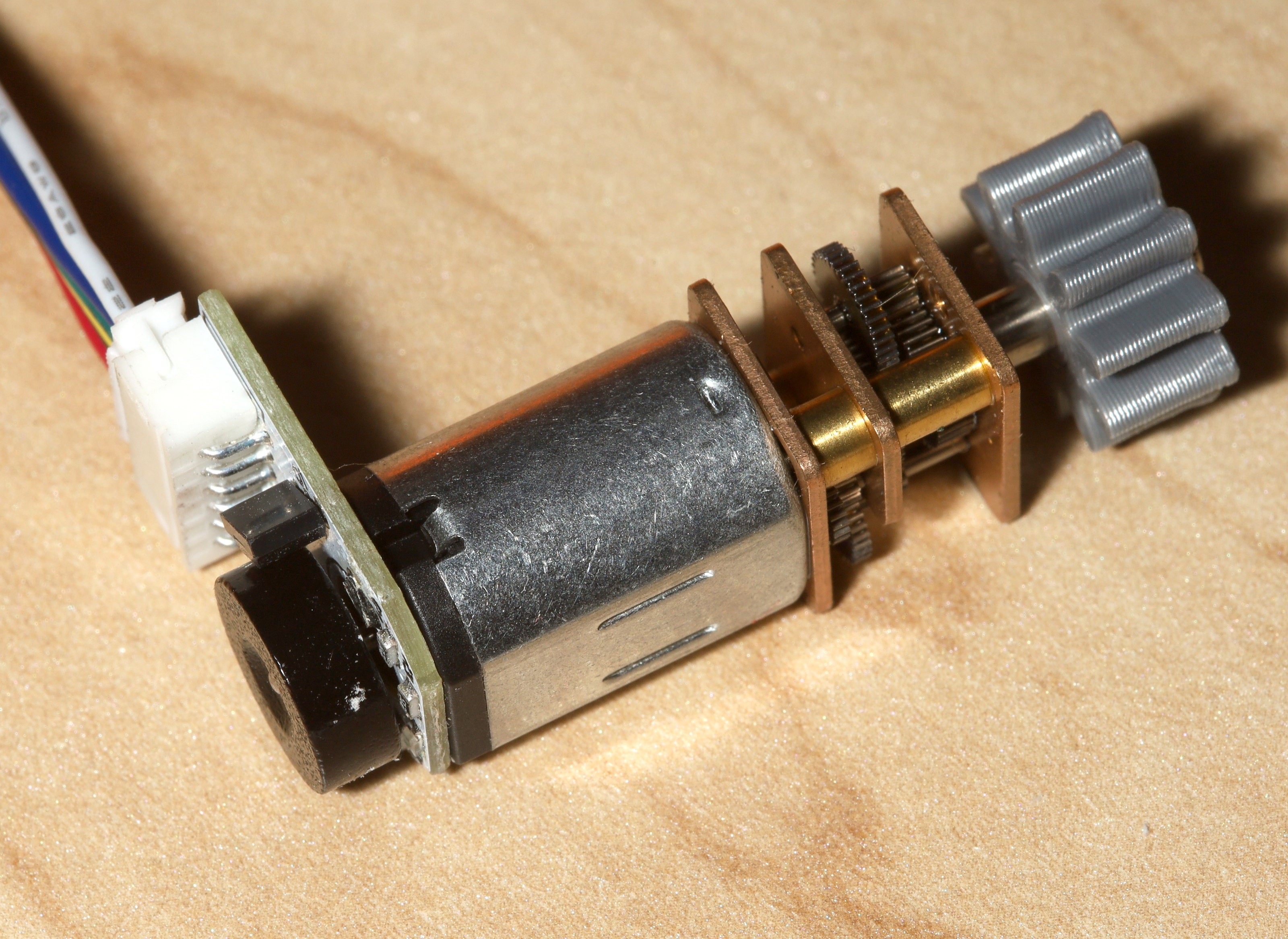

While press fitting the gears on, it became clear that the encoder wheel is very easy to press into the circuit board, rendering it immobile. The gear has to be heated to press on, but can't be pressed on by force against the encoder wheel. This probably requires a new tool, but for now the outside of the motor is the only place to grab.

