While looking at glass shelves for gd0105, I stumbled on some listings for cheap glass:

The long pane of glass was miles cheaper than the one I was thinking I was going to have to get for the 4 segment bed:

The square panes would also be much cheaper than the 300x400mm worktop savers I was planning to use for the 2 segment rotary bed. The last time I checked, which was months ago, the best I could find was 6 for £20. Seems that kind of deal is gone now, because I can only find £10 per each now.

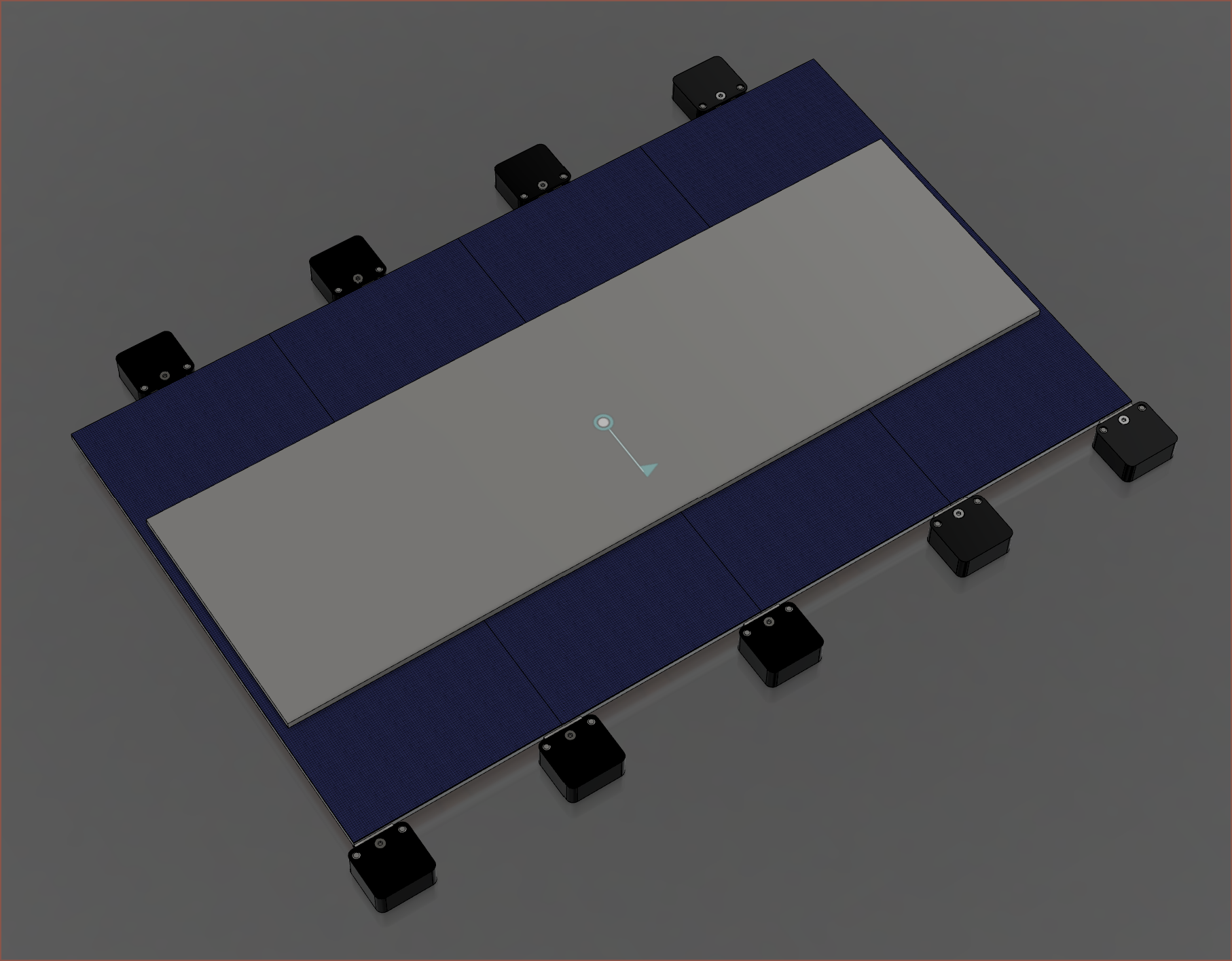

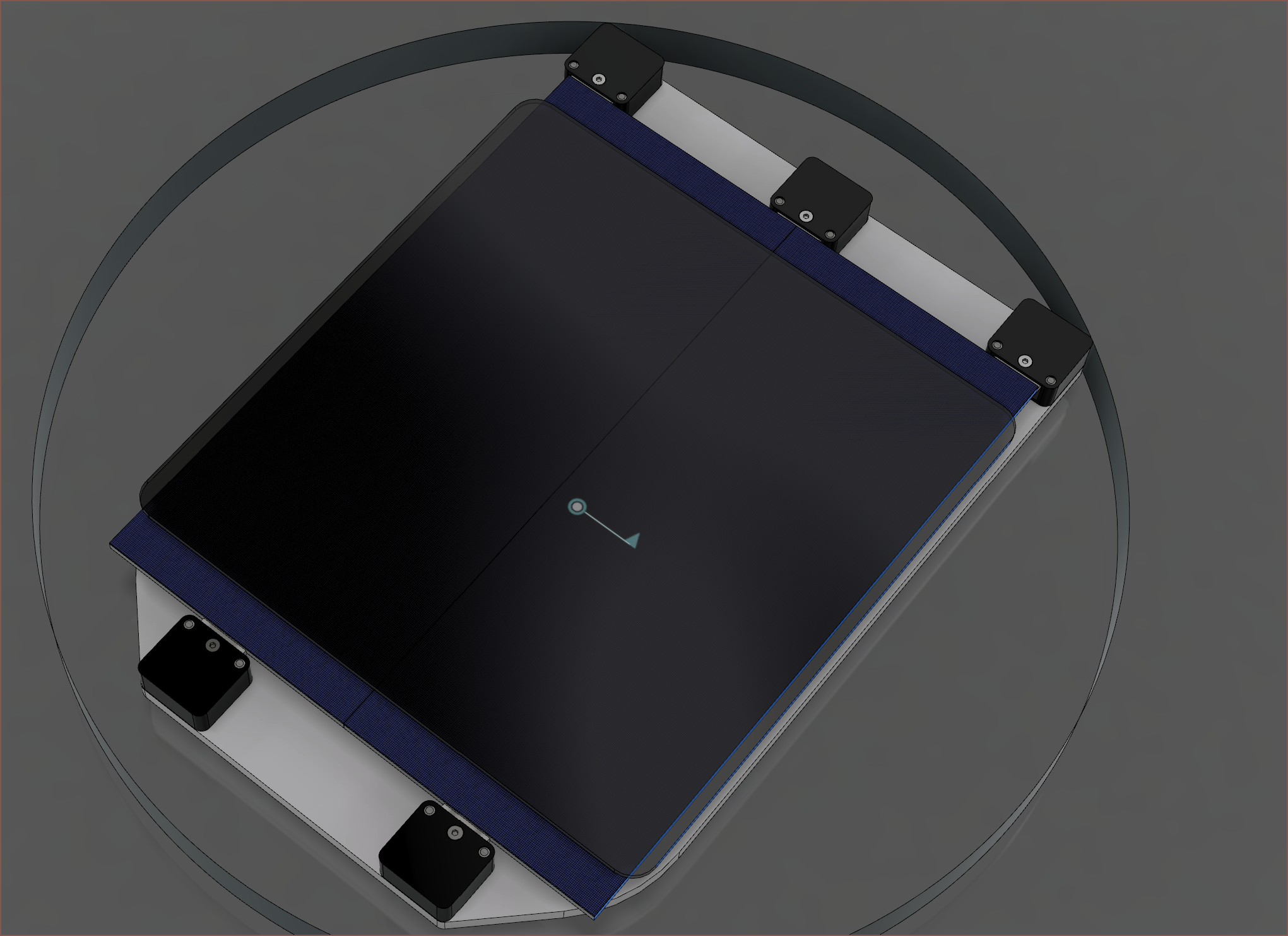

These glass sizes weren't exactly the kinds of sizes I'd need, so I modelled them:

