I did my first sintering test past weekend. Goal was to start tests of the sintering parameters (laser power, scanning speed, hatching distance, layer thickness, temperatures...) to find best setup for PA12 powder I am using.

Test objects

- Rectangular pattern of squares/cubes 20x20 mm across whole bed size.

Key parameters of the test

- Printer preheat: 1:20 min to 145°C

- Surface temp: 171°C

- Layer thickness: 0,15mm

- Laser power: 4900mW

- Laser spot size: approx: 0,25mm

- Energy density: 22 mJ/mm2

- Nr. of outlines: 2

- Hatching overlap: 25%

Bed preparation

- Surface temp: 160°C

- Nr. of layers for bed preparation: 30 (it will be higher during parts printings)

Cooling procedure

- Controlled cooling was not set. Printer was opened a few minutes after the printing had finished (reason why is below) During part printings will be controlled cooling function set to 0,5-1°C/min. (upraveno)

A few pictures from the testing

1. Nesting of test object

2. Print parameters setup

3. Sliced test object

3. Sliced test object

4. Plot feature of the laser scanning process

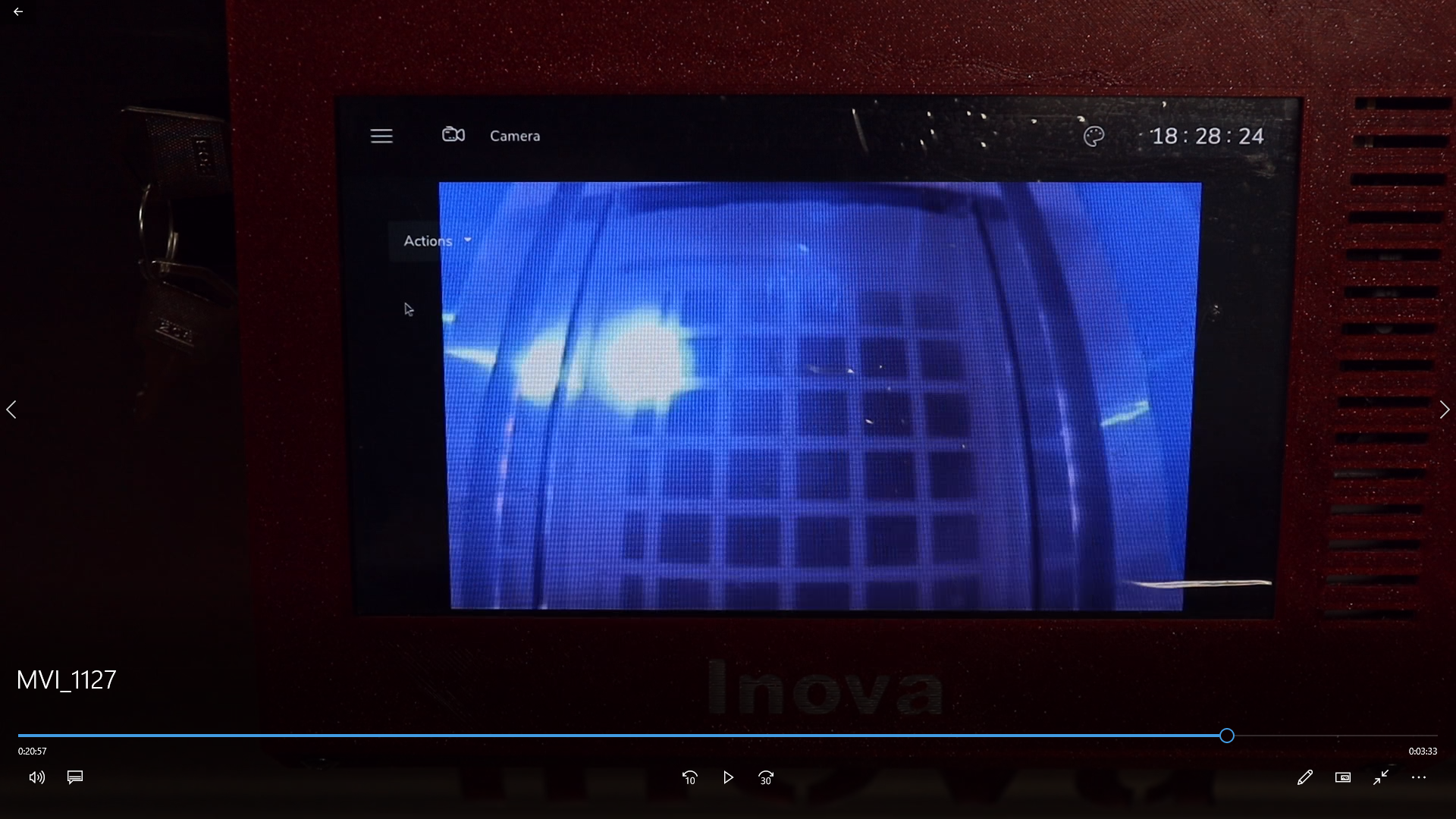

5. Printing/Sintering of the test object

Until now it was just WOW ... but than it went wrong ... Recoater failed to complete next layer.

