I have a treadmill.

I have "arduino" skills due to Covida.

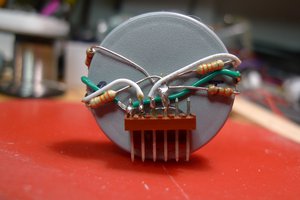

I wanted to create a simple but meaningful project to present to my coworkers in order to ignite the curiosity in some of them. I decided to augment my treadmill capabilities with BLE in order to broadcast speed and inclination. I was prepared to reverse engineer complex communications between the motor and the control panel, but after looking at the schematics of my model, I realized that it came with an RPM sensor which would have been a great start. After a bit of Google-fu, I realized that this type of sensor - although in different shapes and forms - is very common in a lot of basic treadmills and it's a simple Reed switch coupled to some magnets on the pulley driving the belt, so things started to look great.

I was thinking that with an opto-isolator circuit I would be able to tap into this ready available datasource but to my surprise I discovered that, while the pulleys have embedded magnets, there is no RPM sensor / Reed switch installed at all. That means I can buy one on eBay and build a circuit around it.

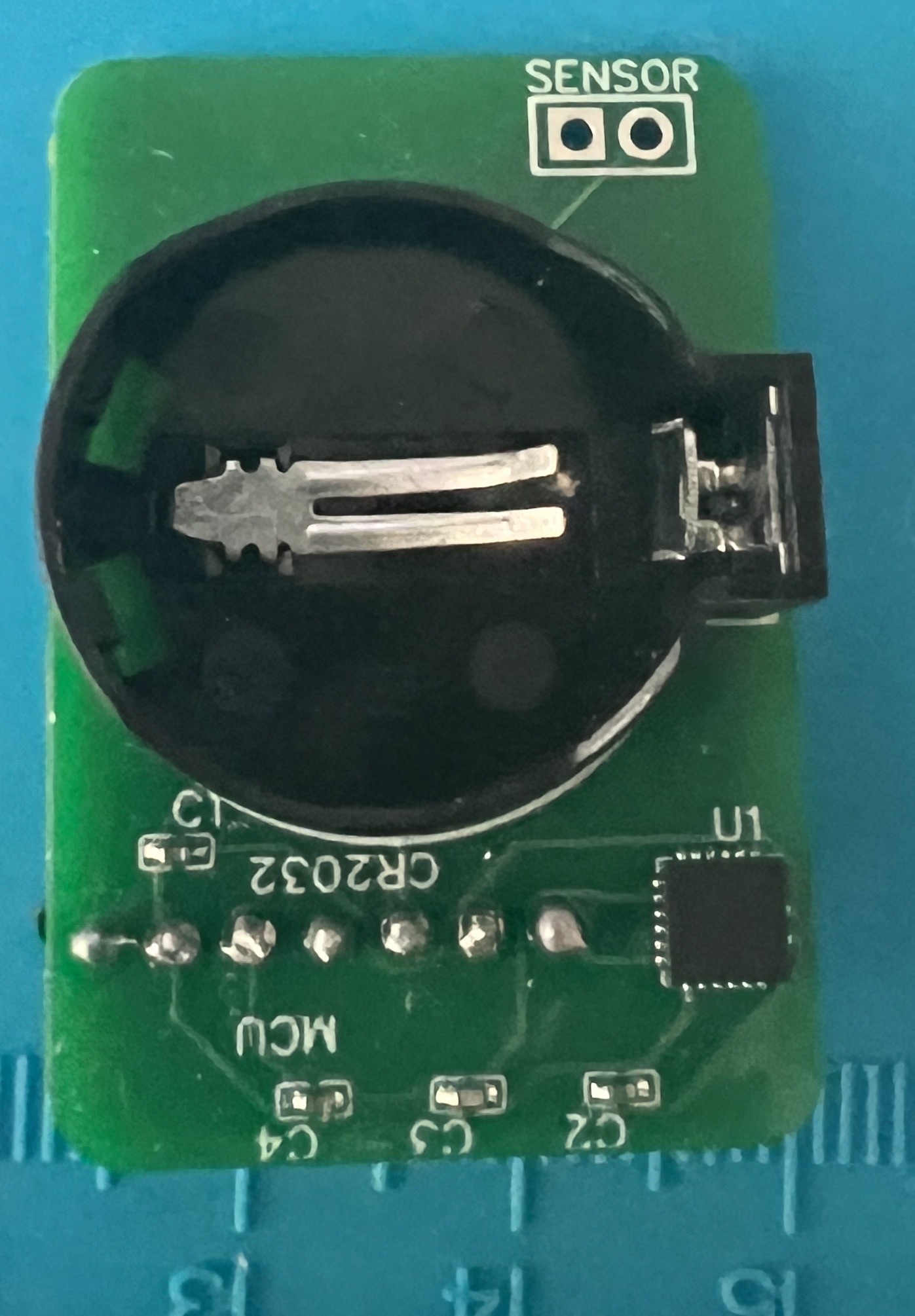

I chose to use the nRF52 MCU in the shape of the Seeeduino BLE in order to do the heavy lifting. The switch/sensor is arriving in the mail. Next steps:

1. test the sensor with a simple CR2032 LED bread board circuit and figure out a 3D attachment harness

2. 3D print the harness

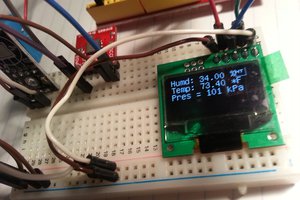

3. write BLE code. The new "sensor" will be a BLE peripheral with two subscribe-able attributes, speed (from the switch) and inclination (from a Time of Flight sensor that I still need to pick)

4. present to my coworkers as part of what I learned during Covida

5. profit

I will post progress in here.

Enzo Lombardi

Enzo Lombardi

Alex Hunt

Alex Hunt

Sam The Samuri

Sam The Samuri

Ana

Ana

It's very likely that you ProForm treadmill has the proper magnet in place.

I am lazy too, but this is kind of fun.