They're both pretty close though, and I feel like I'd be able to find suitable binder clips. I hope an edge in the middle of the 65x40cm print area won't be an issue, but from research into gd0105's build area, I doubt I'd even have prints wider than 20cm anyway. As for the 35x35cm, it's likely a better choice than 30x40 anyway because the usable circle diameter increases from maybe 29cm to maybe 34cm if no other limitations get in the way.

They're both pretty close though, and I feel like I'd be able to find suitable binder clips. I hope an edge in the middle of the 65x40cm print area won't be an issue, but from research into gd0105's build area, I doubt I'd even have prints wider than 20cm anyway. As for the 35x35cm, it's likely a better choice than 30x40 anyway because the usable circle diameter increases from maybe 29cm to maybe 34cm if no other limitations get in the way. Glass Arrives

They came yesterday, together in a well sized box and it was a heavy one. I do wonder what kind of margins the sellers were actually making on this glass and I feel like it's just some sort of clearance.

The square panes were bubble wrapped in 2 packs of 3, and the bubble wrapped pack of 4 were under them. each pane is then further protected by a wrap of cardboard each.

The square panes were bubble wrapped in 2 packs of 3, and the bubble wrapped pack of 4 were under them. each pane is then further protected by a wrap of cardboard each.  The glass is actually a nice light grey, if not off-white. What interested me was the matte backing:

The glass is actually a nice light grey, if not off-white. What interested me was the matte backing: According to the listing, this glass is rated to 90C, but since glass is glass, I can only assume that this bottom coating or possible binding agent is what limits the working temperature.

According to the listing, this glass is rated to 90C, but since glass is glass, I can only assume that this bottom coating or possible binding agent is what limits the working temperature.

