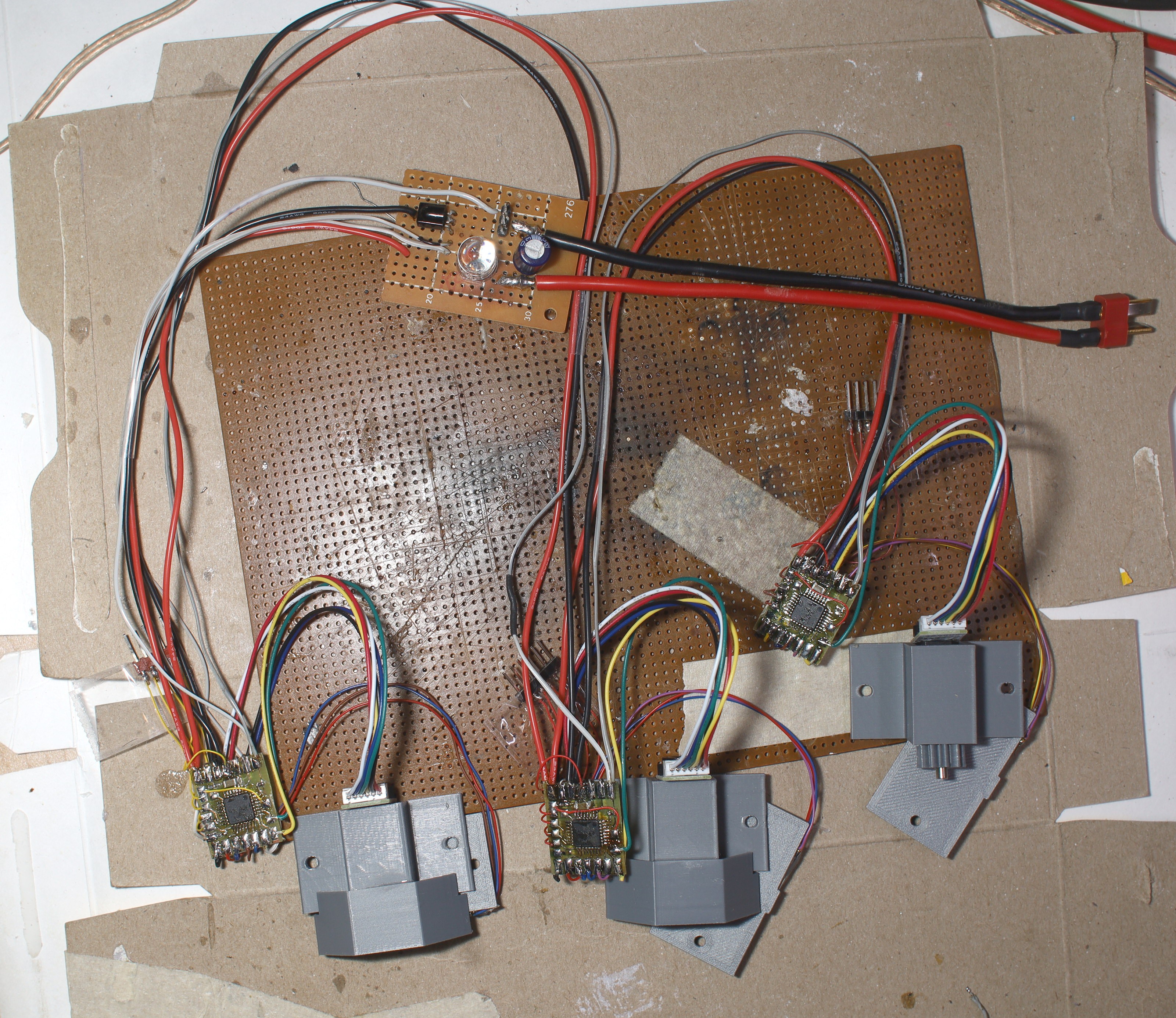

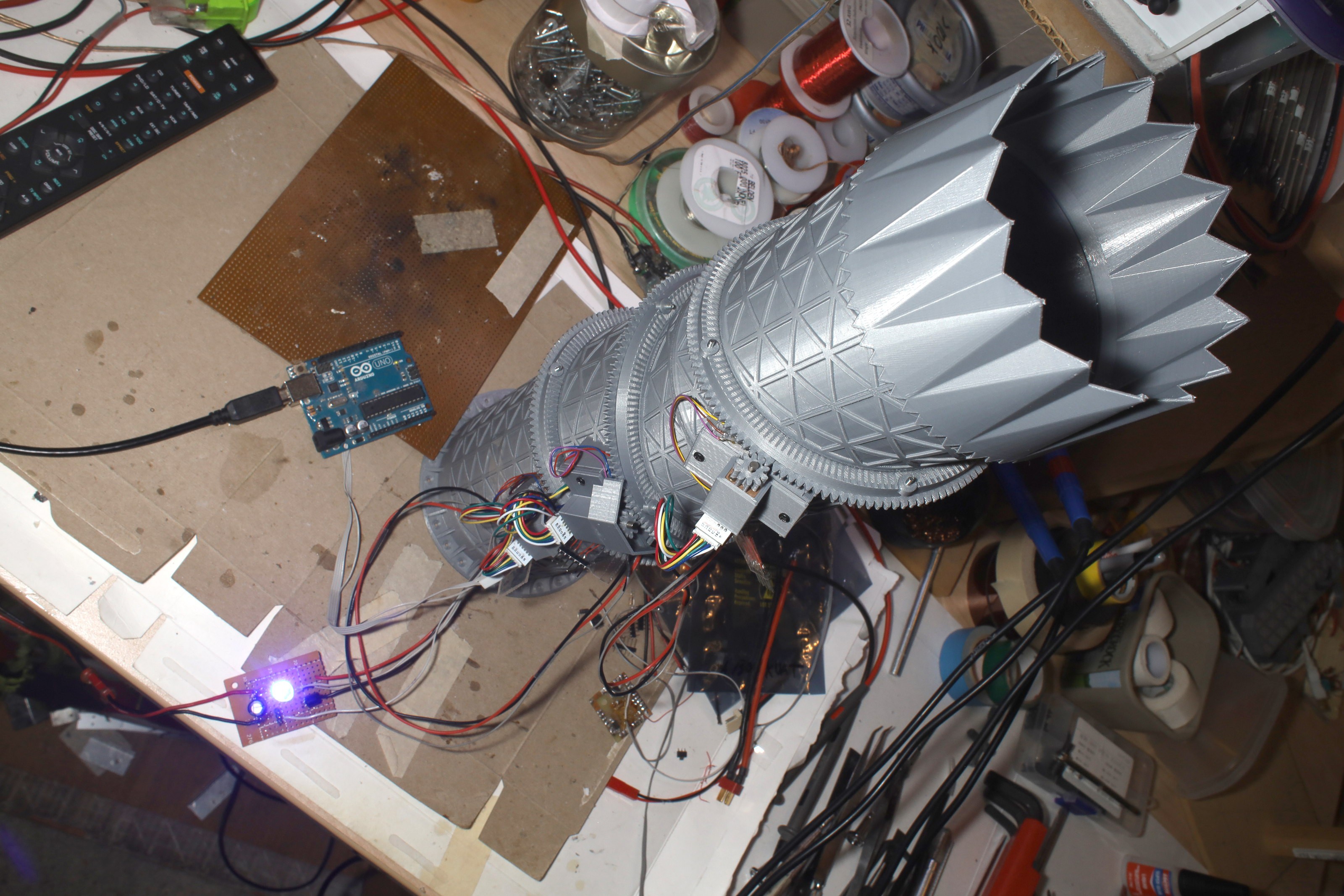

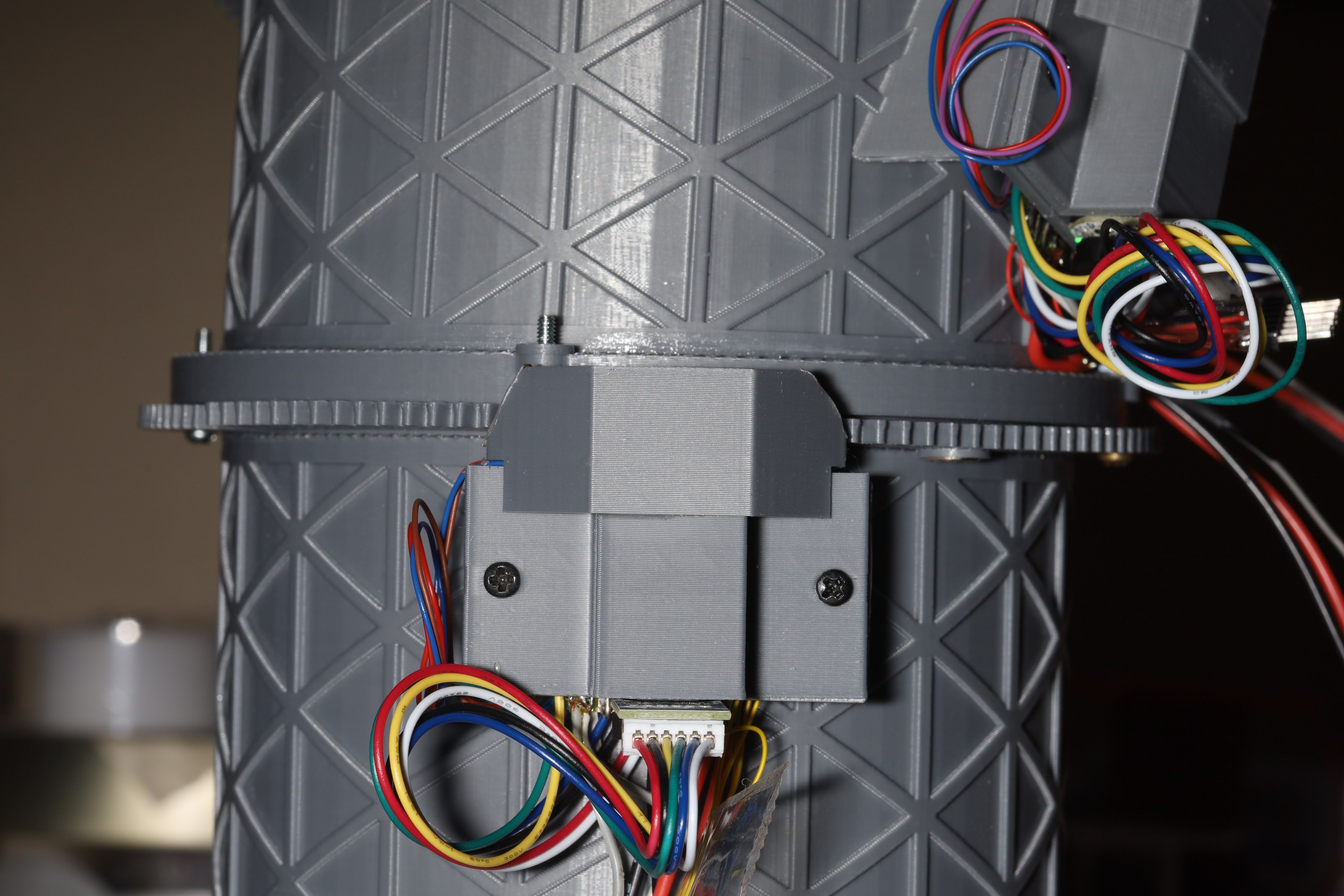

Motor boards all hooked up. User interface board hooked up. Wrong power connector. Lions use JST connectors for 5V & T connectors for 12V. Noted the 2020 revision of the H bridge had a green LED while the 2022 revision has a red LED & bigger vias. All 3 encoders have green LED's, so it's kind of an xmas tree.

The control boards were scotched in to allow future removal of the programming headers.