The 300:1 gear ratio now requires powering the motor to move it.

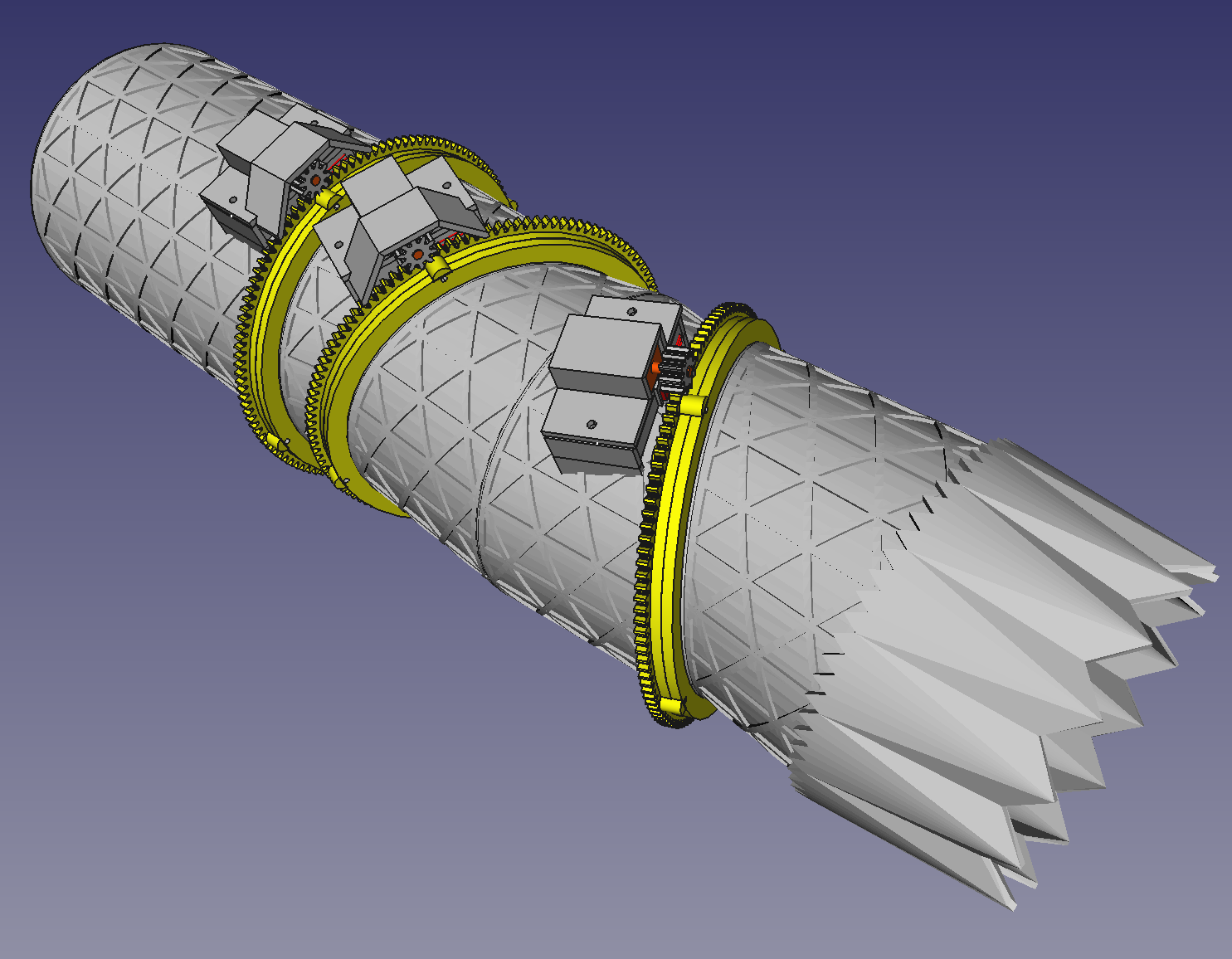

The updated motor mounts were laboriously put on the tube segments. Models & supports were updated with new techniques. Passed on adding wire harnesses to the tube segments. It might be easier to put wire harnesses on the motor straps.