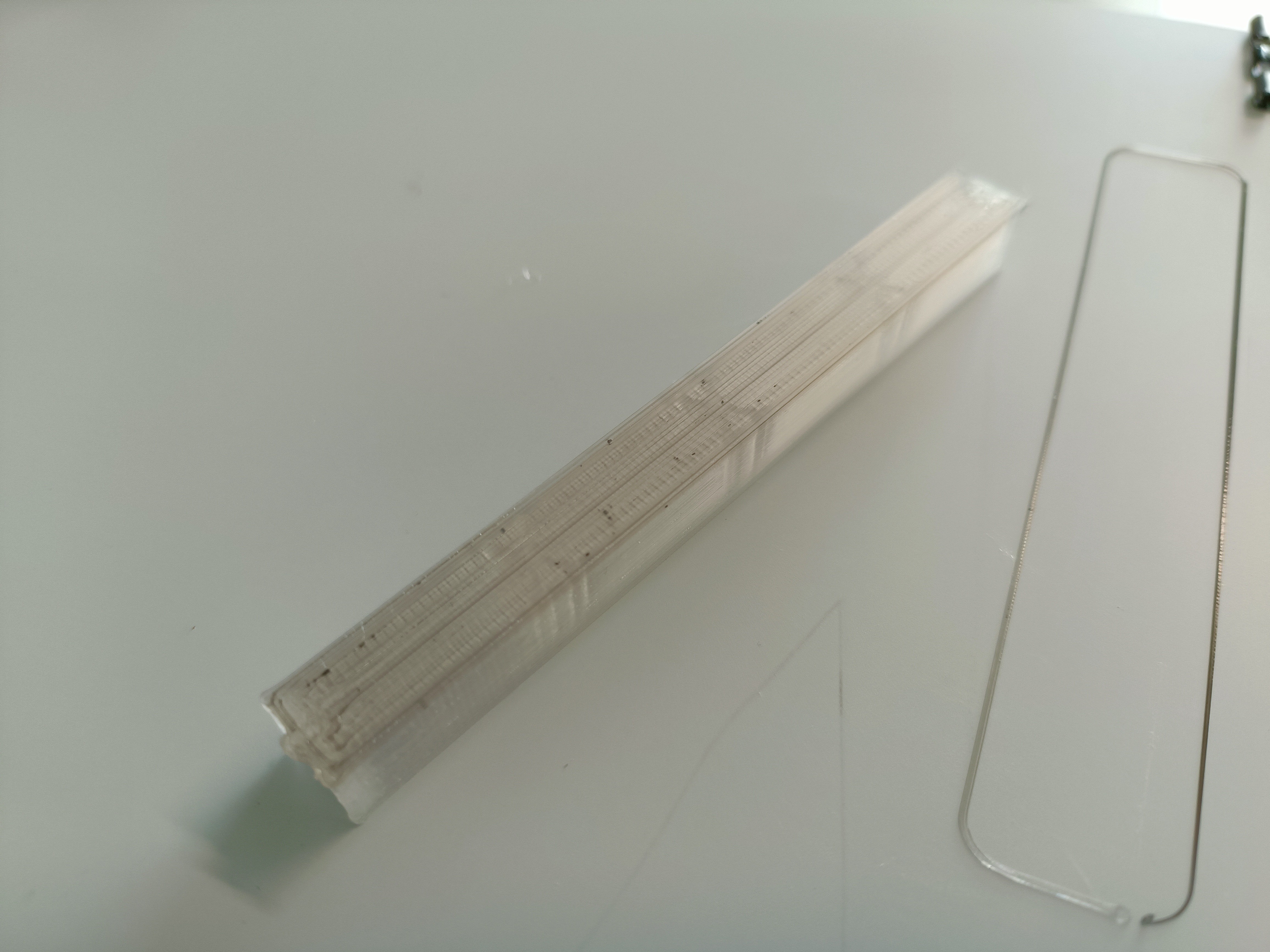

Contrary to the listing's image, the 65x20cm "glass placemat" also came in this lovely off-white and matte backing. Nice to have something better than the listing image for once. I was still suprised that the glass was actually delivered at all.

Contrary to the listing's image, the 65x20cm "glass placemat" also came in this lovely off-white and matte backing. Nice to have something better than the listing image for once. I was still suprised that the glass was actually delivered at all.Testing the glass backing

