Scalable Silent Air Compressor

Powerful silent air compressor made from multiple fridge compressors

Powerful silent air compressor made from multiple fridge compressors

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

I finally connected all venting solenoids and added an oil separator and a muffler.

With, that there is no more oil on the bottom and the venting got a lot quieter.

And with that, I think the project is complete.

I already used the new compressor for plasma-cutting, cleaning, and powering my old industrial CIJ printer and it's working very well and it's quiet enough for using it at night without disturbing my neighbors/roommates.

I got a 50l air tank from my workmate that he no longer needed.

It's a nice coincidence, that it fits perfectly inside the shelf with the fridge compressors.

Fillingling the tank up to 6 bar takes around 2:15min, which I think is very good for plasma cutting, pneumatics, and spray painting.

So, I'm pretty happy with the new tank and the only thing that's left to do is adding another oil separator some tubing, and a muffler to make the venting more silent and the floor less oily.

I did some testing with the plasma cutter in the bucket and realized that working with it was really ... not what I was looking for.

So, I decided to rather use the plasma cutting machine that I built back in 2019 in combination with the new air compressor.

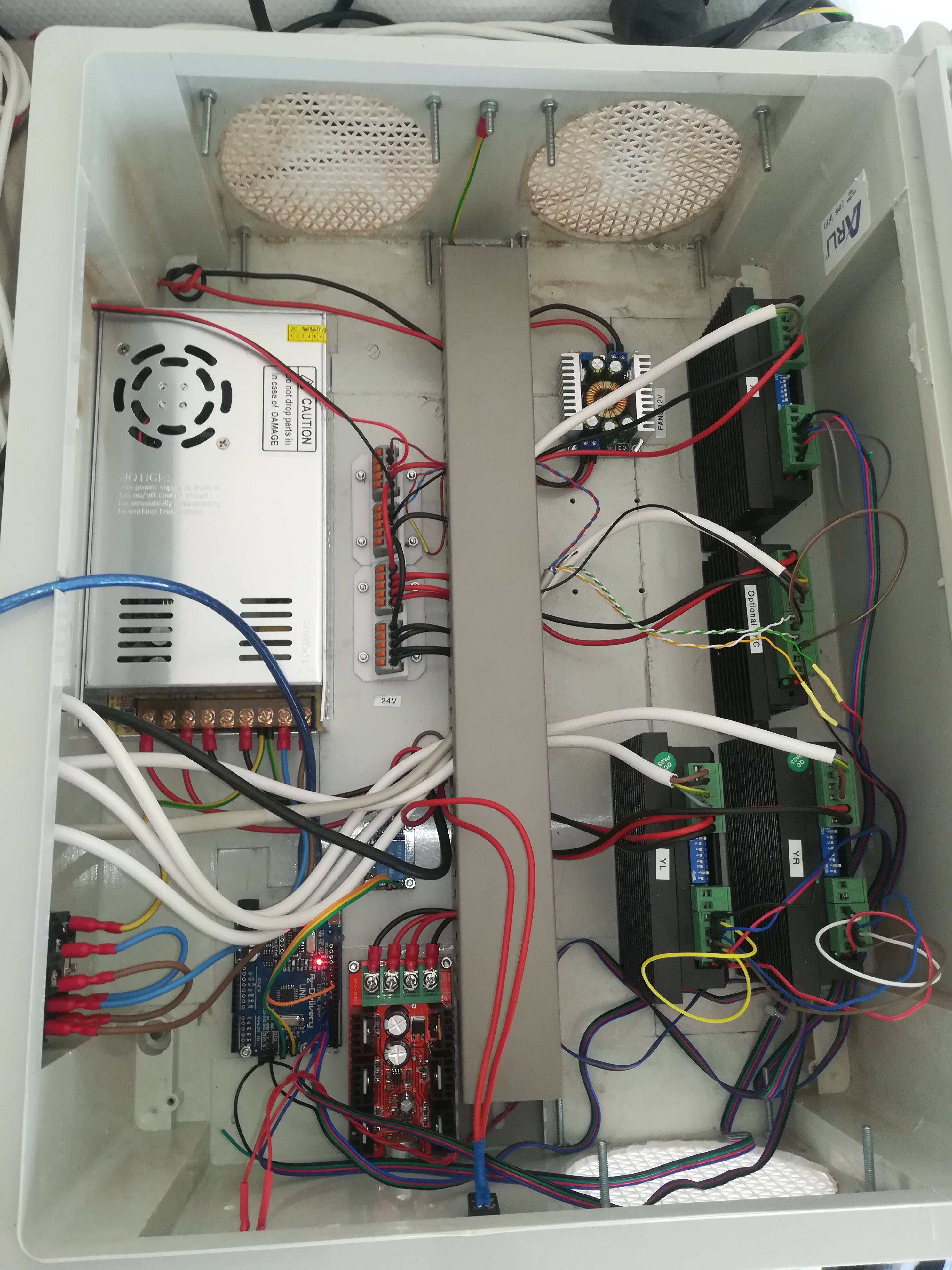

To make it less noisy I replaced the power supply with a quieter one and removed the fans that are not necessary because the stepper drivers barely heat up while running. I also cleaned up the wiring a bit (compared to 2019).

After the initial setup I did some testing with it and the air compressor:

- The quality is fine and besides the torch being not mounted perfectly straight which leads to a slightly angled cut it works pretty well. The new machine has a water table that reduces the bending of the material by cooling it down and it also reduces the sparks that fell into the water while cutting. The machine frame is also completely closed and made of metal so there should be no fire hazard. The machine also has an optional torch height controller that can be helpful for larger cuts with a height difference over the whole length of the cut.

- The noise is also pretty low and suited for working at night. When the door of the machine is closed you no longer hear the cutting noise when you stand in the room next door. The air compressor is even quieter than the cutting noise, besides the noise from the venting of the lines at the shutdown of the fridge compressors which is necessary for the next startup (I will fix that soon).

- The only "real" problem at the moment is the small size of the air tank which leads to a too short restarting time of the fridge compressors - which have overload protection that prevents them from starting up in quick succession so that after the first run most of them stay OFF when they should turn ON again.