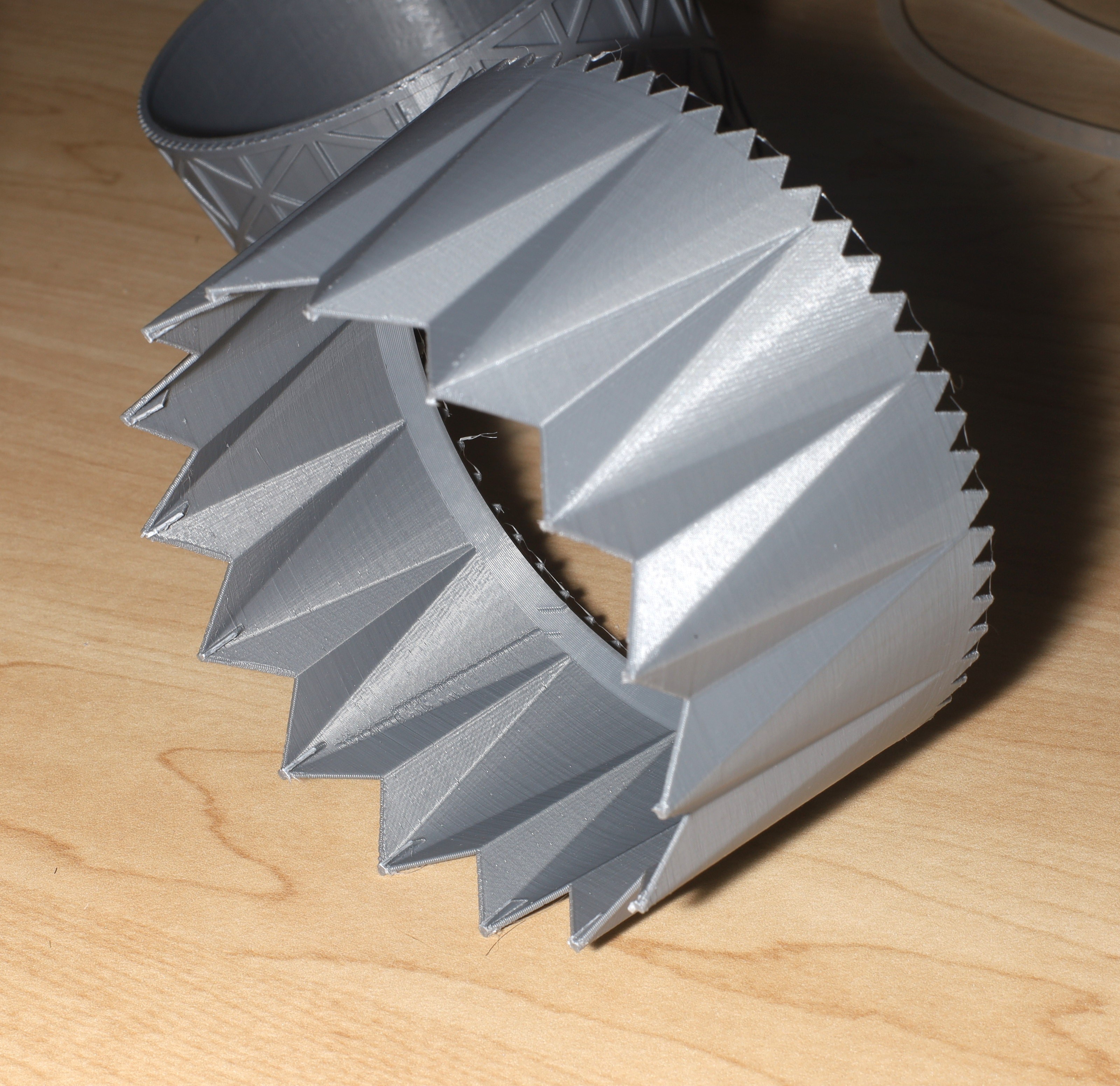

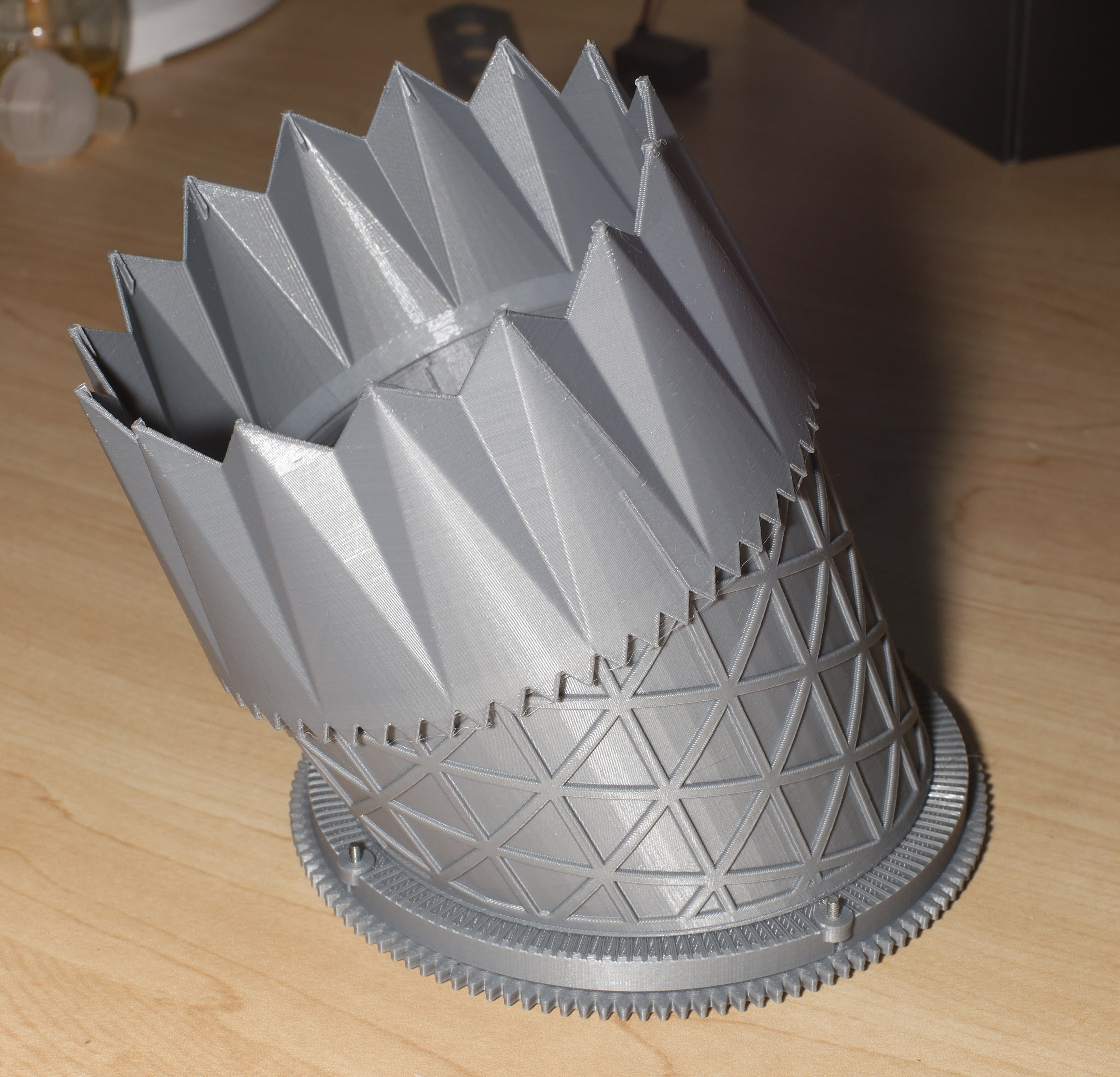

The 1st structural print was the exit nozzle. A new support method was tried.