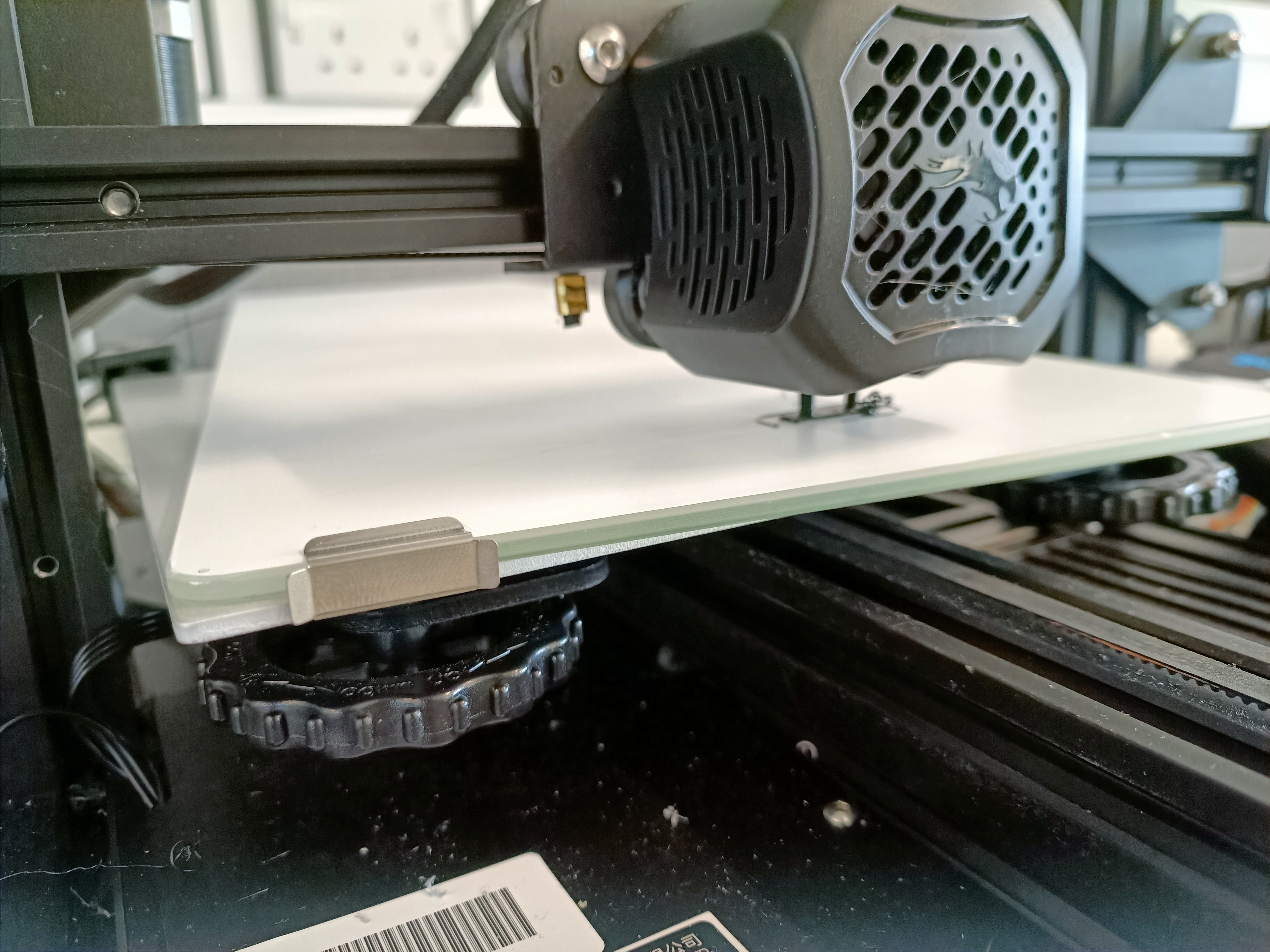

I rushed over to the 3D printers my university just happens to have and eventually installed it into the Ender3 V2.

The first thing I tried was a stringing test as I've also updated to Cura 5.0 now that the Materials Settings plugin has been updated. This PLA+ (never used this before) and printed with temps of 206/60 at a initial speed of 60mm/s.

That seemed to stick ok and had a gloriously matte bottom layer:

