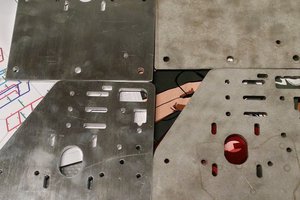

Before doing anything, I had to remove all the grass and dirt build-up under the deck (figure 1). This took quite a while, since it was never done that much, apart from unclogging the grass path to the catcher.

After inspection, it is quite understandable that the traction cable broke off. The enabling mechanism is buried in with and dirt (figure 2). To put tension on the belt, a bolt has to be tightened. The black case is the traction gearbox.

The new traction cable was a bit difficult to get in place. The anker point where the hook is supposed to grab was hidden behind the traction gearbox, hard to reach with your hand. Eventually I got it to sit right after a few attempts.

The replacement traction cable comes with a new motor brake cable as well. They both pass through the same guiding piece. So I also had to replace this one. For the first test after repair, it did not work. Eventually I discovered I mounted the carburetor throttle cable in the wrong hole (figure 7).

What was done:

- Clean the 15 years of solid grass all inside the lawn mower.

- Change the traction and motor brake cable

- Change the spark plug

What is left to do:

- Check rubber tubing from gas filter to carburetor.

- If no problem, disassemble the carburetor and give it a good ultrasonic vinegar bath at 50 °C for 30 minutes.

By injecting fuel directly throught the spark plug port with a syringe, I managed to get the motor to run a few cycles but never longer. My first thought was that the carburetor was the culprit.

The carburetor is held into place by 4 long screws going through the air filter inlet piece, a gasket, the carburator itself, another gasket, then into the motor's body.I can'lt remember why but it was a pain to unmount. Oh yeah, the throttle control cable was impossible to remove without bending it. I was preventing the carburator from sliding form the long screws.

So I took it apart, counted the number of turns to get the mixture and idle set screws to the same places, and cleaned everything in a hot vinegar ultrasonic bath.

There is one part I shouldn't have dumped into hot vinegar : the bowl. It ended up eating through the coating. I hope it won't affect anything (apart from corrosion resistance).

I injected some fuel through the carburetor's tiny holes (low speed passageways) to make sure there was nothing preventing the flow.

It ended up being the fuel filter that prevented any fuel input to the carburator. It was completely clogged with dirt and dry grass dust, I guess. Once I replaced it with a new one, the motor did finally run smoothly without hiccups or random speed loss. Success!

Nonetheless, all that effort to clean the carburetor was worth it, I learned a lot.

The traction was still a bit weak. The wheels only turned when not in contact with a surface. On I put them down onto grass, they stopped.

I first investigated the traction gearbox. But while opening it, I messed up the oil sealant around the box's junction edge. I suppose this is the kind of seal you have to replace everytime you open the thing. Because after closing it back as is, I had oil leakage. I would eventually need to replace it. The traction weakness also worsened, I guess from the leftover sealant not siting where it should (cause the traction was worse only with the gearbox cover screwed back).

Theory 1: Grease in wheels gearing too old and dry. Results in too much friction, weakening the traction.

Theory 2: traction cable tension too weak, clutching the gearbox half-way.

Ilyas Siouda

Ilyas Siouda

RudyAramayo

RudyAramayo

Jarrod

Jarrod

charliex

charliex

It must be die hard if it lasts for 15 years. Good luck repairing it.