These supports could be clipped out but left ugly bits on the inside.

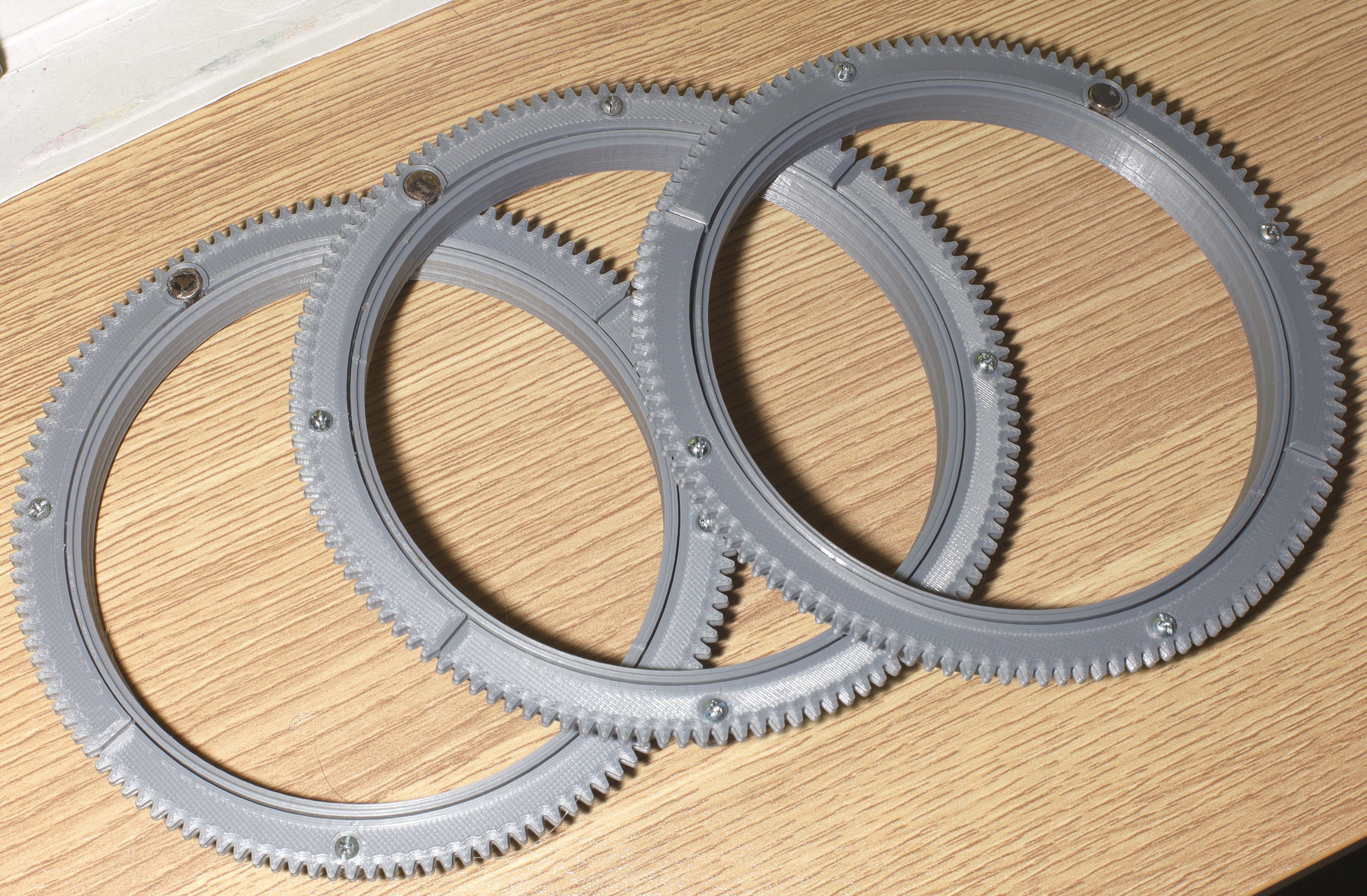