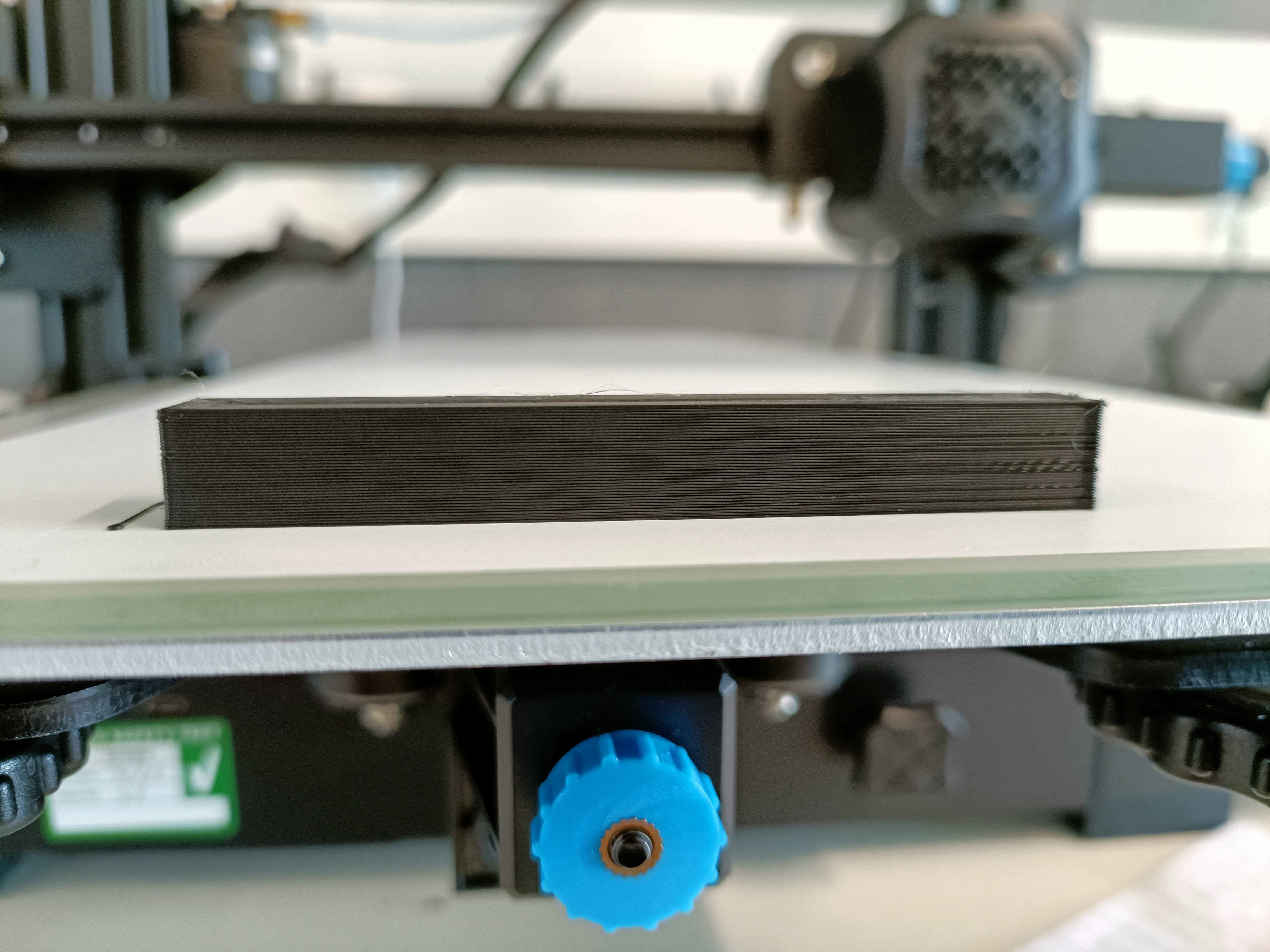

That seemed to stick ok and had a gloriously matte bottom layer: Thus I printed a 10x80x10mm print to see if I could get some warping.

Thus I printed a 10x80x10mm print to see if I could get some warping. No it came out flat.

No it came out flat.