I think that problem should be solved by just using a larger tank.

I needed a way to generate pressurized air without making too much noise and so I built my own air compressor out of 8 modified fridge compressors, a 9l tank, a pressure switch, a relay, an oil separator, 8 check valves, 8 solenoids, cables, tubing, and fittings.

For reducing the venting noise and oil on the floor I will likely connect all solenoids to another oil separator and add a suppressor to it.

The combined output of 8 fridge compressors is also not that bad and so I will look for a larger tank, in the future.

I just finished the multi fridge compressor unit and did some testing with it.

(I built a unit made of 8 fridge compressors that I converted to air compressors)

The airflow is pretty high and I think it will do its job pretty well. I will add another build log with pictures of it soon.

I also did more testing of underwater plasma cutting, but I think for the sake of cutting quality and prevention of rusty linear rails I will ditch that idea and do the cutting in the common way.

Maybe I add a water pump for protection or part cooling, but no more underwater cutting for now (until I change my mind again 😅)

Now I will focus my work on doing test cuts and finding ways to optimize the system.

So, I think solving the problem of a loud air compressor is a major step toward making plasma cutting as apartment friendly as 3D printing.

I cut a hole in the top of the cover to prevent water condensation and rust on the bearings. I also lowered the water level to a minimum to extinguish the sparks that falls to the bottom.

For silently producing pressurized air I plan to build an air compressor unit made of multiple fridge compressors.

For that, I have to collect fridge compressors until they produce enough airflow to drive the plasma cutter.

Here you can see the two fridge compressors that I got so far. I added an air filter and two oil ports for filling and draining + a tube between them to show the oil level. As oil, I used 0W-20 motor oil.

On the outlet, I added connectors for 8mm tubing and a T fitting. The compressors can not start up when the air line is pressurized and so I added a check valve to one end of the T fitting and a solenoid to the other to depressurize the line when the compressors are turned off. Off-the-shelf compressors use normally open solenoids, but it seems like they are not quite as common as normally closed solenoids and also more expensive.

So, my current plan is to use a relay to switch off normally closed solenoids, whenever the compressors are running. Doing so would close the valves when the compressors are running and would open them again when they are off. The solenoids have a 100% duty cycle so they should be able to stay active the whole time without overheating.