Reason was that I used wrong ratio of the volume change after sintering. Therefore, the next layer has not enough powder. But that is minor issue - just SW setup.

From now on, I will calculate it dynamicaly for each layer based on the sintered surface area.

So, the first sintering test results:

- Amount of fresh powder was not OK for such a huge sintered area.

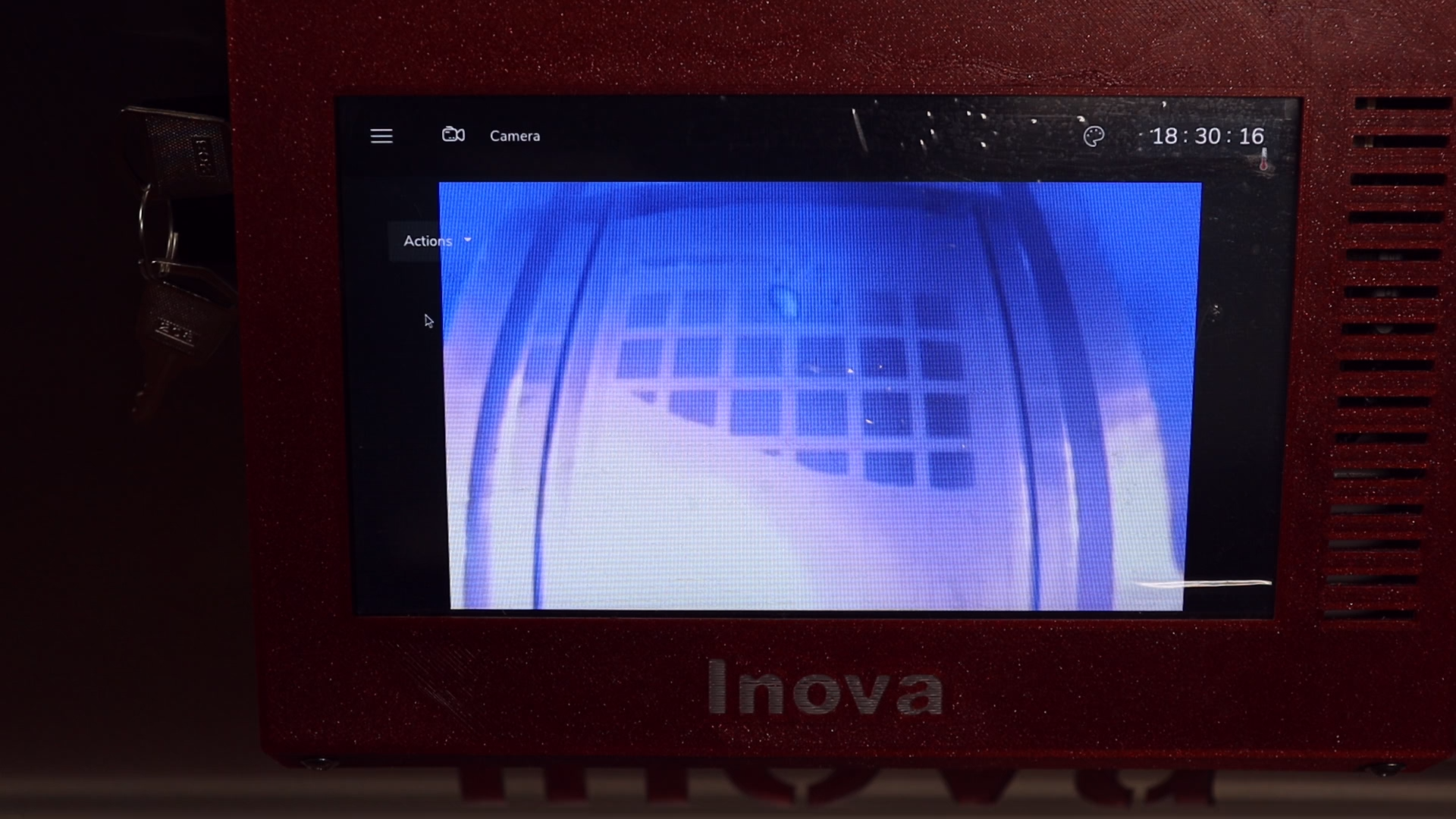

- Surface temperature was a bit low. The print cake was not at expected structure.

- Sintering in XY axis was relatively OK - for the first attempt. I will set up the hatching overlap to 30% next time.