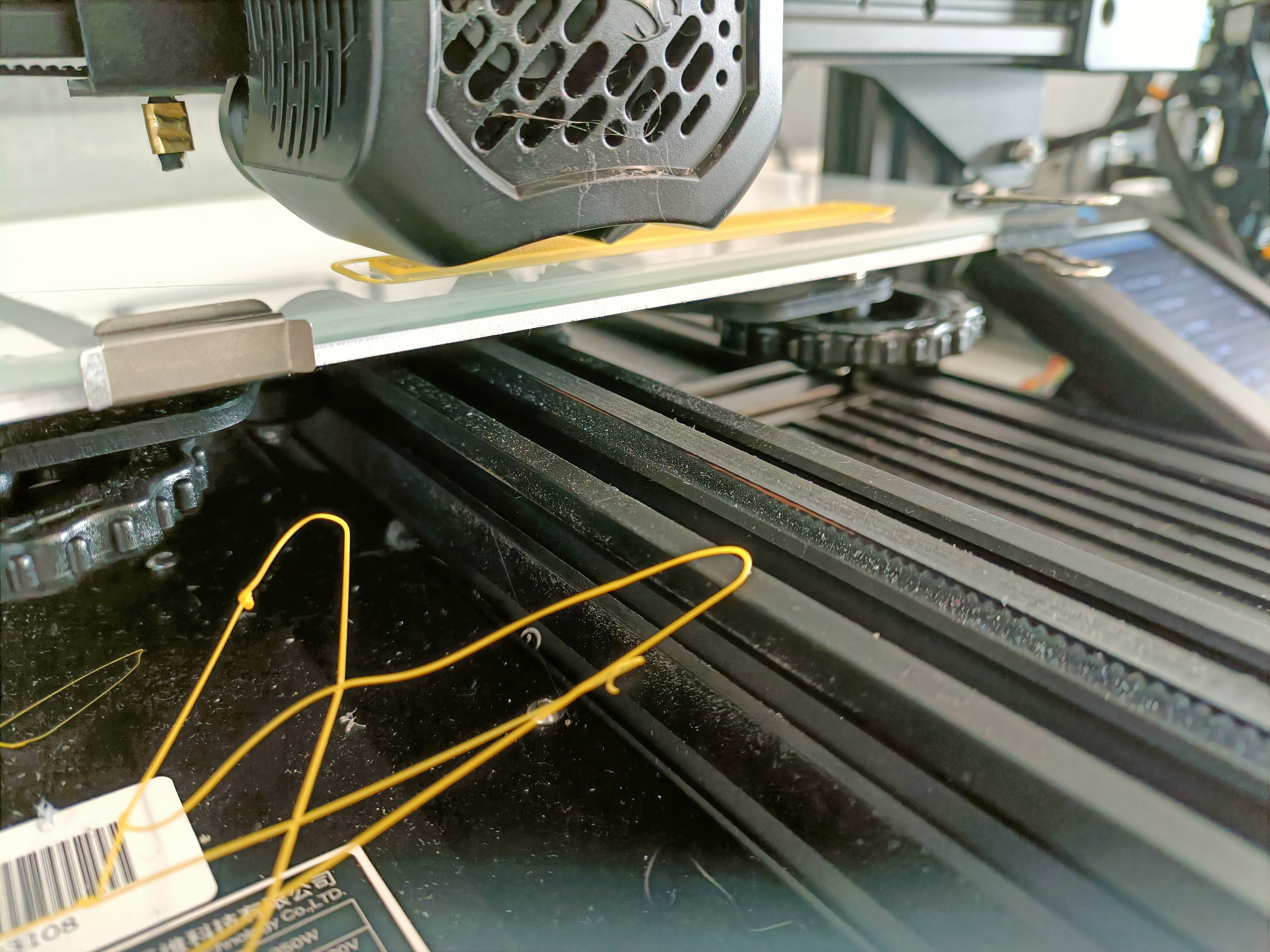

The bottom looked like the nozzle was a tad far from the bed, so I adjusted the levelling screws and upped the stakes a bit: PETG, 240/82, 60mm/s, 10x100x10mm. As it was printing, I noticed that the material looks kind of familiar to the stuff ontop of the Ender glass:

The bottom looked like the nozzle was a tad far from the bed, so I adjusted the levelling screws and upped the stakes a bit: PETG, 240/82, 60mm/s, 10x100x10mm. As it was printing, I noticed that the material looks kind of familiar to the stuff ontop of the Ender glass: I also tried to scratch it with a filament cutter and there didin't seem to be any visible damage, so it's at least more durable than something like a printer bed sticker, lexan or the Ultrabase I briefly tried years ago. Anyway, the PETG seemed to have stuck even better to the surface:

I also tried to scratch it with a filament cutter and there didin't seem to be any visible damage, so it's at least more durable than something like a printer bed sticker, lexan or the Ultrabase I briefly tried years ago. Anyway, the PETG seemed to have stuck even better to the surface: ABS, however, wasn't happening:

ABS, however, wasn't happening:

It just didn't want to stay on, even with the glass side. It wasn't even on there long enough to warp. It just popped off as if it was too cold, even though the bed was set to 108C.

It just didn't want to stay on, even with the glass side. It wasn't even on there long enough to warp. It just popped off as if it was too cold, even though the bed was set to 108C. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.