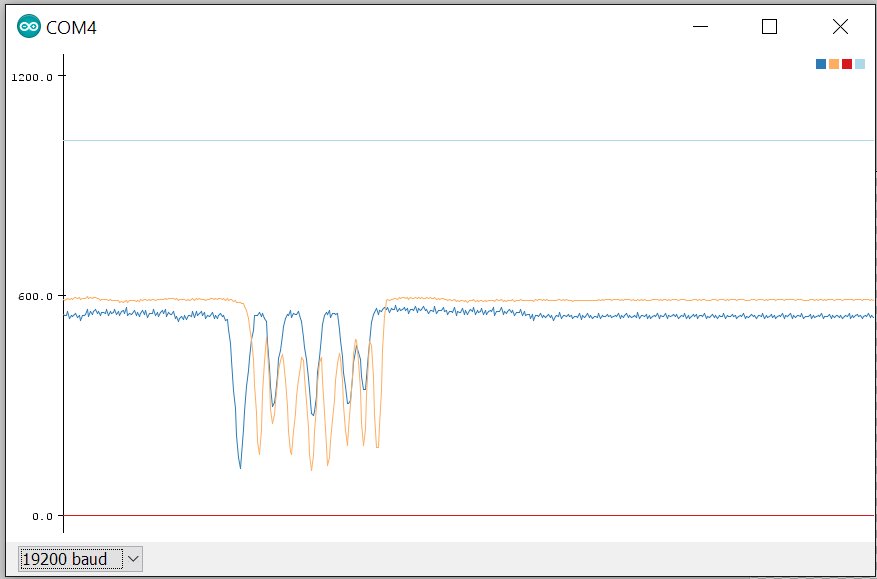

The tricky part might be to get a proper construction : if you manage to read 0.5mm wide band, and can have less than 0.5mm synchronization error between the reading of the data and clock tracks, you will have one bit per millimeter, which means you can only print 32 bytes on a A4 sheet.

Another problem might be to get something sensitive enough so we don't have to amplify the signal too much (because then we would also amplify any error and noise, leading to potential problems). For now, I use two layers of transparent paper (hence doubling the quantity of black ink), but is would be better to have a single layer of standard paper.

Let's try.

ftregan

ftregan

doctek

doctek

Jianjia Ma

Jianjia Ma

Ben Hencke

Ben Hencke

I'll be watching from the back of the room, maybe i'll find interesting tricks to progress with #Low-resolution scanner for cheap data input :-)