- Sintering in Z axis was poor/undersintered. I made mistake in setting the energy density. Based on this number scanning speeds are changed dynamically across print bed. It is based on the laser spot size change due to its defocus. I set it for 22mJ/mm2 but it was my base point for 0,1mm layer thickess not for 0,15mm :-(

- After deep look at the sintered squares, it was possible to see big layer shifts. I am persuaded it is caused by the big speed of roller surface rotation. It is the real problem because I can't to significantly change it easily. It is an mechanical design issue I didn't count with. I can decrease it by say 30% in Klipper but it will not be enough. As I am facing also other mechanical issues with recoater I really think of major changes even it is complicating my life. I will let you know soon.

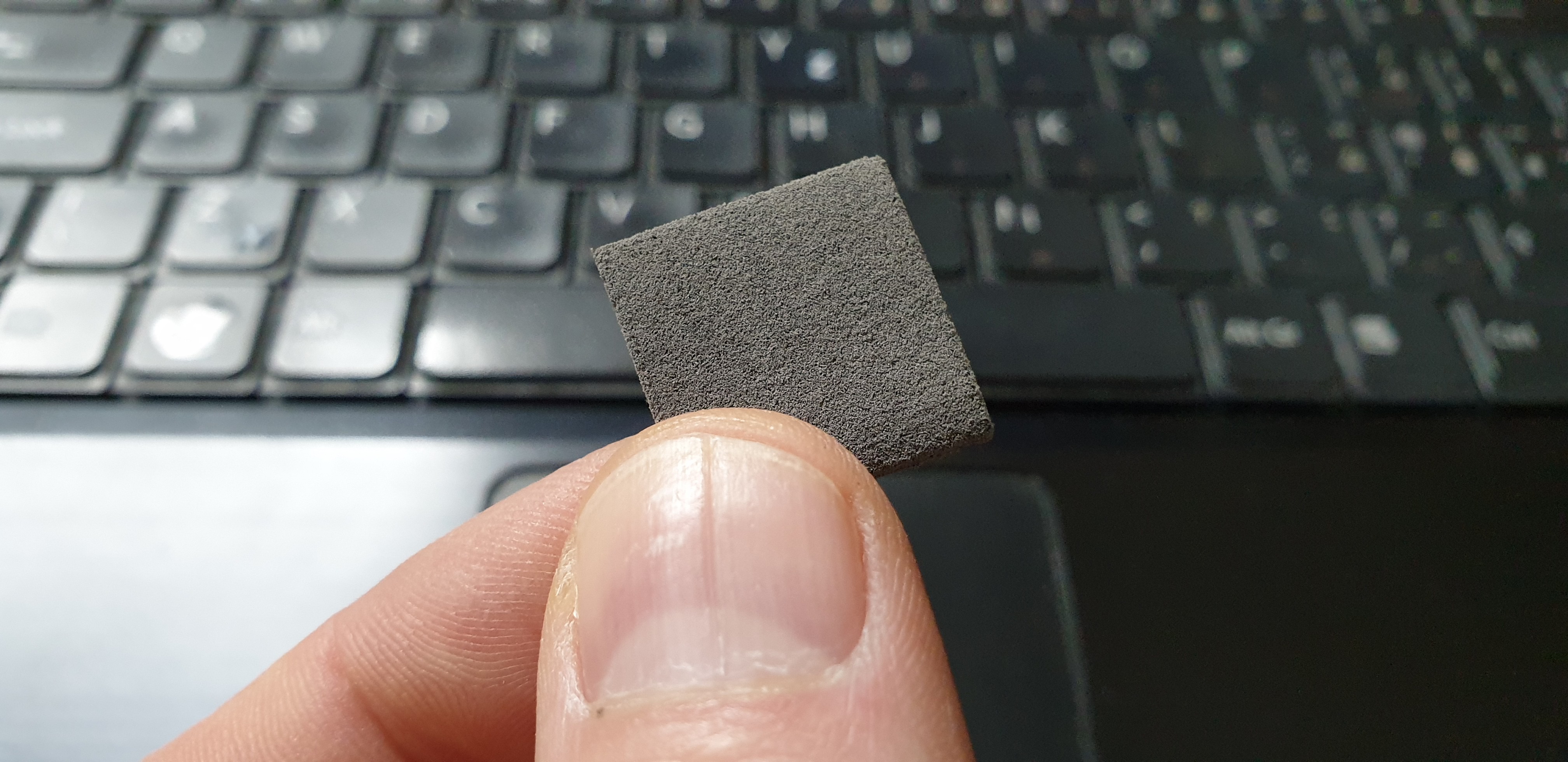

Here is one of printed squares. This one was placed in the bed area where was recoater able to wipe more than one layer. These are I think 3 or 4 here. It is warped a bit because of really really quick cooling.

-

So, this is my base point for further tests. I hope to see first Benchy before I will be in my 60's :-)

Tomas Starek

Tomas Starek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.