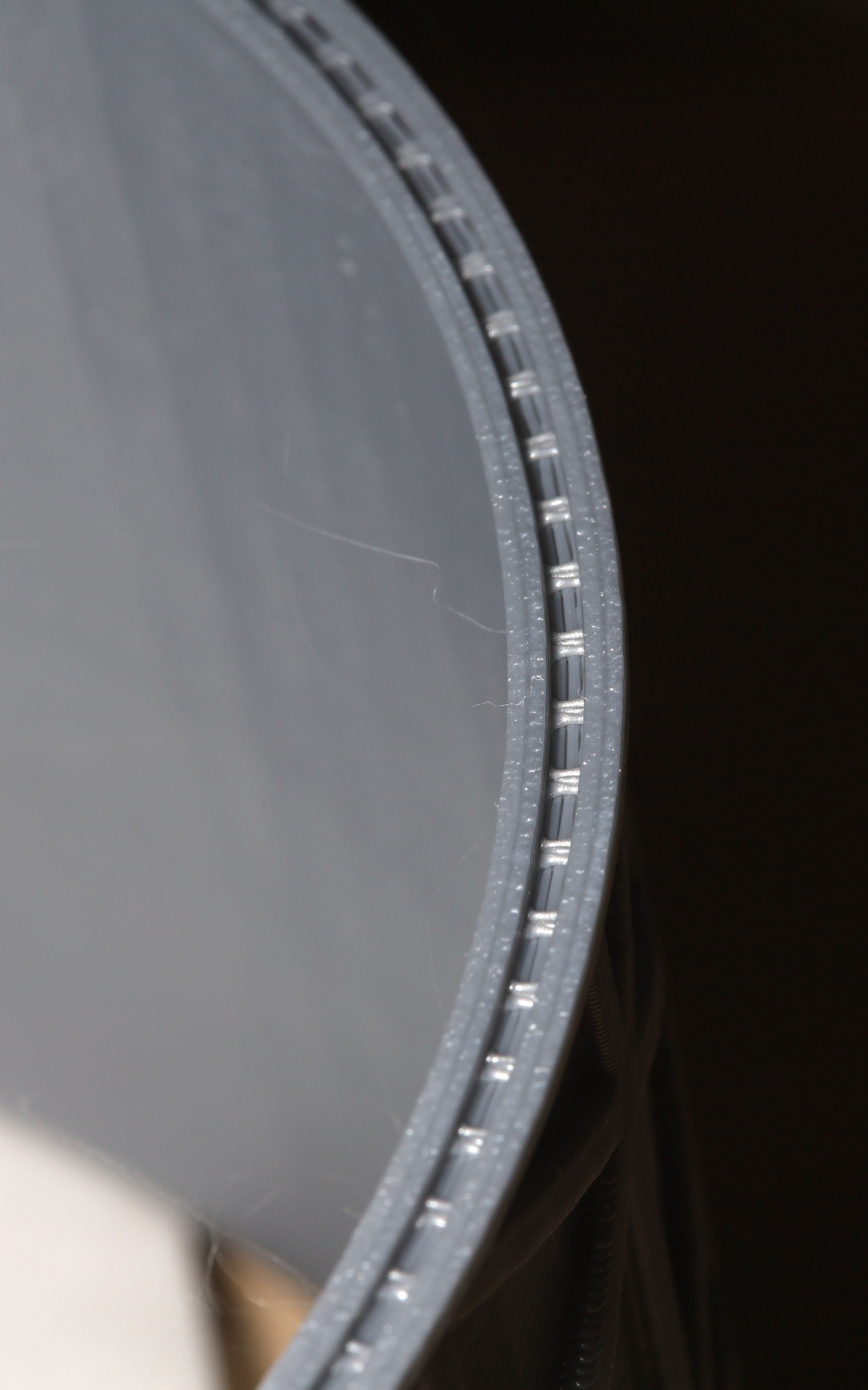

New bearings were complete. The magnets ended up not the same polarity.