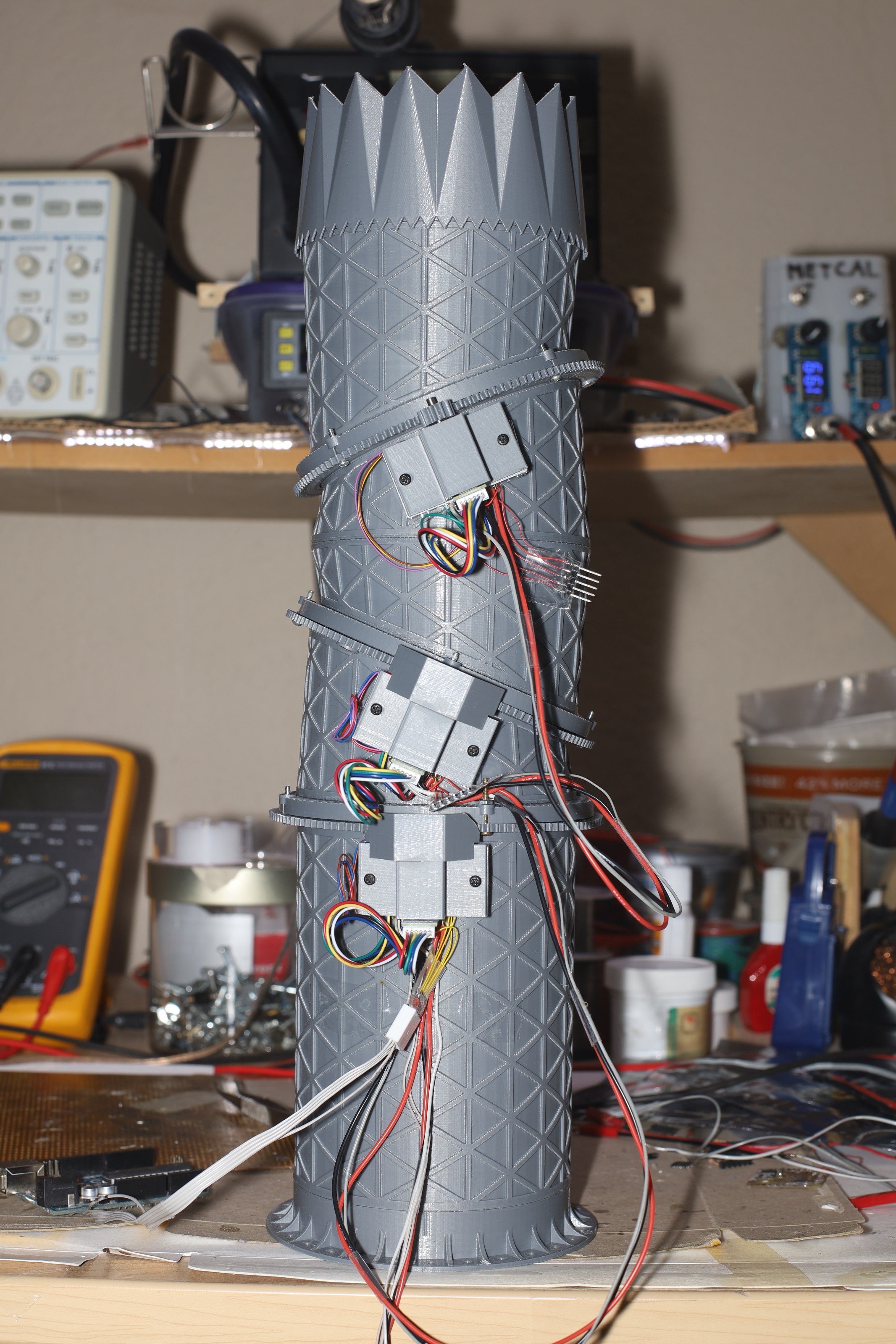

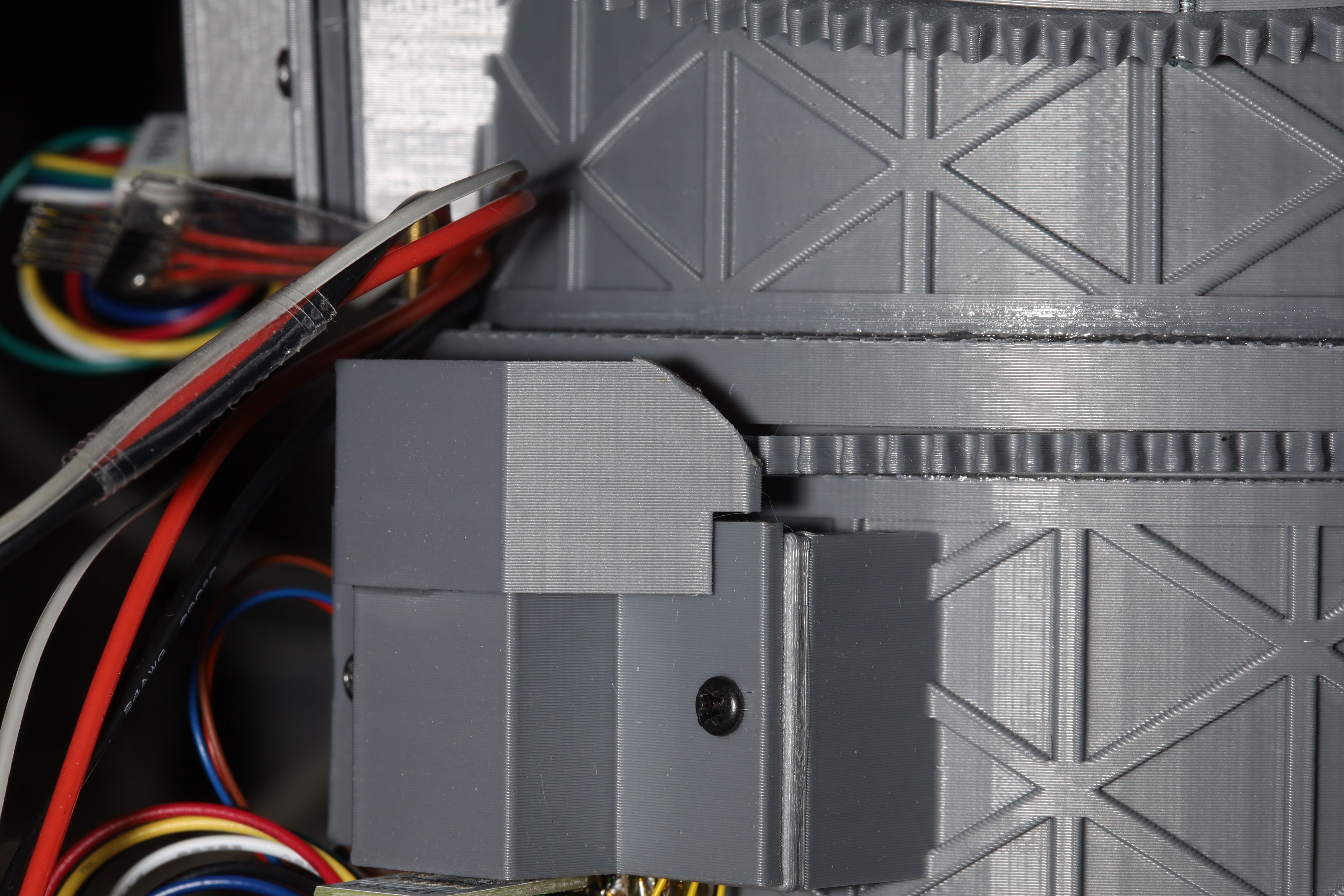

A bit of sandwiching got them all in.

There was a case of too much motor shroud snagging the cables.

The 2nd motor shroud has so far proven unnecessary, so it hasn't been shaved down. So far, there hasn't been any issue sharing the motor & logic power lines.

The single wire UART scheme worked. The maximum update rate ended up 20Hz per motor. The tricky bit is fitting debug statements between the control packets. Instead of a terminal program, it uses monitor.c. monitor.c filters out the control packets. It still needs to buffer the debug statements separately from the control packets & send fragments of the debug statements between the control packets.

The IR scheme is horrendous since it requires delaying if it misses a code. It needs to go back to an algorithm which continually checks every byte against every code. When the motors are disarmed, the remote control directly controls the motors with the arrow buttons. There are cases where motors get stuck on after the remote control stops transmitting. There's also crosstalk between the 2 nozzles in the room.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.