The wiring of the machine was quite simple because there were only two stepper motors to control and a relay for switching the plasma cutter on and off. For that, I used two TB6600 stepper drivers, a 12V 5A power supply, a relay module, and an Arduino Nano. I used grbl as the firmware because there are a lot of different CNC / CAM / Control tools available that support grbl. I wired the stepper motors according to the grbl pinout and wired the relay module to the water cooling pin (M8, M9 Gcode Command). The stepper motor drivers are powered by the 12V power supply and the Arduino NANO is powered by the connected USB device.

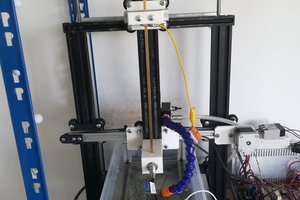

Over the last few days, I built a CoreXZ machine based on the Voron Switchwire.

I chose a CoreXZ design because I want to place most parts of the machine underwater for noise and fume reduction. The motors that I'm using are IP65 rated. So they are safe from water splashing and condensation, but can also not be permanently placed underwater. By using the CoreXZ design I can place the motors at the top of the machine to keep them out of the water. Another reason for choosing this design is the L shape of standard handheld plasma torches. By mounting the torch in a vertical orientation with the grip pointing to the top and by moving the torch in the X and Z direction, the torch does not reach outside the machine dimensions in the X (and Y) axis and so the water container has to be only large enough to fit the machine into it.

For now, I'm using two 90l buckets stacked on top of each other.

Cutting takes place underwater, so the hot metal particles from cutting should cool down very fast before they can damage the plastic bucket. I will still keep an eye on it and maybe build a metal inlet for protection.

For reducing the noise of the plasma cutter unit I ordered a case fan from a different brand because I thought the new fan would be quieter.

Unfortunately, it did not make a big difference compared to the old fan and so tried out something else.

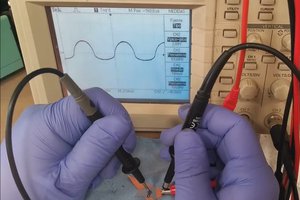

I used an LM2596 to reduce the voltage for the fan from 24V to 16V which led to way less noise.

The plasma cutter unit is a 40A one and I think I will keep the power setting at 30A or less most of the time. I hope/guess driving the fan with only 2/3 of the intended voltage while not driving the machine to its limit will also not lead to overheating.

Time will tell...

For now, the noise of the plasma cutter unit got reduced and so I can move to the next part which is making all parts on the CNC part waterproof.

I already removed all electronics besides the stepper motors from the machine and it seems like waterproof stepper motors are expensive and hard to get. I will try to find a solution for that in the next few days.

Update:

I just found some IP65-rated Nema23 on eBay which should arrive later next week.

I ordered two for building a CoreXZ machine.

Over the last few days I tested out how to eliminate the main sources of noise in the CNC plasma cutter system which are:

- The air compressor

- The plasma cutter unit case fan

- The plasma arc + airstream

First I tested out how much pressure and airflow is the absolute minimum for cutting 3mm steel which is the material that I later want to cut with the system.

I tested out multiple small air compressors and air pumps and could successfully cut 3mm steel by using a 480W "Silent" air compressor with a 40A pilot/blowback start plasma cutter unit. The air compressor has an output of around 90l/min and is likely the most silent "normal" air compressor that I could find with around 50dB of noise.

But 50dB of noise is still too loud for an apartment at night so I have to find another solution.

So, my current plan is to get multiple fridge compressors and connect them in parallel to reach the same airflow as the 480W air compressor.

Some time ago I converted a fridge compressor to an air compressor so that should not be a problem. I only have to find another sort of oil for it because the current "air compressor oil" that I am using needs to be heated up first before the fridge compressor can start up.

To reduce the noise of the plasma cutter unit I need to replace the case fan with a new fan that has the same airflow but less noise - I guess that should not be a problem.

To reduce the noise of the plasma arc + airstream I did some tests with underwater plasma cutting (with success).

I could also cut the 3mm steel underwater, even though the cutting quality was not as good as cutting in the air. I think 3mm cutting depth is the maximum for this setup, but it is just what I wanted, so it's perfectly fine for me.