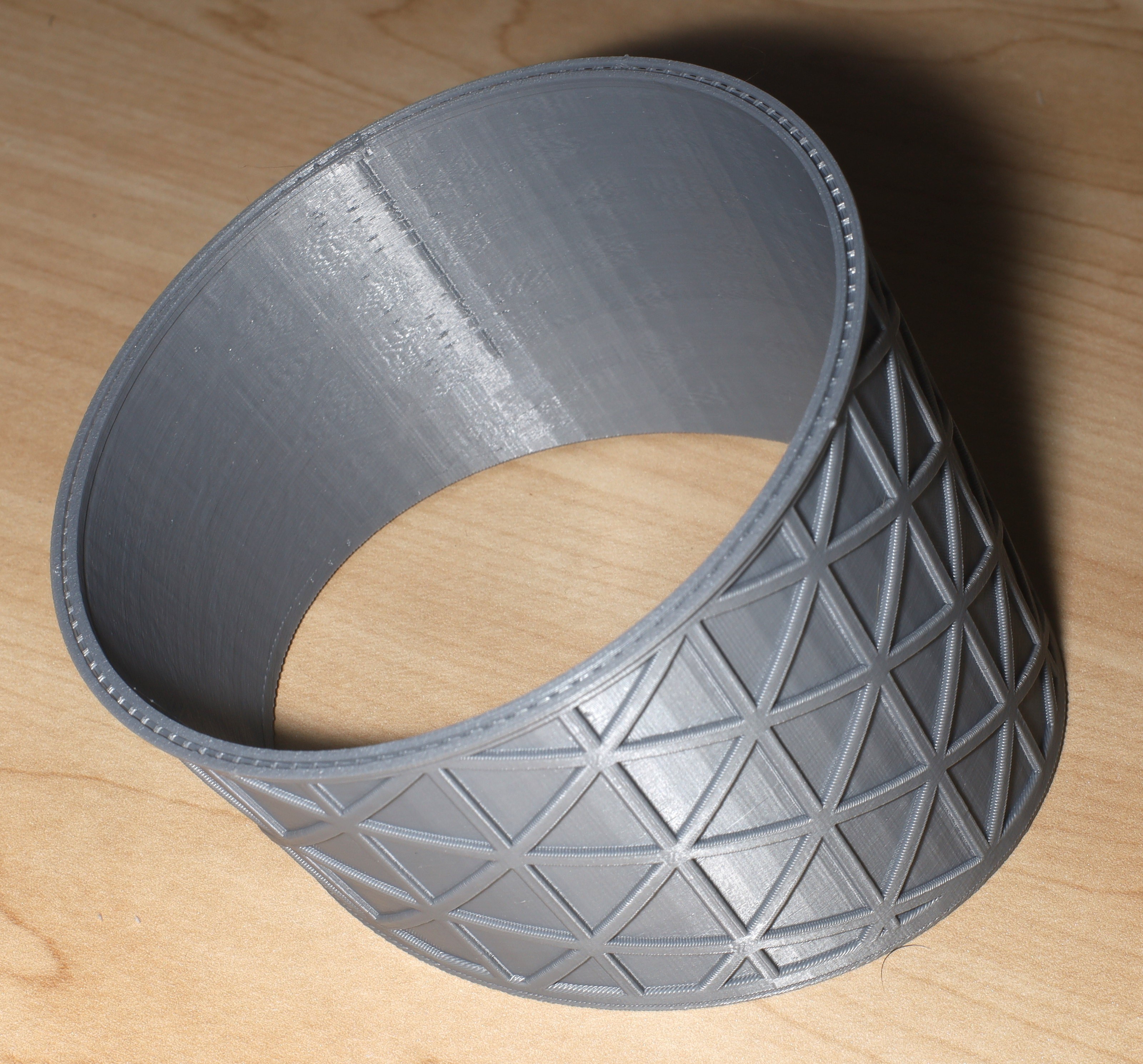

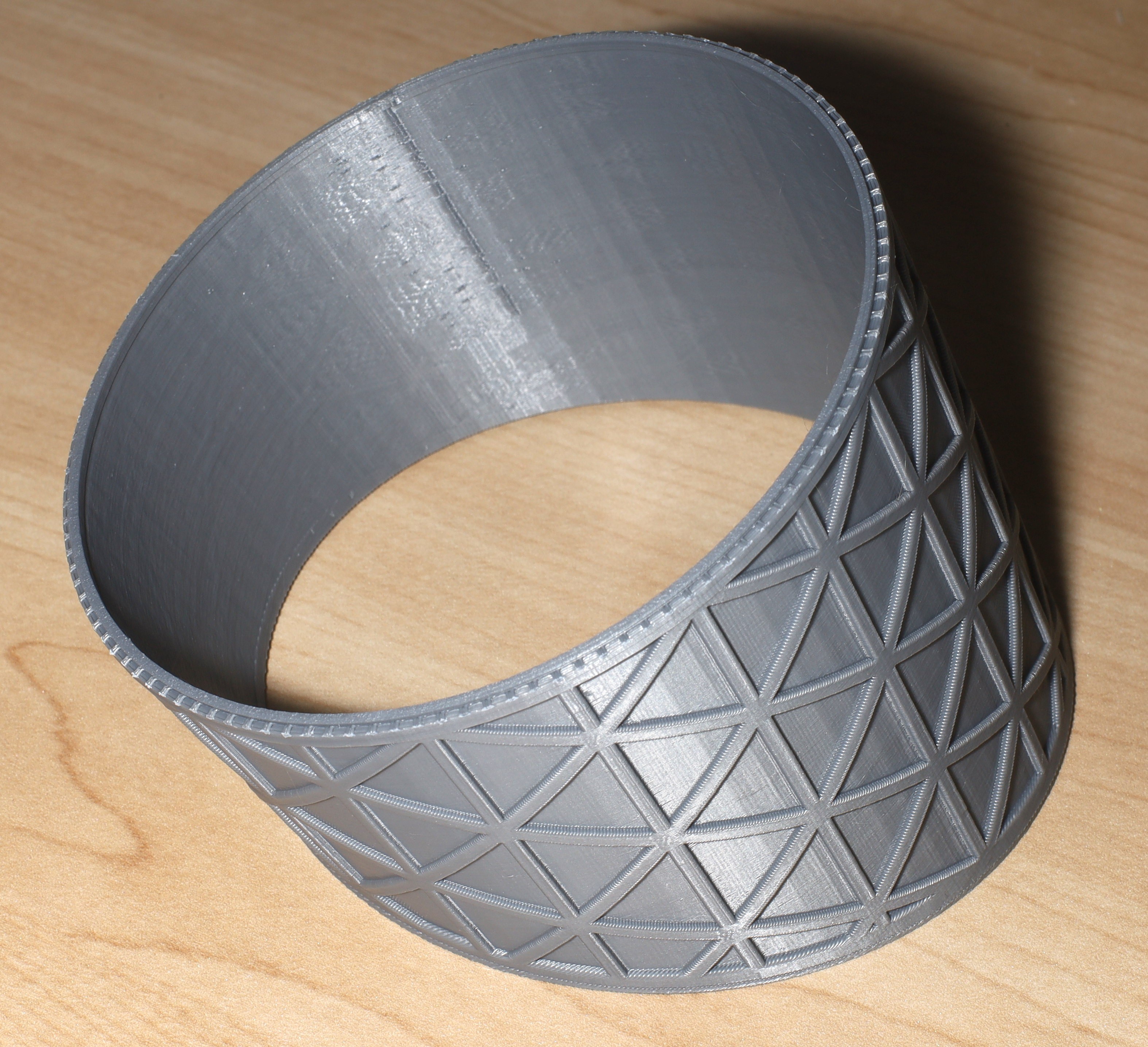

The 1st tube segment was printed. The isogrid pattern is hard to clean, but the decision was made to keep it.

New support method was much easier. There were still blobs near the Z seam which had to be scraped out.

The exit nozzle fit together.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.