I performed the latest test in a 90l concrete bucket with the plasma torch located around 10cm away from the bottom and the water level got raised to around 20cm (50l of water in the bucket).

While cutting I covered the bucket with another bucket. By doing so I could reduce the noise so much that you can barely hear the air bubbles from cutting. A nice side effect of cutting underwater is that the water absorbs the major part of the fumes from cutting so that very little of it gets released into the air. So this part of the project seems to work so far.

On the machine there are a few things left to do:

- Finding another location for the X axis motor to protect it better from water splashing.

- Include a camera + display to see what's going on inside the bucket.

- Wiring everything up.

All essential features are already working and I think the hardest part will be building the multi fridge compressor unit.

So, I will fix all the smaller problems first and then start working on the fridge compressors.

Create an account to leave a comment. Already have an account? Log In.

I got inspired by these "silent air compressors" with multiple compressor motors that you can buy. They have one solenoid valve + check valve per compressor motor and so I did the same thing on my compressor.

I guess that it has something to do with the startup of the individual motors. They can not start up against pressure and maybe they would prevent each other from starting up, because they all are different models and they have slightly different start up times.

All I can give you on this project is well done, but... those refrigeration compressors will eventually pump all the oil out of themselves and seize, its by design. On small refrigeration circuit its never an issue as the refrigerant gas will return the oil on a closed loop design, larger system would have an oil seperator to return the oil, yours just has an oil trap and no return.

Thank you.

Yes, they lose oil over time, but for that, I added an oil level indicator to every compressor so that I can see when it's time for refilling.

Interesting idea. Would it only work for the vacuum pump config or also for the air compressor config?

You could eliminate the compressor by running the plasma cutter off a cylinder of nitrogen. I did this before I got an air dryer. It is expensive though because a plasma cutter wants a fair amount of gas.

One other thought, running a plasma cutter under water may result in free hydrogen and oxygen from the cut area. I am not sure of this, but it might be worth investigating.

I recently found some small and silent 125W airbrush compressors for around 60€ per unit. I think I will wire up 4-8 of these in parallel to get a high enough airflow. They cause almost no vibration and do not heat up fast so I maybe can cover them up or place them inside a box for further noise reduction.

Do you mean free hydrogen and oxygen in terms of an explosion hazard?

Correct. The high temperature may cause any free hydrogen and oxygen to recombine, or maybe not. It's just a thought.

Will those airbrush compressors produce enough pressure for a plasma cutter? My plasma cutter has a switch so that if the input pressure drops below 40 or 45PSI, it turns off the machine.

I always thought of airbrushes as low pressure tools. That may not be correct though.

That's a good point. I will try to ensure that everything is well ventilated.

The airbrush compressors (Fengda FD-18-2) produce up to around 60 psi. I think when I connect enough of these in parallel I should get enough airflow and pressure to power the plasma cutter.

I just tried out testing the airbrush compressor against a modified fridge compressor (flushed and filled with air compressor oil) and the fridge compressor performed at least as good or maybe even better than the airbrush compressor while being absolutely silent. It was also able (just like the airbrush compressor) to start up against 3bar of pressure so that it doesn't need a relief valve. I just have to find another type of oil with lower viscosity, because the current oil needs to be heated first before the fridge compressor can start up. What do you think about using fridge compressors?

As long as you can lubricate them, they should be good. You might want a fan or something blowing across them for cooling. An air filter/dryer would be good for separating oil and moisture from the compressed air.

I like the idea. I played with fridge compressors for vacuum purposes. I often wondered about creating an expansion/collection area for the oil after the pump and from the bottom of that feeding some capillary tubing back to the inlet. Should sacrifice a tiny bit of pressure as you will be pumping the oil, but you would get self lubrication. Never tried it though.

I almost finished my air compressor. I got a bunch of fridge compressors and replaced their oil with 0W20 motor oil. They don't heat up much, because their combined output is pretty high so they don't have to run for a long time. I added an oil separator and today I added a 50l air tank. Now only some tubing, another oil separator, and a muffler are missing.

Become a member to follow this project and never miss any updates

Dominik Meffert

Dominik Meffert

Roger

Roger

Nixie

Nixie

Interesting. As for venting, I'd use a single solenoid valve for the main manifold, and an additional check valve placed between the filter and the tank.